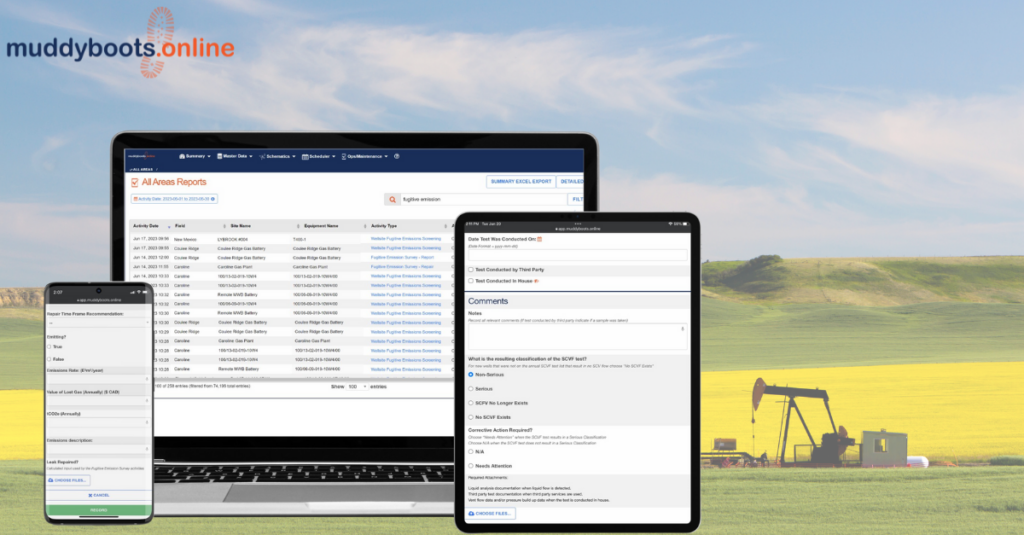

Here’s a quick look at how we’re working with our clients to streamline their Fugitive Emissions Reporting with Muddy Boots.

Emissions Reporting in Muddy Boots

- Pneumatic Devices

- Wellsite Emission Screening Reports (AVO)

- Fugitive Emissions Surveys Management

- Surface Casing Vent Flow Testing

- Scheduled/Unscheduled Releases

Pneumatic Devices Vent Gas Volume Reporting Process and Maintenance

Routine pneumatic device (pneumatic instruments and pneumatic pumps) vent gas reporting can be completed in MBO allowing vent volumes to be calculated within an executable report for year-end volumetric reporting. This executable report summarizes all calculations per device and update record along with summating total volumes per facility by device type (instrument or pump).

- Inventory Pneumatic Device Master List

- Record Pneumatic Device Updates

- Operating Status

- Emission control method

- Fuel type (Natural Gas, IA, Nitrogen, Hydraulic)

- Export Annual Emissions Reports that include both device summaries along with Facility Vent and Flare summaries

Wellsite Fugitive Emission Screenings

Wellsite fugitive emissions screening reports using the AVO (audio visual olfactory) emissions screening method, triggering automated Work Order responses.

- Complete AVO inspections generating automated leak response work orders.

- Manage and schedule the repairs.

- Complete the repair tasks to close the loop.

LDAR: Fugitive Emission Leak Management

LDAR (Leak Detection and Repair) activities are a group of three reports that complete Fugitive Emission Survey leak detection and response. Manage the leak Details, Repairs, and have the calculated emissions Report generated.

- Import your leak reports from your FES Survey provider(s).

- Schedule your repair tasks to your operations team or third-party repair groups.

- Repair the leaks when possible, according to the recommendations and feasibility.

- Muddy Boots automatically generates annual volumetric reports where leaks are pending repair + automated leak volume reports are generated when repairs are completed.

SCVF Testing

SCVF (Surface Casing Vent Flow) testing and classification management (Refer to AER Directive 087 (Well Integrity Management) Section 3.0 for clarification of serious and non-serious surface casing vent flows.) for operations.

- Record or attach your SCVF test results in Muddyboots directly against the applicable well using the appropriate PD or Orifice meter.

- Determine the vent flow classification and when required.

- Notify via work order/workflow the appropriate internal resource for follow-up actions to remediate.

Scheduled / Unscheduled Releases (Shutdowns / Blowdowns / Pigging)

Record all scheduled and unscheduled release volumes directly from pigging activities, shutdowns, blowdowns, etc. Pull reports as needed to quantify volume releases month over month/annually.

- Pig Launches/Receipts

- Compressor Shutdowns/Startups

- Blowdowns

- FFV Log Tracking

Contact us today for a customized demo to see how Muddy Boots can help you manage your fugitive emissions reporting.

Share This:

Next Article