Westech Industrial, a proud distributor of Hobré Instruments, is excited to share a groundbreaking solution for total sulfur analysis in petroleum products. The XRF method, championed by Hobré Instruments, stands out as the most suitable and reliable technique, especially when dealing with products with a final boiling point exceeding 450 ºC.

Traditional methods based on injection techniques and conversion to SO2 and H2S are rendered ineffective in such scenarios, and X-ray absorption techniques are not considered due to matrix effects and safety concerns associated with radioactive sources. This is where Hobré Instruments’ Metorex C100-SXT analyzer comes into play, offering a safe, accurate, and cost-effective solution.

Key Advantages of the Metorex C100-SXT Analyzer:

- Safety First: The X-ray source is an X-ray tube, ensuring that radiation ceases immediately once the power is switched off.

- Consistent Accuracy: Analysis remains unaffected by variations in product density or C/H ratio.

- Low Maintenance: With no moving sample wetted parts, the analyzer boasts a very low cost of ownership.

- Stable Performance: Internal auto-referencing on solid reference material reduces electronic drift and mitigates the impact of ambient temperature changes within operational limits.

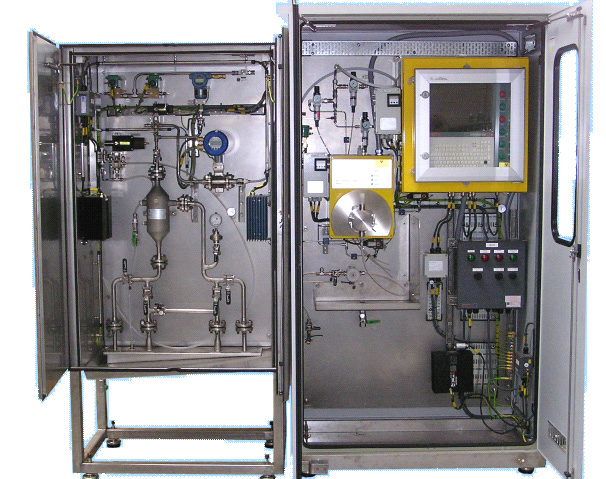

With over two decades of experience in process analyzers, Hobré Instruments BV brings practical expertise to online analysis, including sample conditioning, flushing systems, and sample recovery systems. The Metorex model C100 has a substantial installed base, attesting to the technology’s reliability and effectiveness.

Operational Requirements for Optimal Performance:

- Temperature Control: The operating temperature of the sample must be below the Initial Boiling Point (IBP) of the product.

- Viscosity Limits: At the operating temperature of the sample cell, the product’s viscosity must not exceed 100 cSt.

Adhering to these requirements ensures the precise determination of the sample temperature to the analyzer cell. Additionally, we strongly recommend directing the analyzer’s outlet to an atmospheric drain or a sample recovery vessel. This practice not only minimizes the risk of window damage due to pressure shocks or vibrations but also prevents the common issue of window deformation, a known cause of drift in XRF analysis.

For EDXRF method analysis, it is crucial to remove free water and most particles from the sample. In this regard, Hobré’s maintenance-free HLSS separators are the perfect complement to the sampling system, ensuring the purity and integrity of the sample.

Westech Industrial is proud to stand alongside Hobré Instruments in bringing innovative and reliable solutions to the Oil & Gas and Energy industry. The Metorex C100-SXT analyzer is a testament to our commitment to quality, safety, and excellence in every aspect of our operations. To learn more call, us at 1-800-912-9262 or visiting our website at https://bit.ly/49bJbd9.

Share This:

Next Article