In the dynamic landscape of energy production, the precision measurement of hydrogen and hydrogen-enriched natural gas is paramount. Ultrasonic flow meters are at the heart of this technological evolution, offering unparalleled accuracy and dependability.

The energy sector is undergoing a significant transformation. Renewable sources such as wind, water, and solar are becoming increasingly important in our journey towards a decarbonized energy supply. Amidst this shift, natural gas continues to play a critical role, and hydrogen is emerging as a key player in the quest for sustainable energy solutions. The integration of hydrogen into existing gas networks is not just a possibility but a necessity for a CO2-neutral future, leveraging the full potential of renewable energy sources for efficient storage and transport.

Hydrogen’s Role in the Gas Network

The production and incorporation of hydrogen from renewable energies into the gas network are critical steps towards a greener energy supply. It can be stored and transported through the existing natural gas infrastructure, with the potential for up to 30 vol.% integration. The vision for a comprehensive hydrogen network across Europe by 2040 is becoming clearer as regional networks expand and interconnect.

The Measurement Challenge

The ability to reliably and stably measure the flow of natural gas with admixed hydrogen is becoming increasingly important these days. The change in gas composition poses new measurement challenges for the various metering technologies. This is because the added hydrogen affects the properties of the natural gas: the density, viscosity, explosivity, flow rate, and sound velocities of the gas change. This poses completely new challenges for pipelines, compressors, seals, valves, measurement technology, etc., for example in regard to the risk of leaks and explosions or the determination of the calorific value. Gas network operators and gas suppliers are therefore wondering how this will affect the performance of their gas flow meters.

Ultrasonic flow measurement has set a new standard for reliability, durability, and measurement accuracy in both the natural gas and process gas industries over the past two decades.

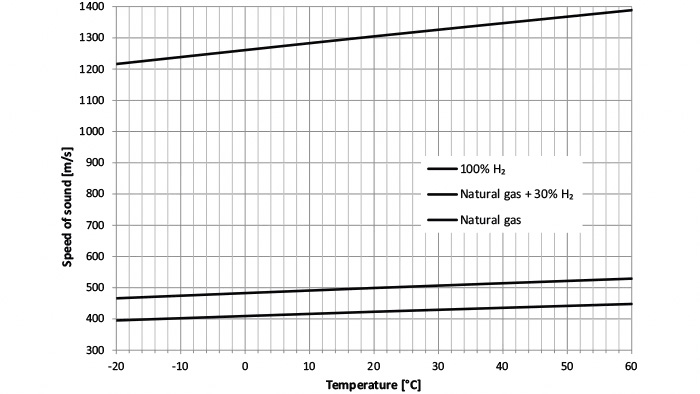

Adding a small percentage of hydrogen to natural gas already significantly increases the speed of sound (SOS) of the gas mixture. At 100% hydrogen by volume, it is about three times that of natural gas. The diagrams in Figure 1 show the SOS for natural gas, a hydrogen mixture of 30 vol%, and pure hydrogen.

Figure 1: Speed of sound for a typical natural gas (methane content of 90 vol%) and hydrogen admixtures up to 100

This places several requirements on the USM design. Both the natural gas-equivalent measuring range and the required measurement uncertainty must be ensured. This includes reducing the scatter of measured values, reducing cross-sensitivities to pressure, temperature and media fluctuations, and reducing fluid-mechanical effects.

For natural gas with hydrogen admixtures of up to 30 vol%, it is still possible to compensate for this effect.

Ultrasonic Flow Meters: Precision Engineered for Tomorrow’s Energy

Ultrasonic flow meters are at the forefront of addressing the complexities of measuring gas flows with hydrogen content. These meters, including the advanced offerings from SICK, such as the FLOWSIC600-XT and FLOWSIC500, are designed to maintain accuracy and reliability, even with significant hydrogen admixtures.

Advantages of Ultrasonic Flow Meters:

- Versatile range of diameters (Dn50 to DN1400) for various pipeline sizes

- High measuring span of ≥ 1:100

- Non-intrusive measurement to maintain pipeline integrity

- No mechanical moving parts, minimizing maintenance

- Accommodates higher flow rates with hydrogen

- Transferability of the calibration to other media

Specialized Applications:

- Process Gas Measurement: Enhanced for higher hydrogen content measurements in process gas plants.

- Transport Network Measurement: Approved for custody transfer volume measurement, these meters handle significant hydrogen content with ease.

- Distribution Network Measurement: Specially designed for natural gas distribution networks, they accurately measure up to 30% hydrogen by volume.

Innovative Gas Quality Indicator (GQI):

These ultrasonic flow meters are not just quantitative tools but also offer qualitative insights with the GQI. This feature enables the detection of changes in hydrogen content, offering a precise analysis of the gas mixture and potentially simplifying the determination of hydrogen content.

The picture below shows an example of a FLOWSIC500 USM in the mixing station of the “Hydrogen in the gas network” pilot project in the Fläming region, Saxony-Anhalt, Germany. This communal project will add hydrogen admixtures of up to 20% by volume to the natural gas distribution network. The meter is used to measure the volume of the natural gas/hydrogen mixture. At the same time, the hydrogen content of the natural gas is measured by means of the GQI.

FLOWSIC500 in the mixing station of the avacon pilot project “Hydrogen in the gas network”

Advancing with Hydrogen

As the industry moves towards embracing hydrogen, these ultrasonic flow meters ensure a smooth transition, enabling operators to measure gas flow accurately without the need for investing in new meters.

Partnering with Westech Industrial

Westech Industrial is proud to be the distributor of these cutting-edge ultrasonic flow meters by SICK Sensor Intelligence in Eastern Canada. As the energy sector pivots towards hydrogen, we are your trusted partner, offering solutions that ensure accuracy and reliability in gas measurement.

For those in Canada looking to stay ahead in the hydrogen economy, Westech Industrial provides the expertise and technology to meet your measurement needs. To explore how these ultrasonic flow meters can benefit your operations and to support your transition to a hydrogen-inclusive energy system, contact Westech Industrial or visit our website for more information.

Embrace Canada’s energy future with precision measurement technology from Westech Industrial.

This article is informed by insights from SICK Sensor Intelligence’s detailed exploration of ultrasonic flow meters for hydrogen and hydrogen-enriched natural gas measurement. For a deeper understanding of the technical aspects and the original study, please refer to their comprehensive article here.

Share This: