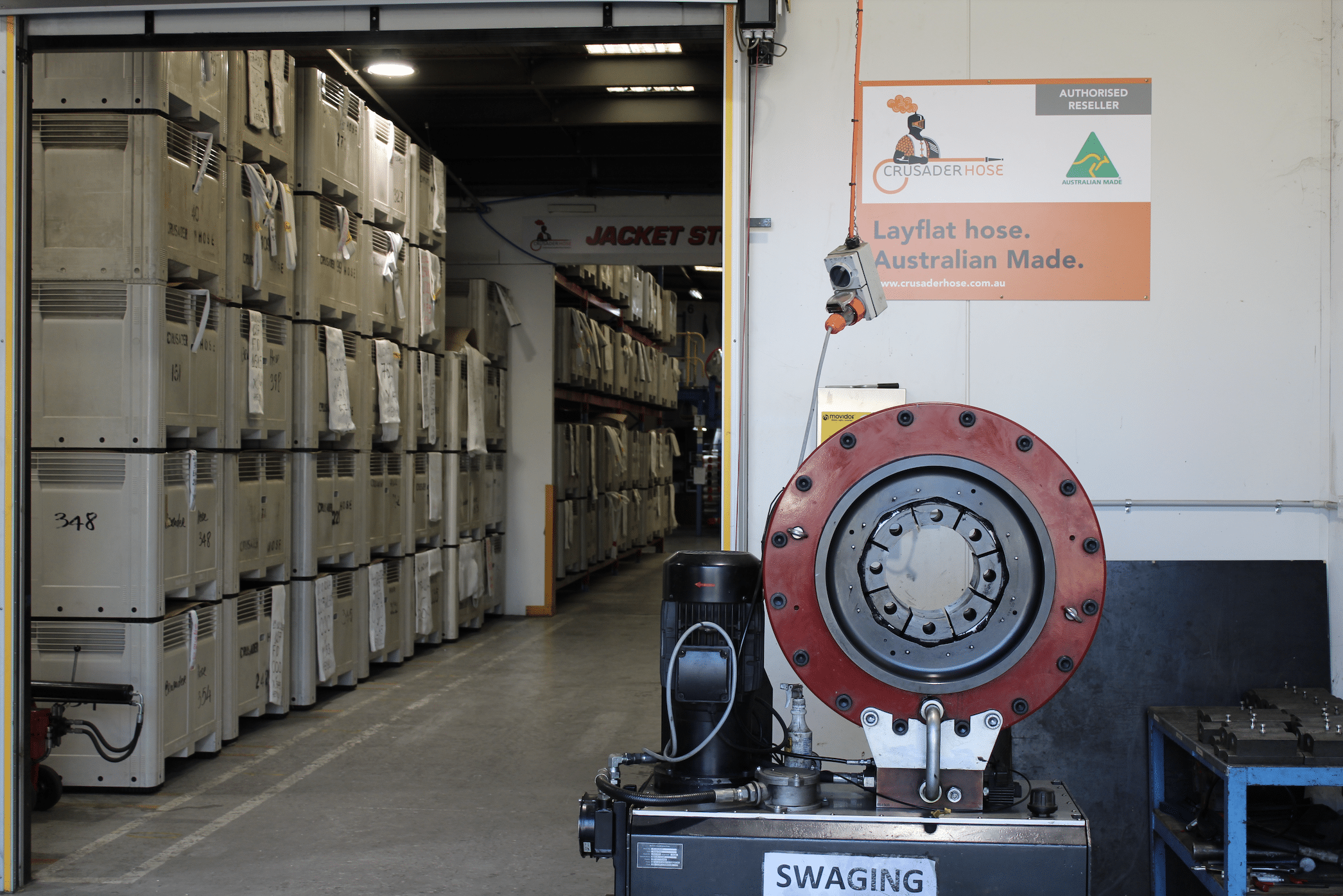

On the occasion of Crusader Hose’s open day, Australian Mining had the opportunity of getting a full behind the scenes tour of the fascinating layflat hose fabrication process.

“Innovation in action” is Crusader Hose’s motto, and the company lives by it.

The family business, located in Bayswater, Victoria, opened its door to the public on 1 May.

This was an incredible opportunity for Australian Mining to see the company’s motto, innovation in action, come to life, thanks to the full factory tour provided by the Crusader Hose team.

The company has a long and proud history of being a major provider of layflat hose and reel systems to prominent Australian industry and government organisations, including the Australian army, Rio Tinto, the Country Fire Authority, New South Wales Fire Brigade, Yarra Valley Water, BHP Billiton, and most recently the Korean army.

Crusader Hose was created by Francois Steverlynck, who has been managing director for the past 28 years, leading the company from strength to strength.

The company has been manufacturing layflat hoses for 38 years, and the products are 100 per cent Australian made.

The business’ number one priority is to make a difference by creating products that add real value to its customers.

Crusader Hose’s core value of continuous improvement has brought the company to where it is today – a progressive and innovative company, led by a passionate team.

The reason why the company specialises in layflat hose is simple: it offers countless advantages compared to more traditional and rigid products.

Laying HDPE pipelines can be time-consuming and costly compared to installing a flexible system.

Handling rigid pipe is also cumbersome and often adds complexity to projects.

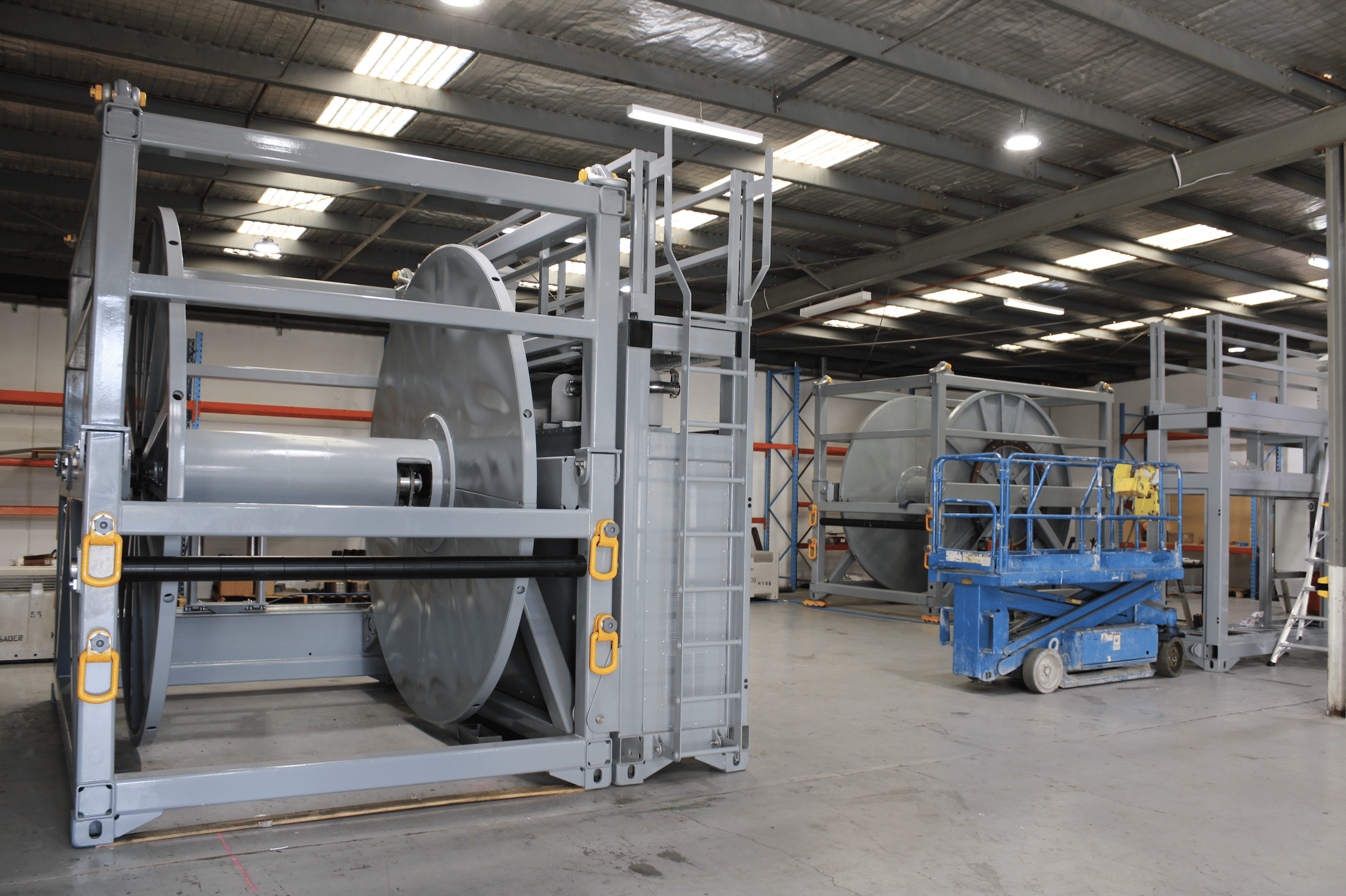

Layflat hose comes rolled compactly onto reels and can be deployed quickly and easily with any one of Crusader Hose’s reel systems.

Subscribe to Australian Mining and receive the latest news on product announcements, industry developments, commodities and more.