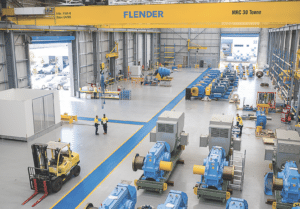

Gear unit and coupling manufacturer Flender is playing a key role in enabling sustainability across the Australian mining industry.

For 125 years, Flender has delivered high-quality mechanical and electrical drive systems that have performance and innovation at the forefront.

“The two product brands ‘Flender’ and ‘Winergy’ offer a wide range of gearboxes, couplings, generators and related services with a focus on key industries such as mining,” Flender Australia chief financial officer Bree Denton told Australian Mining. “Traditional machine-builders may be considered old-fashioned, non-fancy and not particularly green; however, Flender has evolved into a modern company – a pioneer in terms of driving industries towards sustainability.”

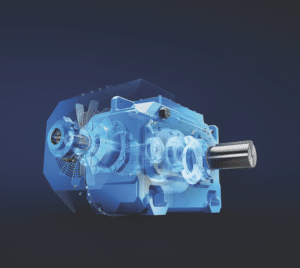

Flender’s commitment to sustainability is illustrated by its gear units and couplings, including its flagship gearbox solution, FLENDER ONE, which drives higher energy savings and efficiency.

Image: Flender

“FLENDER ONE is more than just a new gearbox generation,” Denton said. “It is the successor to the well-established Flender standard gearbox series that had become the grey standard in many industries globally.

“With a market that evolves and demands more efficient and faster-to-deploy gearbox solutions, FLENDER ONE is as individual as its predecessor, with higher efficiency resulting in lower operating expenditure.”

FLENDER ONE has a variety of benefits suited for the Australian mining industry.

“FLENDER ONE boasts a 30 per cent higher thermal capacity, 80 per cent longer bearing life and lower weight than its predecessor,” Denton said. “FLENDER ONE is available in nearly any configuration and comes as a single-stage and multi-stage gearbox.”

FLENDER ONE also features AIQ smart condition-monitoring out of the box, ensuring greater uptime.

AIQ is Flender’s new gear unit intelligence system that provides customers with diagnostic information on conveyors, mills and other key assets at their mine sites, including how their machines are operating and the lifecycle of the product. It uses intelligence, knowledge, and extensive experience to meet customer requirements for diagnosis, early fault detection and process optimisation. All AIQ solutions are based on gearbox analysis that turns sensor signals into direct information for further analysis.

“With AIQ pre-installed on FLENDER ONE, customers benefit from less unplanned downtime and can expect to cut maintenance costs significantly,” Denton said. “Our upcoming multi-stage models of FLENDER ONE are best suited for belt conveyors and bucket elevators, whereas the single-stage FLENDER ONE should be used in pumping, water and waste-water applications.”

Image: Flender

By utilising AIQ, mine operators can keep an eye on their drives and immediately act when a situation presents unusual data.

“The measurement data is analysed, interpreted, and provides concrete recommendations for action,” Denton said. “The operator has full access to important information at all times.

“This is especially useful when the operator is not in close proximity to their equipment or when plant needs to be visible, resulting in greater transparency around operations, utilisation and necessary maintenance activities.”

Sustainability is the basis of all Flender activity, including the environment, employees, customers, community, and production processes along its delivery chain.

Encompassing this connection between sustainability and market competitiveness is Flender’s 2023 sustainability report, ‘We move the world’, marking the third time the company has released such a report.

“Flender has achieved remarkable milestones in terms of sustainability, notably earning the prestigious platinum medal from EcoVadis – the global standard for business sustainability ratings – placing Flender among the top one per cent of the world’s most sustainable companies,” Denton said.

“Flender was recognised in areas such as environment, labour and human rights, ethics and sustainable procurement.

“The company also received the 2024 German Sustainability Award in the field of mechanical engineering.

“These external recognitions reinforce our standing as a preferred partner for a sustainable future.”

Last year also saw Flender develop a diversity, equity, inclusion and belonging (DEIB) program and statement to emphasise the significant value diversity brings to the company’s workforce.

“Flender prioritises communication and inclusivity, fostering active employee participation across all levels,” Denton said.

“By setting ambitious goals and challenging the status quo, employees are poised to make significant strides towards a more sustainable future.”

Image: Flender

Throughout the remainder of 2024, Flender will work towards objectives and measures across its four sustainability strategy pillars: environmental sustainability; employer of choice; governance and compliance; and health and safety.

“Initiatives include the implementation of an energy management system at Flender’s largest international production sites, aligning with ISO 50001 standards,” Denton said.

“A coordinated global program focusing on water and waste prevention will be introduced. Collaborative emission-reduction efforts with key suppliers and the prioritisation of green steel usage are also underway. Flender plans to launch an extensive awareness campaign aimed at reinforcing regulatory adherence and ethical practices throughout operations.

“These targeted efforts underscore a commitment to advancing across all spheres of sustainability.”

FLENDER ONE multi-stage gear units will be available to the Australian mining industry from July 2024. And Flender continues to expand its local service presence.

“Over the last 45 years, Flender has established that customer proximity is key,” Denton said. “This has led to the expansion of our service footprint; we now have Flender workshops in Perth, Sydney, Rockhampton and Melbourne that are all equipped to provide full OEM (original equipment manufacturer) support, repairs and testing.

“As Flender grows its footprint in Australia, we have the potential to be a frontrunner and pioneer in enabling sustainable mining operations.”

This feature appeared in the July 2024 issue of Australian Mining.