Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

A primer on refrigerants and their impacts on climate change.

Refrigerants are everywhere. They’re in our air conditioners and heat pumps, in our fridges — even in our cars! Yet, despite this ubiquity, refrigerants are an oft-neglected subject within electrification strategies despite their major contribution to the greenhouse effect.

Perhaps this disregard stems from the perception that refrigeration is either a mundane or overly technical subject. Many resources are dense and chock-full of acronyms.

In this article, I’ll hopefully convince you that refrigerants can be a fascinating subject, and one that’s essential to understand if we’re serious about decarbonizing our buildings.

I’ll start with some refrigerant basics, then dive into a few big-picture questions, including: How has the refrigerant industry evolved over time? How common are leaks and why are those leaks problematic? And, lastly, how much do refrigerants contribute to building sector emissions?

What makes a (good) refrigerant?

Refrigerants are fluids that can be easily heated into a vapor (evaporated) and then cooled back to a liquid (condensed) over and over again. “Easily” means boiling at a very low temperature — we’re talking colder than -25°F for many common refrigerants.

You might be asking — what’s the point of all this evaporating and condensing? In short, it allows refrigerants to capture heat and transport it from one place to another. For instance, they soak up heat from inside your fridge and dump it outside.

Refrigerants can also be used to move energy for thermal storage. For heat pump water heaters, refrigerants absorb heat from the surrounding air and channel it into a hot water storage tank. Refrigerants make the magic of heat pumps possible — by transferring heat rather than creating it, heat pump systems can operate at more than 300% efficiency!

Ideally, refrigerants are also low- or non-flammable, low- or non-toxic, don’t deplete the ozone layer, and aren’t horrible for the climate (more on this later). There are millions of potentially usable refrigerants, but only a couple dozen that meet these criteria.

Are refrigerant leaks common? If so, why does it matter?

Refrigerant leaks are never a good thing. At best, they’re a pain for building owners and a potential indication of a faulty system. At worst, they can severely damage the ozone layer and contribute to global warming.

So, how much do refrigerant systems leak? This question is complex — leakage varies based on factors like equipment type, installation quality, and maintenance (or lack thereof).

Grocery store refrigerators are among the worst offenders, losing 30% of their charge each year on average. Variable refrigerant flow (VRF) systems are another potential concern. While less prone to leaks (estimated 6% annual loss), VRF units contain large volumes of refrigerant. So, even a small percentage leak equals a lot of refrigerant in the atmosphere.

An annual leakage rate of 4% is typical for both heat pumps and chillers. While 4% might not sound like a lot, keep in mind that these units continue to lose refrigerant over their decade-plus lifespan.

It’s not realistic to completely prevent leaks from happening. That’s why it’s essential to convert to lower-emission alternatives. That way, when leaks happen, they don’t contribute so significantly to global warming.

How much do refrigerants contribute to climate change?

It depends.

Some refrigerants are dramatically worse than others in terms of climate damage. That damage is denoted by two metrics: Ozone Depletion Potential (ODP) — i.e., how good a refrigerant is at tearing apart the ozone layer — and Global Warming Potential (GWP), which measures a chemical’s ability to trap heat in the atmosphere. For GWP, carbon dioxide (CO2) is used as the baseline and has a GWP of 1.

Luckily, ozone-depleting refrigerants have largely gotten the ax. In 1987, in an inspiring example of countries coming together to solve a human-caused problem with the climate, world leaders agreed to ban halons and chlorofluorocarbons (CFCs) — the refrigerant groups with the highest ODP. Hydrochlorofluorocarbons (HCFCs), a group of refrigerants with weaker ODP, were finally phased out as of 2020. Popular HCFCs like R22 can no longer be produced or imported to the U.S., but may be used from recycled or stockpiled capacity.

Okay, that was a lot of acronyms. Any easy mnemonic is that refrigerants with “CFC” in the name release chlorine molecules that tear apart the ozone layer.

Hydrofluorocarbons (HFCs), refrigerants commercialized in the 1990s to replace CFCs, are the most commonly used refrigerants today. While they don’t damage the ozone, HFCs typically have 1000+ GWP; the most potent among them exceed 10,000.

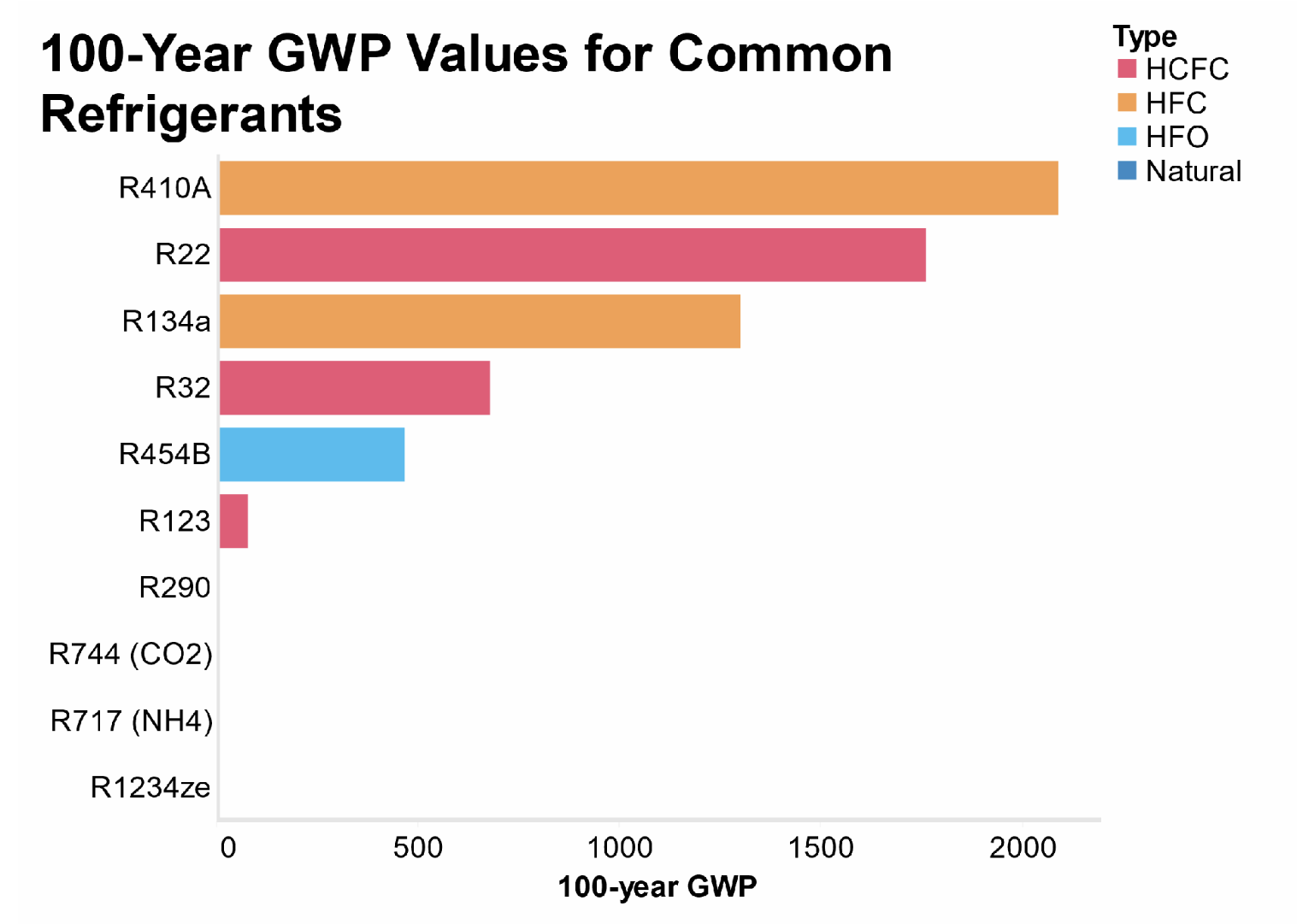

The graphic below displays some commonly used HFCs and HCFCs, as well as some low-carbon alternatives.

There are billions of cooling appliances across the world, and most use HFCs. Left unchecked, emissions from these devices alone could contribute 0.3–0.5°C of global warming by 2100.

Not-so-fun fact: Leaking one 12-oz can of R134a is like burning 110+ gallons of gas!

Fortunately, 197 countries agreed to constrict HFC production through the 2016 Kigali Amendment. While this pact is a great first step, implementation and enforcement at the country-level is still necessary. The U.S. is leading by example through the 2020 American Innovation and Manufacturing (AIM) Act.

Under AIM, the EPA will attempt to curtail HFC consumption by 85% over the next twelve years. There’s an important milestone coming up at the start of 2025: new heat pumps and air conditioners cannot use refrigerants with GWP greater than 750. This means that manufacturers will have to find a replacement for the ubiquitous R410A (which far exceeds that threshold with a GWP of 2,088). It will likely be replaced by R454B (the blue bar in the graphic above) in many applications.

In my next article, I’ll discuss some of the available low-GWP refrigerants. I’ll also explain why the transition away from HFCs will be far harder than it was for CFCs.

Noah Gabriel is a Project Manager at New Buildings Institute (NBI). At NBI, Noah manages multiple projects involving cutting-edge heat pump water heater (HPWH) research and deployment. Noah is a subject matter expert on HPWH load shifting and leads the demand response component of the Advanced Water Heating Initiative.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica.TV Videos

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy