In the face of global challenges, sustainability is a critical concept many organizations are working to integrate into their practices. If we think about all the ways companies strive to be sustainable, we can get lost in the concept. But collectively, these initiatives are about activating small changes that combine to make a big impact. Environmentally conscious, we’ve started using biodegradable straws, reusable shopping bags, and annoying vehicles that shut off at stop lights.

Applying this concept to road building, is it even possible to build roads sustainably?

You don’t have to be an engineer to know that road building is often an arduous task that takes an incredible amount of time and resources and can leave a negative, lasting impact on the environment. Bearing this in mind, visionary Marc Breault, President of Paradox, believes in challenging the norm by synergizing road building and sustainability into a uniquely viable, revolutionary solution. Research-driven, the company undertakes seemingly impossible challenges centered around sustainability. Who would have thought that you could pave the way for access with minimal disturbance to the land?

As industry disrupters, Paradox’s mission is to create accessibility with minimal environmental impact.

Through Paradox, sustainable solutions revolve around meeting the needs of the present without compromising the needs of future generations through environmental preservation, reducing social impact, and optimizing cost.

Let’s get technical.

Paradox uses Tough Cell®, a unique high-performance geocell, soil stabilization technology that allows fast, year-round, sustainable road construction over the most challenging of soils.

In fact, when compared to traditional roadbuilding applications, Tough Cell® not only saves time and costs but is a green solution that makes roadbuilding sustainable. Here are the key benefits of this choice solution:

1. Environmental Benefits

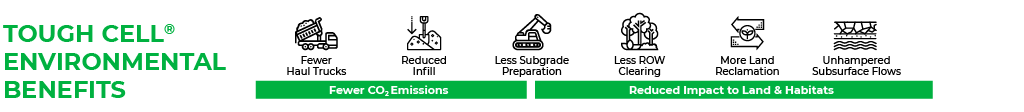

The greatest sustainable benefits of Tough Cell® are the environmental benefits it delivers when compared to roads built using conventional methods. These include:

- Minimal subgrade preparation and reduced infill:

- Fewer trucks are needed to haul material to and from the site, thus lowering the carbon emissions released by burning diesel/gasoline.

- In some instances, roads can be built directly on weak subgrade such as muskeg without removing the existing material and backfilling the area with engineered fill. This reduces the impact on the environment.

- Roads built with Tough Cell® are thinner compared to conventional road structures. This reduces the size of the right-of-way needed alongside the road causing fewer disturbances to the natural land, including less tree clearing.

- Tough Cell® roads can be built during extreme weather conditions.

- Preservation of soils under Tough Cell® layers and removability of the materials allows for extensive land reclamation for temporary roads.

- Tough Cell® designs do not require the removal of on-site permeable subgrade materials and, when used in combination with permeable infill, leave the existing subsurface water flow unaltered.

2. Cost Savings

Road infrastructure built with Tough Cell® benefits from short-term and long-term cost savings:

- Reduced construction costs are realized because Tough Cell® can be filled and compacted with cheaper, locally sourced materials to reduce haul expenses. These materials include:

- Gravel (well-graded, poorly graded, and gap-graded)

- Recycled asphalt

- Quarry waste

- Sand

- Shorter construction periods incur lower manpower costs.

- Fewer long-term maintenance requirements save on recurring costs.

3. Positive Social Impact

Believe it or not, Tough Cell® projects deliver positive social impacts:

- Local labour jobs are created to install Tough Cell®.

- Road safety and fuel efficiency are increased as Tough Cell® reduces surface deflection.

- Road downtime is greatly reduced because of lower road maintenance needs.

- All-season and all-weather access supports remote communities and projects in difficult-to-reach areas.

Tough Cell® put to the test.

In the following scenarios, Paradox constructed 3 types of access roads with different design specs to meet varying needs. With the use of Tough Cell® technology, each project benefitted from monetary, environmental, and time savings.

Project 1: Temporary access road- Christina Lake Area

MEG commissioned Paradox to construct a 3.2km access road for heavy drilling equipment. Building a conventional road would have required removing muskeg and long-distance hauling for the clay and gravel needed. However, given the restricted right-of-way, a conventional road would not have been possible.

Paradox’s solution: The road was constructed using a single layer of Tough Cell® to provide a top layer and was reinforced with a second layer of Tough Cell® where muskeg was present. This second layer eliminated the need to remove the muskeg and backfill. It also saved an average of one meter of clay and 270mm of crushed gravel along the length of the section.

Success: The road remained in excellent condition years post-construction.

Project 2: Main access road

MEG commissioned Paradox to improve the condition of a 7km seasonal road for all-weather access and to widen the existing driving surface from 8m to 10m.

Paradox’s solution: The entire road was widened over muskeg up to 6m deep. It was designed with 300mm thick gravel reinforced with a single layer of Tough Cell®. The construction avoided the removal and backfill of the muskeg and saved 150mm of crushed gravel along the length of the road.

Success: The road remained in excellent condition years post-construction and requires low maintenance.

Project 3: Township Road 762, Smoky River

Paradox was tasked by a top oil and gas client to reconstruct a 3.2km stretch of Township Road 762 in the Municipal District of Smoky River that succumbed to weathering over time. With changing seasons, the road infrastructure weakened due to freezing and thawing causing issues such as rutting, potholes, heaving, and cracking.

Paradox’s solution: The road was constructed using 200mm of sand reinforced by one layer of 150mm Tough Cell® with a 40mm gravel surface layer.

Success: The road performed excellently for years after reconstruction and has not required maintenance.

All three projects were done in collaboration with our partner civil engineering firm Stratum Logics who has extensive project experience, a deep understanding of geotechnical engineering, and expertise in the working mechanisms of cellular confinement technology. For more in-depth analysis of these projects, please refer to this technical paper.

Sustainability and the future of road building

Paradox’s mission is clear and paves the way sustainably, one project at a time. Whether by reducing carbon emissions, lowering maintenance requirements, or using recycled materials for infill, Paradox strives to build affordable and accessible roads in the greenest way possible.

From industrial access roads to residential streets, site preparation to slope stabilization, load distribution to rail repair, and everything in between, Tough Cell® is a cost-effective, solid-ground solution for projects large and small.

Do you have a road that gets mud ugly? Paradox is up for the challenge.

Learn more here or call 1.877.MUD.UGLY to chat with a Paradox sales specialist to get started.

Share This:

Next Article