- Licensable Cypress™ Li-Metal battery cell chemistry designed to seamlessly integrate into today’s roll-to-roll battery manufacturing process

- Li-Metal pouch cells achieving 950 Watt hours per liter of active area

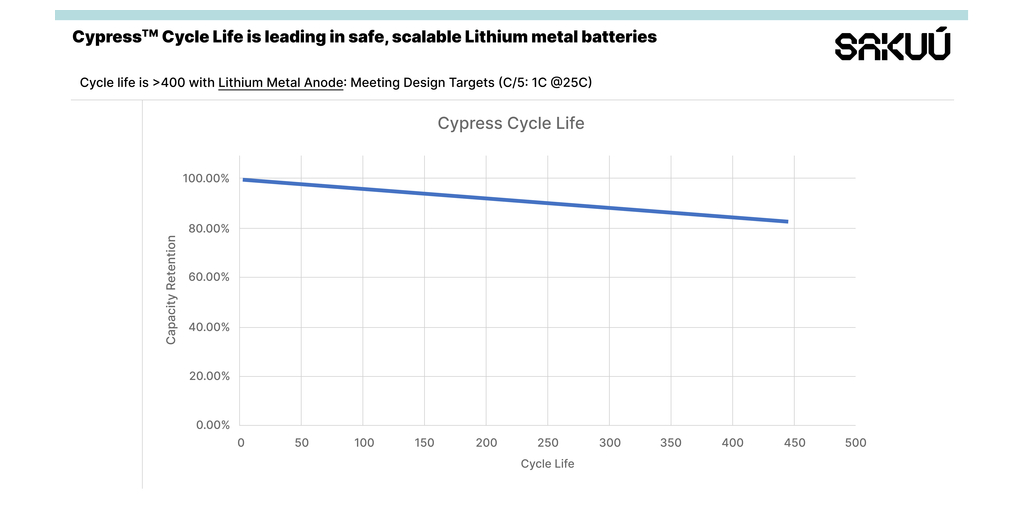

- Li-Metal anode cell delivering cycle life exceeding 400 (1C @25ºC) to 80% capacity retention

- Li-Metal anode with high nickel cathode delivering 10C peak discharge with full recovery

SAN JOSE, Calif.–(BUSINESS WIRE)–Sakuu Corporation (“Sakuu”), transformative additive manufacturing and battery manufacturing equipment technology company, and creator of the Kavian™ platform solution for the commercial-scale production of next-generation batteries and other complex active devices, has recently achieved several impressive milestones. Samples of its licensable high-energy, high-power Li-Metal Cypress battery cell chemistry, commercially available since May 2023, have been delivered to strategic customers around the world in the electric 2W mobility/motorcycle space, as well as e-aviation/drone, defense, and power tool industries.

Sakuu has overcome the challenges of high-performance Li-Metal chemistry by demonstrating industry-leading battery safety and performance:

- 750–950 Wh/l Energy Density of active cell area

- 260+ Wh/kg Specific Energy

- 792 W/kg Specific Power (@ 3C)

- 3C Sustained Discharge, 10C Peak, with full recovery

- 400+ Cycles to 80% SOH (100% DoD)

Lithium metal chemistries enable higher energy and higher power applications, now with a breakthrough cycle life. Full-size electric vehicles target high-energy density and long cycle life.

In addition to its Cypress battery cell technology Sakuu is continuing to make progress on its longer-term initiative known as Kavian, an additive manufacturing platform. Sakuu innovation is pioneering a new era in battery development, design, and manufacturing capability. Arwed Niestroj, Sakuu Senior Vice President of Customer Success, presented at the 2023 Battery Electric Vehicle Architectures USA Congress in Detroit on June 21, stating, “We have proven with our platform that we can print polymers, ceramics, and metals — using various dry processes in one device and also in one layer — which no other additive manufacturing company can do. This enables Sakuu to print batteries as well as other active devices.”

“We are in the business of developing and licensing revolutionary manufacturing technology for OEMs to mass produce batteries with higher performance at less cost,” said Robert Bagheri, CEO and Founder of Sakuu. “Creating an advanced Cypress battery chemistry uniquely positions Sakuu to deliver on our innovative Kavian manufacturing platform. This is our invitation to battery manufacturers everywhere to work with us on pushing boundaries and capturing previously unattainable benefits.”

About Sakuu

Sakuu is the creator of the Kavian™ platform, a transformative additive manufacturing approach for commercial-scale production of batteries and other complex active devices by its partners. Additionally, Sakuu is licensing its proprietary battery chemistry to enable partners to produce batteries with significant performance and safety advantages. Initial efforts will focus on using our Kavian™ platform to print a range of next-generation batteries — from lithium metal to all-solid-state — that can help reduce society’s reliance on fossil fuels. Founded in 2016, Sakuu operates two facilities in Silicon Valley, California, where it is headquartered: an innovative battery pilot line facility, and an additive manufacturing engineering facility. To learn more about Sakuu’s advancements towards and dedication to a safer, more sustainable electrified future, please visit our website: Sakuu.com.

Contacts

Contact Information for Media

Michelle Denny, Sterling Communications