In his iconic song A Pirate Looks At Forty, Jimmy Buffett laments the passage from the days of sailing ships to the age of steam power. For centuries, sailors got where they were going and back home again in ships powered by the wind. In the golden age of sail, navigators guarded their records of where the wind blew hardest and where there were no breezes at all costs. Stealing that information was punishable by death!

Globalization has spawned a tremendous increase in the number of ships crisscrossing the world’s oceans. Ships the size of small cities haul thousands of containers and tankers as large as aircraft carriers transport millions of gallons of oil from one continent to another. Many of them run on bunker oil — a gelatinous mass of whatever is left over after the refining process is over. The stuff is so thick, it needs to be heated in order to flow and when it is burned, it leaves behind sulfurous clouds of carbon dioxide so thick they can be tracked by satellites.

Many shipping companies are aware of the damage these vessels are causing to the world’s environment, but other means of propulsion costs more money — often a lot more money. In a business where a half a penny per ton/mile can be the difference between making money or going broke, and doing the right thing is wrong thing to do if you want to stay in business.

Decarbonizing Ships

There are lots of ideas for how to lower the carbon emissions of ships. Burning LNG instead of bunker oil is one, but it is hardly the ideal solution from an emissions standpoint. Some companies are experimenting with methanol and ammonia, both of which have their environmental drawbacks. So what is a progressive shipping company that wants to be a good steward of the Earth and still make a profit supposed to do?

Cargill is one of the world’s largest ocean cargo companies. It operates a fleet of 650 ships that together deliver more than 200 million tons of cargo to 70 countries and burn 2 million tons of fuel. It has chartered the The Pyxis Ocean, a 6-year old vessel owned by Mitsubishi, to carry a cargo of grain from China to Brazil. The ship was recently retrofitted with wing sails at a shipyard in Shanghai. British firm BAR Technologies designed the WindWings, which are manufactured from many of the materials used to make wind turbine blades by Norway’s Yara Marine Technologies.

The video below illustrates how the WindWings work. The sound track sounds like something John Williams might compose for the next Star Wars movie, but if you mute it, the video is actually quite interesting.

“Today is the culmination of years of pioneering research,” John Cooper, CEO of BAR Technologies, said in a statement. The project received funding through a European Union led initiative to lower the carbon emissions associated with shipping by exploring new technologies.

A variety of factors will determine how much fuel ships with equipped with WindWings will actually save and therefore how many emissions will be avoided, according to Canary Media. The results will vary depending on where the vessels are sailing, how many devices can fit on their deck, and how favorable the wind and weather conditions are. BAR estimates that, on an average global route, the technology can save 1.5 metric tons of petroleum-based fuel per WindWing per day.

Cargill and BAR said they will closely monitor the performance of the WindWings over the coming months to improve design, operation, and performance. The lessons learned from this first voyage will help determine whether Cargill will add WindWing sails to more ships in its fleet of bulk carriers. BAR said it is already planning to build hundreds of its 21st century sails over the next four years and is considering building new vessels with different hydrodynamic forms.

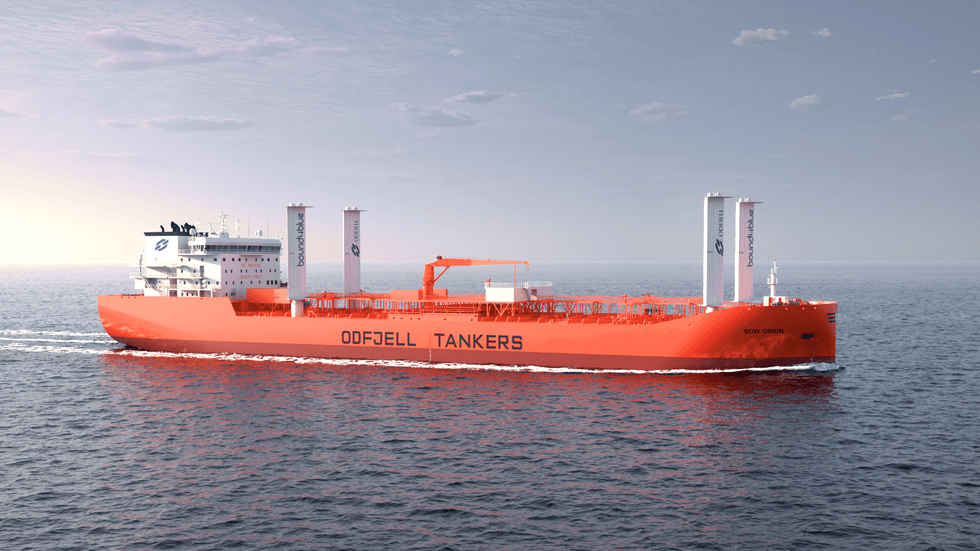

Odfjell First to Install Sails On Tanker

Image courtesy of Odjfell

Odfjell, one of the world’s largest chemical shipping companies, says it is partnering with bound4blue, a pioneering developer of wind-assisted propulsion technology. Odfjell will install the innovative eSAIL® system on a chemical tanker, making it the first tanker vessel in the world to harness this groundbreaking technology.

“Since 2020, we have been studying sail technologies as a potential energy efficiency measure for our fleet, and we are excited to now take the next step by partnering with bound4blue to implement their pioneering eSAIL® system on one of our chemical tankers,” said Jan Opedal, project manager at Odfjell. “This technology has significant potential to reduce emissions by harvesting the energy on the ship itself and transforming it directly into a forward thrust.”

Bound4blue autonomous rigid sail systems can be integrated into a wide range of vessels. Conceived as a complementary propulsion system, the rigid sail produce effective thrust from existing winds, reducing the main engine power required, and, therefore delivering fuel consumption and pollutant emissions reductions of up to 40%. The return on investment from reduced fuel consumption is less than 5 years.

“This project marks another leap in our dedication to decarbonization. As the first tanker company to test the suction-sail technology, we demonstrate our innovative capabilities and dedication to a more sustainable shipping sector. We all have a responsibility to use as few resources as possible, and Odfjell’s long-time efforts in energy efficiency have significantly reduced our fleet’s emissions. The work continues, and we look forward to documenting further improvements with the installation of suction sails,” says Erik Hjortland, vice president for technology at Odjfells.

The Takeaway

There is no law that applies to the high seas. Beyond territorial waters, ship owners are free to do whatever they want, for all practical purposes. The shipping industry and the nations of the world have been struggling for years to create a framework for reducing carbon emissions from ships, but any such plan is largely unenforceable.

The shipping industry agreed in July to reduce its greenhouse gas emissions to net zero “by or around, i.e., close to, 2050.” The nonbinding agreement is essentially toothless, but meant as a signal to governments of where to benchmark their (binding) targets, according to The New York Times. The agreement would have been even more lax if not for a “strong last-minute push” from small island nations and other less economically developed coastal countries.

My colleague Michael Barnard is cool to the idea of adding sails to cargo ships. Not everyone on the CleanTechnica sled dog team agrees with him. The real issue is whether sails can help cut fuel consumption enough to pay for the technology in a reasonable period of time. BAR Technologies, Cargill, bound4blue, and Odjfell seem to think they can.

It may take a few years for the data to prove or disprove that sails can help decarbonize ships, but doing something is better than doing nothing. The companies testing these new technologies should be applauded for thinking outside the box. If a new age of (partial) sailing ships is in the offing, Jimmy Buffett will be pleased.

I don’t like paywalls. You don’t like paywalls. Who likes paywalls? Here at CleanTechnica, we implemented a limited paywall for a while, but it always felt wrong — and it was always tough to decide what we should put behind there. In theory, your most exclusive and best content goes behind a paywall. But then fewer people read it! We just don’t like paywalls, and so we’ve decided to ditch ours. Unfortunately, the media business is still a tough, cut-throat business with tiny margins. It’s a never-ending Olympic challenge to stay above water or even perhaps — gasp — grow. So …