Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

The Small Wind Guidebook helps homeowners, ranchers, and small business owners decide if wind energy will work for them by addressing the following questions:

- Is wind energy practical for me?

- What size wind turbine do I need?

- What are the basic parts of a small wind electric system?

- What do wind systems cost?

- Where can I find installation and maintenance support?

- How much energy will my system generate?

- Is there enough wind on my site?

- How do I choose the best site for my wind turbine?

- Can I connect my system to the utility grid?

- Can I go off grid?

Introduction

Can I use wind energy to power my home? More people across the country are asking this question as they look for a hedge against increasing electricity rates and a way to harvest their local wind resources. Although wind turbines large enough to provide a significant portion of the electricity needed by the average U.S. home generally require 1 acre of property or more, approximately 19.3% of the U.S. population lives in rural areas[1] and may own land parcels large enough to accommodate a wind energy system.

A small wind electric system will work for you if:

- There is enough wind where you live

- Tall towers are allowed in your neighborhood or rural area (or you live in flat terrain with no tall obstacles nearby)

- You have enough space

- You can determine how much electricity you need or want to produce

- You can interconnect with your utility service provider (assuming you have a grid-connection application)

- It works for you economically.

Small wind electric systems can contribute to our nation’s energy needs. This guide will provide you with basic information about small wind electric systems to help you decide if wind energy will work for you.

Why Should I Choose Wind?

Wind energy systems can be one of the most cost-effective home-based renewable energy systems. Depending on your wind resource, a small wind energy system can lower your electricity bill slightly or up to 100%, help you avoid the high costs of extending utility power lines to remote locations, and sometimes can provide DC or off-grid power.[2] In addition, wind energy is clean, indigenous, renewable energy.

How Do Wind Turbines Work?

Wind is created by the unequal heating of the Earth’s surface by the sun. Wind turbines convert the kinetic energy in wind into mechanical power that runs a generator to produce clean electricity. Today’s turbines are versatile modular sources of electricity.[3] Their blades are aerodynamically designed to capture the maximum energy from the wind.[4] The wind turns the blades, which spin a shaft connected to a generator or the generator’s rotor, which makes electricity.

First, How Can I Make My Home More Energy Efficient?

Before choosing a wind system for your home, you should consider reducing your energy consumption by making your home or business more energy efficient. You can start by learning how electricity is used in U.S. homes. Reducing your energy consumption will significantly lower your utility bills and will reduce the size of the home-based renewable energy system you need. To achieve maximum energy efficiency, you should take a whole-building approach. View your home as an energy system with interrelated parts, all of which work synergistically to contribute to the efficiency of the system. From the insulation in your home’s walls to the light bulbs in its fixtures, there are many ways to make your home more efficient.

- Improving insulation and sealing air leaks in a home are two of the fastest and most cost-effective ways to reduce energy waste. Homes built prior to 1950 use approximately 60% more energy per square foot than those constructed in 2000 or later.

- Turning your thermostat down 7° to 10°F for 8 hours a day from its normal setting can save as much as 10% on heating and cooling.

- Low-e exterior or interior storm windows can save you 12% to 33% on heating and cooling costs, depending on the type of window already installed in the home.[5]

- By replacing your home’s five most frequently used light fixtures or bulbs with models that have earned the ENERGY STAR, you can save money on utility bills and protect the environment by reducing greenhouse gas emissions.

- When shopping for appliances, look for the Energy Star® label. Energy Star® appliances have been identified by the U.S. Environmental Protection Agency and U.S. Department of Energy as being the most energy-efficient products in their classes.[6]

For more information on how to make your home energy efficient, see Energy Saver Guide: Tips on Saving Money and Energy at Home.

Is Wind Energy Practical for Me?

A small wind energy system can provide you with a practical and economical source of electricity if:

- Your property has a good wind resource.[7]

- Your home or business is located on at least 1 acre of land.

- Your local zoning codes or covenants allow wind turbines.

- You can determine how much electricity you need or want to produce.

- It works for you economically (you may be eligible for state/utility or federal incentives).

- You’re comfortable with long-term investments.

- Your average electricity bills are high or you don’t have access to utility grid power.

Zoning and Permitting Issues

Zoning refers to the general local regulations that allow and restrict various types of projects, whereas permitting refers to acquiring permits for a specific project within the scope of those zoning rules.

The zoning and permitting processes for wind energy installations seek to address safety, aesthetics, and community interests and concerns. Some of these concerns might include sound level, visual impact, wildlife impact, TV/radio interference, ice shedding, or broken equipment.

Practices vary dramatically across the country so becoming familiar with the local regulations, authorities, and general requirements is helpful. In some cases, zoning and permitting expectations are consistent and straightforward. In other cases, hearings may be required and the process is uncertain. A project designed within the existing limitations will experience a much smoother permitting process and will be more likely to receive a permit. But if your project falls outside of defined limits, it must usually undergo a special review process to obtain a variance from the existing rules and regulations — a potentially expensive and time-consuming process that often involves at least one public hearing and has no guarantee of success.[8]

Before you invest in a wind energy system, you should research potential zoning and permitting obstacles. Some jurisdictions restrict the height of the structures permitted in residential-zoned areas, although variances may be obtained. Most zoning ordinances have a height limit of 35 feet.[9]

You can find out more about zoning and permitting requirements by:

In addition to zoning issues, your neighbors might object to a wind turbine that blocks their view, or they might be concerned about the sound it produces. Most zoning and aesthetic concerns can be addressed by supplying objective data. For example, a typical 2-kilowatt wind turbine operates at a noise level of approximately 55 dB 50 feet away from the hub of the turbine.[10] At that level, the sound of the wind turbine can be picked out of surrounding noise if a conscious effort is made to hear it.

What Size Wind Turbine Do I Need?

The size of the wind turbine you need depends on your application. Small turbines range in size from 20 Watts to 100 kilowatts (kW). The smaller or “micro” (20- to 500-Watt) turbines are used in applications such as charging batteries for recreational vehicles and sailboats.

One- to 10-kW turbines can be used in applications such as pumping water. Wind energy has been used for centuries to pump water and grind grain. Although mechanical windmills still provide a sensible, low-cost option for pumping water in low-wind areas, farmers and ranchers are finding that wind-electric pumping is more versatile and they can pump twice the volume for the same initial investment. In addition, mechanical windmills must be placed directly above the well, which may not take advantage of available wind resources. Wind-electric pumping systems can be placed where the wind resource is the best and connected to the pump motor with an electric cable. However, in areas with a low wind resource, mechanical windmills can provide more efficient water pumping.

Turbines used in residential applications can range in size from 400 Watts to 100 kW (100 kW for very large loads), depending on the amount of electricity you want to generate. For residential applications, you should establish an energy budget and see whether financial incentives are available. This information will help determine the turbine size you will need. Because energy efficiency is usually less expensive than energy production, making your house more energy efficient will probably be more cost effective and will reduce the size of the wind turbine you need (see How Can I Make My Home More Energy Efficient?). Wind turbine manufacturers, dealers, and installers can help you size your system based on your electricity needs and the specifics of your local wind resource and micro-siting.

A typical home uses approximately 10,649 kilowatt-hours (kWh), an average of 877 kWh per month.[11] Depending on the average wind speed in the area, a wind turbine rated in the range of 5 to 15 kW would be required to make a significant contribution to this demand. A 1.5-kW wind turbine will meet the needs of a home requiring 300 kWh per month in a location with a 14 MPH (6.26 meters per second) annual average wind speed.[12] The manufacturer, dealer, or installer can provide you with the expected annual energy output of the turbine as a function of annual average wind speed. The manufacturer will also provide information about any maximum wind speeds at which the turbine is designed to operate safely. Most turbines have automatic overspeed-governing systems to keep the rotor from spinning out of control in extremely high winds.

Along with information about your local wind resource (wind speed and direction) and your energy budget, this information will help you decide which size turbine will best meet your electricity needs.

What Are the Basic Parts of a Small Wind Electric System?

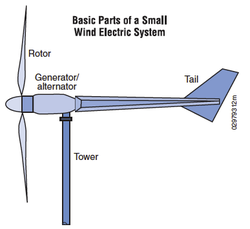

Home wind energy systems generally comprise a rotor, a generator or alternator mounted on a frame, a tail (usually), a tower, wiring, and the “balance of system” components: controllers, inverters, and/or batteries. Through the spinning blades, the rotor captures the kinetic energy of the wind and converts it into rotary motion to drive the generator, which produces either AC or wild AC (variable frequency, variable voltage), which is typically converted to grid-compatible AC electricity.

Wind Turbine

Small wind turbines can be divided into two groups: horizontal axis and vertical axis. The most commonly used turbine in today’s market is the horizontal-axis wind turbine. These turbines typically have two or three blades that are usually made of a composite material such as fiberglass. Vertical-axis wind turbines consist of two types: Savonius and Darrieus. A Savonius turbine can be recognized by its “S” shaped design when viewed from above. Darrieus turbines look like an eggbeater and have vertical blades that rotate into and out of the wind.[13]

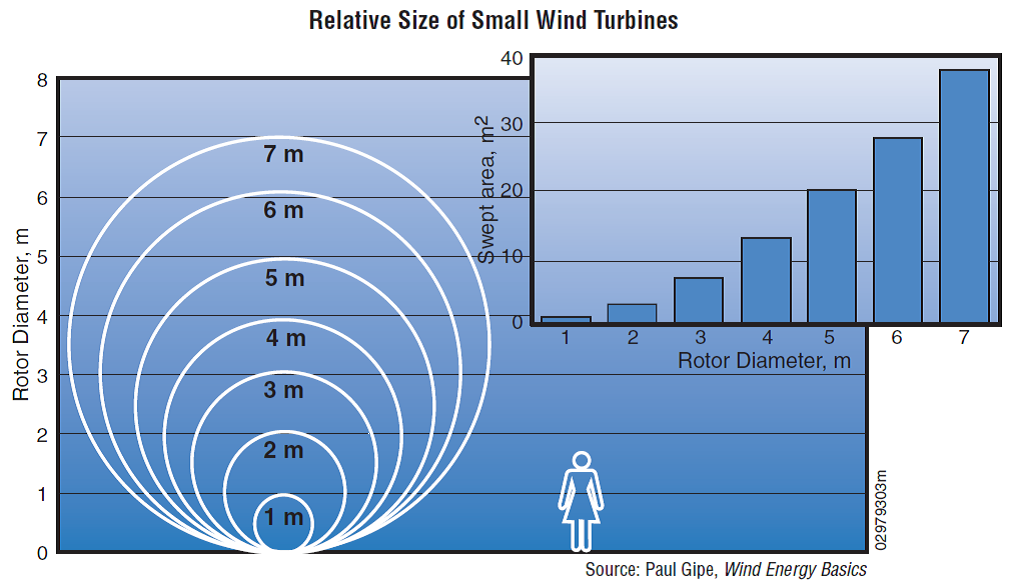

The amount of power a horizontal-axis turbine will produce is determined by the diameter of its rotor. The diameter of the rotor defines its “swept area,” or the quantity of wind intercepted by the turbine. The turbine’s frame is the structure onto which the rotor, generator, and tail are attached. The tail keeps the turbine facing into the wind.

Tower

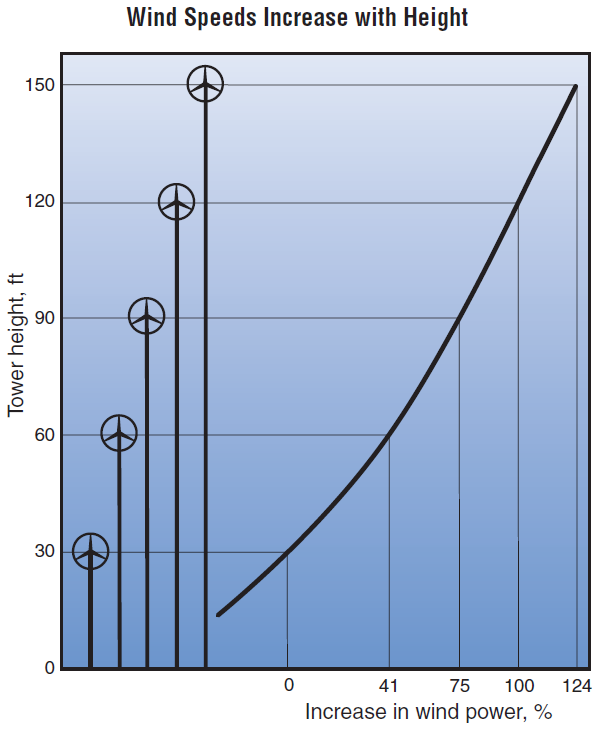

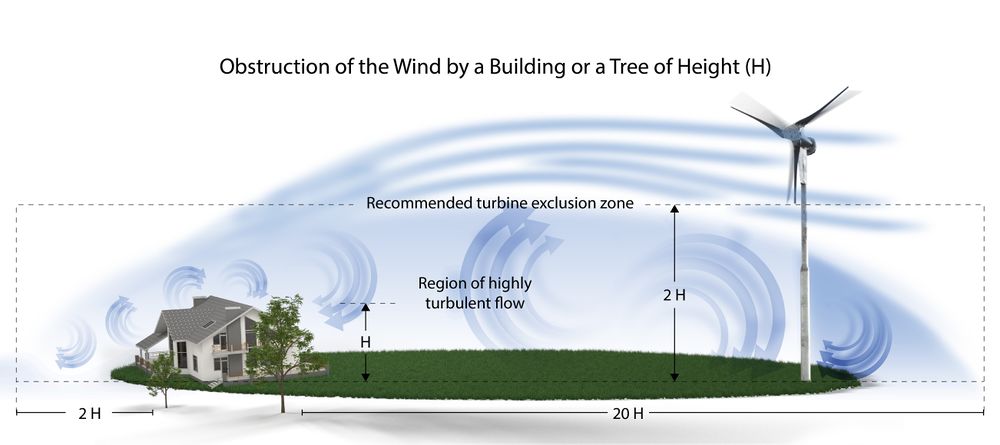

Because wind speeds increase with height, the turbine is mounted on a tower. In general, the higher the tower, the more power the wind system can produce. The tower also raises the turbine above the air turbulence that can exist close to the ground because of obstructions such as hills, buildings, and trees. A general rule of thumb is to install a wind turbine on a tower with the bottom of the rotor blades at least 30 feet (9 meters) above any obstacle that is within 300 feet (90 meters) of the tower.[14] Relatively small investments in increased tower height can yield very high rates of return in power production.

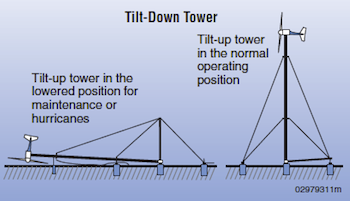

There are two types of towers: self-supporting (free-standing) and guyed. Guyed towers, which are the least expensive, can consist of lattice sections, pipe, or tubing (depending on the design); supporting guy wires; and the foundation. They are easier to install than self-supporting towers. However, because the guy radius must be one-half to three-quarters of the tower height, guyed towers require space to accommodate them. Although tilt-down towers are more expensive, they offer the consumer an easy way to perform maintenance on smaller lightweight turbines (usually 5 kW or smaller). Tilt-down towers can also be lowered to the ground during hurricanes and other hazardous weather conditions. Aluminum towers are prone to cracking and should be avoided. Most turbine manufacturers provide wind energy system packages that include a range of tower options.[15]

Balance of System

Costs in addition to the turbine and the tower are the balance of system, including parts and labor, which will depend on your application. Most manufacturers can provide you with a system package that includes all the parts you need for your application. For example, the parts required for a water-pumping system will be different from the parts required for a residential, grid-connected application. The balance of system equipment required will also depend on whether the system is grid-connected, stand-alone, or part of a hybrid system. For a residential grid-connected application, the balance of system parts may include a controller, storage batteries, a power conditioning unit (inverter), wiring, foundation, and installation. Many wind turbine controllers, inverters, or other electrical devices may be stamped by a recognized testing agency, such as Underwriters Laboratories or Intertek.

Batteries for Stand-Alone Systems

Stand-alone systems (systems not connected to the utility grid) require batteries to store excess power generated for use when the wind is calm. They also need a charge controller to keep the batteries from overcharging. Deep-cycle batteries, such as those used for golf carts, can discharge and recharge 80% of their capacity hundreds of times, which makes them a good option for remote renewable energy systems. Automotive batteries are shallow-cycle batteries and should not be used in renewable energy systems because of their short life in deep-cycling operations.[16]

Small wind turbines generate direct current (DC) electricity. In very small systems, DC appliances operate directly off the batteries. If you want to use standard appliances that use conventional household alternating current (AC), you must install an inverter to convert DC electricity from the batteries to AC. Although the inverter slightly lowers the overall efficiency of the system, it allows the home to be wired for AC, a definite plus with lenders, electrical code officials, and future homebuyers.

For safety, batteries should be isolated from living areas and electronics because they contain corrosive and explosive substances. Lead-acid batteries also require protection from temperature extremes.

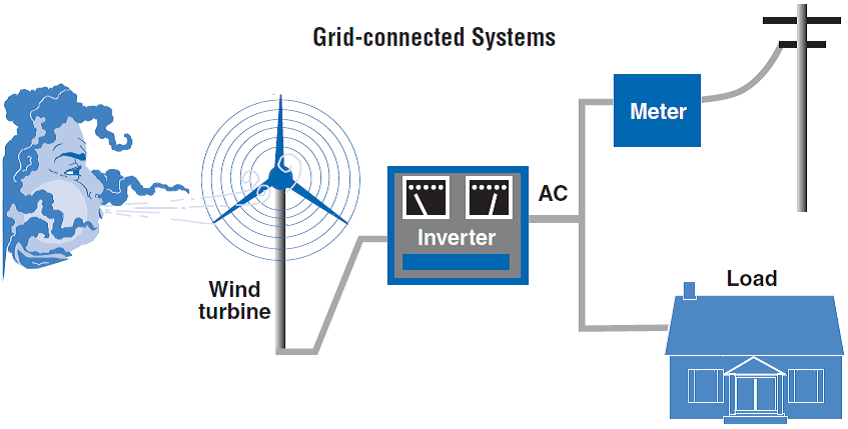

Inverters for Grid-Connected Systems

In grid-connected systems, the only additional equipment required is a power conditioning unit (inverter) that makes the turbine output electrically compatible with the utility grid. Batteries are usually not required.

What Do Wind Systems Cost?

Installation costs vary greatly depending on local zoning, permitting, and utility interconnection costs. The capacity-weighted average cost of small wind projects installed in 2021 was $5,120/kilowatt (based on 16 projects in three states for a combined rated capacity of 396 kW).[17]

Although wind energy systems involve a significant initial investment, they can be competitive with conventional energy sources when you account for a lifetime of reduced or avoided utility costs. The length of the payback period—the time before the savings resulting from your system equal the cost of the system—depends on the system you choose, the wind resource on your site, electricity costs in your area, and how you use your wind system.

Compare prices when shopping for a wind system as you would any major purchase by reviewing the product literature from several manufacturers.

How Do I Find a Certified Small Wind Turbine?

To justify your investment in a small wind turbine, you will want assurances that your turbine model has been evaluated for safety, performance, and functionality.[18] The following resources will help you.

-

- The Small Wind Certification Council provides independent, accredited certification of small wind turbines and consumer information, and you should familiarize yourself with this material.

- The Interstate Turbine Advisory Council (ITAC) compiles a national unified list of small and mid-size wind turbines eligible for incentive funding from ITAC state and utility member programs. As a collaborative and common inventory of turbines, the unified list assures customers that rate- or taxpayer funding is “supporting the installation of technology with a demonstrated record of durability, safety, and warranty service, as well as reasonable acoustic and performance characteristics.”[19]

Research small wind turbine companies to be sure they offer certified turbines and that parts and service will be available when you need them. Ask for references from past customers with installations similar to the one you are considering. Ask the system owners about performance, reliability, and maintenance and repair requirements, and whether the system is meeting their expectations. Also, find out how long the warranty lasts and what it includes.

Where Can I Find Installation and Maintenance Support?

You must decide whether you will perform the installation and maintenance work on your small wind turbine or whether you will hire an experienced small wind installer. This decision will affect your system’s cost. Many people elect to install their own turbines. Before attempting to install your wind turbine, ask yourself the following questions:

- Can I pour a proper cement foundation?

- Do I have access to a lift or a way to safely erect the tower?

- Do I know the difference between AC and DC wiring?

- Do I know enough about electricity to safely wire my turbine?

- Do I know how to safely handle and install batteries?[20]

If you answered no to any of the above questions, you should probably hire a system integrator or installer. Contact the manufacturer for help or call your state energy office and local utility for a list of local system installers. A credible installer may be able to provide many services such as permitting, obtaining interconnection approval, etc. Find out if the installer is a licensed electrician. Ask for references and check them. You may also want to check with the Better Business Bureau.

Turbine and tower manufacturers should provide their own operations and maintenance plan; however, turbine owners should be aware that all rotating equipment will require some maintenance. Many turbines require periodic lubrication, oil changes, and replacement of wear surfaces such as brake pads.[21] Bolts and electrical connections should be checked and tightened if necessary. The machines should be checked for corrosion and the guy wires for proper tension. In addition, you should check for and replace any worn leading edge tape on the blades, if appropriate. After 10 years, the blades or bearings may need to be replaced, but with proper installation and maintenance, the machine should last 20 years or longer.

Every turbine should include an owner’s manual or operations manual to provide the consumer with scheduled and unscheduled maintenance information as well as other unique product information. Scheduled maintenance guidelines should be followed. If you do not have the expertise to maintain the machine, ask whether your installer provides a service and maintenance program.

How Much Energy Will My System Generate?

According to the AWEA Small Wind Turbine Performance and Safety Standard, the Rated Annual Energy of a wind turbine is the calculated total energy that would be produced during a 1-year period with an average wind speed of 5 meters/second (m/s, or 11.2 mph).[22] The following formula illustrates factors that are important to the performance of a wind turbine. Notice that the wind speed (V) has an exponent of 3 applied to it. This means that even a small increase in wind speed results in a large increase in power. That is why a taller tower will increase the productivity of any wind turbine by giving it access to higher wind speeds.

The formula for calculating the power from a wind turbine is:

- Power = Cp 1/2 ρ A V³

Where:

- P = Power output, watts

- Cp = Maximum power coefficient, ranging from 0.25 to 0.45, dimension less (theoretical maximum = 0.59)

- ρ = Air density, kg/m³

- A = Rotor swept area, m² or

- π D² / 4 (D is the rotor diameter in m, π = 3.1416)

- V = Wind speed, mps[23]

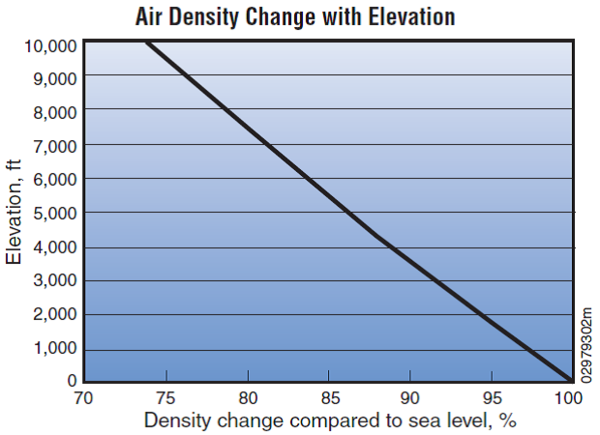

The rotor-swept area (A) is important because the rotor captures the wind energy. So the larger the rotor, the more energy it can capture. The air density, ρ, changes slightly with air temperature and with elevation. The ratings for wind turbines are based on standard conditions of 59° F (15° C) at sea level. A density correction should be made for higher elevations as shown in the Air Density Change with Elevation graph. A correction for temperature is typically not needed for predicting the long-term performance of a wind turbine.

Although the calculation of wind power illustrates important features about wind turbines, the best measure of wind turbine performance is annual energy output. The difference between power and energy is that power (kilowatts [kW]) is the rate at which electricity is consumed while energy (kilowatt-hours [kWh]) is the quantity consumed. An estimate of the annual energy output from your wind turbine, kWh/year, is the best way to determine whether a particular wind turbine and tower will produce enough electricity to meet your needs. Contact a wind turbine manufacturer, a dealer/installer, or a site assessor to help you estimate the energy production you can expect. They will use a calculation based on the particular wind turbine power curve, the average annual wind speed at your site, the height of the tower that you plan to use, micro-siting characteristics of your site and, if available, the frequency distribution of the wind (an estimate of the number of hours that the wind will blow at each speed during an average year). They should also adjust this calculation for the elevation of your site.

To get a preliminary estimate of the performance of a particular wind turbine, use the formula below.

- AEO = 0.01328 D² V³

Where:

- AEO = Annual energy output, kWh/year

- D = Rotor diameter, feet

- V = Annual average wind speed, mph[24]

The Wind Energy Payback Period Workbook is a Microsoft Excel spreadsheet tool that can help you analyze the economics of a small wind electric system and decide whether wind energy will work for you. It asks you to provide information about how you will finance the system, the characteristics of your site, and the properties of the system you’re considering. It then provides you with a simple payback estimation (assumes no increase in electricity rates) in years. If the number of years required to regain your capital investment is greater than or almost equal to the life of the system, then wind energy will not be practical for you.

Is There Enough Wind on My Site?

Is the wind resource at your site good enough to justify your investment in a small wind turbine system? That is a key question and not always easily answered. The wind resource can vary significantly over an area of just a few miles because of local terrain influences on the wind flow. Yet, there are steps you can take to answer the above question.

The highest average wind speeds in the United States are generally found along seacoasts, on ridgelines, and on the Great Plains;[25] however, many areas have wind resources strong enough to make a small wind turbine project economically feasible.

Although there may be many methodologies for understanding the wind resource at a specific location, gathering on-site, measured wind data is typically preferred.

Prior to conducting an on-site measurement campaign, some small wind project developers use state wind maps to conservatively estimate the wind resource at turbine hub height. While these maps can provide a general indication of good or poor wind resources, they do not provide a resolution high enough to identify local site features. State wind maps cannot include information on complex terrain, ground cover, wind speed distribution, direction distribution, turbulence intensity, and other local effects. Purchased maps or services can often provide higher resolution and more flexibility with zooming, orientation, and additional features. Pay attention to a map’s height above ground as it relates to the potential project’s tower height. Adjusting the wind speed for the height difference between the map and the turbine height adds a potential source of error depending on the wind shear exponent that is selected, and the greater the height difference the greater the potential error. Therefore, for small wind generator applications, 30- to 40-m wind maps are far more useful than 10-, 60-, 80-, or 100-m wind maps. It is also important to understand the resolution of the wind map or model-generated data set. If the resolution is lower than the terrain features, adjustments will be needed to account for local terrain effects.[26]

Local airport or weather stations can offer local wind data, but these data may be less reliable than actual site data. If airport data (typically recorded at 30 ft or 10 m above ground) or weather station data (typically recorded at 5 to 20 ft above ground) are used, inquire not only about the site’s current equipment and location but also if it is historically consistent with the data collection equipment and siting. Equipment at these sites is not primarily intended for wind resource assessment, so it may not be positioned at an appropriate height or in a location free of obstructions. Unfortunately, airport and weather stations are usually far from the site of interest, with considerably different topography, tree cover, and monitoring height, making these data of questionable usefulness. Given the expertise required to effectively establish and correlate wind resource data, the data provided by airport and weather stations may only provide a rough screening assessment.[27]

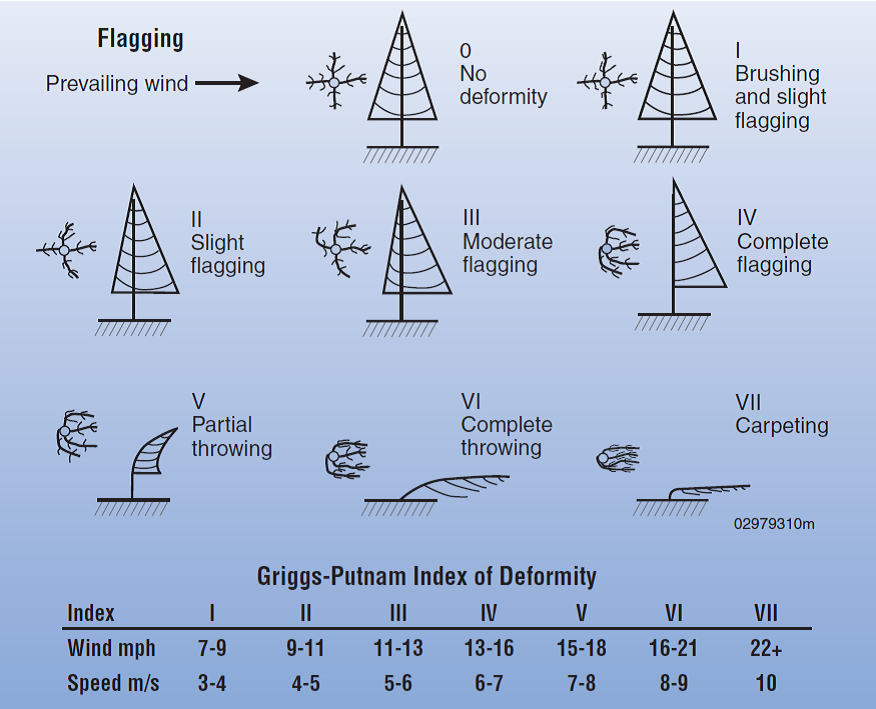

Average wind speeds increase with height and may be 15% to 25% greater at a typical wind turbine hub height of 80 ft (24 m) than those measured at airport anemometer heights. The National Climatic Data Center collects data from airports in the United States and makes wind data summaries available for purchase.Another useful indirect measurement of the wind resource is the observation of an area’s vegetation. Trees, especially conifers or evergreens, can be permanently deformed by strong winds. This deformity, known as “flagging,” has been used to estimate the average wind speed for an area.

Flagging, the effect of strong winds on area vegetation, can help determine area wind speeds. Small wind site assessors can help you determine whether you have a good wind resource on your site. State or utility incentive programs may be able to refer you to site assessors with training in assessing the wind resource at specific sites. Computer programs that estimate the wind resource at a particular site given specific obstacles are also available. Site assessors and computer programs can help to refine the estimates provided on wind resource maps.

On-site data measurement adds a new layer of confidence to the techniques discussed above, but with substantial additional costs, effort, and time, especially when the preferred methodology is to match turbine hub height and collect data for a minimum of 1 year. Obtaining several years of data is better, or 1 year that can be referenced to a longer-term data set if there is good correlation with the on-site data. A number of small, affordable wind data collection systems are available for on-site measurement and are best run for at least 1 year. These systems include anemometers, wind vanes, and temperature sensors that are mounted as close to hub height as possible. Calculating the wind shear exponent requires collecting data at two different heights. Having wind shear data is essential for conducting an accurate analysis of the cost versus benefits of taller towers. In addition, analysis must be performed to determine wind speed averages and extremes, wind distribution, Weibull parameters, the wind direction rose, turbulence intensity, vertical wind shear exponent, and associated uncertainties.[28]

Finally, if there is a small wind turbine system in your area, you may be able to obtain information on the annual output of the system and also wind speed data if available.[29]

How Do I Choose the Best Site for My Wind Turbine?

The farther you place your wind turbine from obstacles such as buildings or trees, the less turbulence you will encounter.

A proper site assessment is a detailed process that includes wind resource assessment and the evaluation of site characteristics. With this in mind, you may wish to consider hiring an experienced small wind site assessor who can determine your property’s optimal turbine location. The following information highlights key steps in the site selection/assessment process.

If the surrounding area of a potential site is not relatively flat for several miles, then an evaluation of the main topographic features is necessary, both nearby (macro siting) and at the proposed turbine site (micro siting). The topographical evaluation should include shape, height, length, width, and distance and direction away from the proposed turbine site of any landforms. “Nearby” could include influences from large objects such as hills, groves of trees, or high wind breaks up to a mile away, and smaller objects could include single trees and buildings, especially within 500 feet of the proposed turbine location.

Owners of projects located near complex terrain should take care in selecting the installation site. Landforms (or orography) can influence wind speed, which affects the amount of electricity that a wind turbine can generate. Elevated areas not only experience increased wind speeds because of their increased height in the wind profile but also may cause local acceleration of the wind speed, depending on the size and shape of the landform. If you site your wind turbine on the top of or on the windy side of a hill, for example, you will have more access to prevailing winds than in a gully or on the leeward (sheltered) side of a hill on the same property. Other elevated landforms (bluffs, cliffs) can create turbulence, including back eddies, as the wind passes up and over them. Siting the tower to avoid the zones of turbulence created by the landform is critical.

Turbulence intensity is a major issue for small turbines because of their tower height and location around “ground clutter.” Turbulence can reduce the annual energy output estimate from 15% to 25% because wind turbine power curves are typically developed based on measurements taken at sites with relatively low turbulence intensity compared to typical small wind project sites.

Varied wind resources can exist within the same property. In addition to measuring or finding the annual wind speeds, you need to know about the prevailing directions of the wind at your site. Knowing the prevailing wind direction(s) is essential to determining the impact of obstacles and landforms when seeking the best available site location and estimating the wind resource at that location. To help with this process, small wind site assessors typically develop a wind rose, which shows the wind direction distributions of a given area. The wind rose divides a compass into sectors (usually 8 or 16) and indicates the average wind speed, average percentage of time that the wind blows from each direction, and/or the percentage of energy in the wind by sector. Wind roses can be generated based on annual average wind speeds, or by season, month, or even time of day as needed.[30]

In addition to geologic formations, you need to consider existing obstacles such as trees, houses, and sheds, and you need to plan for future obstructions such as new buildings or trees that have not reached their full height.[31] Your turbine needs to be sited upwind of buildings and trees[32], and it needs to be 30 feet above anything within a 500-foot horizontal radius.[33] You also need enough room to raise and lower the tower for maintenance, and if your tower is guyed, you must allow room for the guy wires.

Whether the system is stand-alone or grid-connected, you also need to consider the length of the wire run between the turbine and the load (house, batteries, water pumps, etc.). A substantial amount of electricity can be lost as a result of the wire resistance—the longer the wire run, the more electricity is lost. Using more or larger wire will also increase your installation cost. Your wire run losses are greater when you have direct current (DC) instead of alternating current (AC). So, if you have a long wire run, it is advisable to invert DC to AC.[34]

You may wish to consider hiring an experienced small wind site assessor who can determine where the turbine should be located on your property.

Wind Turbines Mounted on Buildings

While there have been instances of wind turbines mounted on rooftops, it should be noted that all wind turbines vibrate and transmit the vibration to the structure on which they are mounted. This can lead to noise problems within the building. Also, the wind resource on the rooftop is in an area of increased turbulence, which can shorten the life of the turbine and reduce energy production. Additional costs related to mitigating these concerns, combined with the fact that they produce less power, make rooftop-mounted wind turbines less cost-effective than small wind systems that are installed on a tower connected to the ground. For more information, see Deployment of Wind Turbines in the Built Environment: Risks, Lessons, and Recommended Practices.

Can I Connect My System to the Utility Grid?

Small wind energy systems can be connected to the electricity distribution system. A grid-connected wind turbine can reduce your consumption of utility-supplied electricity for lighting, appliances, and electric heat. If the turbine cannot deliver the amount of energy you need, the utility makes up the difference. When the wind system produces more electricity than the household requires, the excess is sent or sold to the utility. These arrangements with the utility company are typically called net metering or net billing, and they address the value of the electricity sold or net excess generation, the time period for valuing the electricity (typically annually or monthly), and any other contractual requirements with the utility.

Grid-connected systems can be practical if the following conditions exist:

- You live in an area with average annual wind speed of at least 10 mph (4.5 m/s).

- Utility-supplied electricity is expensive in your area (about 10 to 15 cents per kilowatt-hour).

- The utility’s requirements for connecting your system to its grid are not prohibitively expensive.

- There are good incentives for the sale of excess electricity, sale of the renewable energy credit, and/or for the purchase of wind turbines.

Federal regulations (the Public Utility Regulatory Policies Act of 1978, or PURPA) require utilities to connect with and purchase power from small wind energy systems. However, you should contact your utility before purchasing a wind turbine system and connecting to their distribution lines to address any power quality and safety concerns. Your utility can provide you with a list of requirements for connecting your system to the grid.

Net Metering

Net metering programs are designed to allow the electric meters of customers with generating facilities to “turn backwards” when their generators are producing more energy than the customers’ demand. Net metering allows customers to use their generation to offset their consumption over the entire billing period, not just instantaneously. This offset would enable customers with generating facilities to receive retail prices for more of the electricity they generate.[35]

Net metering varies by state and by utility company, depending on whether net metering was legislated or directed by the Public Utility Commission. Net metering programs specify a way to handle the net excess generation (NEG) in terms of payment for electricity and/or length of time allowed for NEG credit. If the net metering requirements define NEG on a monthly basis, consumers can only receive credit for their excess that month. But if the net metering rules allow for annual NEG, the NEG credit can be carried for up to a year. Most of North America sees more wind in the winter than in the summer. For people using wind energy to displace a large load in the summer (like air conditioning or irrigation water pumping), having an annual NEG credit allows them to produce NEG in the winter and receive credits in the summer.[36]

Safety Requirements

Whether or not your wind turbine is connected to the utility grid, the installation and operation of the wind turbine is probably subject to the electrical codes that your local city or county government, or in some instances your state government, has in place. The government’s principal concern is the safety of the facility, so these code requirements emphasize proper wiring and installation and the use of components that have been certified for fire and electrical safety by approved testing laboratories, such as Underwriters Laboratories. Most local electrical codes requirements are based on the National Electrical Code (NEC), which is published by the National Fire Protection Association. The latest version of the NEC includes sections specific to the installation of small wind energy facilities. It is available for purchase online at the National Fire Protection Association website[37] and can also be found at most local libraries.

If your wind turbine is connected to the local utility grid so that any of the power produced by your wind turbine is delivered to the grid, then your utility also has legitimate concerns about safety and power quality that need to be addressed. The utility’s principal concern is that your wind turbine automatically stops delivering any electricity to its power lines during a power outage. Otherwise line workers and the public, thinking that the line is “dead,” might not take normal precautions and might be hurt or even killed by the power from your turbine. Another concern among utilities is whether the power from your facility synchronizes properly with the utility grid and it matches the utility’s power in terms of voltage, frequency, and power quality.

A few years ago, some state governments started developing new standardized interconnection requirements for small renewable energy generating facilities (including wind turbines). In most cases, the new requirements are based on consensus-based standards and testing procedures developed by independent third-party authorities, such as the Institute of Electrical and Electronic Engineers (IEEE) and Underwriters Laboratories. Utility companies will typically require compliance with IEEE 1547, which addresses electrical safety requirements for wind turbine systems. Some utilities may require appropriate electrical listing before allowing interconnection of the wind system.

Interconnection Requirements

In most cases, it is quite advantageous to interconnect a small turbine with the customer’s utility service, thereby using the utility for backup power to cover the variability of the turbine’s energy production as well as storage of excess energy. Such interconnection typically requires utility permission, which is usually in the form of an interconnection agreement. This agreement will address metering and billing arrangements with the utility and may include requirements for additional safety equipment or procedures, protection devices, and inspections.[38]

In states that have retail competition for electricity service (e.g., your utility operates the local wires, but you have a choice of electricity provider), you may have to sign a separate agreement with each company. Usually these agreements are written by the utility or the electricity provider. In the case of private (investor-owned) utilities, the terms and conditions in these agreements must be reviewed and approved by state regulatory authorities.

Insurance

Some utilities require small wind turbine owners to maintain liability insurance in amounts of $1 million or more to protect them from liability for facilities they do not own and have no control over. Other utilities consider the insurance requirements excessive and unduly burdensome, making wind energy uneconomic. In seven states (California, Georgia, Maryland, Nevada, Oklahoma, Oregon, and Washington), laws or regulatory authorities prohibit utilities from imposing any insurance requirements on small wind systems that qualify for net metering. In at least two other states (Idaho, Virginia), regulatory authorities have allowed utilities to impose insurance requirements but have reduced the required coverage amounts to levels consistent with conventional residential or commercial insurance policies (e.g., $100,000 to $300,000). If your insurance amounts seem excessive, you can ask for a reconsideration from regulatory authorities (in the case of private investor-owned utilities) or the utility’s governing board (in the case of publicly owned utilities).

Indemnification

An indemnity is an agreement between two parties in which one agrees to secure the other against loss or damage arising from some act or some assumed responsibility. In the context of customer-owned generating facilities, utilities often want customers to indemnify them for any potential liability arising from the operation of the customer’s generating facility. Although the basic principle is sound—utilities should not be held responsible for property damage or personal injury attributable to someone else—indemnity provisions should not favor the utility but should be fair to both parties. Look for language that says, “each party shall indemnify the other . . .” rather than “the customer shall indemnify the utility . . .”

Customer Charges

Customer charges can take a variety of forms, including interconnection charges, metering charges, and standby charges. You should not hesitate to question any charges that seem inappropriate to you. Federal law (Public Utility Regulatory Policies Act of 1978, or PURPA, Section 210) prohibits utilities from assessing discriminatory charges to customers who have their own generation facilities.

Can I Go Off-Grid?

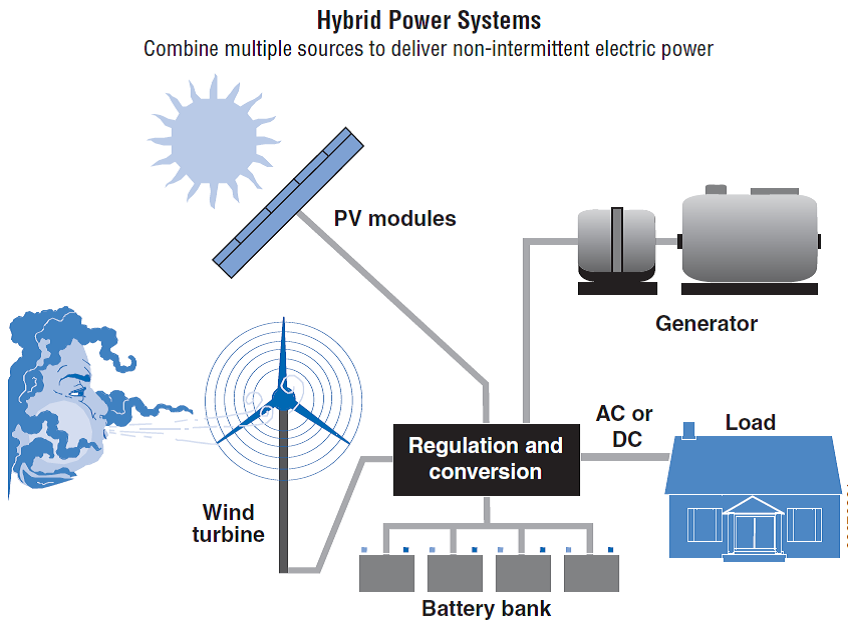

Hybrid Systems

Hybrid wind energy systems can provide reliable off-grid power for homes, farms, or even entire communities (a co-housing project, for example) that are far from the nearest utility lines. According to many renewable energy experts, a “hybrid” system that combines wind and photovoltaic (PV) technologies offers several advantages over either single system. In much of the United States, wind speeds are low in the summer when the sun shines brightest and longest. The wind is strong in the winter when less sunlight is available and may be stronger at night compared to the day. Because the peak operating times for wind and PV occur at different times of the day and year, hybrid systems are more likely to produce power when you need it. (For more information on solar electric or PV systems, see Using Solar Electricity at Home).

For the times when neither the wind turbine nor the PV modules are producing, most hybrid systems provide power through batteries and/or an engine-generator powered by conventional fuels such as diesel. If the batteries run low, the engine-generator can provide power and recharge the batteries. Adding an engine-generator makes the system more complex, but modern electronic controllers can operate these systems automatically. An engine-generator can also reduce the size of the other components needed for the system. Keep in mind that the storage capacity must be large enough to supply electrical needs during non-charging periods. Battery banks are typically sized to supply the electric load for 1 to 3 days.[39]

An off-grid hybrid system may be practical for you if:

- You live in an area with an average annual wind speed of at least 9 mph (4 m/s).

- A grid connection is not available or can only be made through an expensive extension. The cost of running a power line to a remote site to connect with the utility grid can be prohibitive, ranging from $15,000 to more than $50,000 per mile, depending on terrain.[40]

- You would like to gain energy independence from the utility.

- You would like to generate clean power.

Glossary of Terms

Airfoil—The shape of the blade cross-section, which for most modern horizontal-axis wind turbines is designed to enhance the lift and improve turbine performance.

Alternator—An electric generator for producing alternating current. See also generator.*

Ambient—Of the surrounding area or environment; completely surrounding; encompassing. Used to distinguish environmental conditions, e.g. temperature or sound, from what is added by mechanical devices.*

Ampere-hour—A unit for the quantity of electricity obtained by integrating current flow in amperes over the time in hours for its flow; used as a measure of battery capacity.

Anemometer—A device to measure the wind speed.

Authority Having Jurisdiction (AHJ)—The building authority for the area, generally a city or county building department, including its inspectors.*

Availability—A measure of the ability of a wind turbine to make power, regardless of environmental conditions. Generally defined as the time in a period when a turbine is able to make power, expressed as a percentage.*

Average wind speed—The mean wind speed over a specified period of time.

Beaufort scale—A scale of wind forces, described by name and range of velocity, and classified from force 0 to 12, with an extension to 17. The initial (1805) Francis Beaufort wind force scale of 13 classes (0 to 12) did not reference wind speed numbers but related qualitative wind conditions to effects on the sails of a frigate, then the main ship of the Royal Navy, from “just sufficient to give steerage” to “that which no canvas sails could withstand.” Although the Beaufort scale has little use in site assessments, a system of tree flagging observations has been used to estimate prevailing wind directions and levels on the scale over time.

Behind-the-meter / behind-the-fence generation—An electrical generating system connected on the user’s side of a utility meter, primarily for energy usage on site instead of for sale to energy retailers. See also net metering.*

Betz limit—The maximum power coefficient (Cp) of a theoretically perfect wind turbine equal to 16/27 (59.3%) as proven by German physicist Albert Betz in 1919. This is the maximum amount of power that can be captured from the wind. In reality, this limit is never achived because of drag, electrical losses, and mechanical inefficiencies. See also Cp.*

Blades—The aerodynamic surface that catches the wind. See also wing, airfoil, rotor.

Brake—Various systems used to stop the rotor from turning.

Certification—A process by which small wind turbines (100 kW and under) can be certified by an independent certification body to meet or exceed the performance and durability requirements of the American Wind Energy Association (AWEA) Standard.*

Converter—See Inverter.

Corrosivity—A measure of oxidation and/or material degradation.*

Cp—Power coefficient; the ratio of the power extracted from the wind by a wind turbine relative to the power available in the wind. See also Betz limit.*

Cut-in wind speed—The wind speed at which a wind turbine begins to generate electricity.

Cut-out wind speed—The wind speed at which a wind turbine ceases to generate electricity.

Density—Mass per unit of volume.

Direct drive—A blade and generator configuration where the blades are connected directly to the electrical generating device so that one revolution of the rotor equates to one revolution of the electrical generating device.*

Displacement height—The height above ground level where wind speed is theoretically zero based on the effects of ground cover.

Distributed generation—Energy generation projects where electrical energy is generated primarily for on-site consumption. Term is applied for wind, solar, and non-renewable energy.*

Diurnal—Having a daily cycle or pattern. It may be useful to average many daily cycles of wind speed or wind energy production to understand a typical daily pattern, by month, season, or year.

Downwind—On the opposite side from the direction from which the wind blows.

Drag—An aerodynamic force that acts in the direction of the airstream flowing over an airfoil.*

Dual-metering—Buying electricity from the utility and selling it to the utility with two different energy rates, typically retail (buying) and wholesale (selling).

Electric cost adjustment—An energy charge (dollars per kilowatt-hour) on a utility bill in addition to the standard rate in the tariff, which is associated with extra costs to purchase fuel, control emissions, construct transmission upgrades, and so on. These various costs may be itemized or rolled into one electric cost adjustment rate. Sometimes referred to as fuel cost adjustment.

Electric utility company—A company that engages in the generation, transmission, and distribution of electricity for sale, generally in a regulated market. Electric utilities may be investor owned, publicly owned, cooperatives, or nationalized entities.*

Energy curve—A diagram showing the annual energy production at different average wind speeds, typically assuming a Rayleigh wind distribution (with a Weibull shape factor of 2.0).

Energy production—Energy is power exerted over time. Energy production is hence the energy produced in a specific period of time. Electrical energy is generally measured in kilowatt-hours ( kWh). See also power.*

Environmental conditions—Of or pertaining to ambient state of the environment. See also temperature, wind, humidity, corrosivity.*

Flagging—The deformation of local vegetation toward one direction, indicating the prevailing wind direction and relative strength (more formally called Krummholtz formation). Flagging is sometimes used with the Beaufort scale to generate an initial estimate of local site conditions. (Note: flagging does not determine the wind resource, but is a confirming indicator of it. For example, sometimes flagging is the result of sunlight availability, or trimming of tree branches near electrical lines. The assessor needs to understand when flagging is relevant, or when it is a confirming indicator of another condition at the site.)

Frequency distribution—A statistical function presenting the amount of time at each wind speed level for a given data set and location, usually in percent of time or hours per year.

Furling—A passive protection for the turbine in which the rotor folds up or around the tail vane.

Gearbox—A compact, enclosed unit of gears or the like for the purpose of transferring force between machines or mechanisms, often with changes of torque and speed. In wind turbines, gearboxes are used to increase the low rotational speed of the turbine rotor to a higher speed required by many electrical generators.*

Generator—A machine that converts mechanical energy to electricity. The mechanical power for an electric generator is usually obtained from a rotating shaft. In a wind turbine, the mechanical power comes from the wind causing the blades on a rotor to rotate. See also blade, rotor, stator, alternator.*

Geographic information system (GIS) software—GIS software is used for managing map-based information and data. It may also be used to visualize the relationships between terrain, wind data, land-use boundaries, obstacles, and potential wind turbine locations.

Governor—A device used to limit the RPM of the rotor. Limiting RPM serves to reduce centrifugal forces acting on the wind turbine and rotor as well as limit the electrical output of the generating device. Governors can be electrical, also know as “dynamic braking,” or mechanical. Mechanical governors can be “passive,” using springs to pitch the blades out of their ideal orientation, or an offset rotor that pitches out of the wind, or “active” by electrically or hydraulically pitching blades out of their ideal orientation.*

Grid—The utility distribution system. The network that connects electricity generators to electricity users.

Grid-connected—Small wind energy systems that are connected to the electricity distribution system. These often require a power-conditioning unit that makes the turbine output electrically compatible with the utility grid. See also inverter.*

Gross annual energy production—The amount of annual energy (usually in kilowatt-hours) estimated for a given wind turbine at a given location, before adjusting for losses (see net annual energy production).

Guyline—A guyline (or guy wire) supports guyed towers, which are the least expensive way to support a wind turbine. Guyed towers can consist of lattice sections, pipe, or tubing. Because the guy radius must be one-half to three-quarters of the tower height, guyed towers require more space to accommodate them than monopole or self-standing lattice towers.*

Horizontal-axis wind turbine (HAWT)—A wind turbine with a rotor axis that lies in or close to a horizontal plane. Often called a “propeller-style” wind turbine.*

Hub—That component of a wind turbine to which the blades are affixed. See also rotor, blade.*

Hub Height—The distance from the foundation to which the tower is attached to the center of the hub of a HAWT.*

Humidity—A measure of moisture content in the air.*

Induction generator—An asynchronous AC motor designed for use as a generator. Generates electricity by being spun faster than the motor’s standard “synchronous” speed. Must be connected to an already-powered circuit to function (i.e. the grid), but does not require an inverter to produce grid-ready electricity.*

Interannual variability—The variation from year to year in average wind speed, distribution, and patterns.

Interconnection standards—Specifies the technical and procedural process by which a customer connects an electricity-generating device to the grid. Such standards include the technical and contractual terms that system owners and utilities must abide by. State public utility commissions typically establish standards for interconnection to the distribution grid, while the Federal Energy Regulatory Commission (FERC) establishes standards for interconnection to the transmission grid. While many states have adopted interconnection standards, some states’ standards apply only to investor-owned utilities and not to municipal utilities or electric cooperatives.*

Intermittency—Stopping or ceasing for a time; alternately ceasing and beginning again. Wind and solar resources are described as intermittent because they change without regard to peoples’ needs or wants.*

International Electrotechnical Commission (IEC)—The international wind-industry standards body.*

Inverter—A device that converts direct current (DC) to alternating current (AC).

kW—Kilowatt, a measure of power for electrical current (1,000 Watts).

kWh—Kilowatt-hour, a measure of energy equal to the use of 1 kilowatt in 1 hour.

Lattice—A structure of crossed wooden or metal strips usually arranged to form a diagonal pattern of open spaces between the strips. Lattice towers, either guyed or freestanding, are often used to support small wind turbines.*

Lift—An aerodynamic force that acts at right angles to the airstream flowing over an airfoil.*

Micrositing—A resource assessment tool used to determine the exact position of one or more wind turbines on a parcel of land to optimize the power production.

Microturbine—A very small wind turbine, usually under a 1,000 Watt rating, which is appropriate for small energy needs (e.g., for cabins, campers, sailboats, very small communication stations, or other small off-grid loads).

Monopole—A freestanding type of tower that is essentially a tube, often tapered.*

MW—Megawatt, a measure of power (1,000,000 Watts).

Nacelle—The body of a propeller-type wind turbine, containing the gearbox, generator, blade hub, and other parts.

Nameplate capacity—The power capacity of a generating device that is typically affixed to the generating device. Nameplate capacity typically, but not necessarily, represents the maximum continuous power output of the generating device.*

Net annual energy production—The amount of annual energy (usually in kilowatt hours) produced or estimated for a given wind turbine at a given location, after subtracting losses from the gross annual energy production. A variety of losses may be estimated for obstacle wind shadows, turbulence, turbine wake effects, turbine availability, high-wind hysteresis effects, electrical efficiency, blade icing, blade soiling and surface degradation, idling parasitic losses, control errors, low temperature shutdown, utility system maintenance, and other issues specific to a given turbine installation.

Net metering / net billing—For electric customers who generate their own electricity, net metering allows for the flow of electricity both to and from the customer. When a customer’s generation exceeds the customer’s use, electricity from the customer flows back to the grid, offsetting electricity consumed by the customer at a different time during the same billing cycle. In effect, the customer uses excess generation to offset electricity that the customer otherwise would have to purchase at the utility’s full retail rate. Net metering is required by law in most U.S. states, but state policies vary widely. See also behind-the-meter.*

Noise—Generally defined as unwanted sound. Sound power is measured in decibels, dB. Building and planning authorities often regulate sound power levels from facilities. See also sound, electrical noise.*

O & M costs—Operation and maintenance costs.

Obstruction—A general term for any significant object that would disturb wind flow passing through a turbine rotor. Most common examples are homes, buildings, trees, silos, and fences. Topographical features such as hills or cliffs that might also affect wind flow and are not called obstructions.*

Off-grid—Energy-generating systems that are not interconnected directly into an electrical grid. Energy produced in these systems is often used for battery charging.*

Orography—A branch of physical geography that deals with mountains.

Overall height—The total height of a wind turbine from its base at grade to its uppermost extent. See also total height.*

Peak demand—The maximum electricity consumption level (in kilowatts) reached during the month or billing period, usually for a 15- or 30-minute duration. The definition of peak demand may vary by electric utility. This is a simplified definition of a complex topic.

Peak power—The maximum instantaneous power than can be produced by a power-generating system or consumed by a load. Peak power may be significantly higher than average power.*

Permitting—The process of obtaining legal permission to build a project, potentially from a number of government agencies, but primarily from the local building department (i.e., the city, county, or state). During this process, a set of project plans is submitted for review to assure that the project meets local requirements for safety, sound, aesthetics, setbacks, engineering, and completeness. The permitting agency typically inspects the project at various milestones for adherence to the plans and building safety standards.

Power coefficient—The ratio of the power extracted by a wind turbine to the power available in the wind stream.

Power curve—A chart showing a wind turbine’s power output across a range of wind speeds.

Prevailing wind—The most common direction or directions that the wind comes from at a site. Prevailing wind usually refers to the amount of time the wind blows from that particular direction but may also refer to the direction the wind with the greatest power density comes from.*

PUC—Public Utility Commission, a state agency that regulates utilities. In some areas known as Public Service Commission (PSC).

PURPA—Public Utility Regulatory Policies Act (1978), 16 U.S.C. § 2601.18 CFR §292 that refers to small generator utility-connection rules.

Rated output capacity—The output power of a wind machine operating at the rated wind speed.

Rated wind speed—The lowest wind speed at which the rated output power of a wind turbine is produced.

Reactive power—When the voltage and current waveforms for AC power are out of phase the resulting instantaneous power flow is modeled as real power and reactive power. The presence of reactive power increases the instantaneous current flow required to do work. The increase in current flow results in additional line losses. The utility tariff for larger customers may include a charge for reactive power compensation, measured in kilo-volt-amp-reactive.

Rotor—The rotating part of a wind turbine, including either the blades and blade assembly or the rotating portion of a generator.

Rotor diameter—The diameter of the circle swept by the rotor.

Rotor speed—The revolutions per minute of the wind turbine rotor.

Setback—In zoning parlance, the distance required between a structure and another structure, property line, utility easement or other demarkation.*

Shadow flicker—A moving shadow that occurs when rotating turbine blades come between the viewer and the sun.

Site assessment—The act of evaluating a site to determine a favorable location for a wind turbine, which includes assessing the expected wind resource and potential turbine performance at that location.

Small wind turbine—A wind turbine that has a rating of up to 100-kilowatts, and is typically installed near the point of electric usage, such as near homes, businesses, remote villages, and other kinds of buildings.

Sound—Pressure waves occurring at a frequency in the audible range of human hearing that are registered as sensory input by the ear. See also noise.*

Start-up wind speed—The wind speed at which a wind turbine rotor will begin to spin. See also Cut-in wind speed.

Stator—The stationary part of a rotary machine or device, especially a generator or motor. Most especially related to the collection of stationary parts in its magnetic circuits. The stator and rotor interact to generate electricity in a generator and to turn the driveshaft in a motor.*

Swept area—The area swept by the turbine rotor, A = π R2, where R is the radius of the rotor. See also rotor diameter.

Tariff—An official schedule of rates or charges from a utility, usually with different rate schedules by customer classification (e.g., residential, commercial, industrial, farm, or other designation) and/or a service or meter rating for the customer.

Temperature—A measure of thermal energy.*

Tip-speed ratio—The speed at the tip of the rotor blade as it moves through the air divided by the wind velocity. This is typically a design requirement for the turbine.

Topography—The surface configuration and relief features of an area, such as hills and bluffs, and the detailed mapping and description thereof.

Total height—The height of the wind system from the top of the foundation to which the tower is attached to the tip of a blade extended upwards. See also overall height.*

Tower—A structure designed to support a wind turbine at a substantial height above grade in a wind flow. Typical types include monopole, guyed lattice, and self-supporting lattice designs.*

Turbulence—The changes in wind speed and direction, frequently caused by obstacles.

Turbulence intensity—A basic measure of turbulence that is defined by the ratio of the standard deviation of the wind speed to the mean wind speed. For wind energy applications this is typically defined as a 10-minute average wind speed and standard deviation based on 1-second samples. Turbulence intensity is important for wind energy applications because it has implications for both power performance and turbine loading. Experience indicates that it can be a significant issue for small turbines because of their tower height and location around ground clutter, which puts them in the most turbulent area of the atmospheric boundary layer. The effects of turbulence on distributed wind turbines can be seen in both power production and loading

Upwind—On the same side as the direction from which the wind is blowing—windward.

Upwind rotor—A horizontal-axis wind turbine whose propeller is located upwind of the tower; a wind turbine with an architecture such that the wind flow passes through the propeller prior to flowing past the tower.*

Vertical-axis wind turbine (VAWT)—A wind turbine whose rotor spins about a vertical or near-vertical axis.*

Wet stamp—Refers to a specific engineering review of a specific plan or set of drawings by an in-state licensed engineer who subsequently approves the plan or drawings with his/her stamp. A wet stamp implies an original stamped document, not a copy.*

Wind—The movement of an air mass.*

Wind farm—A group of wind turbines, often owned and maintained by one company. Also known as a wind power plant.

Wind rose—A visual means of representing the frequency with which the wind blows from different directions.*

Wind shadow—A turbulent and/or low-wind-speed region downwind of (behind) an object such as a building, tower, or trees.

Wind shear—The difference in wind speed and direction over a relatively short distance in the atmosphere. Wind shear can be broken down into vertical and horizontal components, with horizontal wind shear seen across storm fronts and near the coast, and vertical shear seen typically near the surface (though also at higher levels in the atmosphere near upper-level jets and frontal zones aloft).

Wind turbine—A mechanical device that converts kinetic energy in the wind into electrical energy.*

Yaw—The movement of the tower top turbine that allows the turbine to stay into the wind.

Zoning—Most land has been delegated to various zones by a region’s local government and building department officials (at the city, county, or state level [occasionally]). The zones control types of land use, such as agricultural, residential, commercial, and industrial, and include subcategories. Each type of zoning carries its own specific permitting restrictions, such as building height and property line offsets (required separation distance).

* This definition was contributed by the Distributed Wind Energy Association (DWEA).

Web Resources

Database of State Incentives for Renewables & Efficiency (DSIRE)

DSIRE is a comprehensive source of information on state, local, utility, and federal incentives and policies that promote renewable energy and energy efficiency.

Distributed Wind Energy Association (DWEA)

DWEA provides info about distributed and community wind, including a Permitting and Zoning Resource Center.

E3A: Exploring Energy Efficiency and Alternatives

This site explores small wind applications for the home, farm, or ranch and includes informative fact sheets.

Energy Saver Guide: Tips on Saving Money and Energy at Home

Energy Savers provides the latest information on energy-saving, efficient technologies, as well as tips for using clean, renewable energy to power your home.

Interstate Turbine Advisory Council (ITAC)

ITAC offers a Unified List of Wind Turbines that participating clean energy programs and utilities can use as the basis for incentive or other funding eligibility.

Islanded Grid Wind Resource Center

With funding support from the U.S. Department of Energy, the Islanded Grid Resource Center is committed to creating a self-sustaining knowledge center and resource for isolated islanded grids using or considering wind power.

National Renewable Energy Laboratory’s National Wind Technology Center

Learn about NREL’s distributed wind turbine research: turbine testing, turbine development, and prototype refinement.

New Hampshire’s Office of Energy and Planning: Small Wind Energy Systems

In 2008, the New Hampshire legislature passed HB310, creating a framework for municipalities to regulate the construction of small-scale wind turbines. In compliance with HB310, the Office of Energy and Planning developed a technical bulletin on Small Wind Energy Systems, which includes a model ordinance to aid communities in drafting regulations that conform with state laws. Although some of these materials are specific to New Hampshire, they should assist anyone planning to install a small wind turbine.

Pacific Northwest National Laboratory

Pacific Northwest National Laboratory provides market analysis and policy tools for distributed wind stakeholders that enable increased understanding of the U.S. and international markets, state and federal policies, as well as trends and projections that help accelerate the widespread and intentional implementation of wind technologies. Annual distributed wind market reports are available.

Small Wind Certification Council

Established in 2008, the Small Wind Certification Council (SWCC) certifies small and medium wind turbines. Consumers can use the information provided by the SWCC to obtain rated annual energy, power, and sound estimates from an independent ISO/IEC 17065 accredited certification body to better understand the product they are purchasing. In 2016, the SWCC joined the International Code Council Evaluation Service (ICC-ES). ICC-ES is a nonprofit that conducts “technical evaluations of building products, components, methods, and materials.”

SPARK Northwest

Spark Northwest provides educational events to community members to support renewable energy project development.

U.S. Department of Energy’s Guidance Memo on Quality Assurance through Wind Turbine Certification Requirements

The Energy Department’s Wind and Water Power Technology Office issued a memorandum in 2014 recommending certification as a means of consumer and stakeholder protection. The memo encourages that public funds be provided only for wind turbines that have been tested and certified for safety, function, performance, and durability.

U.S. Department of Energy’s Small Wind Electric Systems

Learn more about wind energy and energy efficiency.

U.S. Department of Energy’s WINDExchange Initiative

The U.S. Department of Energy’s WINDExchange initiative educates, engages, and enables critical stakeholders to make informed decisions about how wind energy contributes to the U.S. electricity supply.

Vermont Public Service Board: Siting a Wind Turbine on Your Property

This booklet serves as an aid for siting small, net-metered wind turbines in Vermont. Some of this information will apply to turbine installations in other states as well.

Wind for Schools

The U.S. Department of Energy funds the Wind for Schools project, which helps develop a future wind energy workforce by engaging students at higher education institutions to join Wind Application Centers and serve as project consultants for small wind turbine installations at rural elementary and secondary schools. Teacher training and hands-on curricula are implemented at each K-12 host school to bring the wind turbine into the classroom through interactive and interschool research tasks, engaging young people interested in science.

Windustry

Windustry offers information on wind energy for homes and farms, as well as community-scale wind projects.

From the U.S. DOE.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Our Latest EVObsession Video

I don’t like paywalls. You don’t like paywalls. Who likes paywalls? Here at CleanTechnica, we implemented a limited paywall for a while, but it always felt wrong — and it was always tough to decide what we should put behind there. In theory, your most exclusive and best content goes behind a paywall. But then fewer people read it!! So, we’ve decided to completely nix paywalls here at CleanTechnica. But…

Thank you!

CleanTechnica uses affiliate links. See our policy here.