DomeShelter Australia’s fabric shelters have become an essential part of mine sites across the globe.

According to Maslow’s Hierarchy of Needs, a key physiological need for humans is shelter.

This is especially true in the Australian mining industry, where workers operate under challenging weather conditions daily.

Enter DomeShelter Australia, a leading fabric shelter manufacturing company based in multiple locations across Australia.

“Our mission is to protect people and assets from the elements, quickly, simply and effectively,” DomeShelter Australia’s director of global sales Roy Fawkes told Australian Mining.

“Mine sites are dynamic environments, with commodity prices, expanding and contracting operations, and the weather all dictating what a site looks like and needs. Our semi-permanent DomeShelter Structures adapt to these changes.

“Our shelters are relocatable, reusable, repairable, and resellable, meeting the needs of evolving mine sites.”

As a mining operation expands, its design and infrastructure scope changes. A site might require a maintenance facility to be built close to the mining area, to eliminate travel time and operational downtime.

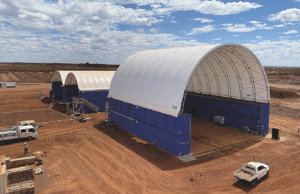

Image: DomeShelter

This is where DomeShelter Australia comes to the fore, with its fabric shelters offering an array of benefits, including the ability to be swiftly installed, disassembled and relocated.

“Instead of heavy vehicles travelling to a maintenance facility off-site, they can visit a purpose-built DomeShelter nearby,” Fawkes said.

“Then as the mine changes or expands, the mining company can easily relocate as needed. Being semi-permanent, our structures can adapt to suit the evolving nature of a mine site.”

The mobility of the shelters also has environmental advantages.

“Getting approval to build a large permanent facility can take months if not years, whereas one of our semi-permanent structures can be designed, engineered, manufactured and shipped within five or six weeks,” Fawkes said.

“The structures make less of an environmental impact, because we’re not installing deep concrete footings or concrete pads which is often the case with permanent structures.

“All the material needed to build the structure can be packed up in a light, compact kit when transported to site. And once the mine has reached its end of life, the shelter can be easily packed up again and moved on, making things easy for mine-closure teams and post-mining land use.”

Having a fabric structure on-site for maintenance can also increase staff retention and satisfaction, leading to increased productivity.

“If you have a permanent shelter, when equipment breaks down it can take too long to get the machine back to the main facility,” Fawkes said. “This means maintenance crews will often complete their work out in the open for long hours, exposed to the sun, rain, and snow – conditions that can be challenging.

“Workers can be put at risk of heat stress, sunburn and dehydration, and even frostbite if they’re working in snow.

“By having our semi-permanent structures closer to the mining pit, workers can safely carry out maintenance under shelter and away from the elements.”

DomeShelter Australia follows its unique six-element design methodology – dubbed DomeShelter Logic – to manage the thinking, processes and outputs that go into delivering tailored shelter solutions to the mining industry.

Fawkes said by maintaining the DomeShelter Logic, the company ensures the shelter does what it’s designed to do.

“The orientation and design are extremely critical to the success of our structures, so we’re committed to assisting our customers from the very start of a shelter’s creation,” Fawkes said.

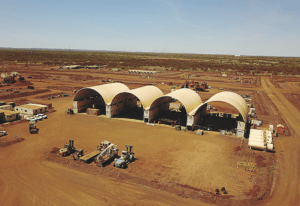

Image: DomeShelter

“We work closely on the initial design, ensuring the shelters always meet the unique requirements of our clients’ sites.”

DomeShelter Australia ensures all material used is the highest-grade material sourced in Australia. This ensures the facilities adhere to international quality assurance standards such as ISO 9001, AS 4801 and OHSAS 18001.

The company also recommends regular site audits, which involves a DomeShelter representative visiting site to make sure fabric structures are continually maintained.

“Our after-sales service gives customers peace of mind that structures are doing what they’re meant to be doing and abide by the standards they were designed against,” Fawkes said.

DomeShelter Australia utilises its multiple manufacturing facilities across Australia to ship fabric shelters from various ports, guaranteeing fast and efficient delivery to even the most remote locations.

“We have an in-house design and engineering team that collaborates with customers to ensure we’re building a structure that meets clients’ needs,” Fawkes said.

DomeShelter fabric structures are in high demand locally and internationally.

In 2022, the Bald Hill lithium mine in WA required several shelter solutions to use as on-site maintenance workshops.

The operation reached out to DomeShelter Australia with its specifications and the end result comprised three interconnected container-mounted structures with end walls, which are used as workshops for heavy vehicles, light vehicles and drill maintenance.

Soon after, the Kibali gold mine in Africa asked DomeShelter Australia to create a solution that could be quickly transported and installed without compromising size and durability.

Several DomeShelter structures were provided for purposes such as maintenance, boilermaker workshops, lubrication and tyre bays.

Fawkes said these case studies illustrate how DomeShelter Australia puts customers first.

“We’re looking forward to strengthening existing partnerships and building new ones across Australia and the rest of the world,” he said.

Backed by over 30 years’ experience, and with over 8000 shelters installed across 50 countries, DomeShelter Australia builds quality fabric shelters tailor-made for the mining industry.

“We’re creating an oasis for workers to go in and service their vehicles to ensure they get what they need out of their equipment,” Fawkes said.

This feature appeared in the March 2025 issue of Australian Mining.