Capital-intensive industries such as mining are typically slow to pick up new technology. However, this is beginning to change, and the mining sector is increasingly embracing technology to meet the demands of a rapidly evolving world.

As mines become more complex and the need for efficiency, safety, and sustainability grows, digital innovations are reshaping how mining operations are conducted. At the forefront of this technological shift are companies such as Normet, a global leader in underground mining and tunnelling solutions. With a strong focus on developing advanced tools and systems, Normet is helping to redefine the future of mining, integrating digital technology into every aspect of the industry to drive improvements in performance and environmental impact.

Automation and remote monitoring: A new era of efficiency

One of the most significant developments in today’s digital mines is the rise of automation. Where once operators had to control every aspect of heavy machinery manually, much of this work is now handled by automated systems. These systems not only take over repetitive tasks but also enhance safety by reducing the need for human presence in hazardous areas.

Eric Stigzelius, who leads the connected solutions business at Normet, highlights the importance of this shift: “Equipment is becoming more and more automatic. Along with other digital tools, it can help the operator do their work more efficiently and safely.” This move towards automation is complemented by the development of remote monitoring systems, which allow real-time oversight of mining equipment from anywhere in the world. These systems are essential in predicting and preventing failures before they occur, significantly reducing downtime and maintenance costs.

“With real-time data, the service team can fix components before bigger issues arise,” Stigzelius explains. This approach, known as predictive maintenance, leverages data to foresee potential problems, enabling timely interventions. By predicting when a piece of equipment is likely to fail, maintenance can be scheduled more strategically, reducing the risk of unexpected breakdowns that could halt production.

While the effectiveness of automated equipment will depend on a number of factors, including which system is used and how well personnel are trained to use it, GlobalData’s Development of tele-remote and autonomous equipment in the global underground mining sector, 2023 states that miners, OEMs and automation providers in the mining industry report impressive benefits, including between 10-30% improvements in productivity, up to 50% reduction in operating costs, up to 40% increase in machine utilisation, and up to 20% increase in total operating time.

“We conducted a case study in a mine in India where we provided remote monitoring services,” Stigzelius explains. “We compared the uptime of connected equipment with non-connected equipment in the same mine. The connected equipment had higher uptime.”

Advanced analytics: The Normet approach

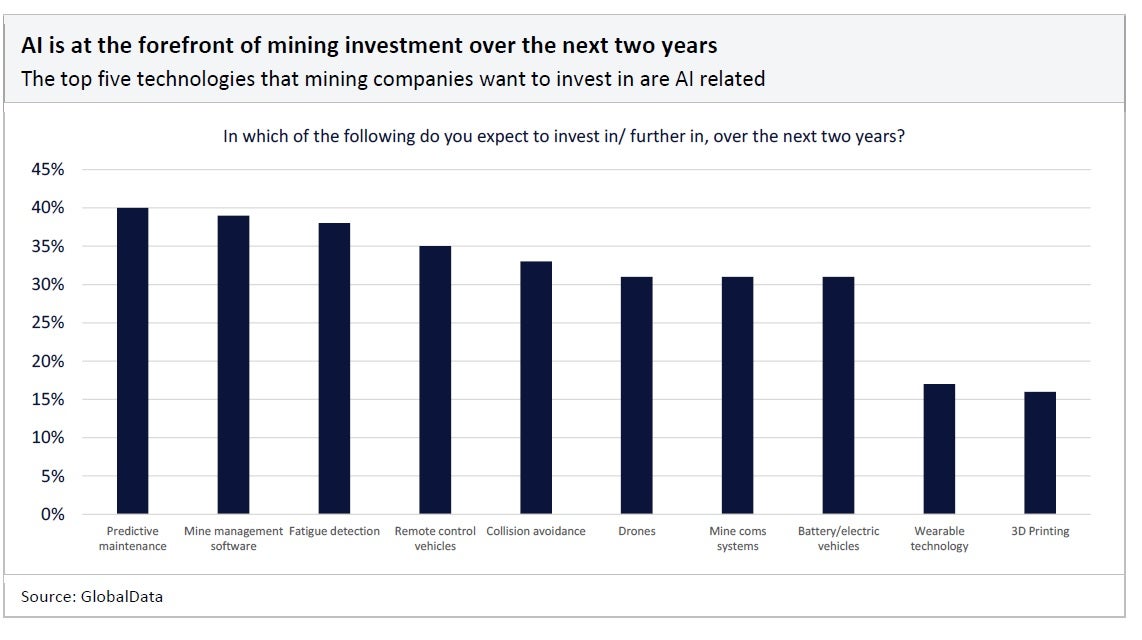

While equipment already has real-time monitoring sensors and data-gathering capabilities, this data is often not fully utilised. Machine learning can process and understand data in real-time, using it to predict when a machine is about to fail and to stop it from operating before it does so, therefore improving productivity. GlobalData’s 2023 mine-site technology adoption survey found that the top five technologies that mining companies want to invest in are AI related, including predictive maintenance and site management.

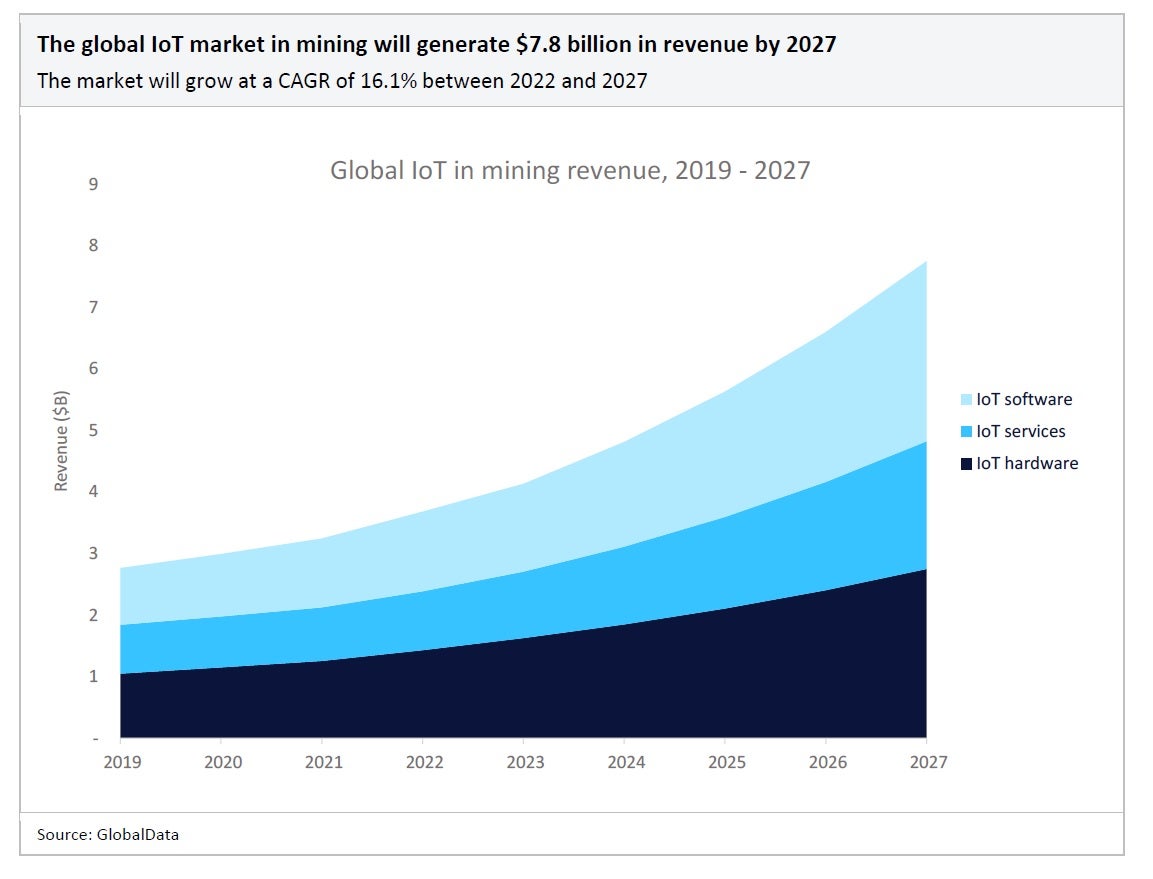

The integration of advanced analytics in mining is one of the most transformative aspects of digitalisation, and gathering quality data is key. According to GlobalData’s Internet of Things in Mining, 2023 thematic research, the total IoT market in mining will be worth $7.8 billion in 2027, having grown at a compound annual growth rate (CAGR) of 16.1% from $3.7 billion in 2022.

Normet’s approach to analytics goes beyond mere data collection; it’s about turning data into actionable insights that drive better decision-making. A prime example of this is Normet’s analysis of brake violations, which involved tracking braking patterns on mining vehicles, especially when navigating steep inclines or declines.

“We were able to tell if equipment is going downhill, how much braking is happening, and what the speed is,” says Stigzelius. By analysing this data, Normet can identify when operators are overusing brakes, which can lead to accelerated wear and tear on the equipment.

Normet combined this brake data with oil quality analysis. Regular oil samples were taken from the equipment and categorised based on their condition. The results revealed a clear pattern: equipment with frequent brake violations showed a faster deterioration in oil quality. “We noticed that when the oil quality was decreasing, there were more brake violations happening,” Stigzelius explains. This correlation allowed Normet to predict potential equipment failures and recommend timely maintenance, thus preventing costly downtime and extending the life of the machinery.

Sustainability through smart technologies

Digital technologies are proving instrumental in making mining more sustainable. One such innovation is Normet’s smart scanner, which measures the thickness of concrete applied to the walls of tunnels and mines.

“By knowing the right thickness, we can help operators reduce the actual amount of concrete used,” Stigzelius notes. “This is a big sustainability factor. It reduces CO2 emissions and also cuts costs for mines and tunnels.” This precise application not only minimises waste but also helps in reducing the carbon footprint of mining operations, a crucial consideration as industries worldwide strive to meet stricter environmental standards.

Overcoming challenges in digital mining

While the benefits of digital technologies in mining are evident, there are challenges to be addressed, with one significant hurdle being finding consistent connectivity underground.

“We understand that underground networks may not always be reliable, so our equipment is designed to store data when there’s no network and send it once the network is available,” Stigzelius explains. “Additionally, some mines prefer to have a local server to protect their network, and we provide solutions for that too.”

As the industry becomes more digital, there is a growing need for skilled personnel who can manage and maintain these sophisticated systems. Normet supports its clients by providing training and technical assistance, ensuring that their teams are equipped to handle the demands of a digital mine.

The future of mining is digital

As the mining industry continues its digital transformation, the role of companies like Normet becomes increasingly crucial. The technologies being developed and implemented today—automation, remote monitoring, digital twins, and advanced analytics—are not just improving efficiency and safety; they are redefining what is possible in mining.

Looking ahead, the future of mining is one where data drives every decision, where equipment communicates in real-time, and where sustainability is at the core of every operation. Normet is leading this change, providing the tools and expertise that will shape the mines of tomorrow. With the right technologies and the right partners, mining companies can achieve new levels of productivity and sustainability, ensuring they are well-positioned to meet the demands of the future.