Growing recognition of the potential value locked in tailings and mine wastes has spurred renewed interest in how these materials can be recovered or repurposed. With demand for minerals rising, ore grades declining, and environmental risks from tailings storage becoming more pressing, the industry is beginning to see these wastes less as liabilities and more as untapped resources. Several emerging avenues, particularly those leveraging thermal processing and agglomeration, are showing promise in transforming mining byproducts into sources of critical minerals or materials useful in construction and agriculture.

Factors that influencing reuse

Several factors are converging to make tailings and other mining-related wastes increasingly attractive resources for minerals and material inputs.

A) Substantial resource: Mining waste has been produced for as long as mining has occurred. The quantity of tailings continues to grow every year by an estimated 7 billion tonnes globally. With many of these sources containing valuable components, this growing waste represents a potentially major source of already mined, readily accessible minerals and metals. Such resources could be essential in taking the pressure off finite virgin resources, many of which are already strained.

B) Growing demand for minerals and metals: The constant advancement of technology, paired with clean energy pursuits, among other factors, continues to drive demand for various metals and minerals to unprecedented heights, making every possible resource critical to meeting demand.

C) Risks of tailings: The risks associated with the storage of tailings and other mine waste are well-documented, with a growing catalog of disasters prompting calls for a global response and resulting in the Global Industry Standard on Tailings Management (GISTM).

D) Declining ore grades: Ore grades have long been in decline as high-grade, surface-level deposits become depleted.

E) Improved recovery technologies: Advancements in extraction have made mineral recovery more efficient than ever, leading many miners to revisit old tailings piles previously considered economically unviable owing to their low grades.

Hidden opportunities

Waste from the mining and mineral processing industry covers a diverse range of materials and conditions, all with varying physical and chemical attributes; tailings ponds, overburden, and process waste all hold potential value. This diversity across sources and forms translates to the need for an equally diverse approach to valorization, with promising opportunities in both recovering value and reprocessing materials for beneficial reuse.

Recovering value

The potential value that these wastes hold varies significantly across types, but everyone agrees: the value is there; it is just a matter of retrieving it at a cost that makes sense. Old mine sites previously considered too low grade to economically process with the time’s technology cover the gamut from gold to copper, nickel, and even lithium and rare earth elements (REEs).

Earlier this year, a new research report by Action Canada, entitled “Waste Not: Unlocking Critical and Strategic Mineral Opportunities in Canada’s Tailings,” highlighted the significant value locked away in tailings throughout the nation; $8 to $10 billion worth of nickel at one site alone. Considering that these resources are already mined, the return on investment (ROI) for recovering them offers additional economic incentive.

Mineral processing waste streams, such as phosphogypsum, red mud, and coal fly ash also abound, each holding essential metals and minerals.

A 2024 study in the U.S. confirmed what many have long suspected: accessible coal ash piles in the U.S. are holding significant value in REEs; an estimated US$8.4 billion worth.

Beneficial reuse/repurposing

In tailings where inherent values such as REEs or other critical minerals are not present, significant opportunities still exist for reuse and repurposing, most notably in the building and construction materials industry.

A) Building and construction materials

Various types of tailings are under exploration for use in a range of construction and building materials, including aggregates, pozzolans, bricks, mortars, concrete, and geopolymers. Researchers are finding that substituting a portion of raw material with tailings can even offer product improvements in many cases. One study found that, used as an alternative filler to limestone powder, red mud could improve the resistance and wear properties of porous asphalt. Another study looked at using copper tailings as a partial substitute for cement in concrete production and found that it reduced heavy metal leachability.

B) Additional applications

Additional reuse applications are being explored for these wastes as well. Some of the more common ones include soil amendments and fertilizers, soil stabilizers (for erosion prevention), landfill covers, and carbon sequestration.

Advancing progress

Successful scale-up of recovery and reuse processes often hinges on specialized facilities equipped to simulate commercial-scale conditions. Facilities like the FEECO Innovation Center allow mining waste to be evaluated through batch and pilot-scale equipment testing, generating the data needed for commercial scale-up. Mining and waste recovery companies are testing options for legacy sites, looking at old wastes to recover new value, and trialing novel reuse opportunities.

Two technologies have been the central focus of research in the Innovation Center: thermal processing in rotary kilns and agglomeration.

A) Thermal processing via rotary kilns

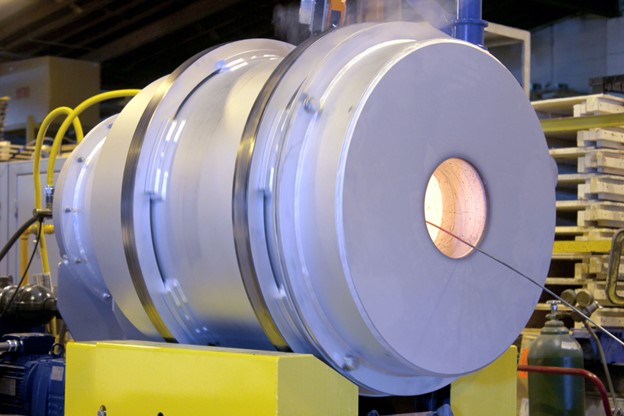

Rotary kilns utilize high temperatures and a controlled processing environment to facilitate a chemical reaction or phase change. Capable of processing a wide array of materials, rotary kilns are a well-established technology in recovering value across different types of materials: spent catalysts, drilling mud, spent activated carbon, and more. As such, they have become a key tool in recovering the value locked away in tailings and mine wastes.

In one example, red mud (the bauxite residue remaining after the conversion of bauxite to alumina in the Bayer process) is constantly being explored for recovery thanks to the waste’s rich metal composition. Iron, REEs, titanium, and aluminum represent a few of the valuable components remaining in the waste known for its iron-red colour.

Batch- and pilot-scale kilns (direct or indirect) can be used to develop the time and temperature profiles required for optimal reduction roasting and eventual iron recovery. The data gathered during testing is then used to engineer and manufacture commercial-scale equipment. Rotary kilns are also being employed in processes that extract REEs from fly ash and many other recovery applications as well.

Credit: FEECO.

B) Recovery and reuse via agglomeration

Agglomeration has also become a vital tool in utilizing mine waste, most notably when combined with the heap leaching process. In the case of historic non-ferrous tailings, the heap leaching technique has already seen widespread adoption in recovering metals from low-grade ores. Gold, copper, nickel, uranium, and the like can be piled and irrigated with a leachate that dissolves the target component into a solution collected for recovery. This hydrometallurgical technology has breathed new life into old mines and opened the door to other low-grade ore sources.

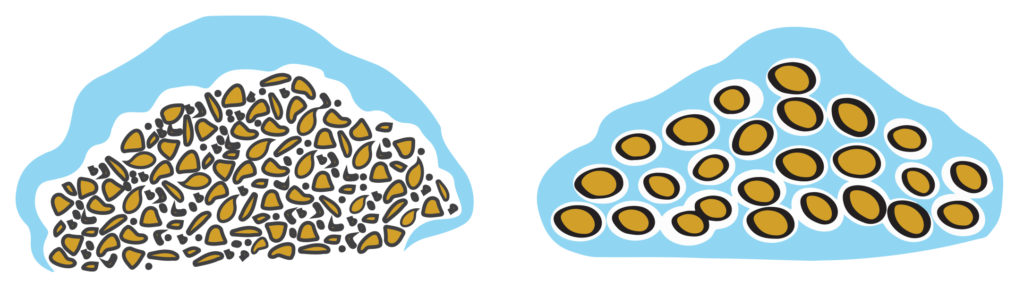

By agglomerating ore fines prior to heap leaching, producers can significantly increase recovery. This is because ore fines and leachate can be premixed in the agglomeration drum, ensuring uniform leachate distribution. Improved leachate percolation through the heap also boosts recovery thanks to a greater uniformity in ore particle size and shape.

Agglomeration has also improved efforts to recover materials from waste in the form of dust and fine powder. Agglomerating fines into larger, more uniform particles allows for improved bed permeability in reactors. The recovery of zinc from electric arc furnace (EAF) dust, for example, is largely made possible by agglomerating the dust into spherical granules, allowing it to be effectively heat-treated.

Credit: FEECO.

In the same way, agglomeration improves the reusability of tailings and wastes in the form of fines by converting them into products that are easier to handle, store, and apply. This is frequently seen in the soil amendment and fertilizer industry, as well as in construction materials, owing to the otherwise difficult nature of managing a dusty product.

Concluding remarks

Recovering and reusing tailings presents significant opportunity, but scaling these approaches is not without obstacles. Heavy metals, complex mineralogy, regulatory requirements, and economic considerations all pose challenges that must be addressed. Even so, advances in thermal processing and agglomeration are opening new pathways, with batch- and pilot-scale testing facilities proving essential in moving concepts into practice. Progress will depend on continued research and collaboration across industry, equipment manufacturers, and research institutions to turn mine wastes from liabilities into valuable resources.

Shane Le Capitaine is a process sales engineer at FEECO International. With a degree in chemical engineering and nearly 30 years of experience, he specializes in ore agglomeration, fertilizer and animal feed granulation, and bulk solids drying and cooling. Alex Ebben is a process sales engineer at FEECO International. Alex has a degree in chemical engineering and has over a decade of experience in advanced thermal processing systems.