In the vast and varied landscapes of Canada, industries face unique challenges when it comes to ensuring the safety of their operations, especially in the realm of flame and gas detection. The extreme conditions characteristic of Canada’s environment—ranging from the searing summers to the frigid winters, not to mention the peculiarities of its natural phenomena—demand robust and reliable detection systems.

The Intricacies of Fire Detection in Extreme Conditions

Flame detection systems are crucial for early warning and prevention measures in industrial settings. However, in extreme conditions, several factors can complicate the efficacy of these systems. From the electrical storms that light up the sky to the dust storms that cloak the horizon, each element poses a specific challenge to the reliability of fire detection.

Lightning storms, for example, are a common occurrence in many parts of Canada. These natural phenomena can interfere with detection signals, leading to false alarms or, worse, missed detections. However, advancements in detection technology have led to the development of detectors capable of differentiating between the electrical signatures of natural lightning and actual fire events, thereby ensuring accurate alerts.

Dust and airborne particles can obscure detection sensors, significantly reducing their effectiveness. In response to this challenge, innovative solutions like the “Airshield” have been introduced. This special accessory is designed to prevent dust and sand from entering the detector area, ensuring that the sensors remain clear and functional even in the midst of a dust storm.

The impact of heavy rain and sun glare cannot be understated either. These weather conditions affect the visibility and performance of detection systems. Weather-resistant designs and anti-glare technologies are employed to mitigate these issues, ensuring that the systems can operate reliably even under less-than-ideal conditions.

Furthermore, the presence of electromagnetic fields from nearby equipment or electrical systems can disrupt detection signals. To combat this, modern detectors are shielded against electromagnetic interference, maintaining consistent performance regardless of the surrounding electronic environment.

Perhaps one of the most challenging conditions is the extreme cold that defines the Canadian winter. Icy conditions can affect the functionality of detection systems. Yet, through the use of specialized technologies, such as heated windows detectors today are capable of identifying a flame even in temperatures well below freezing.

In the face of challenges such as lightning storms, dust storms, heavy rain, sun glare, and below zero temperatures, the Rosemount 975 series stands out with its advanced flame detection technologies. Their detectors are specifically designed to differentiate between natural lightning and actual fire events, reducing the chances of false alarms while ensuring no real threats go unnoticed. The “Airshield” accessory by Rosemount for their 975 Flame detector series is a testament to the commitment to innovation, effectively preventing dust and sand from compromising detector sensitivity in harsh conditions. Weather-resistant designs ensure that Rosemount 975 series detectors maintain high performance during heavy rain, while anti-glare technologies address the challenge of sun glare, ensuring accurate flame detection regardless of sunlight intensity. Furthermore, Rosemount 975’s are engineered to be immune to electromagnetic interference, providing consistent and reliable detection even in areas with high levels of electromagnetic activity. These features underscore the Rosemount 975 series can perform reliably in extreme conditions, offering peace of mind and enhanced safety for industries operating in challenging environments.

The Critical Role of Gas Detection in Harsh Environments

Just as flame detection is essential for industrial safety, gas detection plays a pivotal role in safeguarding facilities from the invisible threats that can lurk in the air. Gas leaks represent a significant risk, not only because of their potential for explosion but also due to the health hazards they pose to personnel. In Canada’s extreme conditions, from the deep cold of the Arctic territories to the industrial expanses in the warmer south, the challenges of gas detection are amplified.

Challenges in Gas Detection

The detection of hazardous gases in extreme environments is fraught with challenges. Temperature extremes can impact sensor performance, potentially leading to slower response times or a failure to detect gas concentrations at critically low temperatures. Environmental conditions, such as high humidity, dust, or the presence of other chemicals, can also interfere with the accuracy of gas detectors, either by damaging the sensors or by producing false readings.

Moreover, remote locations and expansive industrial sites in Canada demand robust gas detection solutions that can operate reliably over large areas and transmit data effectively, even in the absence of a direct human presence to monitor them.

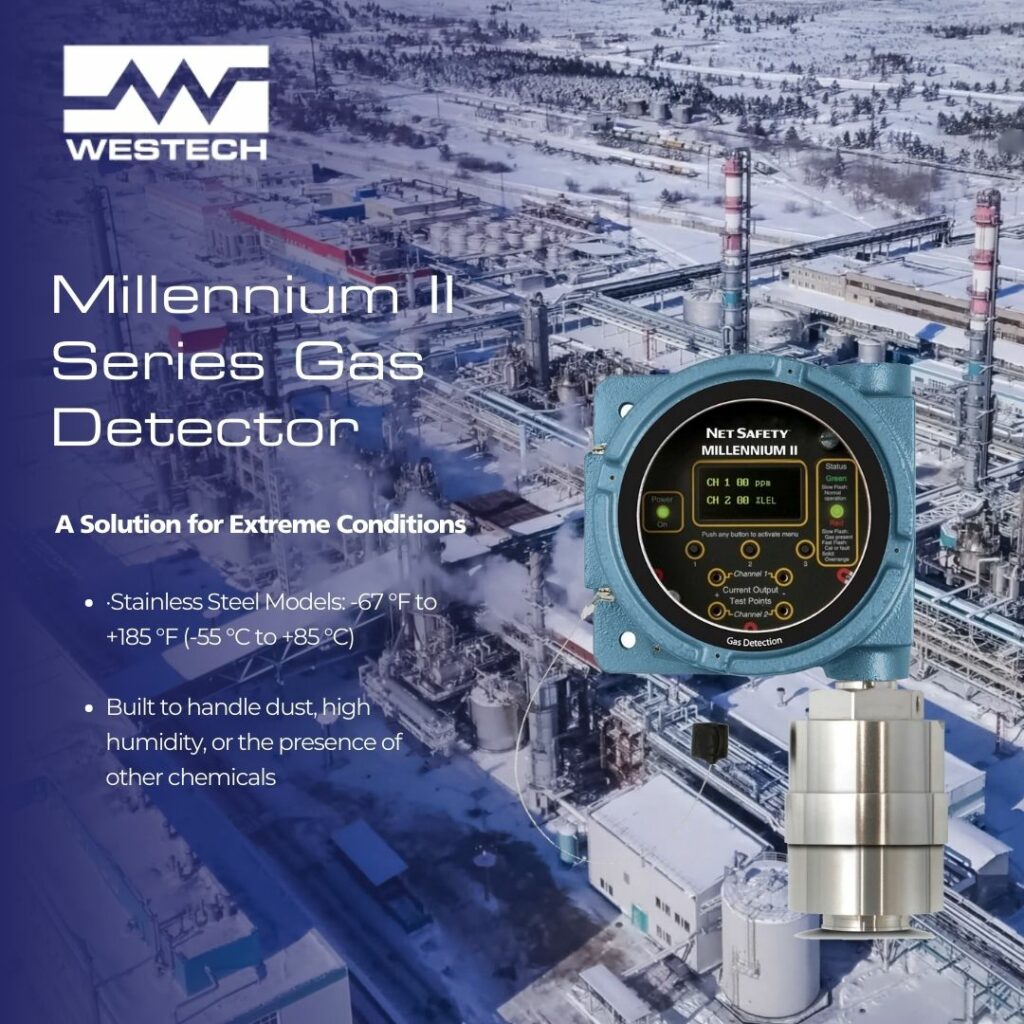

NetSafety Gas Detection Millennium II: A Solution for Extreme Conditions

The NetSafety Gas Detection Millennium II series emerges as a beacon of reliability in the face of the formidable challenges posed by Canada’s diverse environments. Engineered with precision to cater to the needs of industries operating under the harshest conditions, these gas transmitters and sensors stand out for their robustness, versatility, and advanced technology.

Operational Temperature Ranges:

- Stainless Steel Models: -67 °F to +185 °F (-55 °C to +85 °C)

- Stainless Steel – North American Explosion-Proof Certification: -58 °F to +185 °F (-50 °C to +85 °C)

- Aluminum Models: -40 °F to +185 °F (-40 °C to +85 °C)

These ranges ensure that, regardless of whether you’re facing the biting cold of the Arctic or the searing heat of a southern summer, the Millennium II series provides consistent and reliable performance.

Addressing the Challenges:

- Temperature Extremes: Equipped to function across a broad temperature spectrum, these devices ensure accurate gas detection in conditions that would compromise lesser systems.

- Environmental Conditions: The Millennium II series is designed with durability in mind. Whether it’s dust, high humidity, or the presence of other chemicals, these gas detectors maintain operational integrity, thanks to their robust construction and advanced sensor technologies.

- Large Area Operation: With state-of-the-art connectivity options, these detectors offer effective area coverage and data transmission capabilities, ensuring that even the most remote or expansive sites are adequately monitored.

- Versatility and Customization: Understanding the varied nature of gas detection needs, the Millennium II series offers a high degree of customization, allowing for the detection of a wide range of gases at different concentrations.

Rosemount 975 and NetSafety: Leading the Way in Reliable Detection

In the face of these challenges, it’s essential to choose detection systems that can withstand the rigors of the Canadian climate. Emerson’s Rosemount brand, known for its industrial flame and gas detection solutions, has been at the forefront of developing technologies designed to address extreme conditions.

Conclusion

The unique environmental conditions of Canada require equally unique solutions when it comes to fire and gas detection. Through the innovative efforts of companies like Emerson, with their Rosemount flame and gas detectors, industries operating in extreme conditions can have access to detection systems that offer not just reliability, but also peace of mind. As we continue to navigate the complexities of ensuring safety in challenging environments, these technologies play a crucial role in protecting lives and assets.

For those interested in exploring these advanced detection solutions further Westech offers a range of life safety solutions that we can tailor to meet the specific needs of industries facing the harshest conditions. Our commitment to innovation and safety ensures that, no matter the challenge, preparedness and protection are always within reach.

To learn more about how these solutions can be integrated into your safety protocols, or to explore a broader range of our industrial safety and detection solutions, visit Westech Industrial at https://westech-ind.com or contact us at 1-800-912-9262. Our team of experts is dedicated to providing you with the technology and support needed to navigate the extreme conditions faced by Canadian industries, ensuring your operations are safe and secure.

Share This: