ABB has opened a new manufacturing, distribution and repair centre in Mechanicsville, Virginia, USA, to support its Motion Traction business. ABB’s Motion Traction division offers a comprehensive range of high-performance products for use in passenger railway cars and e-mobility commercial vehicles. From individual components to highly integrated traction systems, the product portfolio includes compact converters and auxiliary converters, battery chargers, energy storage systems, as well as service and retrofit solutions.

The facility is equipped with state-of-the-art manufacturing equipment to produce converters and batteries for the railway and transportation industries as well as electric off-road construction machinery for mining as well as electrical buses. The $6 million investment includes more than 65,000 square feet of operational space and will employ nearly 100 skilled production workers when at scale. This venture follows ABB’s recent announcement to invest $170 million in the US to meet increased demand from industry-leading customers, while supporting the clean energy transition and the trend towards reshoring of production.

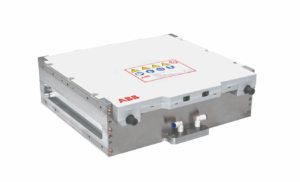

ABB BORDLINE battery pack

“This investment demonstrates ABB’s commitment to bring more products and solutions closer to customers and use technology to enable OEMs and operators to improve reliability, performance and energy efficiency,” said Peter Basile, President, US Traction Division, ABB, Inc. “This facility provides a comprehensive offering to our customers that will allow them to enhance their business by utilising ABB technology and support.”

Since 2010, ABB has invested $14 billion in the US for plant expansions, operational improvements, state-of-the-art equipment, products and people, making it the company’s largest market. With approximately 20,000 employees in more than 40 manufacturing and distribution facilities, ABB says it is investing, growing and serving customers across America through industries that create jobs, encourage innovation and achieve a more productive, sustainable future.

ABB’s BORDLINE® Energy Storage System (ESS) is a lithium-ion based onboard energy storage system that it says is characterised by its high safety level and achievable lifetime. Up to sixteen battery modules can be connected in series to form a battery string and multiple strings can be connected in parallel. The series connection of modules are realised with insulated quick coupling power connectors and with a wired serial bus between the modules and the master control unit. BORDLINE Compact Converters are main propulsion converters with integrated auxiliary supply. All power electronics found on a vehicle are integrated in one product. This yields a very compact design with one interface to the vehicle.

In May 2023, First Mode ordered 80 ABB BORDLINE ESS for use in its FCEV nuGen™ zero-emission mining haulage trucks. The batteries, with a total 2.6 megawatt-hours (MWh), will be assembled into larger battery packs and used in the construction of hybrid hydrogen and battery powerplants to power the new ultra-class haulage trucks.

ABB is also working with Hitachi Construction Machinery on its development of an all battery mining truck. ABB is developing the on-board energy storage systems “by customising an existing product” and Hitachi Construction Machinery is leading the overall design and development of the dynamic charging battery dump truck utilising the technology of its existing rigid dump truck with trolley as its base, effectively allowing the accelerated development of this solution.