The world of industrial plant operations is unforgiving, where every moment of downtime can cost millions. Plant operators need solutions that can guarantee maximum uptime without compromising on safety. LESER’s Change-Over Safety Valves rise to the challenge by offering unmatched reliability and operational efficiency.

Safety valves are the backbone of any industrial plant, ensuring that systems are protected against impermissible pressure. There are two primary types of safety valves: spring-loaded and pilot-operated. Then there are change-over valves, which switch the flow of media between two different safety valves, ensuring continuous system availability.

Understanding Change-Over Valves

Change-over valves, like the ones offered by LESER, are used to connect two safety valves with a pipe connection to a pressure system. One safety valve is operational while the other is on standby. The standby safety valve can be disassembled and serviced without interrupting the system’s operation, thanks to the design’s forced control. This ensures continuous protection against impermissible pressure, allowing for planned shutdown periods independent of the safety valves’ maintenance cycles.

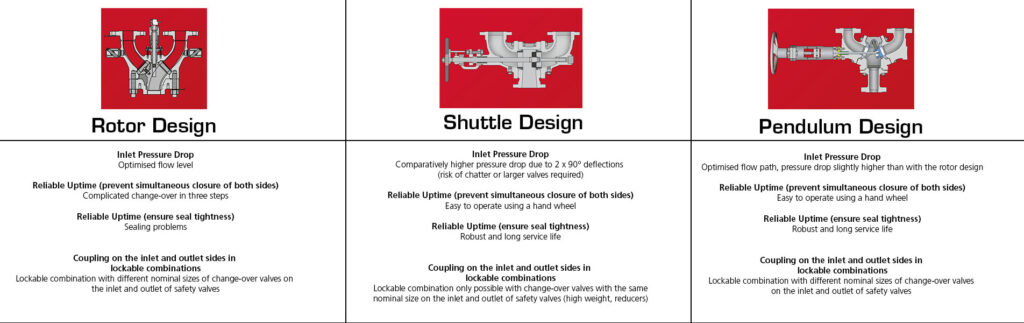

LESER offers different designs of change-over valves, each with unique functionalities.

- Rotor Design: In this design, a rotating actuator blocks one flow path and unblocks the other. Selected based on the same nominal size as the safety valve’s inlet and/or outlet, these valves have an optimized flow path and low pressure drop. However, the switching process is relatively complex and uncertainties can arise when calculating the pressure drop.

- Shuttle Design: Change-over valves with shuttle design have 2 x 90° deflections, resulting in a higher pressure drop. These valves must be at least one nominal size larger than the safety valve’s nominal inlet size, especially for high-capacity safety valves or long inlet piping. Although this design also presents uncertainties when calculating the pressure drop, it ensures the stable functioning of the safety valve.

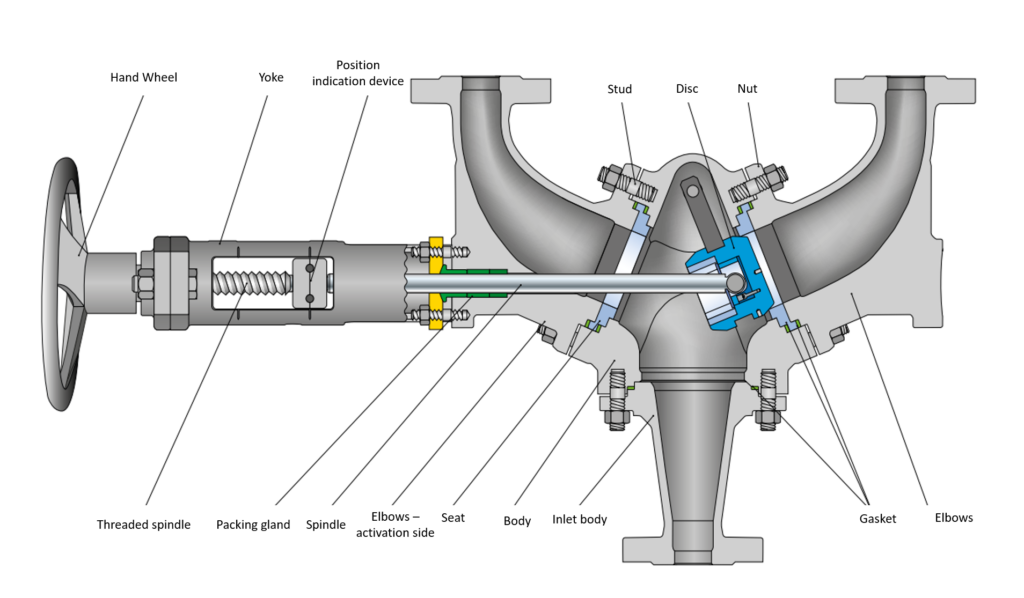

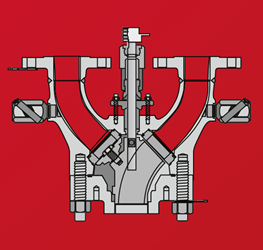

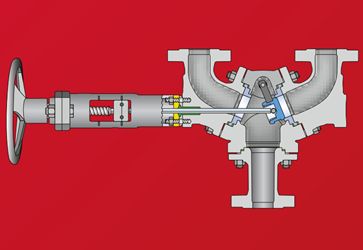

- Pendulum Design: With a unique design that allows the active safety valve to be reliably switched during maintenance, the pendulum design offers a minimal pressure drop and precise calculation of the inlet pressure drop, thanks to clearly defined flow resistance coefficients in each configuration. LESER’s pendulum design change-over valves are built for maintenance-free longevity and 24/7 uptime, and have undergone lifecycle tests with 1,000 changeovers under various conditions.

Change-over Valve Types in Comparison

Westech Industrial and LESER: A Partnership for Efficiency and Safety

At Westech Industrial, we’re proud to be a leading distributor of LESER valves. We understand that the right products and support can turn operational challenges into competitive advantages, and LESER’s Change-Over Safety Valves are a shining example of this philosophy.

Discover the LESER’s Change-Over Safety Valves and learn how they can improve your plant’s operational efficiency and continuity.

To learn more about LESER’s Change-Over Safety Valves, visit our website at https://bit.ly/45ceyl6 Our technical representatives are also available at 1-800-912-9262 to answer any queries you may have about our products and services.

LESER’s Change-Over Safety Valves – Don’t let unplanned shutdowns disrupt your operations. Transform your approach to safety valve maintenance and ensure your industrial processes run smoothly, safely, and efficiently.

Share This: