Split flow pumps and synchronized lifting systems are two innovative solutions widely utilized in engineering, particularly in the fields of construction and maintenance of large structures. These technologies serve distinct purposes and operate on different principles, offering solutions to complex lifting and positioning challenges. Understanding the differences between these systems is crucial for engineers, project managers, and technical teams involved in heavy-lifting operations.

Split Flow Pumps

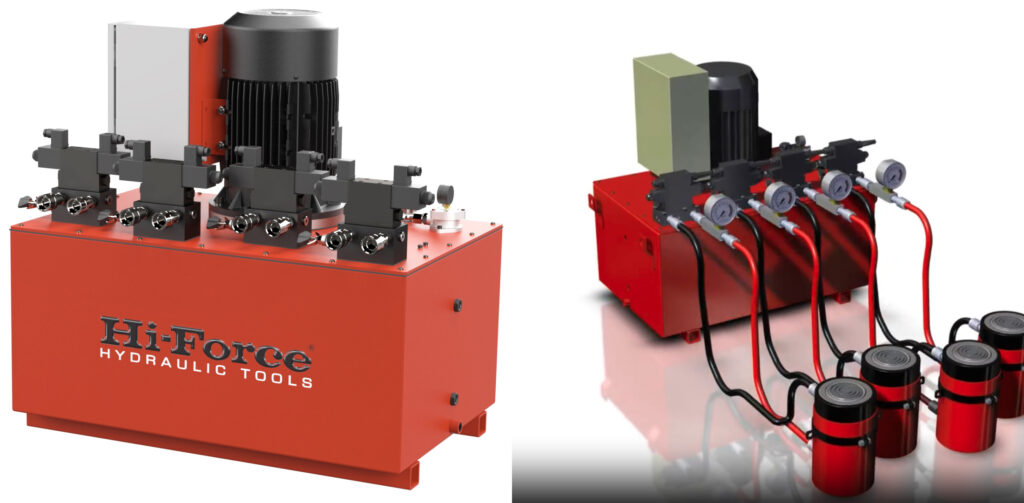

Split flow pumps are hydraulic systems designed to simultaneously operate multiple jacks or hydraulic cylinders while maintaining the ability to control each jack individually. This technology is primarily used in situations where heavy loads need to be lifted, lowered, or positioned with high precision across multiple points. The “split flow” term refers to the pump’s ability to distribute hydraulic fluid at different rates and pressures to various jacks connected to the system, hence allowing for the simultaneous but individual control of each point of the lift.

One of the key advantages of split-flow pumps is their versatility. They can be configured to manage loads of varying weights across multiple lift points, making them ideal for tasks such as bridge lifting, machinery installation, and large-scale structural adjustments. This is achieved through a centralized control system that can precisely adjust the flow and pressure to each jack, ensuring the load remains balanced and controlled throughout the lifting process. Split flow pumps are also considerably less expensive than Synchronize Lifting Systems.

Synchronized Lifting Systems

Synchronized lifting systems, on the other hand, are advanced hydraulic systems designed to ensure the precise lifting, lowering, or positioning of heavy loads with utmost synchronization. These systems use a network of hydraulic jacks or cylinders connected to a central control unit that monitors and adjusts the pressure and flow to each lifting point in real-time. The primary goal of synchronized lifting systems is to maintain the load’s stability and integrity by ensuring that all lifting points move in perfect harmony, minimizing the risk of structural damage or uneven loading.

The technology behind synchronized lifting systems incorporates sophisticated sensors and control algorithms to continuously monitor the position and load on each jack. This real-time feedback allows the system to make immediate adjustments to the hydraulic flow and pressure, ensuring the synchronization of all lifting points throughout the operation. Synchronized lifting systems are particularly useful in applications where maintaining the alignment and structural integrity of the load is critical, such as in the construction of bridges, the maintenance of large industrial machinery, or the relocation of historical buildings.

Key Differences

The primary difference between split flow pumps and synchronized lifting systems lies in their operational focus and application. Split flow pumps excel in scenarios where multiple lifting points require individual control but not necessarily in perfect synchronization. This allows for flexibility in managing complex lifting tasks where each point may need to be adjusted independently to achieve the desired positioning of the load.

Conversely, synchronized lifting systems are designed with the express purpose of maintaining absolute synchronization across all lifting points to protect the load’s structural integrity. These systems are ideal for delicate operations where any discrepancy in lifting could result in damage or misalignment.

In summary, while both split flow pumps and synchronized lifting systems provide valuable solutions for managing heavy loads, they cater to different needs within the spectrum of lifting operations. Split flow pumps offer the advantage of individual control across multiple points, making them suitable for a wide range of lifting and positioning tasks. Synchronized lifting systems, however, are tailored for operations requiring high precision and synchronization to preserve the load’s integrity and alignment. The choice between these two technologies ultimately depends on the specific requirements of the project at hand, including the nature of the load, the desired outcome, and the operational environment.

At KASI, we understand the diverse demands of lifting and construction projects. That’s why we offer a full range of equipment capable of meeting your specific needs. Our team is Backed by Field Experience and provides the best solutions for our clients. Whether you require split flow pumps, synchronized lifting systems, or any other specialized equipment, KASI is Your Reliable Source in Canada.

Summarized by Scott Fong

Group Director of KASI Technologies Inc.

Share This:

Next Article