New technology is optimizing productivity and reducing risk

Cave-based mining is increasing worldwide as a way of extending the life of open pit mines where near-surface ore has been depleted. It allows mining companies to reach large, lower-grade deposits deep underground (typically porphyry-style deposits), achieving high production rates at a fraction of the operating cost and environmental impact of conventional surface mining methods. Block caving, specifically, is a process that involves undermining an ore body and then allowing it to collapse under its own weight. The broken ore then falls into funnels (draw bells) built underneath the caving zone, where it is then extracted.

CREDIT: IDEON

For all its advantages, the block-caving technique also comes with a set of unique challenges. Once a block cave is initially developed (through drilling in underground tunnels), it propagates upwards in a largely uncontrolled process, and it is not possible to directly observe the void as it evolves over time. Cave miners also encounter stalling of progressive caving and draw bell blockages, alongside challenges in reliably predicting ore body cave-ability, understanding cave propagation, managing ore flow effectively and predictably.

Geological uncertainty drives inefficiency, delays investment, and slows time to market

At a time where a looming multi-trillion-dollar supply gap in critical metals is putting the mining industry in the spotlight, there is immense pressure on mining companies to deliver outputs quickly — with less cost, risk, and environmental impact than ever before. Caving can deliver against these objectives, but the geological uncertainty involved in the process directly impedes that growth and slows time to market.

Operators constantly evaluate and monitor cave propagation, and mitigate geotechnical hazards during the deposit investigation, mine design and planning, and operational stages of the caving process. Current monitoring methods offer point measurements only, leaving operators to interpolate what may be happening between discrete points inside the cave. They have not been able to confidently or accurately delineate the ever-changing parameters of the cave edges, the growing air gap created, and the muck pile forming at the cave bottom. Until now.

Canadian-made mining tech uses natural energy from space

The new technology uses naturally occurring energy from supernova explosions, in the form of subatomic particles called muons, to image deep beneath the Earth’s surface. A subsurface intelligence platform — called “REVEAL” — comprises proprietary data generation; data integration and multi-physics; data science and artificial intelligence (AI); modelling and analysis tools; and 3D/4D/XR visualization — that helps mining companies map and monitor mineral deposits and other anomalies with precision and confidence.

New to the world this year, the REVEAL for caving solution allows mining companies to remotely and fully monitor progression of cave propagation for the first time — supporting operational performance and safety, while reducing geological uncertainty in understanding the rock volume surrounding the cave.

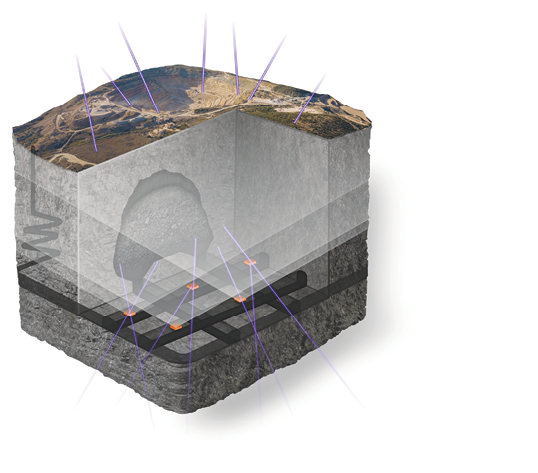

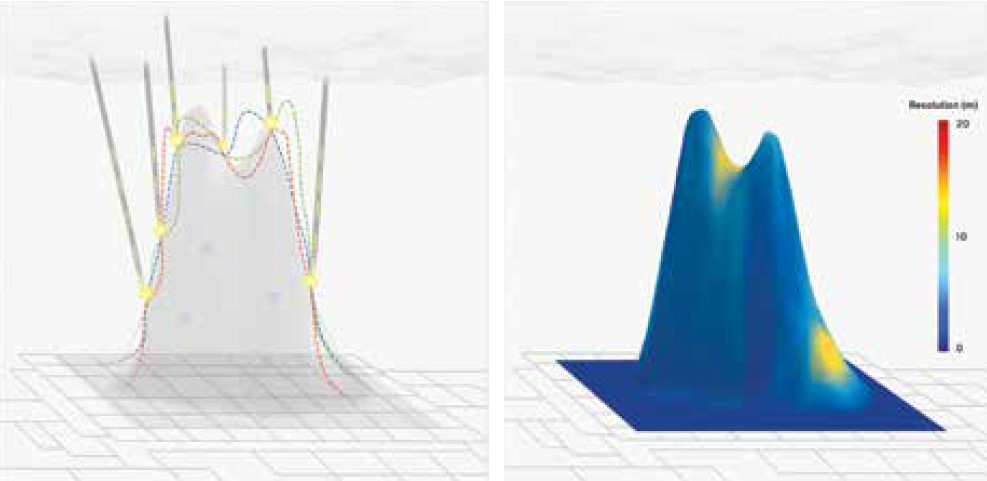

By measuring muon activity through detectors positioned in the extraction layer (deep beneath the surface), the average density in the overburden can be determined within a wide field of view above each detector. Each detector produces a radiographic (X-Ray-like) image of the rock mass above it, and combining these images enables three-dimensional tomographic reconstructions of subsurface density (CAT-scan-like). Subsurface voids like caves stand out clearly because of their density contrast with the surrounding rock. Ongoing imaging of evolving block caves yields a dynamic, high-resolution 4D model that shows how a cave and the surrounding rock evolve over time.

The innovative foundational technology — muon tomography — is the only straight-line subsurface imaging technology available today, delivering the highest available resolution along with precise anomaly location information. It uses a passive and free energy source (from space), offers the ability to image in noisy or conductive environments (where other techniques do not), provides insights from depths that other techniques cannot, and captures data continuously — improving imaging results over the course of a survey. This unique data source, combined with advanced processing algorithms and multi-data-set analysis, gives block caving companies a comprehensive set of subsurface intelligence that they have never had access to before. It is a game-changer.

CASE STUDY: Muon tomography for cave mapping at New Gold’s New Afton mine, Kamloops, B.C.

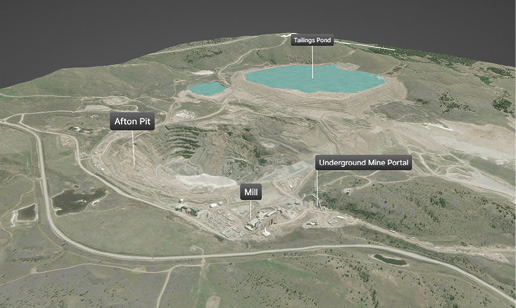

Located about 15 km west of the city of Kamloops in central B.C., the New Afton mine is a gold and copper mine situated within the Iron Mask batholith complex. The silica-saturated, alkalic porphyry-style deposit is being mined with the block caving method. In fact, New Afton mine is currently the only operating block cave mine in Canada and has a mine life that extends beyond 2030. The current operation occupies the site of the historic Afton open pit mine, which operated from 1977 until 1997, and includes an inactive open pit and other historic facilities.

Ideon worked with New Gold to install the world’s first muon tomography-based block cave monitoring solution in the operating B3 zone at New Afton mine, with a goal of demonstrating the power of muon tomography to delineate the full 3D extent of the target cave, map heterogenous density variations in cave zones, and measure any observed temporal changes in both rock flow and cave extents.

Outcomes opened a window of insight into cave characteristics previously unavailable

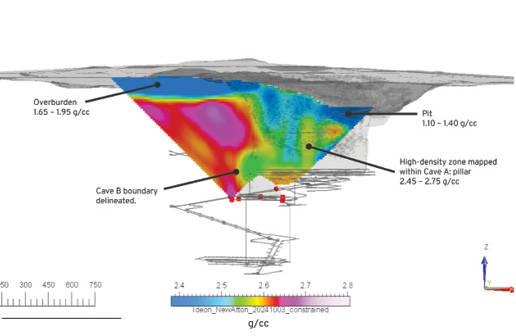

The technology provided New Gold with high-resolution visibility of a volume of earth measuring 830 million m3 using no drillholes. The unconstrained analysis, later validated and constrained with New Gold-provided data, provided high-resolution geological and geotechnical insights throughout the survey area, resolved directly with measurement data, and mapped the full cave back to 10 to 25 m or less spatial resolution at a depth of approximately 800 m, using no additional drilling.

The full expanse and boundaries of New Afton’s active block cave was accurately delineated, and a pillar of denser material separating two caving phases in a neighbouring cave was mapped. This was achieved remotely and without any instrumentation inside the cave itself. Deploying instrumentation in existing workings enabled broadscale monitoring with minimal operational disruption and no surface environmental impact.

“Blind” imaging program was designed to map and monitor cave structures, completely remotely

Commissioned in March 2024, the “REVEAL” for caving solution used nine imaging locations in New Afton mine, leveraging various formats of muon detectors to suit each location. Detectors were situated at approximately 600 to 800 m deep and gathered data over five months (to date of publication). Data intake and analysis were conducted remotely via the New Afton mine network, unlocking near-real-time subsurface density imaging with continuously improving resolution. Imaging updates were provided on a monthly cadence to reflect typical cave reporting timelines.

This was a blind, unconstrained data analysis — except that LIDAR constrains the top of the model and the known extraction level was incorporated as a bound on the bottom. Even in the constrained model, the prior cave shape is not used as a constraining factor in the analysis. The reconstructed muon trajectories from all detectors were incorporated into the “REVEAL” platform. A robust 3D density model of the target area was generated using muon data alone, yielding a mesh-based representation of the best-fit current cave shape, that satisfies the observed muon data and a full 3D distribution of subsurface density across the cave zone.

The New Gold team is excited about muon tomography and the value it can add to its block-caving operations. A follow-on commercial deployment is being advanced for a new cave at depths down to 1.2 km as part of New Gold’s production plan for the development of Cave C, New Afton.

Leveraging technology to increase visibility, improve productivity, and reduce risk

By mapping and monitoring cave behaviour over time, this technology can help companies assess and track multiple scenarios for mapping propagation of the cave back of the mine, allowing for detailed production schedules to be generated based on targeted production rate and ore flow. This data can also be used to identify potential geotechnical hazards and inform “what-if” scenario planning by the operator. By leveraging existing mine infrastructure rather than drilling and cementing dozens of holes for beacon instrumentation, Ideon can help mining companies save time and money to efficiently recover lower-grade ore.

The new technology is effectively de-risking critical metal exploration and mining processes by quantifying and reducing geological uncertainty. With few ways to unambiguously know what lies beneath the Earth’s surface, most mining companies rely heavily on point data and interpolation to develop models to guide their work. This technology is reducing uncertainty in an environment that has traditionally been very uncertain. As a result, block caving miners are equipped to make better informed decisions, saving costs, improving productivity, while minimizing risk, and environmental impact.

Gary Agnew is CEO & co-founder of Ideon Technologies. He has led Ideon through the transition from R&D to successful commercialization and engagements with the world’s top five mining companies, leveraging 25 years’ experience in mining technology, equipment, and services sector.