Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

In June, we told our readers about Sublime Systems, a company that makes cement without releasing massive clouds of carbon emissions into the atmosphere. It is one of many ideas to come from the fertile brain of Yet-Ming Chiang, the creative genius at MIT who is responsible for several innovative companies, among them American Superconductor Corporation, A123 Systems, Desktop Metal, Form Energy, and 24M Technologies.

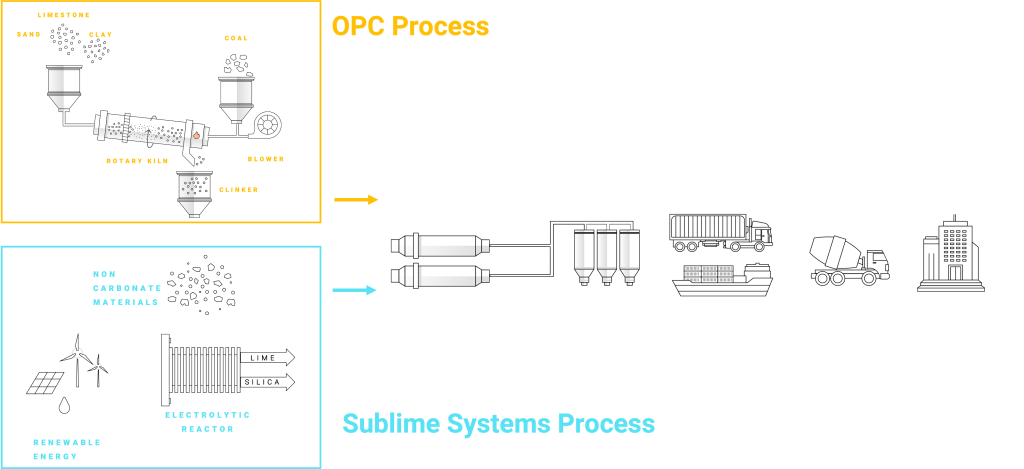

Making Portland cement is responsible for about 8% of all carbon emissions globally every year. There are two reasons for that. First, limestone needs to be heated to around 2700º F in giant kilns to create the basic materials for cement. It takes a lot of energy to do that, energy that typically comes from burning methane gas. Second, the chemical reaction inside those kilns releases even more carbon dioxide.

It is all well and good to develop a new technology that cuts carbon emissions — the Earth needs all the help it can get — but if your spiffy new product doesn’t have the right approvals and certifications, no one will use it. Obtaining them means submitting products to rigorous testing procedures — the first step in meeting building codes. No testing means no certification, no code approval, and no market opportunity.

In 1898, the American Society for Testing and Materials was founded. It is now known as ASTM International and manages nearly 13,000 industrial standards worldwide. Until recently, most of the standards relating to cement were based on the recipe, and the key ingredient in that recipe was Portland cement.

30 years ago, ASTM created a new standard known as ASTM C1157 that is performance-based rather than recipe-based. It specifies specifies performance requirements across parameters including strength development, durability, and low shrinkage. This week, Sublime Systems announced that its low carbon, scalable, drop-in replacement for traditional cement in concrete has obtained the ASTM C1157 designation.

Meeting that standard means Sublime cement can be used to make concrete that meets or exceeds applicable US and international building codes, unlocking a path for it to replace ordinary Portland cement at scale to massively lower the carbon output of the global construction infrastructure.

Making Sublime Low Carbon Cement

Image courtesy of Sublime Systems

Sharp-eyed readers will want to know more about how Sublime Systems takes the carbon dioxide out of making cement. The answer is threefold. First, the process is designed to use electricity from renewable sources instead of fossil fuels. Second, the Sublime process takes place at room temperature, which eliminates the need for extreme heating. Third, instead of using limestone as the primary ingredient — which releases carbon dioxide when heated — the Sublime process uses a variety of non-carbonate raw materials.

Those of you who are interested in delving a little deeper into the technical details are invited to visit the company’s technology page on its website, which says, “We use an electrochemical process that can turn abundantly available non-carbonate rocks and centuries of industrial waste that don’t release CO2 when they are decomposed into cement at ambient temperature — eliminating the need for fossil fuels entirely.”

Sublime Cement is manufactured with a “true-zero” (as opposed to net-zero) approach. It does not require offsets or additional carbon capture and storage infrastructure to reduce emissions.

“Sublime was founded to have a swift, massive, and enduring impact on global CO2 emissions, and we’ve designed our process to avoid CO2 at every step, rather than polluting and cleaning up afterwards,” says Sublime CEO Leah Ellis.

“At the same time, we take our responsibility in manufacturing a next-generation product very seriously. We need to make a high performing cement that is safe and easy to adopt. Data-driven performance-based standards, like ASTM C1157, allow us to solve the right problem: safety and carbon avoidance. Passing the ASTM C1157 standard is an important milestone in showing that Sublime’s low carbon cement innovation integrates into the same quality concrete building material that the construction industry requires.”

About ASTM C1157

In a press release on September 15, 2023, Sublime Systems said, “The ASTM C1157 specification is a performance based standard, a category that is being widely adopted by a range of industries as they allow for novel materials that can be produced with minimal emissions while maintaining rigorous and data driven standards for safety and performance.

“ASTM C1157 has more stringent strength requirements than older hydraulic cement standards — ASTM C150 for original Portland cement and ASTM C595 for blended cements, both of which contain prescriptive and performance requirements.”

To achieve the ASTM C1157 compliance certification, Sublime Systems provided its cement to a Cement and Concrete Reference Laboratory certified third party for testing. Sublime Cement — which is based on the recipe for Roman cement — exceeded all ASTM C1157 General Use performance requirements and outperformed many samples of OPC in ultimate strength and durability, which suggests the extension of the final product’s long-term service life relative to today’s industry standard will be excellent.

Sublime Systems is currently conducting additional tests measuring its cement’s performance in concrete through third party ready-mix concrete labs and in-field use cases. Its operational pilot facility has a current design capacity of >100 tonnes of cement per year and the company is in the process of commissioning its first commercial plant, which is expected to become operational in 2025.

“Sublime is on course to make CO2-free cement that performs better and costs less than what pours out of concrete trucks today,” said Clay Dumas, general partner at Lowercarbon Capital. “Now, the ASTM C1157 designation paves the way for global adoption of the world’sbcleanest cement.”

It is estimated that 70% of the infrastructure that will exist in 2050 to shelter the world’s growing urban population remains unbuilt. To balance such global construction goals with emissions reductions targets means a low-carbon approach like that taken by Sublime Systems becomes essential to not only meet this demand, but also surpass the performance of current standards.

It is critical to gain the confidence of the entire ecosystem of buyers in next-generation cement, spanning ready-mix concrete suppliers, concrete contractors, architects, engineers, general contractors, building owners, and government agencies.

Sublime Systems is in active discussions with customers and is actively planning for its first field pours in Q4 2023. “The global construction industry understands the importance of decarbonization of cement and concrete but has to balance this with the responsibility of executing large infrastructure projects that satisfy current specifications and maintain durability requirements,” said Jim Carreira, technical director at Boston Sand and Gravel. “Sublime’s ASTM C1157 compliance is an important step in increasing the industry’s confidence in shifting towards a drastically decarbonized material that performs like the material our industry currently relies on.”

“Thoughtful owners, designers, and contractors have long recognized that performance oriented specifications that ask for what is needed, instead of telling the suppliers what to do, result in the better value solutions,” said Don Davies, a structural engineering leader with projects in 18 countries and more than 50 major metropolitan centers.

“With proper testing and data back-up, we have long seen ASTM C595 and the fully performance oriented ASTM C1157 cements as the low carbon keys to our future. I am personally excited with how these next generation materials, like the C1157 Sublime Cement, will more rapidly slash emissions in concrete.”

The Takeaway

In a post on Medium, Sublime Systems says at first the company was nervous about suggesting to customers that they consider using cement that did not contain ordinary Portland cement, but soon learned that companies like Boston Sand & Gravel were quite comfortable using a product that met performance standards like ASTM C1157 instead of standards based on recipes.

“Customers don’t care about chemical composition of the cement they buy and use,” the company wrote. “We have yet to hear our customers talk about alite, belite, di- or tri-calcium silicate. Instead, they talk in terms of psi, water-to-cement ratio, slump, sulfate resistance, and alkali silica reaction. Ask any ready-mix QA/QC professional and they’ll tell you: Prescription does not assure performance.”

It takes courage to disrupt a global business like cement, but these sorts of technology breakthroughs are exactly what we need if we are to keep the Earth from becoming a baked potato.

Slashing carbon emissions may prove to be nearly as critical to keeping the Earth habitable for humans as electrifying the transportation sector. Obtaining the necessary testing certifications is hard work, but now that that step has been taken, the world is nearly ready for zero emissions cement to find its way into the built environment.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

EV Obsession Daily!

I don’t like paywalls. You don’t like paywalls. Who likes paywalls? Here at CleanTechnica, we implemented a limited paywall for a while, but it always felt wrong — and it was always tough to decide what we should put behind there. In theory, your most exclusive and best content goes behind a paywall. But then fewer people read it!! So, we’ve decided to completely nix paywalls here at CleanTechnica. But…

Thank you!

Tesla Sales in 2023, 2024, and 2030

CleanTechnica uses affiliate links. See our policy here.