Wastewater, also referred to as process water, emerges as an inevitable by-product across various sectors, including chemical, refining, pharmaceutical, and food industries. In line with EPA regulations, it is imperative that any water either returning to or engaging with the natural environment is rendered safe and maintains a consistency akin to that of the naturally occurring water in the vicinity.

In the realm of the fracking industry, the reuse and recycling of water are not mere practices but essential compliance measures. As water is reintegrated into the environment during the fracking process, it is imperative that this water, known as fracking water, is treated meticulously. Contaminated with well materials and chemicals, fracking water poses potential harm if not managed correctly. To mitigate these risks, the water undergoes rigorous filtering and pH balancing processes, ensuring it can be either reused in fracking operations or safely returned to the water table. The incorporation of Tank Liquid Agitators (TLA) technology plays a pivotal role in enhancing the efficiency and effectiveness of treating fracking water, marking a significant advancement in environmental stewardship within the industry.

The process of fracking has faced its share of environmental concerns, primarily due to the use of injection wells and the potential for environmental harm if procedures are not followed with precision. The fracking process unfolds in stages: initially, a mixture of clean water, sand, and chemicals is propelled into wells that extend up to 10,000 feet underground at high pressures. This action fractures the rock layers, creating fissures that are kept open by the injected sand, allowing oil or hydrocarbon liquids to ascend from the shale formations. Following the extraction, the oil is collected and transported to pipelines for further processing. Concurrently, the used fracking water is temporarily stored before being transported to treatment facilities. It is at this juncture that TLA technology becomes indispensable, offering a sophisticated solution to treat the water for reuse or safe release, underscoring the industry’s commitment to minimizing its environmental footprint.

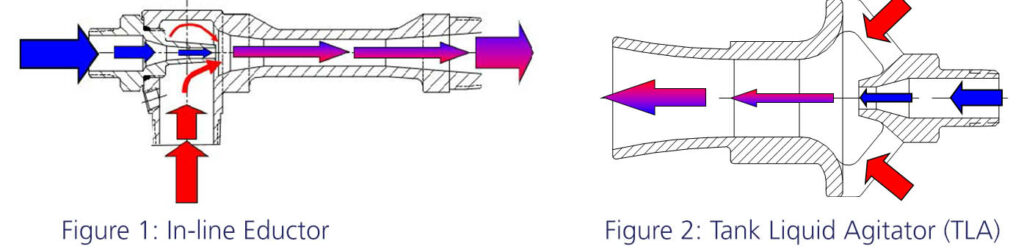

Figures 1 and 2 showcase the operation of both in-line and in-tank Eductors, employing the Venturi principle for effective fluid dynamics. In this setup, a motive fluid—illustrated by a blue arrow—traverses through a Venturi tube, establishing a pressure differential within the mechanism. This differential acts as a catalyst, guiding a secondary fluid—denoted by a red arrow—towards a lower pressure zone. Ordinarily, this secondary fluid would not migrate towards such an area but is instead “educted,” or drawn in, facilitating a controlled process flow.

Before being treated, fracking water is subject to initial evaluations upon its reception at a treatment plant, focusing on its solid content, pH, conductivity, specific gravity, among other parameters. Gathering this information is vital for the treatment facility to aptly adjust the water’s pH, neutralize it, and filter out any contaminants, ensuring the water is fit for reuse. The subsequent purification process is methodically divided into four primary stages, detailed below, each tailored to meticulously cleanse the water for its intended reuse in fracking operations or for safe reintroduction into the environment.

Step 2: Flocculation – Transitioning from the decanting process, the water enters the flocculation stage, enhanced by Tank Liquid Agitator (TLA) technology. This phase involves the addition of specific chemicals into the tank, with TLAs ensuring a thorough mix of the chemicals with the water to facilitate solid formation. At the molecular level, these chemicals induce reactions that promote molecular adhesion, leading to the assembly of small particles, referred to as colloids, into larger aggregates or “flocks”. The intense mixing provided by the Eductor generates a high-velocity environment within the tank, crucial for fostering these molecular interactions.

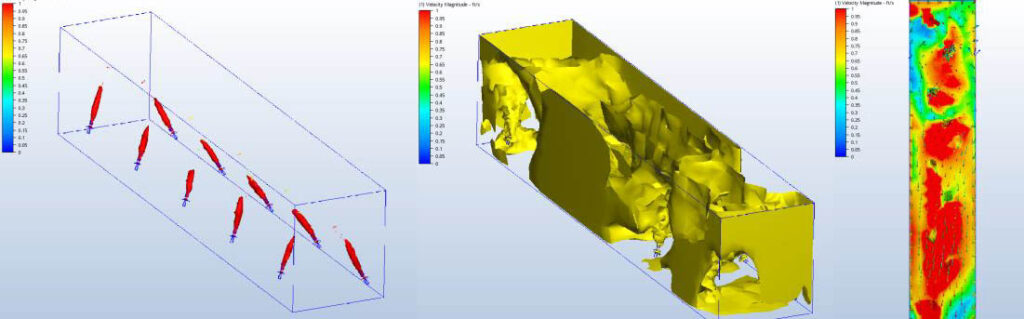

To further refine the process, engineers employ digital modeling to simulate the tank and TLAs, as illustrated in Figure 3. This step involves Computational Fluid Dynamics (CFD) analysis to ascertain the optimal positioning of TLAs within the tank. The analysis aimed for an ideal flow rate of 540 gallons per minute at 30 pounds per square inch gauge (psig), achieving an average velocity of 0.6 feet per second within the tank. This velocity surpasses the required net movement for effective flocculation, ensuring the process’s success.

Figure 3 – Showcases various phases of the Computational Fluid Dynamics (CFD) analysis, depicted from left to right: the initial setup, an intermediate stage highlighting the average velocity profile, and a cross-sectional view revealing the complete velocity profile within the tank.

Step 3: Oxidation – Following the flocculation stage, the treated water is transferred to an oxidation tank. Here, in-line Eductors play a crucial role by infusing oxygen directly from the air into the water. This oxygenation process introduces numerous small bubbles into the tank, which are then circulated to its base to ensure a uniform distribution throughout the water. These oxygen bubbles significantly increase the water’s surface area, enhancing the efficiency of subsequent chemical reactions. Specifically, the added oxygen reacts with metallic elements present in the water, facilitating their removal via chemical oxidation, thereby purifying the water further.

Step 4: Filtration – At this final stage, the process employs a carbon fiber sieve to physically separate the floc from the water, utilizing gravity to facilitate the separation. Once isolated, the floc undergoes environmentally responsible disposal. This step ensures that the remaining water is purified and meets the standards for either reintroduction into fracking operations or release back into the water table, adhering to environmental safety protocols.

Figure 4: Illustrates the filtration process, capturing the sequence from the high-velocity mixing that produces the floc, showcased in the leftmost cup, through the carbon fiber sieve where floc particles are trapped, displayed in the middle, to the resultant clear water, depicted on the right, ready for reuse or environmental discharge.

The adoption of Eductor technology for mixing and aeration has significantly enhanced the efficiency of processing in fracking water treatment applications. Illustratively, a particular fracking wastewater treatment facility has seen its capacity increase to treating and purifying eight to ten trucks of used fracking water daily, thanks to the implementation of in-line Eductors and TLAs. This is a notable improvement from the facility’s previous capability of processing merely one to two trucks per day. The utilization of Computational Fluid Dynamics (CFD) analysis has been instrumental in providing the facility with accurate data regarding the velocity within the tank, instilling confidence in the effective application of this established technology for their specific needs.

In summary, Eductors stand out for their lack of moving parts and the absence of maintenance requirements, setting them apart from mechanical mixers in terms of effectiveness. Tank Liquid Agitators (TLAs) offer the versatility to be ideally situated within tanks of any configuration and dimension. For wastewater and process water treatments, the integration of TLAs and in-line Eductors is instrumental in enhancing the mixing and blending efficiency of plants, simultaneously contributing to a reduction in the water footprint of these facilities.

For more information on the advanced wastewater treatment solutions offered by Westech Industrial and Clark Reliance, and to explore their expertise in the field, visit Westech Industrial’s website at westech-ind.com or call us at 1-800-912-9262.

Share This:

Next Article