We install a state-of-the-art gas sensor in the air intake system of the engine, that reads flammable gases. Unlike Cat bead/Pellister type sensors, the gas sensor calibrates itself every 2.0 seconds using up to date ambient temperature, barometric pressure, and relative humidity. It does not require bump gas, docking stations or an instrument technician to recalibrate 4 times a year. The sensor reads the chemical composition of the air being drawn into the engine, then transmits the data to the ShockerEDGE controller and the ShockerEDGE display. Once the data is received by the controller, it can be programmed to turn the engine off at 7.5% LEL, long before a diesel engine runaway can occur, or a gasoline engine starts to backfire. The controller can also be programmed to activate your ShockerPASS air shutoff valve on a diesel engine.

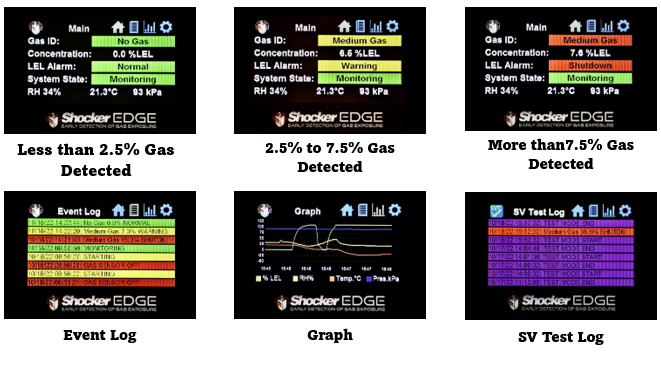

The data is also sent to the display, giving you a real time display of the sensors findings.

Including:

- System and sensor status

- Temperature, humidity, and barometric pressure

- Settings tab

- Gas status and identification

- Concentration of gas detected

- Alarm Status

- Data logging

Main Screens

Headwind Solutions

780-672-2775

TF 1-844-304-7277

www.headwindsolutions.ca

Share This: