Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

I recall in the early days of the modern electric vehicle era when the Tesla Model S and the BYD e6 were top selling electric cars. The BYD e6? Well, if you know, you know. If you weren’t around back then, or even if you were and need a refresher, let’s get into that first. The Model S — well, everyone knows about that, it was super fast and fun. The e6 was chunky and was throttled to not allow you to accelerate fast. It was weird. Nonetheless, because of all the guardrails put around it, it had enough range and usefulness at a decent price that it was a popular car for taxis.

One core difference between the two cars were their battery chemistries. The Model S was using a high-energy-density nickel-cobalt-aluminum (NCA) battery chemistry whereas the BYD e6 was using a low-energy-density lithium-iron-phosphate (LiFePO or LFP) battery. Oh boy, how do I remember the Tesla fans trashing LFP battery chemistry! I could go on and on about how it was ridiculed and how Tesla fans claimed you could never make a good electric car with it. But the chemistry was cheaper, even if you couldn’t pack as much electricity in the same size pack.

Gradually, battery design and production improved, and LFP energy density got better and better, while still being relatively cheap. Eventually, in fact, even Tesla started using LFP batteries in its cheaper models. Major battery makers started making LFP batteries more and more, too. But if you’ve been paying close attention over the past decade or so, you know all that already, right? On to the news.

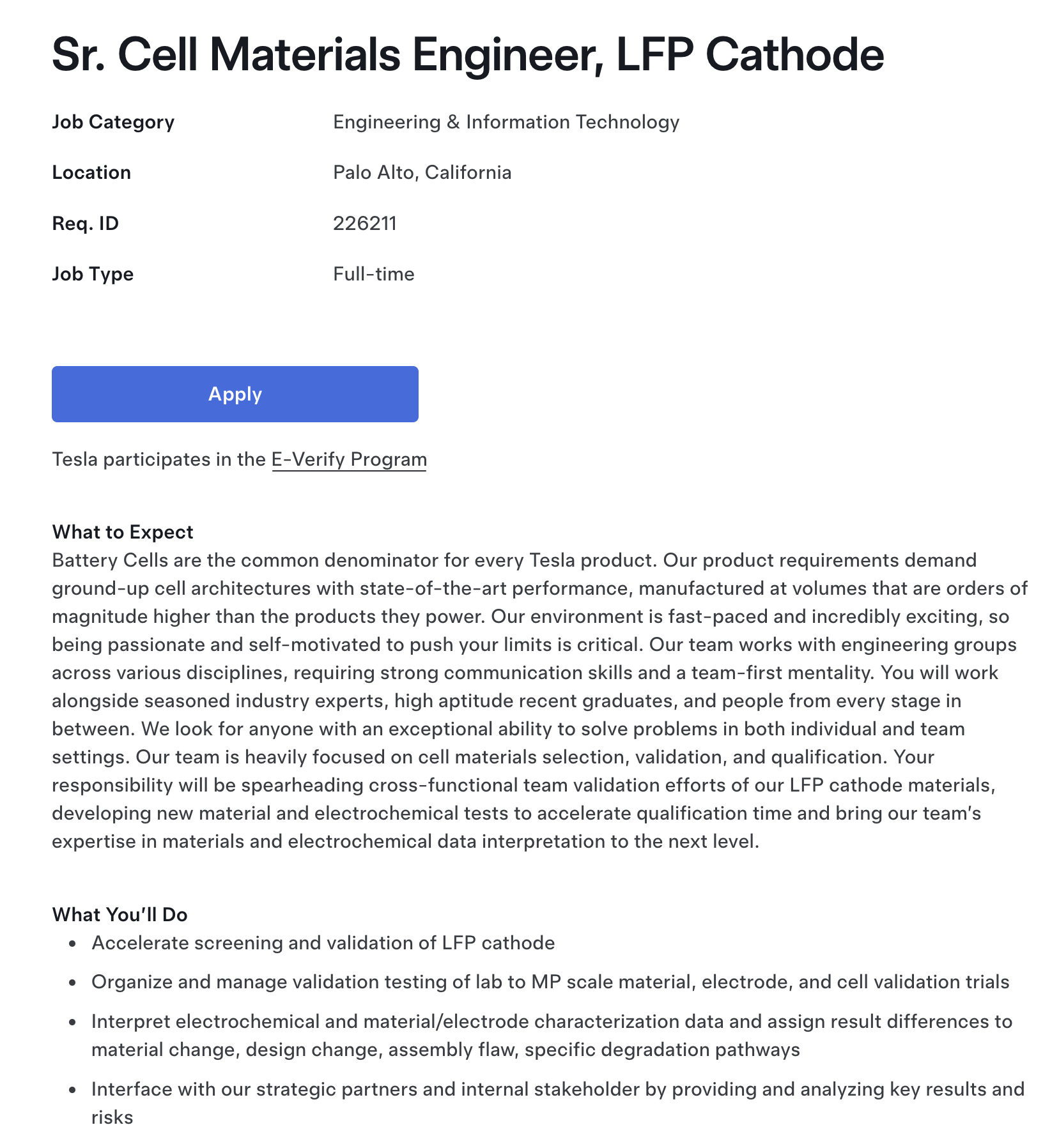

The news is that it now looks like Tesla will start producing its own LFP batteries in-house, or at least its own LFP cathodes. Zachary Visconti spotted that Tesla has posted a new job listing on its careers site — a job opening for a Senior Cell Materials Engineer position specifically for an LFP cathode program. For more detail, here’s part of the job description: “Your responsibility will be spearheading cross-functional team validation efforts of our LFP cathode materials, developing new material and electrochemical tests to accelerate qualification time and bring our team’s expertise in materials and electrochemical data interpretation to the next level.

What You’ll Do

- Accelerate screening and validation of LFP cathode

- Organize and manage validation testing of lab to MP scale material, electrode, and cell validation trials

- Interpret electrochemical and material/electrode characterization data and assign result differences to material change, design change, assembly flaw, specific degradation pathways

- Interface with our strategic partners and internal stakeholder by providing and analyzing key results and risks.”

Cool news. I recall, also, that when Tesla Battery Day was approaching four years ago, our own Maximilian Holland wrote a long piece explaining what he thought Battery Day would be all about — LFP batteries. Elon Musk responded that, although that wasn’t what Battery Day would be about, Max made some very good points.

No, but you make some great points. Important to note that iron’s cost advantage is partly offset by increased pack mass, so the fully considered cost is closer to nickel. That said, iron alleviates much of the scaling problem.

— Elon Musk (@elonmusk) September 17, 2020

As it turns out, four years later, the battery industry is more into LFP than ever and Tesla also continues to move more and more into LFP batteries. Who would’ve guessed it? (Other than Max.)

“The company is also set to work with Chinese manufacturer Contemporary Amperex Technology Co. Limited (CATL), with an executive from CATL earlier this year hinting at plans to develop low-cost batteries for a large-volume EV from the automaker,” Zachary Visconti adds. “A report from Bloomberg in January also said that Tesla would be buying machinery from CATL to build in-house LFP batteries for its Megapack, though it would be 100-percent operated by Tesla.”

We’ll see where it all leads, but with the Inflation Reduction Act heavily supporting reshoring of manufacturing jobs in the US, especially through the production of EV batteries and battery components, I assume Tesla will be building out battery component and LFP battery production plans in the US in coming years and this is part of that.

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy