Flyability, a Swiss developer of collision-tolerant drones and inspection software for confined and hazardous environments, won the Innovation (Mapping) and Safety (Infrastructure Monitoring) awards in the 2025 Mining Technology Excellence Awards for its Elios 3 solution.

The system enables high-fidelity underground mapping and comprehensive condition monitoring while reducing worker exposure. In deployments during 2025 with major mining operators, it demonstrated that complete, actionable datasets can be captured more quickly and without sending personnel into confined or unstable areas.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Accelerated, high-resolution underground mapping

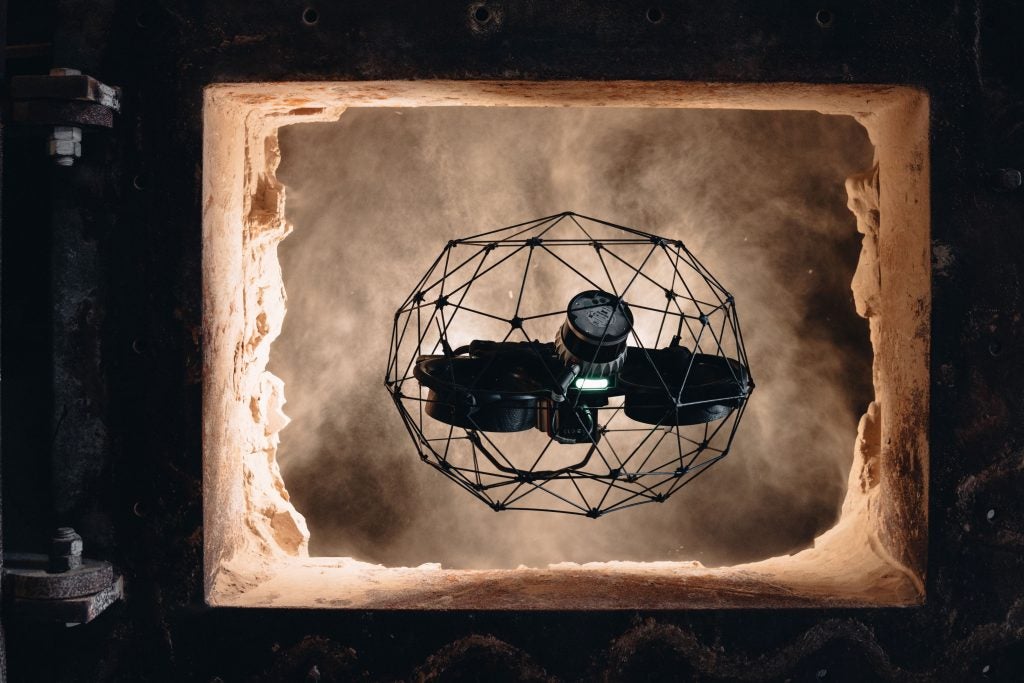

The Elios 3 advances underground mapping by merging Simultaneous Localization and Mapping (SLAM)-based LiDAR with a high-resolution visual payload to produce centimeter-level 3D maps in a single flight. In practice, that means survey teams can capture metric and visual datasets together rather than coordinating separate LiDAR scans and camera passes, reducing handoffs and alignment work. Access is another differentiator: the collision-tolerant airframe can fly into openings as small as 50 x 50 cm, reaching stopes, raises, and voids that are beyond the safe limits of human entry or larger drones. The Elios 3 easily navigates in GPS-denied environments typical of underground headings, aided by its design to withstand incidental contact without compromising data capture.

The technical specifications underpin consistent, repeatable results. The system records dense point clouds—up to 1,310,720 points per second—with approximately ±6 mm precision and SLAM drift near 0.1%, and synchronizes LiDAR with 4K visuals, thermal data, and 16,000-lumen lighting to illuminate complex geometries and reduce data gaps. This helps avoid common pitfalls such as point cloud shadows and incomplete coverage around backs, pillars, or equipment. As a result, the outputs are better suited for downstream tasks such as change detection, volume calculations, and georeferencing.

The efficiency gains continue well after the aircraft lands. Automated post-processing—data alignment, automated GCP detection, and point cloud filtering—compresses the turnaround time from collection to deliverables. The ability to export in standard formats (LAZ, LAS, PLY, TXT, E57) enables straightforward integration with established industry tools such as FARO and Maptek, limiting disruptions to existing workflows. In 2025 deployments, operators reported that complete surveys could be captured in minutes rather than hours, with fewer site interruptions and less need for repeat scans. Successful projects with the Elios 3 have seen inspection times reduced by as much as 60%. Feedback from mining teams emphasized that combining LiDAR and visuals in a single mission was especially valuable for correlating structural features with visual context, supporting faster approvals for rehabilitation or production planning.

Remote infrastructure monitoring that reduces exposure

For infrastructure monitoring in mines, the Elios 3 enables remote inspection of confined, unstable, or inaccessible areas so crews can assess conditions without entering hazardous zones. This applies to tasks such as examining voids behind barricades, inspecting ground support in narrow or compromised access drifts, and reviewing conditions around drawpoints and ore passes. The collision-tolerant cage and robust navigation in GPS-denied environments lower the likelihood of mid-mission intervention, which can introduce risk and delay.

Comprehensive data underpins faster, more reliable safety decisions. The platform delivers full coverage, high-resolution datasets that help eliminate blind spots and point cloud shadows—limitations that often occur with tripod-based tools or line-of-sight cameras. Paired LiDAR and visual outputs allow teams to scrutinize structural elements with both metric accuracy and visual context, aiding assessments of rock mass behavior, identification of changes over time, and prioritization of remedial work. The strong onboard lighting is customized to improve visibility in dusty, low-light headings, and thermal data provides additional context where temperature differences can inform condition checks.

The workflow is designed for timely collaboration. Teams can review live feeds remotely, capture what they need on the first pass, and share inspection results easily for cross-functional input from safety, geotechnical, and operations stakeholders. This reduces the number of people required on site and shortens the window between detection and response. Reports from 2025 field use indicate the Elios 3 was employed as an alternative to manual inspections in risky areas, allowing organizations to evaluate structural conditions and plan interventions without dispatching personnel into potentially unstable environments. The net result is fewer exposure hours, more reliable coverage, and clearer evidence to support safety decisions.

“This award is a profound validation of our founding mission: to keep human inspectors out of dangerous spaces. Mining has been our fastest growing segment in the past years and the Elios 3 drone & software solution is empowering a growing number of mine operators across the globe to safely scan and access complex environments. We are committed to continuing our work as pioneers, driving the future of digitized inspection to make mines globally safer and more efficient.”

– Patrick Thévoz, Flyability Co-Founder and CEO

Company Profile

Flyability is a Swiss company building cutting-edge solutions for gathering data in complex, confined spaces. Flyability designs drones and inspection software to deploy inside buildings, assets, and complex environments, reducing human exposure to risk by remotely collecting data in hard-to-reach areas. Through this, Flyability empowers safe, remote data collection and streamlined analysis of dangerous assets and environments, bringing cutting-edge robotics to industrial inspections.

Company Overview

- Flyability started as a spin-off from the Ecole Polytechnique Federale de Lausanne (EPFL) in 2014.

- As of 2025, Flyability has over 130 full-time employees. The headquarters are in Switzerland, with further offices in Denver and Shanghai alongside sales representatives in Australia, Japan, South Korea, Singapore, and the UAE.

- Flyability’s co-founders, Patrick Thévoz and Dr Adrien Briod work as the company’s respective CEO and CTO.

- Flyability has won multiple awards over the years, including the IMD Startup Competition (2014), the Nuclear Safety Innovation Award at the World Nuclear Expo (2023), and the Safety and Innovation Award from the Ship Technology Excellence Awards (2025).

- Flyability launched its flagship drone, the Elios 3, in 2022.

Product Overview

- The Elios drones are equipped with unique, patented technology designed by Flyability. This includes a collision-tolerant design, comprised of an exoskeleton cage and specialized firmware that can recognize and recover from collisions, enabling successful data collection in complex environments.

- The Elios drones are used across industries, including mining, wastewater, power generation, maritime, oil and gas, and more.

- The Elios 3 has a modular design, where payloads may be changed according to the needs of a mission. The drone has a standard visual inspection payload, comprising of a powerful camera, 16,000 lumen lighting rig, and thermal camera for visual inspections, delivering high-resolution videos and images. The Surveying payload, including an Ouster LiDAR scanner, was developed in partnership with FARO to deliver centimeter-accurate point clouds. The RAD payload, developed in partnership with Mirion, empowers the identification, location, and monitoring of radiological dose fields. The ultrasonic thickness payload was designed in partnership with Cygnus Instruments, and is used to measure steel thickness in confined spaces, including ship hulls. Finally, the explosive gas sensor, which can recognize over 14 different explosive gases, was created in collaboration with NevadaNano to add a layer of safety for Elios 3 pilots operating in flammable environments.

- Flyability’s hardware offering is accompanied by custom software for viewing and analyzing the results from the drones, either on desktop via Inspector or online via Flyability Cloud. There are also rigorous training courses to certify pilots available for purchase and a dedicated support team to empower Elios drone users worldwide.

To contact Flyability, either e-mail to media@flyability.com or visit their dedicated contact page.

Links

Website: http://www.flyability.com/