Alia Instruments has been named winner of the Innovation Award for Performance Analysis and the Safety Award for Non-Nuclear Technology in the 2025 Mining Technology Excellence Awards.

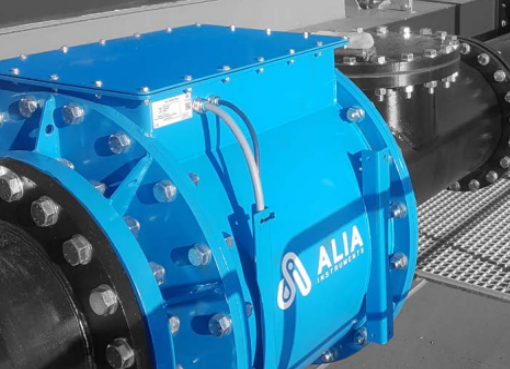

The company won this recognition for an in-line, non-nuclear slurry density meter developed in partnership with Demcon Advanced Mechatronics and the University of Twente. The instrument was engineered using finite element method (FEM) and COMSOL Multiphysics and is manufactured under ISO 9001:2015, with factory wet calibration against ISO 17025/17034-referenced standards. In short, it brings first‑principles physics into a rugged, full-bore device designed for mining applications such as thickener underflow, mineral concentrates, tailings, and other hydro-transport applications.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Performance analysis: Real-time, full-bore slurry density measurement

At the heart of Alia’s innovation is a fundamentally new, but straightforward idea based on Newton’s second law. The meter applies controlled forces at certain frequencies to the slurry and measures the resulting acceleration with high-speed accelerometers. From that response, it calculates mass, and with the known volume of the pipe, it determines density. The excitation and sensing are not in contact with the fluid, and act across the full pipe cross-section to measure bulk density, not just what is happening at the wall. For operators, that means the meter provides dependable data in both homogeneous and heterogeneous slurry flows, and is highly independent of slurry composition, type and size of solids, density, conductivity, and radioactivity.

With a 1‑second response time, the device is built for real-time control. The configurable averaging and a standard 4–20 mA signal proportional to density, make integration into plant control systems simple. Accuracy is specified at 0.5% over a 0–4 kg/L range, giving process teams the precision needed to optimize process circuits and control variability. Installation is practical: the meter bolts directly into pipelines from 3 to 40 inches and works in vertical, horizontal, or sloped pipe runs.

Design choices also reduce ownership effort. The only wetted part is a specially compounded and wire-reinforced liner, which can be made of natural rubber, Neoprene, butyl rubber, and other materials, selected for compatibility with abrasive and/or corrosive slurries. The liner can be inspected or exchanged in the field if required with simple tools, while the instrument itself is maintenance-free during operation. Commissioning is straightforward: once the unit is installed and connected, a single-point check with clean water confirms the factory wet calibration, and compensates for pipe orientation and offset. Fast and simple commissioning, minimal maintenance, and no need for periodic recalibration lower long-term costs and reduce the workload for site teams.

This combination of first‑principles measurement, immediate response, and very broad slurry applicability underpins the recognition for performance analysis.

Non-nuclear technology: Eliminating radioisotope use in density measurement

Use of non-nuclear technology means the instrument uses no radioactive sources. Removing radioisotopes from density measurement also removes the need for all associated activities such as licensing, source handling and storage, training, monitoring and related administration, eliminating exposure to the risks and compliance tied to radiation-based equipment.

Remote digital access adds another layer of safety. After installation, users can enable remote access for diagnostics. This allows checks and troubleshooting without immediately sending personnel to the meter location, which is helpful where access is restricted or local conditions are challenging.

“We are delighted to hear that Alia Instruments has won the Mining Technology Excellence Awards in both the Innovation and Safety categories. With the implementation of Newton’s simple and proven 2nd law in a robust industrial design, Alia’s non-nuclear slurry density meter brings solid customer benefits in the important areas of measurement performance, reliability, maintenance and ease of use in slurry applications.”

– Jan Peters, CEO

Company Profile

Alia Instruments was founded in 2017 in The Netherlands with the clear goal of providing users with a robust, non-nuclear slurry density meter based on a straightforward measurement principle, and built from standard industrial components. The development originated due to a need to optimize productivity in dredging and mining operations.

Today, development continues in partnership with the renowned Dutch engineering and high-tech company Demcon Advanced Mechatronics, as well as the University of Twente. Demcon is now a major shareholder of Alia Instruments, with Alia Instruments well embedded in the Demcon infrastructure.

Recent developments have enabled enhanced suitability for applications in multiple industries. The density meters are manufactured in the Netherlands under ISO 9001-2015 certification.

Jan Peters, CEO

Links

Website: https://aliainstruments.com