DEScycle, a developer of deep eutectic solvent (DES)-based metal recycling technology, has won the Research and Development (Hydrometallurgical Innovation) and Environmental (Circular Decarbonization) awards in the 2025 Mining Technology Excellence Awards.

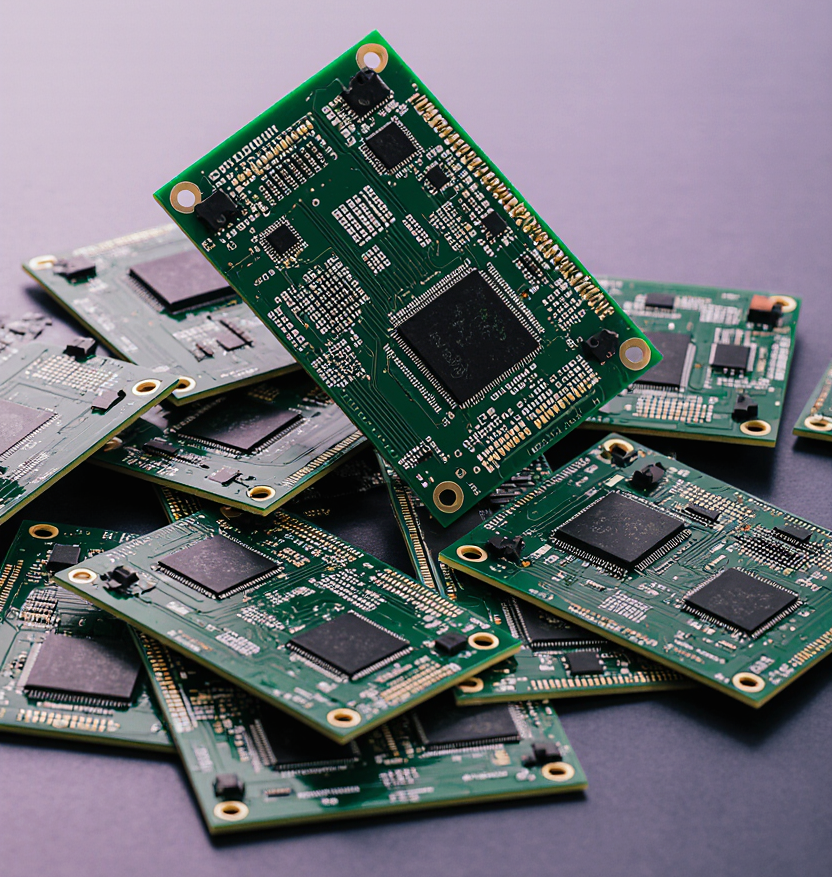

The company has advanced DES chemistry from academic research to pilot-scale application, demonstrating rapid, selective recovery of high-value metals from e-waste and other feedstocks at low temperatures and ambient pressure. Its modular, capital-light design enables local deployment co-located with upstream recyclers.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

“This award recognizes how DEScycle is redefining what’s possible in metal recovery. Our mission is to make circular, low-carbon metals a strategic part of every nation’s supply chain, not just an environmental ambition. We’re proud to be leading that shift from innovation to industrial impact.”

– Dr Leo Howden, CEO

DEScycle’s contribution lies in converting deep eutectic solvent chemistry from a promising academic concept into a robust, engineered process that holds up under continuous operation. The company has designed a full flowsheet that integrates selective dissolution at low temperatures with solvent regeneration and closed-loop recycling. During a 10-week continuous pilot, the system consistently achieved over 99% recovery of high-value metals—copper, gold, silver, and palladium—within minutes and at 50-80°C temperatures. Subsequent development cycles have reduced leach times from six hours to approximately 15 minutes while maintaining exceptional yields, illustrating disciplined optimization rather than one-off lab results.

Industrialization required solving materials-of-construction questions and demonstrating reliable kinetics and solvent recovery—areas where DES had not previously been proven outside academia. DEScycle addressed these gaps to reach TRL6, secured patent protection over the recovery process, and mapped a scale-up route supported by £11m in Series A funding and a €5m EU Horizon grant. The design is modular and capital-light, built for deployment alongside upstream recyclers rather than in centralized, billion-dollar facilities. This enables processing near the point of collection and avoids dependence on smelter blending with mined copper—an entrenched constraint in e-scrap pathways.

Adaptability is another distinguishing factor. The same DES platform has been validated on multiple feedstocks beyond printed circuit boards and server boards, including lithium-ion battery black mass, rare earth magnets, photovoltaic panels, and complex primary ores and concentrates such as copper sulfides and oxides, nickel sulfides and laterites, and rare earth concentrates. Positioning DES as an ionometallurgical route allows for selective tuning of solvent systems to different metals, opening avenues across critical raw materials. Strategic relationships with Cisco and Mitsubishi reinforce the industrial relevance of this approach, while the first demonstration plant in Teesside, UK—targeted for commissioning in Q2 2026—marks the next step to TRL7 and commercial readiness.

“DEScycle’s technology replaces smelting with clean chemistry, achieving over 99% metal recovery with a fraction of the energy and emissions. Recognition from Mining Technology underscores the global relevance of scalable, low-impact solutions that can truly transform the way the world processes metals.”

– Dr Rob Harris, CTO

Circular decarbonization: Low-energy, closed-loop processing with no toxic effluents

The Environmental award for DEScycle recognizes measured reductions in energy use and emissions, coupled with the elimination of hazardous outputs typical of high-temperature routes. By operating at low temperatures and ambient pressure, the process can reduce CO2 emissions by up to 90% versus smelting. It also avoids airborne particulates—a significant health and environmental concern in pyrometallurgy—and eliminates hazardous liquid waste streams. Solvents are recycled in situ, and process water is recovered and reused, reinforcing the closed-loop nature of the system.

The process is designed to valorize all outputs. High-purity recovered metals are sold into the market; plastics and glass are directed to appropriate recyclers; salts can be repurposed, for example as road salt; and lower-value metals are placed with a strategic partner for marketing. This supports a zero-waste target and reduces landfill reliance. By co-locating modular units with collection and pre-processing facilities, DEScycle’s model can cut transport emissions and shrink the environmental footprint relative to centralized smelting hubs. The compact footprint also helps with permitting and community acceptance compared with large-scale plants.

Regulatory alignment has been considered from the outset. The process avoids hazardous acids and cyanide, removes high-temperature steps, and is compatible with REACH and RoHS requirements, with Environment Agency permitting underway. This reduces the need for costly neutralization systems and mitigates risks of toxic gas release. Beyond facility-level metrics, the model supports national objectives to build secure, low-carbon supply chains for critical materials by reshoring recycling capacity. The planned first plant in North East England is expected to create local jobs and serve as a replicable blueprint for expansion to the US and Japan, according to the company’s roadmap, offering a path to scale that matches policy drivers in the UK and EU for circular economy and critical raw materials.

“We see growing momentum from investors and industry alike who recognize that circular metal recovery isn’t optional, it’s inevitable. Its not just our technology that’s a DEScycle USP, with investments from Cisco and Mitsubishi, we are the only company with major strategic backing in our peer group. DEScycle’s modular, capital-light approach delivers both sustainability and commercial value, and we’re excited to scale this technology with strategic partners worldwide.”

– Fred White, CCO

Company Profile

DEScycle transforms e-waste into a geo-secure, low-carbon supply of critical metals—without smelters, billion-dollar capex, or high energy demand. The company addresses a broken $100bn market where 80% of metals are currently lost, enabling nations and industries to reshore critical metals production, build resilient supply chains, and cut carbon and toxic emissions.

The company has developed a smelter-replacement technology to disrupt the $100bn WEEE market, recycling multiple metals including copper, gold, silver, and tin from a variety of feedstocks, including data center hardware. Its capital-light technology integrates into the upstream recycling market to create local circular metal supply, reducing reliance on global supply chains and offering a secure in-country recycling service. DEScycle’s route-to-market is secured through a JV with UK e-waste recycler GAP Group, and it is backed by strategic investments from Cisco, Mitsubishi Corporation, and global leaders in the metals industry.

DEScycle recently closed an £11m Series A to advance its smelter-replacement WEEE recycling technology from the lab (TRL 6) to a demo plant (TRL 7). The demo plant is located in Wilton, Teesside, and is targeted to be operational in Q2 2026. Following this, the company plans to build its first commercial facility, with UK site selection and engineering commencing in 2026.

DEScycle aims to become the world’s cleanest and most scalable metals processor and to expand its offering beyond WEEE, intending to launch in the UK before expanding globally.

Links

Website: https://www.descycle.com/