Ionic Rare Earths’ UK unit Ionic Technologies has formed alliances with Ford Technologies and Less Common Metals (LCM) to build a rare earth supply chain from recycled magnets in the UK.

The company will also partner with the British Geological Survey to complete a feasibility study and supply chain analysis for the establishment of a magnet recycling facility in the country.

These programmes have secured support from the UK Government through grant funding.

Ionic has developed rare earth element separation and refining technology and is using it to recycle spent permanent neodymium-iron-boron (NdFeB) magnets to create sustainable, traceable and sovereign rare-earth supply chains.

One of the programmes will support Ford. The automaker’s European Union (EU) production will come from its Halewood facility in the UK, where it plans to produce nearly half a million units annually by 2026.

More than 600tpa of magnet raw material is required to support the facility’s production.

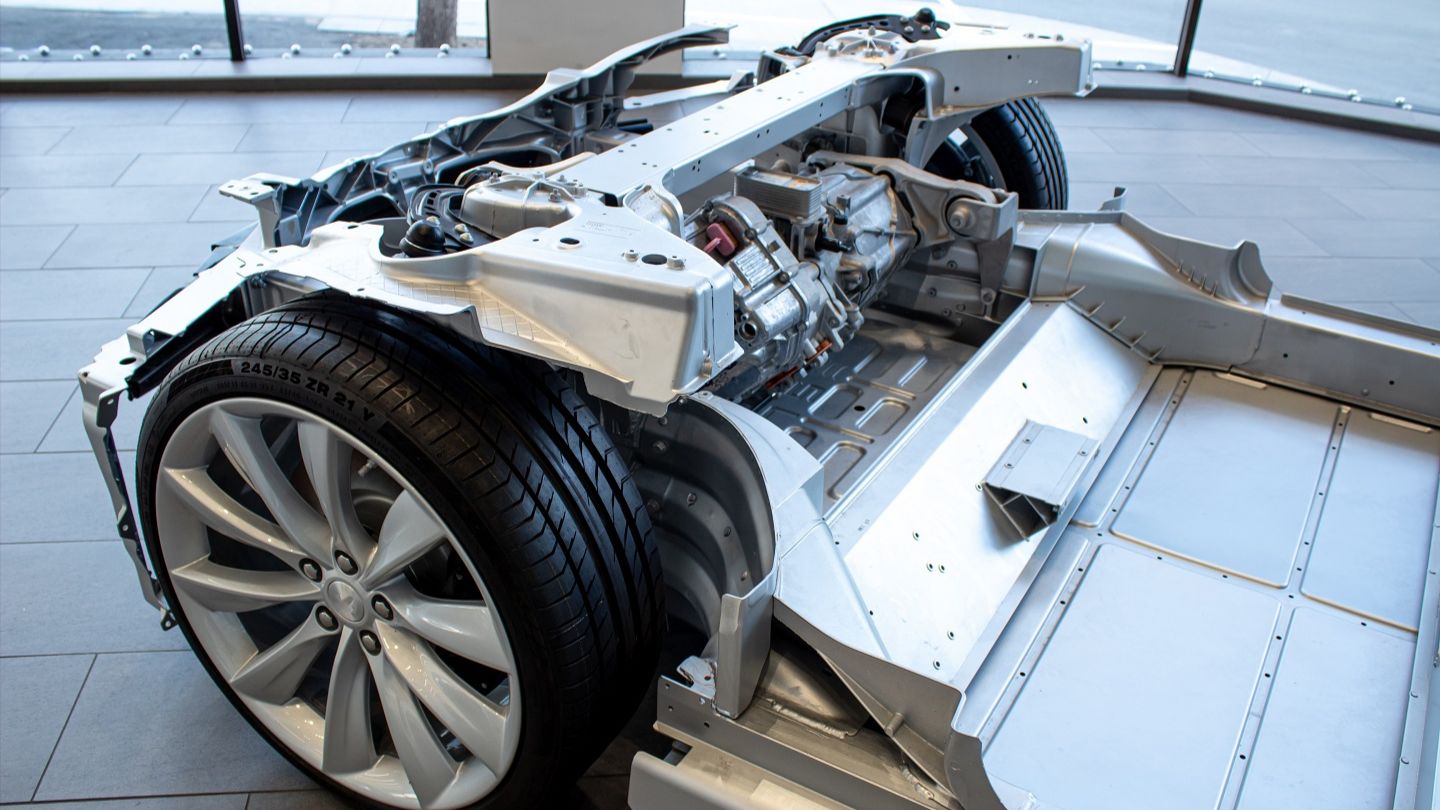

Ford will test and analyse the performance of magnets through the project and ascertain the efficacy of the magnets containing rare earth elements (REEs) of recycled by Ionic. The magnets consequently obtained will be used by Ford in its electric vehicle motors.

Ionic Rare Earth managing director Tim Harrison said: “We are harnessing our technology to accelerate mining, refining and recycling of magnet and heavy rare earths critical for energy transition, advanced manufacturing, and defence.

“CLIMATES funding that Ionic Technologies had been awarded by Innovate UK demonstrated IonicRE’s strategy to create a collaborative, western supply chain for rare earths with Ford Technologies and Less Common Metals in the UK and European Union.”

“The other CLIMATES grant would see Ionic Technologies develop the business case and potential scale-up of a commercial magnet recycling facility in Belfast, in partnership with the British Geological Survey.”

Ionic claims that the grant is based on its demonstrated technology at a demonstration plant in Belfast, where it has produced rare earth oxides (REOs) at a rate of 10tpa, with a purity of 99.5% or higher.

These REOs will be useful in producing high-specification magnets for EVs and other technologies that contribute towards UK’s net zero goals.