As the demand for copper continues to rise due to its essential role in electrification and renewable energy systems, Nuton has positioned itself as a transformative force. The Rio Tinto technology venture was honored with three awards in the 2025 Mining Technology Excellence Awards: the Innovation Award for its groundbreaking bioleaching technologies that significantly enhance copper recovery rates; the Business Expansion Award for establishing strategic partnerships across the Americas that facilitate rapid growth and access to new resources; and the Environmental Award for its commitment to low-impact processing methods that drastically reduce emissions and improve water efficiency.

The Mining Technology Excellence Awards honor the most significant achievements and innovations in the global mining industry. Powered by GlobalData’s business intelligence, the Awards recognize the people and companies leading positive change and shaping the future of the industry.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Improving copper recovery with bioleach technology

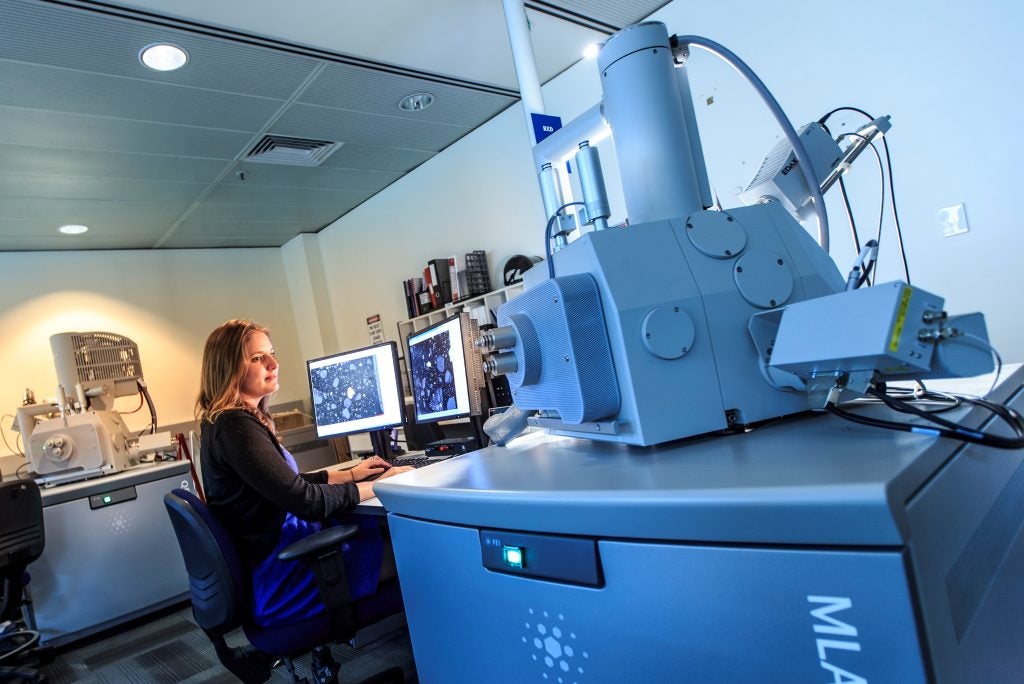

Conventional methods have struggled to efficiently process complex copper ores, particularly those rich in arsenic or other impurities that make traditional extraction methods less effective. The Nuton® Technology, proprietary bioleaching processes, have addressed this long-standing challenge in the industry, achieving an impressive recovery rate of up to 85% from primary sulfide ores.

At the Johnson Camp Mine (JCM) in Arizona, USA, owned and operated by Gunnison Copper Corp., Nuton will scale bioleaching from laboratory settings to industrial applications. The integration of real-time data capture and adaptive process control at JCM allows for continuous monitoring and adjustment of the extraction process, setting a new standard for operational intelligence in copper mining.

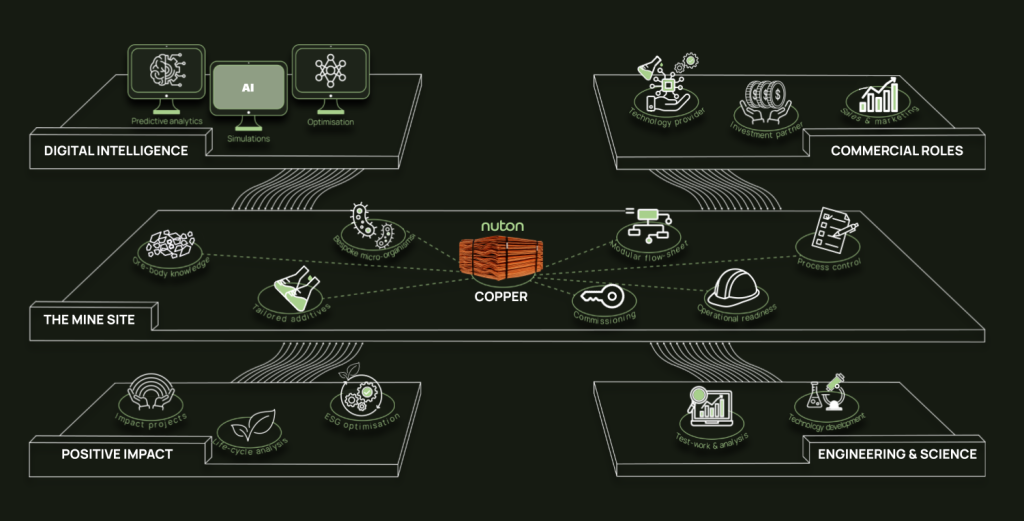

Nuton also developed modular and repeatable deployment systems, including standardized flowsheets, engineered equipment, and operational protocols, enabling rapid adaptation to various ore bodies. By allowing for site-specific customization, Nuton can effectively address the unique challenges posed by different mining environments, thereby unlocking additional copper resources that were previously deemed unviable.

This combination of advanced science and applied engineering not only matches but often surpasses the performance of traditional concentrator and leach technologies, solidifying Nuton’s position as a leader in mining innovation. The ability to economically process complex and lower-grade ores, including those previously considered sub-economic, further underscores Nuton’s transformative impact.

“Nuton brings together the spark of people, the intelligence of nature, and the power of technology to open new pathways for copper production. Our innovations unlock copper resources previously out of reach—delivering more copper with less impact. We are honoured by this recognition, a testament to a hard-working and dedicated Nuton team.”

– Adam Burley, Nuton Chief Executive Officer

Strategic partnerships drive Nuton’s global growth

Since its inception in 2022, Nuton has rapidly evolved from a concept to a global venture, establishing 11 active partnerships across the Americas. These collaborations encompass both brownfield projects, where existing mining operations are enhanced, and greenfield projects, where new sites are developed. This strategic approach showcases Nuton’s ability to adapt its innovative technologies to various regulatory and geological environments, thereby expanding its operational footprint.

Nuton has established innovative partnership models that include technology provision, equity partnerships, and joint venture options. These models not only accelerate project deployment but also unlock new copper resources, allowing Nuton to tap into previously inaccessible deposits. For instance, partnerships with companies like Lion Copper & Gold in Nevada and McEwen Copper in Argentina illustrate Nuton’s commitment to leveraging local expertise while providing cutting-edge technology.

The company’s impressive growth trajectory is evidenced by a tenfold increase in its workforce, expanding from just four to over 50 experts across engineering, technology, sustainability, and commercial functions. This rapid scaling reflects Nuton’s commitment to delivering a revenue-generating business model, with the first Nuton Copper cathode expected from JCM in 2025. The anticipated production marks a significant milestone, demonstrating the commercial viability and scalability of Nuton’s innovative approach.

Moreover, Nuton is currently evaluating the deployment of its technology in four countries, which highlights its global reach and adaptability.

Leading the charge for low-impact processing

Nuton’s commitment to environmental stewardship is exemplified by its low-impact processing methods, which achieve up to 60% lower CO₂-equivalent emissions and 80% greater water efficiency compared to conventional copper production. These achievements have been validated through ISO-compliant Life Cycle Assessments, underscoring Nuton’s dedication to transparency and accountability in its environmental performance.

By eliminating the need for tailings dams, the Nuton® Technology leads to significant reductions in land disturbance and long-term environmental liabilities. This innovation not only minimizes the ecological footprint of mining operations but also addresses regulatory challenges associated with land permits for tailings and long-term waste management. The company’s Positive Impact strategy is embedded in every deployment, with measurable commitments across five pillars: water, energy, land, materials, and society.

Nuton aims to mitigate environmental risks and enhance sustainability through innovative approaches to waste valorization—such as exploring the potential to reuse pyrite from tailings. By investigating ways to transform materials typically considered waste into valuable resources, the initiative seeks to reduce the environmental impact of acid rock drainage and potentially lower closure costs for mining operations.

Moreover, Nuton supports the generation of more renewable energy than consumed and the replenishment of water resources, demonstrating a regenerative approach to mining. This commitment to environmental excellence positions Nuton as a leader in the industry, setting a new standard for sustainable copper production. The company’s proactive measures in transparency and accountability, including GRI-aligned disclosures and independent verification of environmental performance, further reinforce its commitment to responsible mining practices.

“Nuton represents the kind of bold innovation the copper industry needs. The future of copper needs new thinking – and that’s where Nuton is going, unlocking copper resource opportunities while setting a new benchmark for sustainability. It is a key part of how Rio Tinto is reimagining copper and meeting the world’s growing demand for this critical material for the global energy future.”

– Clayton Walker, Rio Tinto Copper Americas Chief Growth & Development Officer

“Nuton’s approach highlights that sustainable innovation is not just possible, but essential. Our Positive Impact strategy is at the core of everything we do, and we are driven by a clear ambition: to set a new standard for sustainable copper production while delivering copper with the world’s lightest environmental footprint.”

– Cecilia Perla, VP Growth & Sustainability at Nuton

Company Profile

Nuton LLC is a Rio Tinto technology venture redefining the future and legacy of copper production. Built on a portfolio of proprietary bioleaching technologies, Nuton combines custom biology, tailored additives, and advanced systems engineering to unlock copper from hard-to-leach ores, including primary sulfides—where nearly 70% of the world’s copper resources remain. By extracting more copper using less, Nuton increases copper production, essential to the global energy transition.

Nuton’s approach delivers market-leading copper recovery rates, up to ~85%, while significantly reducing environmental impacts. Compared to conventional copper processing, the NutonTM Technology cuts carbon emissions by up to 60%, uses up to 80% less water, and enables copper cathode production directly at the mine sites, creating a shorter, more resilient mine-to-metal supply chain.

Nuton operates as both a technology provider, licensing tailored solutions, and an investment partner, backing projects with flexible commercial models that enable growth and shared value. Across all deployments, Nuton is committed to producing copper with the lightest environmental footprint and pursuing a Positive Impact ambition: to give back more than it takes across five pillars—energy, water, land, materials, and society.

Bioleaching isn’t new. How Nuton does it, is.

Media Contact: Jesse Riseborough (jesse.riseborough@riotinto.com)

Contact Nuton: nuton@riotinto.com

Links:

Website: www.nuton.tech