Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

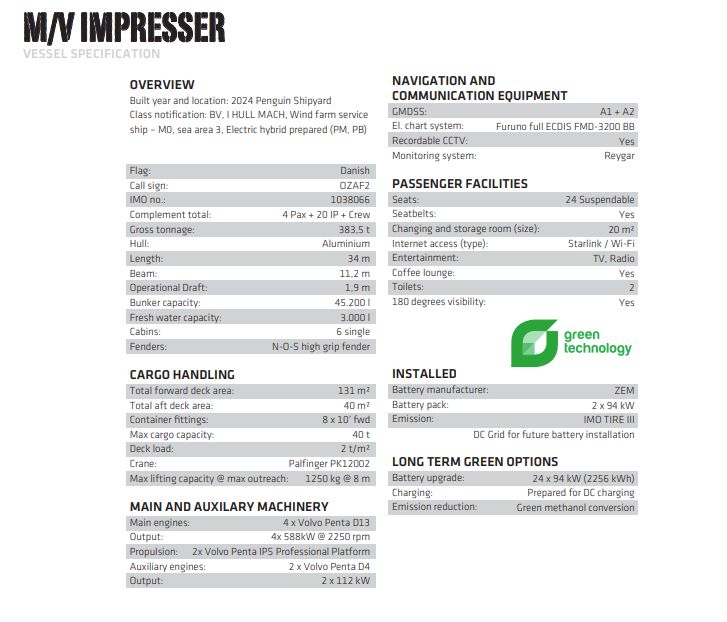

The Volvo Penta IPS Professional Platform offers advanced marine propulsion, integrating dual power sources for efficiency and flexibility. In a significant stride towards sustainability and efficiency in marine transportation, Volvo Penta, in collaboration with Northern Offshore Services (N-O-S), has introduced the world’s first commercial application of the IPS Professional Platform. This groundbreaking technology powers the I-Class Crew Transfer Vessel (CTV), which will begin operations in a UK wind farm on September 1, 2024. This vessel isn’t just a new ship; it’s a symbol of the future of marine technology, designed to evolve with the changing tides of energy solutions.

So, What Is This Volvo Penta IPS Professional Platform & Why Is It Better?

Volvo Penta’s Inboard Performance System (IPS) represents a significant innovation in marine propulsion technology. Here’s a brief history and overview:

Development and Introduction:

-

Early 2000s: The concept of IPS began to take shape as Volvo Penta sought to revolutionize boat propulsion by integrating the engine, drive, and steering into a single unit for better performance and handling.

-

2005: Volvo Penta officially launched the IPS at the Cannes Boat Show. This system was designed to offer better fuel efficiency, increased speed, and improved handling compared to traditional inboard and outboard systems.

Key Features and Technology:

-

Integrated Design: The IPS combines the engine, transmission, and steering into one unit. This integration allows for a more streamlined hull design, reducing drag.

-

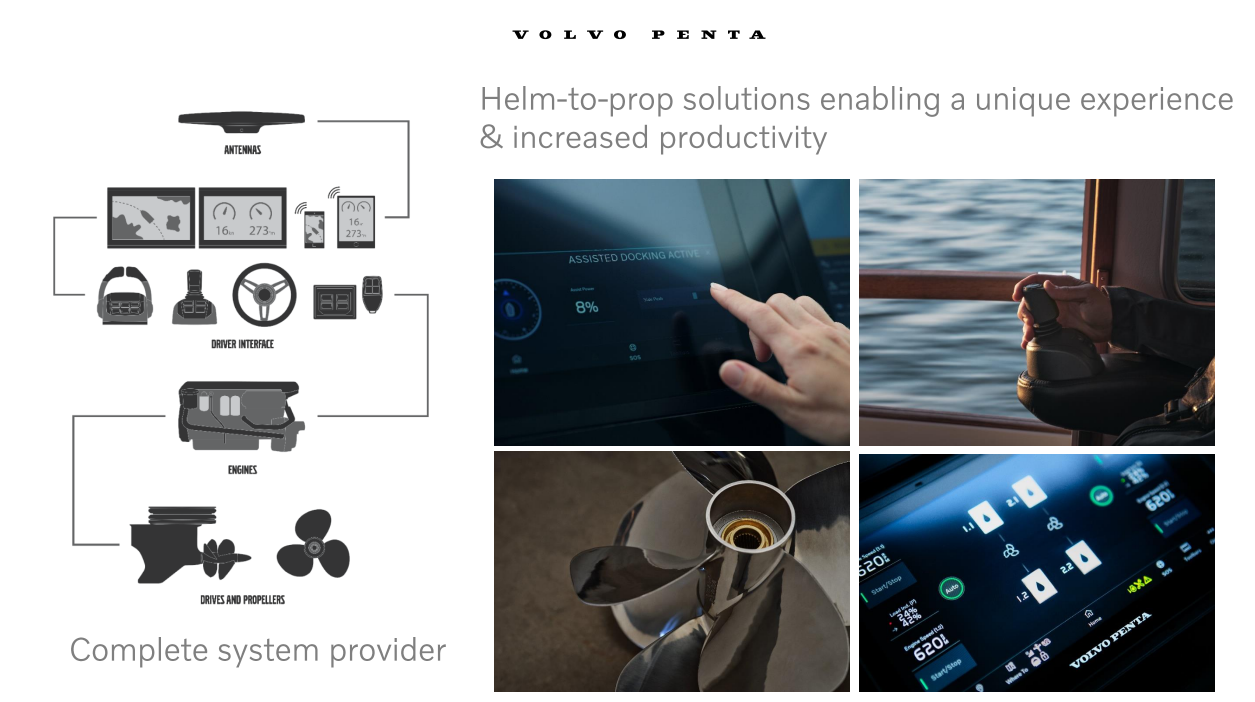

Joystick Docking: One of the standout features of IPS is its joystick control, which simplifies docking by allowing the captain to maneuver the boat with ease, similar to driving a car.

-

Counter-Rotating Propellers: IPS uses dual, counter-rotating propellers which provide better grip on the water, leading to improved acceleration and maneuverability.

-

Electronic Controls: The system uses advanced electronic controls for precise management of engine performance, which contributes to fuel efficiency and reduced emissions.

I got to actually drive two small ships for a short time to experience how easy it is to maneuver with the joystick docking features. It is so much easier than piloting a regular system where you have to control multiple throttles and a rudder. These systems automatically keep your position and heading, reacting to any currents and wind. You just tell it if you want to move a half meter closer to the dock by tilting the joystick once. You can also change your heading easily and the 360-degree bird’s eye view helps ensure you don’t accidentally hit something you don’t intend to.

So, the IPS system has been around for a few years, but now they are adding even more features and scaling it up to serve much larger vessels.

In January, Volvo announced new details of its Professional Version of IPS, summarized below:

The Volvo Penta IPS Professional Platform represents a significant advancement in marine propulsion technology, tailored for professional vessels and super yachts. Here’s a summary of its key features:

-

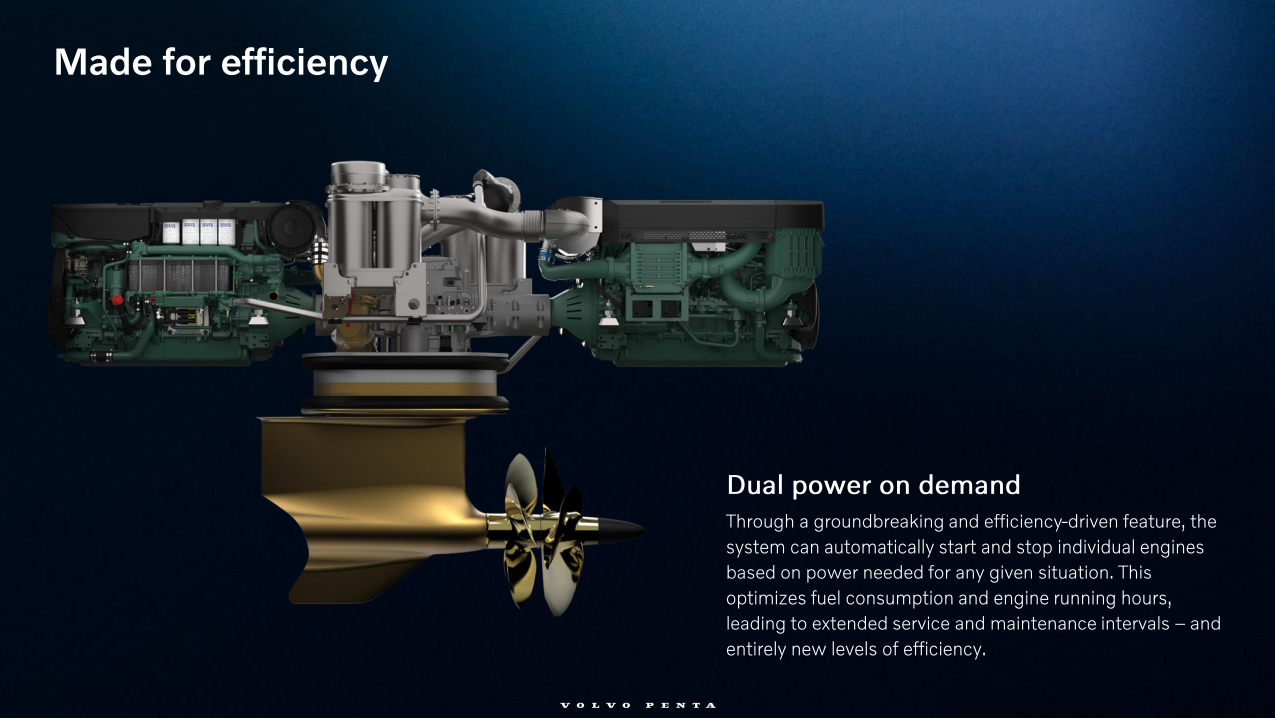

Dual Power Drive System: This system allows vessels to utilize up to eight power sources, combining traditional internal combustion engines (ICE) with electric or hybrid solutions. This flexibility supports various fuel types, including renewable fuels like bio-diesel, aiming for sustainability.

-

Intelligent Technology:

-

Assisted Docking and Dynamic Positioning: Enhances ease of operation.

-

Glass Cockpit Helm Display: Provides advanced control and monitoring for operators.

-

Remote Diagnostics: Improves maintenance and operational efficiency.

-

-

Future-Proof Design: The architecture supports upgrades from ICE to hybrid or fully electric systems without major vessel redesigns, ensuring longevity and adaptability.

-

ECO Mode: An innovative feature that automatically manages engine operation for optimal fuel efficiency, potentially saving up to 10% on fuel in certain scenarios. It can switch engines on or off based on the power demand, reducing overall fuel consumption and engine wear.

-

Sustainability: All engines are compatible with renewable fuels, promoting immediate steps towards environmental sustainability.

-

Operational Efficiency: With smart power management, the system ensures that only necessary engines are running, potentially cutting engine hours by half in many operational scenarios, thus extending maintenance intervals.

This platform not only enhances the performance and comfort of professional vessels, but also significantly boosts their efficiency and environmental footprint, making it a forward-thinking solution in marine technology. Volvo Penta, with its global presence and extensive dealer network, positions this platform as a leader in marine propulsion for the future.

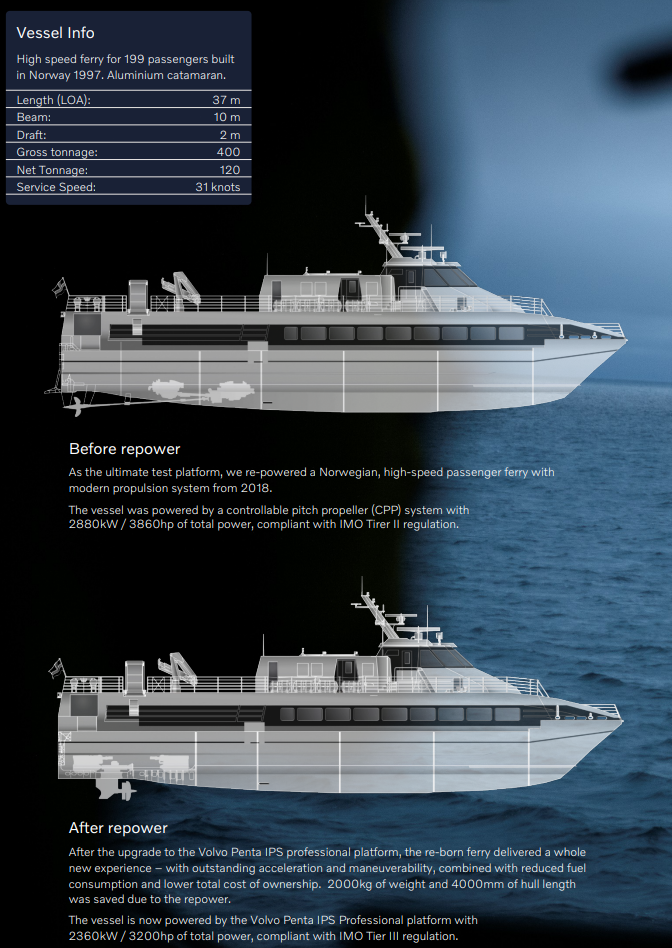

Before Volvo Penta Put It In A New Ship, They Tested It On An Old One For Over A Year To Get The Bugs Out

Why Can’t We Just Go All Electric Now?

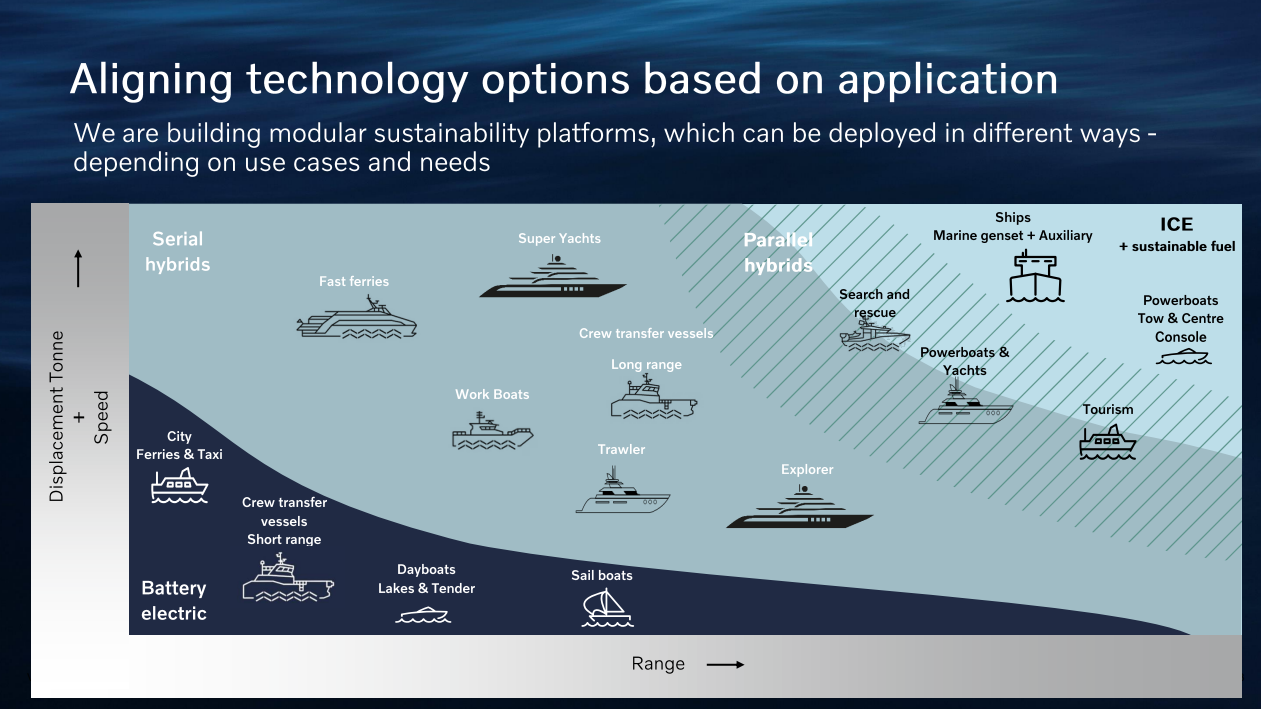

The market reminds me of the auto market 10 or 15 years ago. When all we had were the Nissan Leaf, why didn’t we just convert everyone to an electric car? Because they weren’t very good back then (even though they were fine for limited uses). Similarly, battery electric vessels can meet some use cases, as long as you don’t need too much range or speed. Where you need more of either, serial & parallel hybrids can extend your range considerably since the power density of fuel is much higher than battery density at this time. There are also ICE ships using sustainable fuels which are very expensive at the moment, but there is hope that the price of these come down in the future. I’m hopeful than Casey Handmer’s Terraform Industries will make carbon-free fuels from solar energy competitive with fossil fuels in the next 10 years.

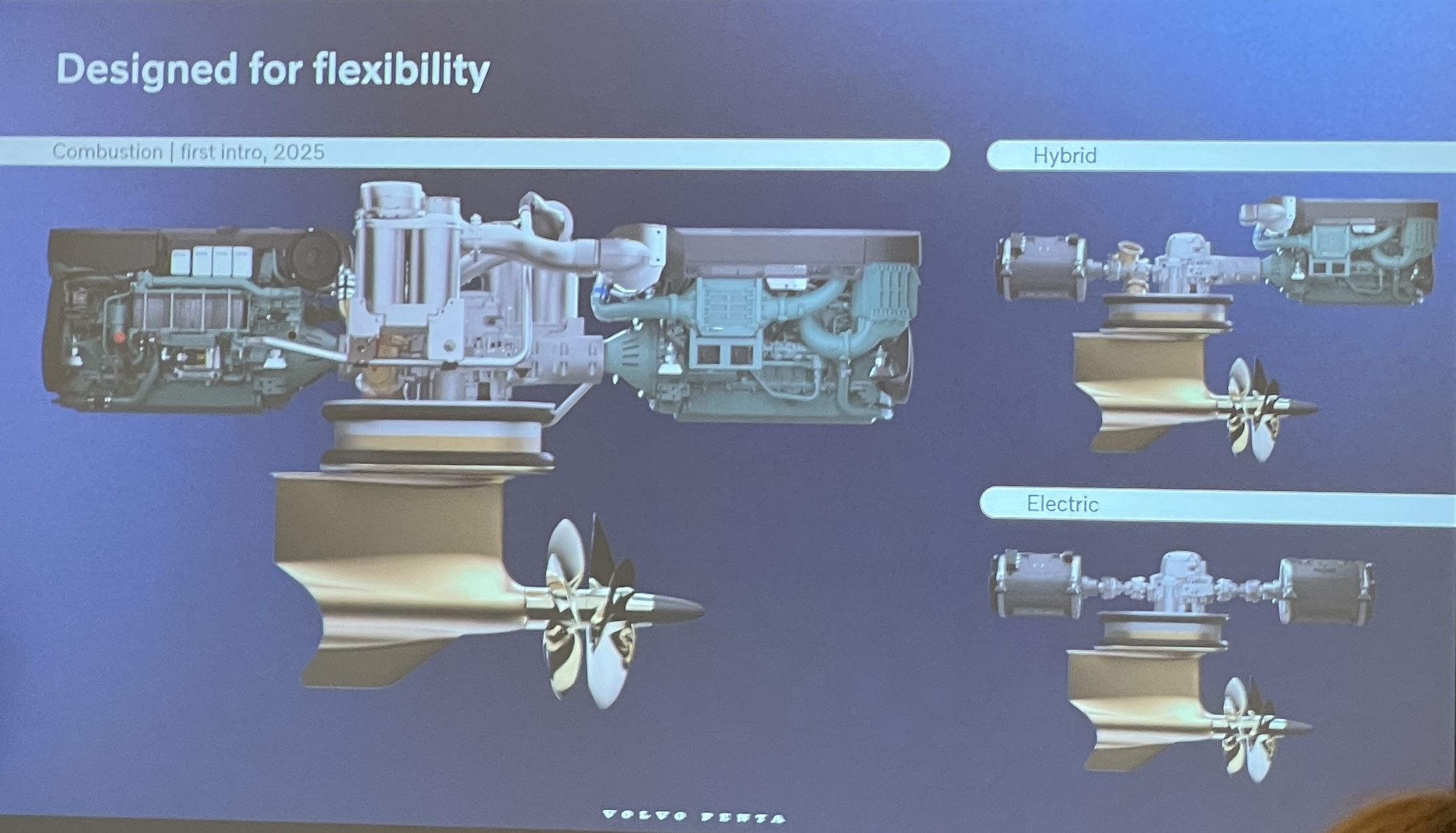

You can change a diesel engine to an electric motor at any time to reduce costs and make the process cleaner. This would let you move into ports that don’t allow diesel emissions. Notice the electric motor on the left and the diesel engine on the right in the image below.

Once you have more charging available at ports and at wind farms, and battery costs are lower, you can install more batteries and go full electric.

Conclusion

What Volvo Penta has provided is a broad vision not just for maintaining wind farms, but for all types of marine vessels where customers can decarbonize as the products meet their needs. One big advantage is you can replace diesel engines with electric motors and add batteries at any time. You don’t have to junk the vessel or even do a major repower (as long as the vessel is designed like the IMPRESSOR with a large box for batteries). We can’t expect the maritime industry to move as quickly as cars and trucks have gone electric, but Volvo Penta is providing the tools for companies to electrify as quickly as they can make it work.

Disclosure: I am a shareholder in Tesla [TSLA], BYD [BYDDY], Nio [NIO], XPeng [XPEV], Hertz [HTZ], NextEra Energy [NEP], and several ARK ETFs. But I offer no investment advice of any sort here. Volvo Penta covered my travel expenses to show me several new products.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica.TV Videos

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy