The new Titan side tipper truck unloader is designed to help remove inefficiencies in bulk material handling.

The OPS Group offers a diverse and extensive range of mineral processing and handling equipment in Australia, and one of its key brands is Telestack.

Through the equipment and products it supplies, OPS aims to remove inefficiencies in bulk material handling processes.

“We see opportunities anywhere where can eliminate loaders or haul trucks, reduce labour requirements or save fuel,” OPS area manager of capital sales Gerry McGuigan told Australian Mining.

“We already offer some really unique track-mounted solutions such as the Telestack Titan T1600-8 mobile truck unloader that can accept rigid haul trucks up to CAT 777 size and the popular Telestack HF24T.

“The HF24T was developed for OPS by Telestack to provide an easily relocatable tracked mobile reclaim feeder capable of up to 3000 tonnes per hour and accept CAT 992 and larger loaders.

“Given the increased number of side tipper road trains in our operation, and feedback from haulage providers, it was quite a natural material handling challenge for us to approach next.”

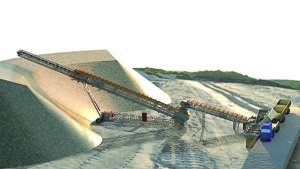

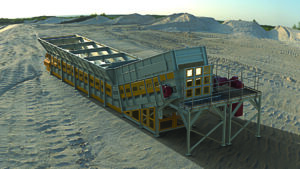

Telestack has now introduced the side tipper truck unloader as part of its Titan range.

The new unloader is a surface feeder that accepts material from side-tipping trucks or road trains. It acts as an alternative solution that allows side tippers to discharge directly into conveying systems.

“The side tipper truck pulls alongside the unit. It can tip its entire (single) trailer contents into the unit and move to next trailer,” McGuigan said.

“The sider tipper unit will then receive the full trailer load onto its apron belt feeder and feed this into a conveyor system for ship-loading at a controlled rate.”

Deep-pit or underground truck tipping hoppers usually require costly civil work to install and cannot be moved or relocated as a plant expands. Rear-tipping truck unloaders are also at a disadvantage since set-up cycle times are longer than a side-tip solution setup.

However, a surface feeder provides operators with a semi-permanent solution that can be being fixed during operation and relocated later.

Enter the Titan side tipper unloader, a semi-permanent installation that can be fixed during operation and moved to suit the needs of an expanding operation.

The new machine was developed after OPS identified a need to eliminate excess handling as mines were moving more material via roads.

The versatile design of the side tipper unloader means it can be fed by wheel loaders, grab cranes and excavators to transfer material, and reclaim to other conveyors if needed.

“The Telestack truck unloader can be quickly assembled and will have multiple height options, so we can run lower profiles and minimise ramps heights where required or higher volume tip area where possible,” McGuigan said. “It is also designed so we can add additional sections to extend the length of the tip area if required.

“OPS will always aim to have a unit in stock or manufacture so lead times will be significantly better than our competitors.”

The feed hopper of the Titan side tipper unloader is designed to receive a larger load under a controlled tipping procedure through its 10m reception hopper. It will also reduce truck cycle time and increase system throughput, further streamlining the process.

“With the increasing number of smaller and more remote mining operations coming online, and more material being moved by road from mine to ports, we saw this as a real opportunity to remove some costs and complexity from the process,” McGuigan said.

“Every time you handle the material, it adds additional cost from the equipment, labour and fuel used. Our aim is to remove some of these rehandling processes and therefore the associated financial and environmental costs.”

This feature appeared in the October 2023 issue of Australian Mining.