Livengood gold mine, owned by International Tower Hill Mines (ITH), is located in Alaska. Credit: ITH mines.

Livengood gold deposit is situated near to money knob, a local topographic high point. Credit: ITH mines.

Endeavour has proposed a merger with Centamin worth £1.5bn. Credit: Roman Bodnarchuk.

Livengood gold project is located 113km from Fairbanks, Alaska, US. International Tower Hill Mines (ITH) is the project developer.

The pre-feasibility study (PFS) for the project was completed in October 2016, while construction is expected to take 27 months to complete. The project is expected to produce approximately 294,100oz of gold a year throughout its estimated 23-year mine life.

Livengood is expected to require a pre-production capital investment of £1.5bn ($1.84bn) and is anticipated to create 350 production jobs, once fully operational.

Livengood gold project location, geology, and mineralisation

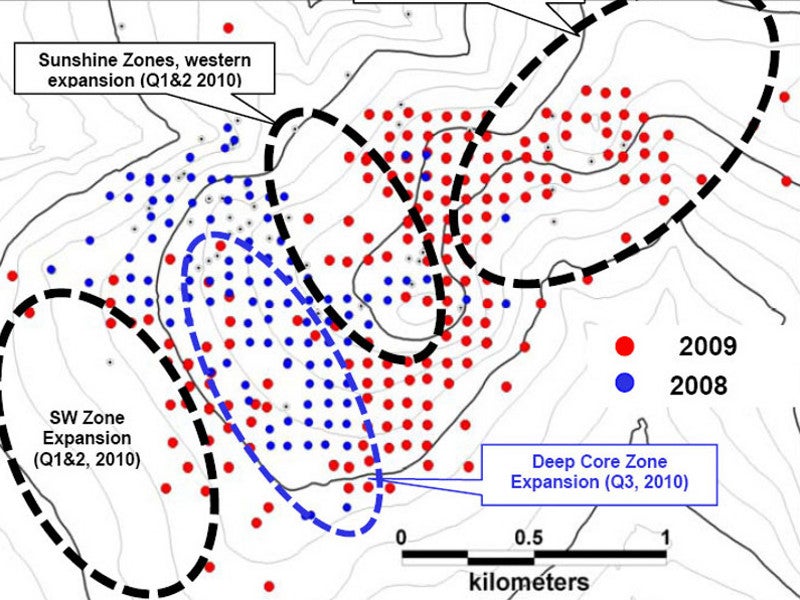

The Livengood gold project is located to the north-west of Fairbanks, Alaska, in the Tolovana Mining District and is a part of the Tintina gold belt. The project covers approximately 19,500ha of land.

The deposit is contained within a thrust-interleaved sequence of Proterozoic to Palaeozoic sedimentary and volcanic rocks.

“The mineralisation is believed to be a 90-million-year-old (Fort Knox age) dyke swarm, which passes through the thrust stack.”

The rocks at the site are a part of the Livengood Terrain, an east-west belt, approximately 240km long and consisting of tectonically interleaved assemblages of various ages.

Most of the mineralisation is associated with disseminated arsenopyrite and pyrite in volcanic, sedimentary and intrusive rocks, and in quartz veins.

The project hosts three stages of mineral alterations, characterised by biotite, albite, and sericite.

Livengood gold project reserves

The Livengood gold project is estimated to hold 391.7 million tonnes (Mt) of proven and probable reserves, graded at 0.71g/t Au. It is expected to contain 8.973 million ounces (Moz) of gold.

Mining at Livengood gold project

The Livengood gold mine will employ conventional open-pit mining methods, involving a drill-blast-load-haul operation. The creation of a mill feed of 52,600tpd, which will be crushed and processed by a gravity-whole ore carbon-in-leach (CIL) plant, has been proposed.

Low-grade mineralised material will be stockpiled and a portion of it will be used to supplement the direct mine production and maintain constant mill throughput. Production mining is expected to recover 60.6Mt of ore a year for 16 years.

Ore processing at Livengood gold project

At the processing plant, ore will be initially crushed in a primary crusher followed by coarse ore stockpiling. The stockpiled material will be pre-crushed and ground in a semi-autogenous grinding mill (SAG) and two ball mill circuits before being conveyed to a gravity concentration circuit.

A pulp feed will be blended from the cyclone feed and treated with eight centrifugal gravity gold separators. The gravity gold will be directly smelted from the gravity concentrate and the resultant tailings directed to the CIL circuit.

Gold will be retrieved from the loaded carbon in an adsorption-desorption-recovery (ADR) circuit. It will be forwarded to the electro-winning to produce doré.

The processed tailings will be thickened, treated to detoxify cyanide, and forwarded to the tailings management facility (TMF).

Infrastructure facilities

The Livengood gold project site is situated on both sides of the paved Highway 2, which links North Slope oil fields to Fairbanks. The site is located 80km north of grid power and along the Trans-Alaska Pipeline route and 112km north-west via all-season highway.

The power supply for the project will be sourced from the local grid through a new 80km, 230kV transmission line along the pipeline corridor.

Workers will be accommodated at the temporary, 1,050-person construction camp developed for the project.

Contractors involved

ITH engaged BBA for preparing the technical report of the Livengood gold project. BBA was supported by New Fields Mining Design & Technical Services, SRK Consulting, Metal Mining Consultants, and Wildcat and Badger in preparing the pre-feasibility study report.