AMCAP is on a mission to revolutionise its parts services to the mining industry, expanding its heavy mobile equipment portfolio.

While many would be familiar with AMCAP thanks to its comprehensive maintenance kits, the company is always looking to take its offerings a step further.

So when the opportunity arose to add heavy mobile equipment (HME) service exchange components to AMCAP’s portfolio, the company seized it without hesitation.

“We ventured into the parts and components category about three years ago and never looked back,” AMCAP general manager Kevin Yap told Australian Mining.

“We were already supplying a lot of individual components that were utilised to fit these larger assets, so it made sense to expand that into its own category. Now, we supply large components for haul trucks, dozers, graders, wheel loaders and any other machinery that a mine uses for its operations.”

AMCAP’s HME parts and components work hand-in-hand with its maintenance service kits, providing customers with a superior level of reliability by having the replacement parts and components available when required.

They also provide logistical cost savings through handling and transport of a single material line item, as well as the accuracy of having all parts consolidated within the kit. The kits are packaged appropriately in bespoke cabinets and containers, ensuring they are securely delivered on-site.

“Large component changeouts like engine replacements require long-term planning because they can cause a considerable amount of downtime,” Yap said.

“Most companies will give us a schedule to work with to ensure minimal downtime for assets that need component replacement, and we’ll make sure they get the required parts on that date maintaining as close to 100 per cent delivery in full.”

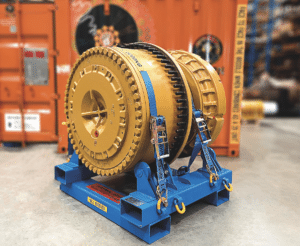

AMCAP’s services operate under three key pillars: minimising downtime, maximising efficiency, and maximising safety and sustainability. AMCAP offers a service exchange program to exchange old components for a remanufactured component that is both cost effective and efficient.

Image: AMCAP

All of the company’s service exchange components are rebuilt to a premium scope of works and backed by comprehensive extended warranty, so customers can be assured their components will perform to original equipment manufacturer (OEM) specifications.

“We plan our inventory six months in advance, so if we’re due to provide a maintenance service kit to a customer in April and they bring forward the shut to February, we will have it ready to go,” Yap said.

“In addition to the efficiency gains our customers experience by working with us, we also take safety and sustainability incredibly seriously.”

In 2021, AMCAP was awarded ‘Best solution to a work health and safety risk’ at the Work Health and Safety Excellence Awards hosted by the Western Australian Government. This was followed by the AIM WA Pinnacle Award in the RAC Environmental Sustainability Excellence category in 2024.

“We’re committed to supplying our kits in a sustainable manner, including reducing waste by cutting down on packaging,” Yap said.

“We have also partnered with key charities including Aboriginal crisis line 13YARN, Lifeline WA and the National Breast Cancer Foundation, creating awareness of their messaging by printing it on our kits that travel around WA.”

The company has supplied service kits to major iron ore miners since 2018, supplying around 4000 kits per month.

Its partnerships with mining companies have enabled AMCAP to further research and develop its kitting services, providing an opportunity to implement different parts from both OEM and non-OEM products to optimise the cost of the finished product.

“Since we were already supplying many of the individual parts needed to fit larger components, it was natural to expand kitting these parts into a fitting kit for major components, e.g. complete corners, nose cones and total plug and play option,” Yap said.

“Whatever we can do to innovate our offerings is worthwhile investing in.”

AMCAP assembles its kits and components out of its modern, purpose-built storage and distribution facility in Welshpool, WA – but this doesn’t restrict them to only WA customers.

“We have the capability and capacity to supply nationally,” Yap said. “The maintenance service kits and components category is a fairly new and innovative market for us, and we’re excited to take that around the country.”

This feature appeared in the March 2025 issue of Australian Mining.

.jpg)