Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Softcar’s newly revealed 4-seater electric microcar, which is a small urban electric vehicle classified as a L7e (heavy quadricycle) in the EU, aims to lead the auto industry “fully into the circular economy” with its net-zero cars that will be built locally in net-zero micro-factories.

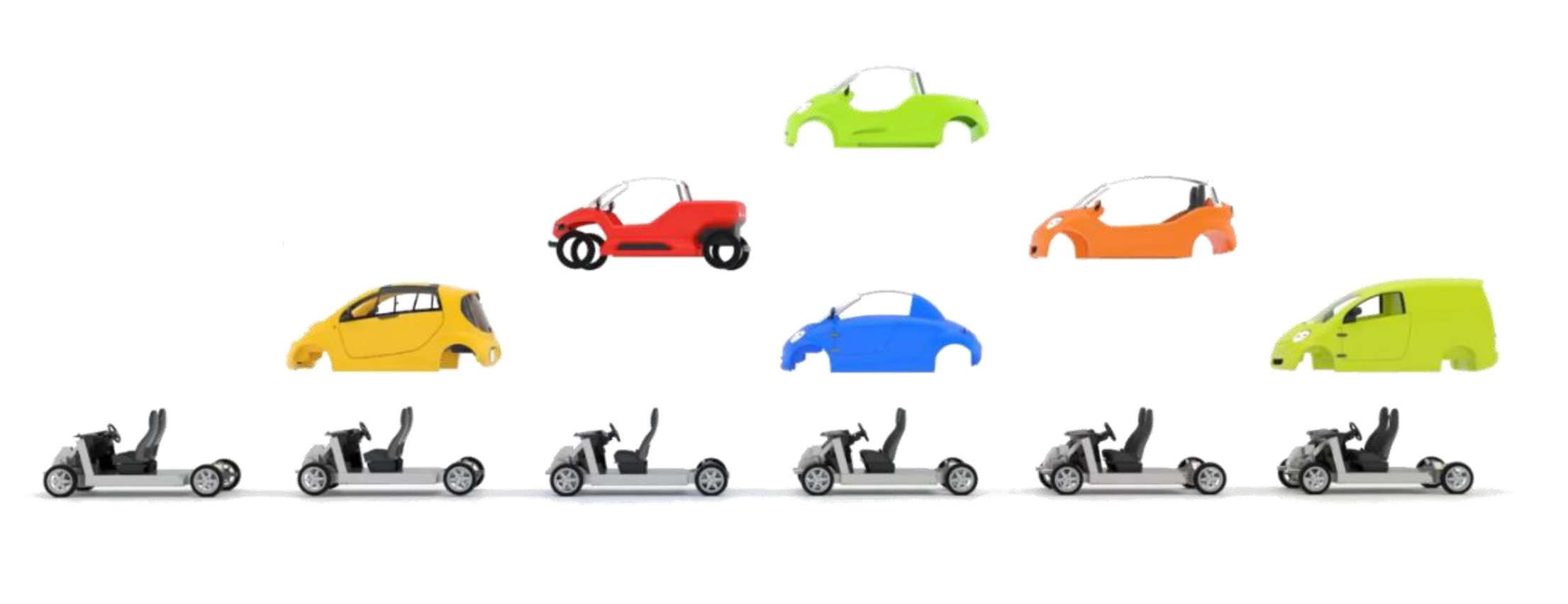

The Softcar’s 4-seater configuration sets it apart from most other microcars or light electric vehicles, allowing for two more passengers (or more stuff) to be transported, while still retaining a very small physical footprint for urban driving and parking. It weighs in at just 630 kg (1389 lb), and is built using only 1800 components, as opposed to the average of some 45,000 components in a conventional car, which alone could represent a significant step forward for sustainable auto manufacturing.

According to the company, the exterior and interior of the body of the Softcar are molded from a polymer into a single part, and when combined with its skateboard chassis, yields a lightweight and recyclable vehicle that has the “lowest achievable environment footprint.” It appears as if the body of the Softcar can be easily removed for replacement or vehicle repairs, or even just to swap in a different body style.

The Softcar is limited to 90 km/h (56 mph) and is powered by a 15kW motor (30kW peak) and a 15kWh battery that are together said to be capable of driving up to 200 kilometers between charges, and the company plans to offer a gas range-extender option in the future, which could mean a range of up to 400 kilometers. According to Welt.de, the vehicle is in the homologation phase, and the company plans to begin manufacturing the first models in 2025, with a price “of at least €23,000” (~$24,890).

The only footage of the Softcar I could find is the below video from Rotovia at the Paris Motor Show, which is the company that collaborated with Softcar in the development of the “innovative rotationally molded bodywork” that sets the vehicle apart.

Softcar claims that it is, “Building an industry for safe, high-quality, super-ecological, recyclable, and affordable vehicles that can be manufactured anywhere in the world, based on a business model that is as innovative as the product.” That business model includes the use of local micro-factories to produce the microcars, and Softcar is looking to attract entrepreneurs and investors to its “fully equipped, turnkey micro-factories” and production licensing, citing its “low-cost, high-flexibility production model” and a “clear path to profitability.”

“The low-carbon footprint automobile factory occupies a minimal area (5000 m²) and allows for the production of fully electric SOFTCAR vehicles or those with a natural gas range extender. This site includes an assembly space where no steel transformation operations are carried out, thereby largely eliminating toxic emissions, the production of chemical waste, noise pollution, vibrations, dust, and water consumption, making it feasible for the factory to be located close to or even within residential areas.”

Softcar is currently taking what it calls “pre-orders” for its microcar, but with no money changing hands and no obligation to purchase, so it’s more akin to an expression of interest plus a subscription to the company’s newsletter, and very few other details about the vehicle are available on the company website.

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy