Effective May 31, 2023, Tier 1 Energy Solutions Inc. and Winterhawk Casing Expansion Services have entered into a new partnership agreement to further increase the commercial application of casing expansion for a variety of wellbore remediation and completion services.

Since 2015 Winterhawk has developed revolutionary, patented wellbore casing expansion tools and services that allow wellbore owners to use their existing production casing as part of the solution for wellbore remediation or improved production.

Founded in 2013 in Edmonton, Tier 1 is a leading provider of downhole tool and wireline solutions for completions, workovers and abandonments.

The two companies have been working together since 2018. Under the new arrangement, Tier 1 will be adding applications and marketing to existing support with field service delivery, operations, quoting and billing, engineering, assembly, testing, warehousing, logistics and outsourced manufacturing.

Since the first test well of current design in the summer of 2018, Winterhawk has made significant progress in many areas These include:

- Tools for 114.3mm (4½”), 139.7 mm (5½”) and 177.8mm (7”) casing

- All sizes available single, dual or triple element configuration

- Elements proven to deliver at least four expansions in a single run, with some runs as high as six expansions depending on casing and cement properties

- The ability to install from 12 to 18 expansions in a single wellbore intervention

- Reliable and predictable tool set and release after nearly 160 expansions

- No stuck tools or tool failures

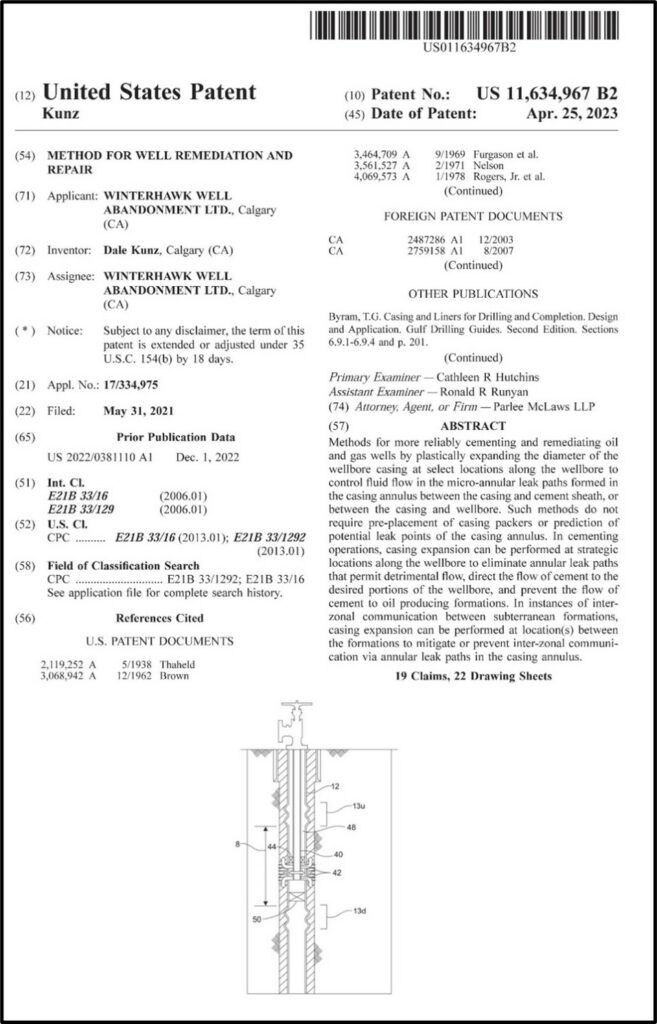

- S. Patent 11,585,178 B2 – Casing Expander for Well Abandonment – issued February 21, 2023

- S. patent 11,634,967B2 – Method for Well Remediation and Repair – issued April 25, 2023

Historically, casing has primarily served as a barrier between the inside and outside of the wellbore. The outside of the casing – the space between the casing and the wellbore through the rock or the next string of casing – is called the annulus.

The properties of the annulus are critical for wellbore integrity, however, this is also the most difficult part of a wellbore to diagnose, access and remediate.

Winterhawk’s vision is to use the casing itself as a method of changing the behavior of the annulus. Before casing expansion, the only way to seal or change the properties of the annulus was either a quality primary cement job when the casing was installed, or perforation of the casing and injection of cement or some other sealant.

Re-cementing the casing annulus after the casing has been installed and cemented is a complex and expensive process that is too often not as effective as wellbore remediation engineers require. Resealing the annulus to remediate surface casing vent flows – the most common use of the so-called “cement squeeze” – has an historically low success rate. Even identifying the source of the troublesome venting gas is a challenge that contributes to unattractive success rates.

The core challenge remains: how to identify the gas source, perforate the casing and squeeze sealant into the annulus in the hope they do the right thing in the right place.

Casing expansion is the first significant new tool in the wellbore remediation toolbox in years. By expanding the casing, the cross-sectional area of the annulus at the expansion point is materially reduced. This has the same effect on flow as pinching a garden hose, except in reverse.

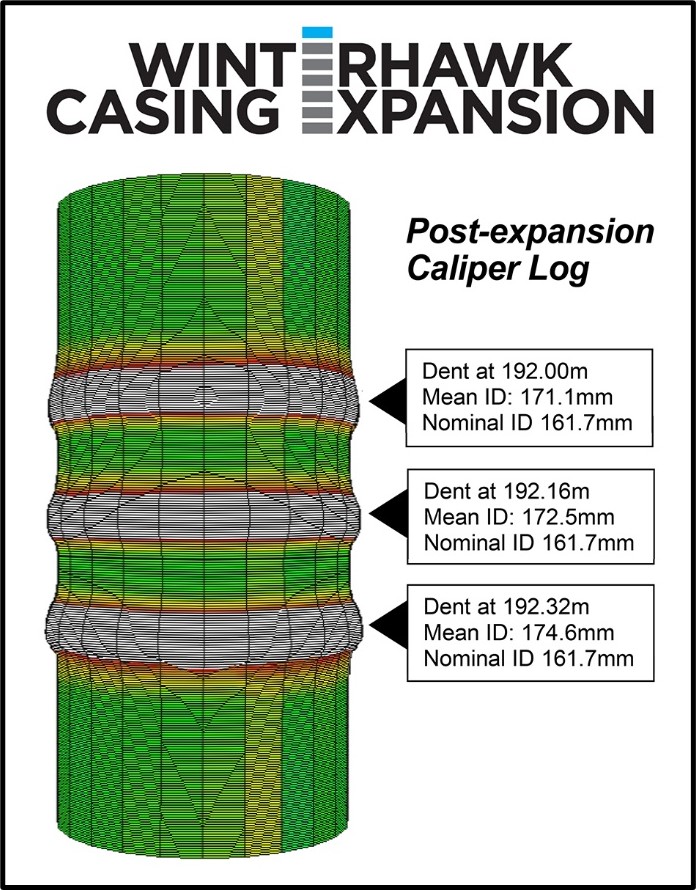

The following digital image of a multi-finger casing caliper log demonstrates how casing expansion works.

In cemented casing, the 177.8mm was increased from 9.4 to 12.9mm, an average of 6.2%. In this scenario, the cross-sectional areas of the annulus of gauge 222.25mm hole are reduced by 23%. This is more than adequate to materially impact the flow of micro-annular leaks, contracted cement or wormholes.

A producing application brought to Winterhawk’s attention is using casing expansion to arrest interzonal flow that can impair production from above or below the perforation in the producing interval. This is a sensitive area in which to add more perforations or inject cement. Casing expansion below or above the producing interval may address this problem.

nother area that can be improved is cement squeezes in extended channels or in wells that did not have primary cement but now require it. Casing expansion can act as a post-cementing external casing packer by restricting the path of fluids in either direction. This greatly improves the likelihood that the cement or other sealant will flow to where it is required, not simply the path of least resistance either up or down the annulus.

These unique applications of annular remediation using casing expansion were regarded as sufficiently novel by the U.S. patent office that this was issued in April 2023.

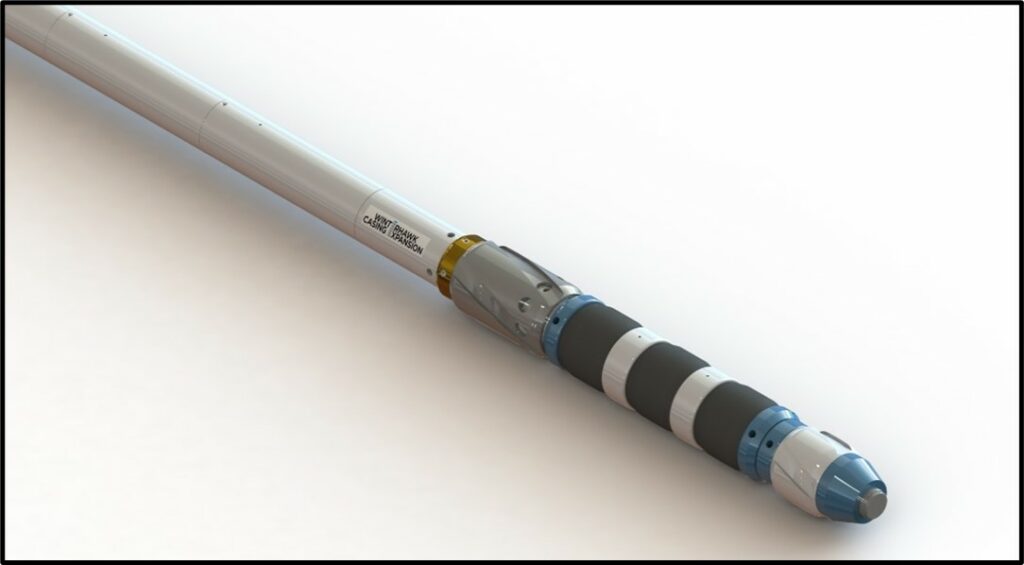

After extensive use of the single-element assembly, one of the most significant advancements was the design and field testing of the three-element assembly. This greatly increased the surface area of each expansion and extended the number of expansions for each run from four to six, to 12 to 18.

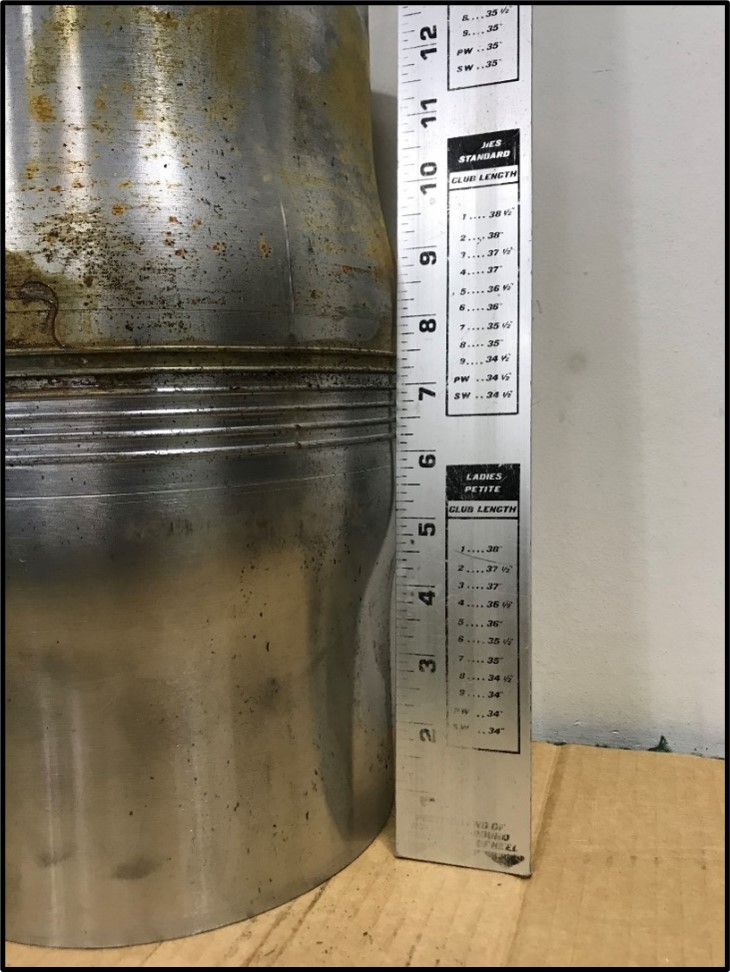

114.3mm three-element expander assembly

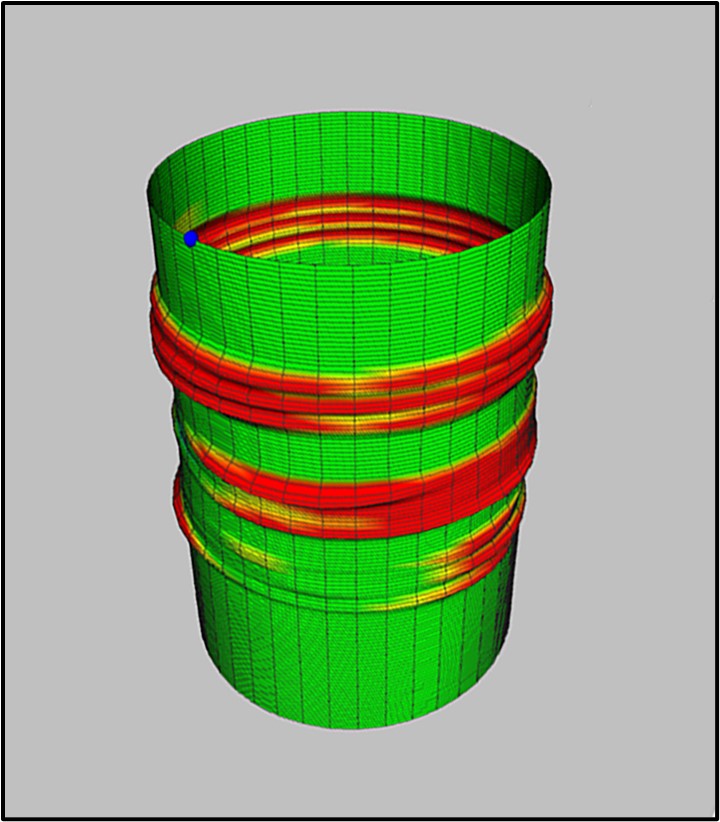

The first successful run for the three-element assembly in 2022 resulted in the following digital image from a multi-finger caliper log.

Multi-Finger Caliper Log of a three-set casing expansion using the three-element assembly. These nine expansions are within one vertical meter. This greatly reduces the cross-sectional area of the annulus in one run and about 40 minutes of operating time on bottom.

This same assembly was recently used to create 57 expansions in three wells for one operator. The results were as expected as experience grows with the CET in terms of application and placement. The CET materially reduces the cross-sectional area of the annulus by increasing the outside diameter of the casing and compressing the cement to effectively reduce gas flow and pressure.

Another use of the CET is for precision gas-source-depth identification. Continuous surface monitoring of the vent flow during CET operations quickly reveals if the expansion is above the gas source. This is proving to be a more effective diagnostic tool than wireline logging or surface sample isotope analysis of captured gas.

The last application for casing expansion that has attracted operator interest is using casing expansion for a “steel-on-steel” seal for hostile applications such as SAGD. Operators and service companies have worked for years to modify a variety of production packers and liner assemblies with various element materials to operate successfully in the high temperatures associated with thermal recovery.

For shop tests, Winterhawk and Tier 1 built a modified extended element and steel-sealing sleeve. The objective is to greatly increase the surface area of expansion and adhere securely inside production casing.

Winterhawk technology generates a 500,000-pound axial force that it has used extensively for the testing of steel expansion properties and element behavior. Winterhawk has tested hundreds of casing and element configurations over the years to simulate the behavior of the CET in the majority of domestic wellbores prior to running.

This illustrates a three-inch long expansion with sealing ridges on the sealing sleeve after it was expanded inside casing then extracted from the casing by cutting it open. The expansion process causes sufficient expansion of the casing to seal and hold it in place.

The addition of an elastomer sealing component would increase the pressure rating of the sealing sleeve. However, as is the case with existing high temperature packer or liner sealing assemblies, elastomeric materials would not be as durable as steel-on-steel during cyclical expansion and contraction.

As with all innovations, the introduction of a disruptive technology like casing expansion takes time for well production, completion engineers and well operators to fully embrace.

With more wells aging and reaching the end of their service life, the properties and behavior of the wellbore annulus has become one of the oil and gas industry’s new challenges.

Tier 1 and Winterhawk believe they have a new and proven method for completion and remediation that will reduce costs and improve wellbore integrity.

For further information contact:

Ian Thomson, Vice-President Business Development C 403 804 4108 E i.thomson@whwa.ca

Ian Cameron, Senior Account Manager C 403 815 7662 E i.cameron@whwa.ca

Share This:

Next Article