A collaboration between Jenike & Johanson and Crescend Technologies promises a major breakthrough in the ore treatment process.

Companies don’t operate for six decades without doing something right. For almost 60 years, Jenike & Johanson has been a global leader in bulk material handling.

The company has established such a strong legacy by constantly seeking to innovate its technology and better support its clients with products and services that understand the demands of the modern mining industry.

That spirit of innovation, collaboration and support is borne out by its recent strategic partnership with Crescend Technologies, a leader in solid-state microwave power systems, to accelerate the development and commercialisation of the innovative Selective Heat Ore Treatment (S.H.O.T.) process.

The collaboration unites two top-flight technologies: Jenike & Johanson’s expertise in advanced material handling design and process engineering, and Crescend’s precision solid-state microwave systems.

Together, these capabilities deliver a scalable, energy-efficient solution for microwave-assisted comminution, offering the mining industry a new approach to ore treatment.

“We’d been exploring microwave treatment of ores for quite some time,” Jenike & Johanson chief executive officer Herman Purutyan told Australian Mining.

“We came across Crescend, who have fantastic expertise in microwave generation and control. A big part of the challenge is being able to deliver that microwave energy to the ore in a controlled and safe way, and Crescend has great technology to do exactly that.”

Purutyan said the partnership represents a significant advance for sustainable ore processing technologies.

“When we met them, it was clear this would be a great partnership,” he said. “Our strength is in handling the material uniformly and reliably as it passes through the microwaves, while Crescend’s strength is in generating and applying those microwaves effectively.

“It’s a perfect match to move this technology forward.”

How S.H.O.T. works

S.H.O.T. applies solid-state microwave energy to ore before mechanical breakage. By selectively heating minerals within the rock matrix, the process weakens grain boundaries, causing fractures that make the ore significantly easier to crush and grind. This not only reduces the energy required for comminution but also improves mineral liberation and enhances downstream recovery.

Unlike magnetron-based microwave generators, solid-state microwave systems allow precise frequency tuning, energy control and integration flexibility. This is designed to ensure that microwave energy is delivered exactly where and how it is needed in S.H.O.T.’s selective heating methodology.

Purutyan said the technology works best with certain ores such as copper, gold, nickel and sulphides that are surrounded by hard rock, offering significant energy reduction and increased production rates.

“For the technology to be at its most effective, you need a particular type of mineral in the rock body, typically one surrounded by very hard rock,” Purutyan said. “The way it works is that the microwaves target certain parts of the ore that absorb energy, while the hard rock – being transparent to microwaves – doesn’t heat up. The heating parts expand, creating micro-cracks, and that’s where the benefits come from. For that to happen, the ore has to have a certain texture.”

Purutyan said the approach is especially valuable because harder rocks usually take much more energy to grind.

Tackling comminution

Among the most significant challenges facing mining operations is comminution, the crushing and grinding of ore to liberate valuable minerals.

According to Purutyan, this process is the single largest consumer of energy in most mining operations. As orebodies age and average grades decline, the energy intensity of comminution only increases, driving up costs and carbon emissions.

S.H.O.T. offers an alternative.

“This technology significantly reduces that energy requirement,” Purutyan said.

“In terms of energy reduction, we’re seeing potential cuts of 20 to 30 per cent in comminution energy for suitable ores. Considering how energy-intensive that process is, that’s a major saving.”

By introducing a non-mechanical, solid-state microwave targeted treatment step prior to grinding, S.H.O.T. significantly reduces the amount of brute force required to fracture ore. The process uses relatively low microwave energy inputs, typically in the range of 0.3–3 kilowatt-hours (kWh) per tonne yet delivers substantial weakening of the ore.

Differential heating at mineral grain boundaries creates micro-fractures, enabling equivalent liberation at coarser grind sizes and reducing the demand on downstream crushers and mills.

Step-change technology

Purutyan said delivering such a process at scale requires a commitment to stringent design methodologies alongside iterative testing that demonstrated real gains for mine operators.

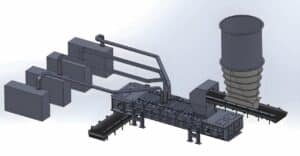

The S.H.O.T. process itself has been demonstrated successfully at a 150-tonne-per-hour pilot scale, showing strong potential to scale to commercial operations.

Alongside the primary gain of a significant reduction in comminution energy requirements, the S.H.O.T. technology provides a compelling set of advantages for mining and mineral processing operations.

These include an increased plant throughput for grinding and beneficiation circuits, equivalent liberation at coarser grind sizes, reducing grinding intensity, and improved leaching recovery, boosting metal yield from ore. By lowering the energy intensity of comminution, S.H.O.T. not only reduces costs but aligns with the mining industry’s commitments to decarbonisation and environmental stewardship.

Jenike & Johanson is currently looking to move S.H.O.T. from pilot testing into full commercial deployment. Mining companies seeking to increase throughput, cut operating costs, and unlock value from lower-grade or previously uneconomic ore bodies stand to benefit significantly from this new approach.

As the resources sector confronts the dual challenges of declining ore grades and rising sustainability expectations, S.H.O.T. represents a timely innovation.

By combining Jenike & Johanson’s expertise in bulk material handling with Crescend’s advanced solid-state microwave systems, the partnership is unlocking a pathway to smarter, greener and more profitable ore processing.

In a sector where incremental gains are celebrated, S.H.O.T. stands out as a step change technology with the potential to transform one of mining’s most energy-hungry processes into a model of efficiency and sustainability.

This feature appeared in the November issue of Australian Mining magazine. Get 50 per cent off your Australian Mining annual magazine subscription during our Black Friday sale. Visit our subscription page and use the code: AMBF25. Ends on 27 November 2025.