An Australian mine recently approached Mineral Processing Solutions with a clear goal in mind to increase production.

The importance of reliable equipment and machinery in the mining industry cannot be understated. Without it, production targets will be missed and revenue reduced.

Understanding these needs, an Australian coal mining operation contacted Mineral Processing Solutions (MPS) – an OPS Group company – to find a forward-thinking solution for material feeding and stacking to achieve an increased feed rate of 1000 tonne per hour (tph).

At the site, coal is processed before being transported by truck to a train load-out facility, where it reaches the Port of Brisbane to be shipped to various Asian markets.

To deliver the desired production rate, MPS teamed up with long-term partner and bulk material handling manufacturer Telestack.

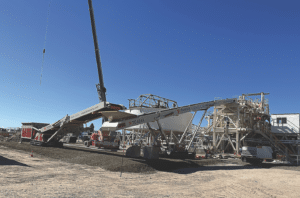

The companies worked together to create an innovative system that comprised several pieces of machinery from Telestack, notably an HF 24T hopper feeder, a HF 10T tracked hopper feeder, two TC 424X tracked stockpiling conveyors, and three TC 624R tracked radial stockpiling conveyors.

The system

In the initial stage of the system, coal is directly stacked from the impact crusher and the TC 424X tracked stockpiling conveyor, with the TC 624R tracked radial stockpiling conveyor helping to stack the material.

Image: Mineral Processing Solutions

The TC 424X then takes the bypass material (50mm-plus) before it enters the impactor and creates a conical stockpile, creating a greater stockpile capacity compared to only using the capacity created by the bypass discharge conveyor.

The TC 624R stacks the coal from the crusher’s product belt, stacking up to 13,000 square metres of material without moving.

When the coal is processed, it’s fed through the HF 10T tracked hopper feeder, which regulates the material flow. The HF 10T then works with a TC 424X to feed the correct material into the coal handling preparation plant (CHPP) at a height of 8m.

Once the material is processed through the CHPP, two TC 624R tracked radial stockpiling conveyors stockpile the product so it’s set for train load-out.

Once the coal is brought to the train load-out stockyard by truck, the HF 24T hopper feeder feeds the train load-out system, which can handle up to 1600tph at 35 hertz, with further capacity to run at 55 hertz if required.

“We seamlessly integrated our equipment with existing on-site infrastructure to enhance automation and user-friendliness,” Telestack international sales manager Philip Waddell said. “The equipment has various applications within the Australian mining operation.

“The ability to integrate the equipment into both mobile and static applications and to supply the equipment quickly with Mineral Processing Solutions stock in Australia was also a factor in winning this project.”

The solution not only met the customer’s desired goal but exceeded it, with a feed rate of 1600tph.

Image: Mineral Processing Solutions

Waddell said the Australian mining operation estimates it has saved millions in engineering and construction costs since the Telestack system became operational, all while maintaining high throughput rates and improving operational flexibility.

According to those involved in the collaboration, the new feed rate cut 50 minutes off the loading time per cycle, significantly increasing the project’s efficiency.

MPS area manager Adam Dever said the project was a significant milestone.

“This collaboration has resulted in substantial cost savings for the customer and minimal downtime for their plant, thanks to the high-quality structure, motors and gearboxes that Telestack provides,” Dever said.

This feature appeared in the October 2024 issue of Australian Mining.