Here, we explore how integrating PACS into the current NDT framework brings significant advantages, impacting various facets of NDT practices.

Integration With Existing NDT Infrastructure

The successful integration of PACS within the existing NDT framework requires a thoughtful approach that considers the specific needs and processes of the industry. NDT encompasses various techniques such as radiography, ultrasonic testing, visual testing, etc. These techniques generate test data that needs to be efficiently managed to ensure seamless workflows.

The seamless workflow is made possible through the integration of various interfaces and gateways, enhancing the efficiency, accuracy, and collaboration within the NDT process. Key components contributing to the streamlined workflow in PACS implementation include:

- Interfaces to ERP, QA, RBI, and other IT Systems: PACS interfaces with various enterprise systems such as Enterprise Resource Planning (ERP), Quality Assurance (QA), and Risk Based Inspection (RBI). This integration facilitates seamless data exchange and information sharing between different departments and phases of the NDT process. For example, when a new inspection order is initiated in the ERP system, the relevant data can be automatically transferred to the PACS to ensure that the inspection order data is assigned to the correct component. Data collected during NDT can also be seamlessly transferred back to these systems for analysis, reporting, and decision-making. This integration minimizes data duplication, reduces manual data entry errors, and speeds up the decision-making process.

- DICONDE Interfaces to Compliant Test Devices and Systems: DICONDE is an international IT standard for managing NDT data. PACS with DICONDE interfaces allows for compatibility with a wide range of compliant test devices and systems, ensuring that data from various NDT methods can be easily integrated into a unified platform. This interoperability enhances collaboration and data sharing among different NDT teams. Technicians and analysts can access, review, and compare images from various testing modalities without the need for specialized software for each device, thereby streamlining the interpretation and analysis process.

- Import Gateways to Transfer Data: PACS systems incorporate import gateways that facilitate the secure transfer of data from various sources to the centralized repository. Field inspectors can directly upload images, signals, videos, and associated metadata to the PACS, eliminating the need to transport physical media or manually transfer files. This real-time data transfer not only saves time but also reduces the risk of data loss or misplacement during data transfer, expedites the review process, allowing analysts and experts to assess the results remotely, make faster decisions, and provide immediate feedback to field personnel if required.

Benefits of Implementing PACS

The adoption of PACS in the NDT industry brings about a range of benefits that significantly enhance efficiency, accuracy, and decision-making. These benefits include, but are not limited to:

- Streamlined Workflow: One of the primary advantages of using PACS in NDT is the streamlined workflow it enables. PACS facilitates the efficient acquisition, evaluation, storage, and retrieval of inspection data, leading to improved productivity and reduced downtime.

- Enhanced Data Accessibility and Collaboration: PACS systems facilitate centralized data storage, allowing authorized personnel to access inspection data from anywhere and at any time. This accessibility is particularly beneficial for industries with multiple locations or remote teams. Authorized users, including inspectors, engineers, and managers, can review and analyze NDT results, fostering collaboration and enabling faster response to critical issues.

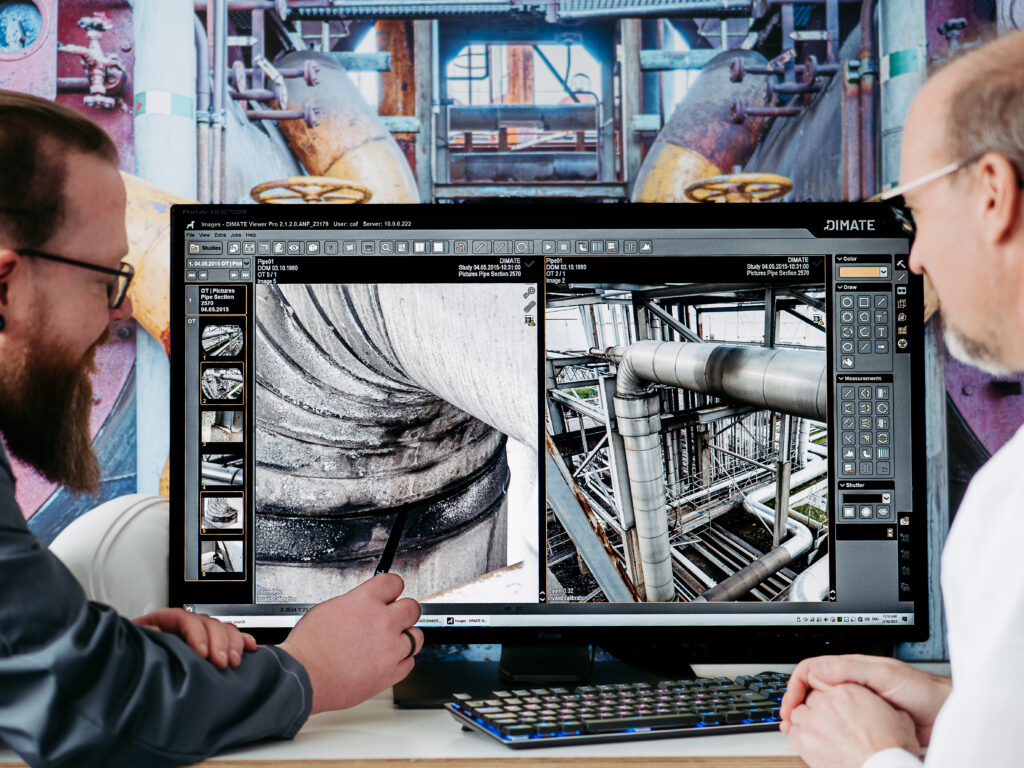

- Efficient Data Analysis and Reporting: PACS systems often come with advanced image analysis tools that enable inspectors to enhance, annotate, and measure images for accurate defect detection and characterization. These tools can significantly expedite the analysis process, leading to quicker identification of defects and informed decision-making. Additionally, PACS simplifies the generation of comprehensive inspection reports, which can be customized based on specific industry standards and requirements.

- Long-Term Data Retention and Compliance: Maintaining historical inspection data for compliance, quality control, and regulatory purposes is crucial. PACS offers robust data retention capabilities, ensuring that inspection records are securely stored and easily retrievable for audits, compliance checks, and investigations.

Time and Cost Savings: Implementing PACS in NDT results in substantial time and cost savings. The streamlined workflow, efficient data transfer, and centralized data accessibility reduce manual intervention, data handling errors, and administrative overhead. Inspectors can conduct inspections more efficiently, analyze data more quickly, and generate accurate reports with fewer resources. This leads to decreased operational costs, increased productivity, and optimized resource allocation.

Request a free demo with our experts at buddy@dimate.de. or visit www.dimate.de/en/ for more information.

Share This:

Next Article

.jpg)