Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

The long-running seminar series for India’s utility professionals through the India Smart Grid Forum closed with hydrogen. The hype glitter is starting to tarnish, but there is still a lot of substance-less shiny noise around the molecule. To that end, I stepped through the challenges and why hydrogen is virtually always a more expensive choice than existing, commercialized alternatives for energy applications.

The video presentation is embedded below, and a lightly edited transcript with slides follows.

Reji Kumar (RK): Good morning, good afternoon, good evening to all the participants and it’s our next edition of this webinar. We are happy to schedule. Now this is on hydrogen. So many of you have seen several waves of hydrogen, maybe for the last 30-40 years, different waves of hydrogen. And the hydrogen economy, people have been talking about it since the 1980s, so none of them became very successful. Billions of investors’ dollars have gone down the train. There are solutions, there are technologies, but not competing with other existing technologies. And currently the last wave of hydrogen we started about five years ago, hundreds of billions of dollars have been committed for green hydrogen which will be made from renewable energy through electrolyzers and that hydrogen will be compressed to -260 degree centigrade and transported to different locations for different use cases. Sounds very energy inefficient.

If you look at the total energy in the value chain of hygiene production, including transportation, people talking about running, in fact experimented running trains, hydrogen trains in fully electrified tracks, things have gone to that extent. We don’t know who is guiding these things, who is investing in these technologies. And all green hydrogen production has, through electrolyzer, involved critical minerals which are short in supply. The projects which have been committed and projects for which funding has been committed to complete. And those electrolysis, the rare materials which will be produced in the next 50 years, may not be sufficient. And another study which Barnard had done early this year says that almost 99% of the projects which are announced, there are no buyers because it’s very expensive.

So he will take us through today in the webinar about the actual economics and dynamics of green hydrogen. Over to Michael.

Michael Barnard (MB): Thank you, Reji, and as always, thank you to the ISGF as well for allowing me to participate in a small way in assisting the great country of India to find that path that includes both prosperity for your, for all and climate action.

So this is an interesting cover page. It’s a grade seven student. He’s making hydrogen in a school lab because that’s about the age, grade seven, around twelve years old, where kids make hydrogen in school. And this leads to a lot of misperceptions. The misperception is, well, if kids can do it’s cheap, it’s easy, and therefore it will scale and become economically viable as an alternative. They let it on fire. They see the energy. Unfortunately, that leads a whole bunch of people down a garden path. This is actually a cover graphic from a short story of a dedicated hydrogen energy researcher that I wrote, which went through every single small backwater of hydrogen and showed why all of them were uneconomic and unviable compared to alternatives.

So I’m going to spin you through some of the framing slides from that representation. Occasionally somebody says, well, you missed x. And I’m thinking, no, I didn’t. I spent a lot of time looking at every part of hydrogen, in part because it’s interesting, in part because why are we spending so much time on it, including this seminar, when it’s not fit for purpose? Now, note, that’s hydrogen for energy, not hydrogen for industrial feedstocks, which it is. Last framing piece. Hydrogen today is a climate change problem on the scale of all aviation. We use it to refine oil, we use it to make fertilizer, we use it to make methanol, we use it to do a bunch of other stuff. And hydrogen today is a massive carbon bomb.

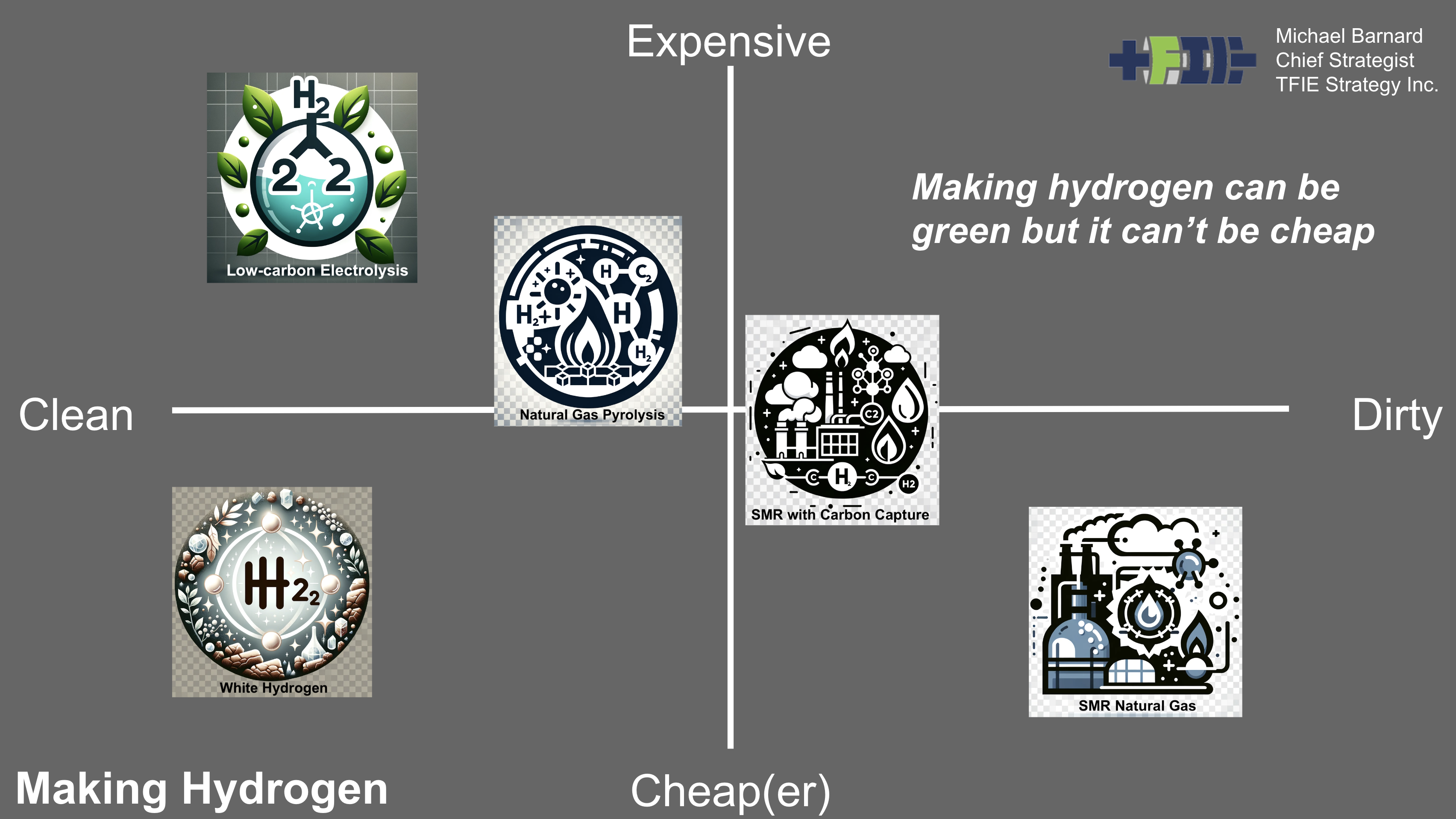

And so we have this real disconnect between solving a climate problem as opposed to solving other climate problems. So I’m going to start out with. I’ve created these framework charts. They’re just little framework charts. They’re very simple. They have a, you know, continuum. In this case, it’s expensive, which is going to be a recurrent theme versus cheaper, and they have dirty versus clean. So after you look at each of these charts, just have a glance at the labels to see what the measurement is. And so this is manufacturing hydrogen. It’s problematic. You know, we can have dirty and cheap, dirty and relatively cheap hydrogen. Just bye. Using steam reformation of natural gas, or coal gas, the two primary methods, or oil, even any hydrocarbon, to separate the hydrogen out and make a bunch of carbon dioxide, which gets made into the atmosphere.

And that’s still. That’s the cheapest hydrogen that exists, and it’s 99.9% of all hydrogen manufactured today. Now, we can add carbon capture to steam reformation, but that makes it quite a bit more expensive. Then there’s something called pyrolysis, which is actually thermolysis, as an expert in the technology told me recently, where we put methane into a sealed chamber in the absence of oxygen, and we heat it up, and it turns into three tons of black carbon and a ton of hydrogen. So it’s really a manufacturing mechanism for black carbon, which we don’t need that much of, but yet again, more expensive than steam reformation of methane. But it is cleaner. Natural gas pyrolysis, while a dead end, as well as most of the others, is problematic.

And then we actually have low carbon electrolysis. In actual low carbon electrolysis, we can’t just use grid electricity, because grid electricity isn’t clean enough to make it actually lower carbon than just making hydrogen from natural gas using the dirtiest mechanism, the grid electricity. What we require is a trifecta of additionality. Additionality, which means we add the same amount of energy in the form of renewables to the grid near the. That we need. For the hydrogen, we need temporality, which means the renewables are generating electricity at the same time as the hydrogen is required, and then we require locality, which is the hydrogen. The renewables are in the same region of the grid as the hydrogen is being manufactured.

The reason for those three requirements is if we take a dirty grid, like right now in Europe, Poland is still using a lot of coal. It has some inadequate plans to get off of them with nuclear, but. And it will eventually learn that it needs a lot of renewables. If people made hydrogen in Poland using the grid and just built a bunch of wind farms and solar farms in Spain, the hydrogen manufactured in Poland would still be filthy, and it would add requirements for electricity in a high carbon grid, which would be met by carbon sources. That’s why the three reasons are there, and they add challenges in terms of doing this right now, it’s a problem for many things. Then there’s white hydrogen. Right now, there’s a lot of hype about geological resources of hydrogen. But there’s resources, and then there’s proven resources. The fact that there’s some hydrogen down there doesn’t mean that it is recoverable economically, and it doesn’t mean it’s recoverable economically.

And in the volumes that are required, the biggest ones that have been identified are just not that big, and they’re unproven resources. There’s an estimation of how much hydrogen is in there, but that doesn’t mean we can recover it. To give you a compare and contrast, one of the common techniques that’s used in the oil and gas industry is enhanced oil recovery, where we put carbon dioxide down a tactile oil well to unlock a whole bunch of the unrecoverable resource that’s in there. Same thing with hydrogen. It comes in a variety of forms underground. We don’t know how much we’ll be able to get out of it. And most of those resources aren’t anywhere near where hydrogen is required. That’s a problem.

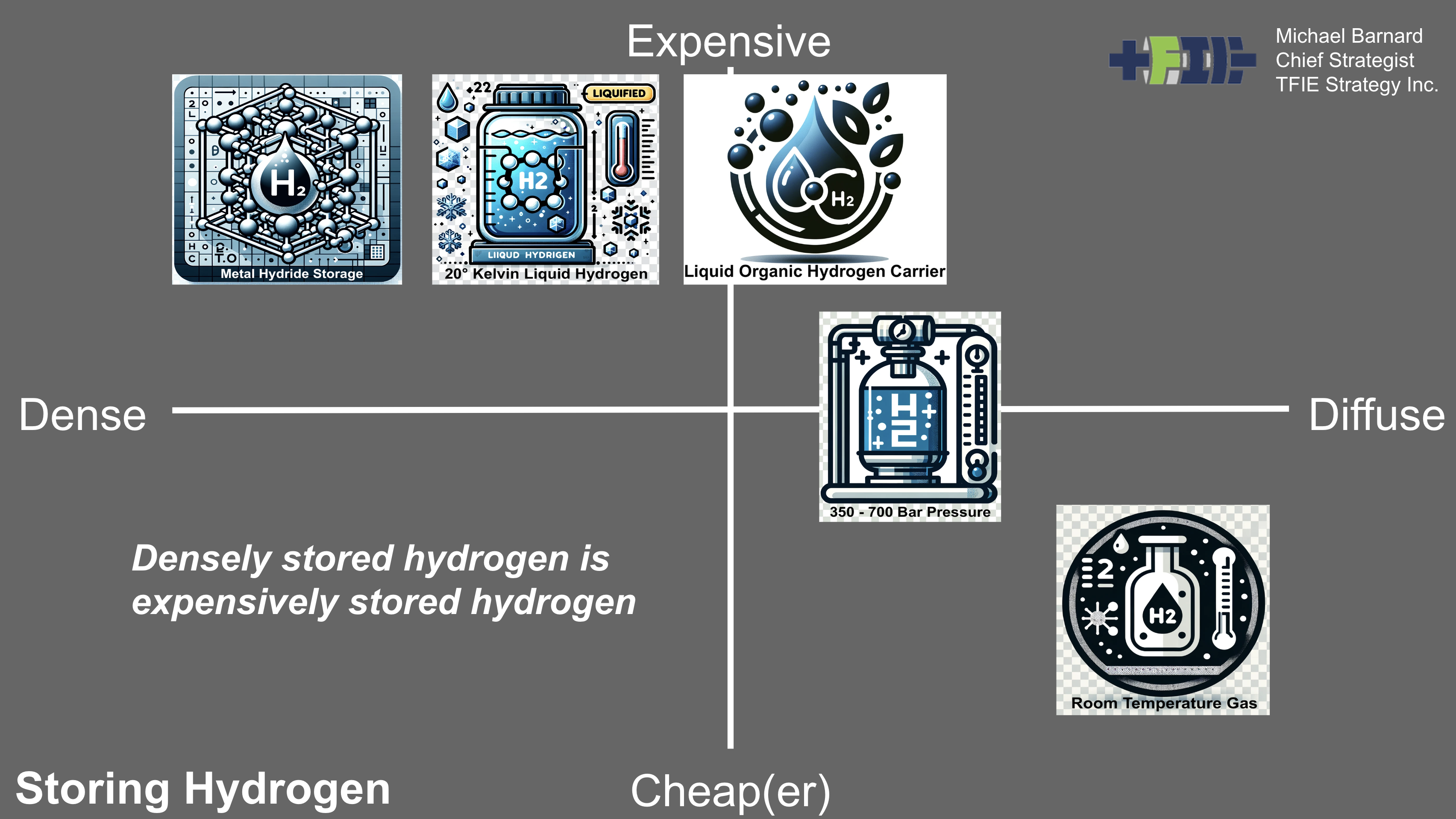

So kind of the next problem with hydrogen is actually storing it. The more this one’s dense versus diffuse, a big problem with hydrogen, and cheaper versus expensive. The big problem with hydrogen is it’s one of the least dense gases in the universe. It is right down there. It’s just the molecules don’t want to be very close together. They separate and scattered like a pack of kittens you put down, and they just all run in different directions. As a room temperature gas, it’s incredibly diffuse. It’s relatively cheap to store, but you can’t store very much of it. And this is kind of a problem. You always hear the thing. Well, it’s incredibly energy dense, but that’s by mass. Unfortunately, hydrogen is not energy dense by volume. And the volume is problematic because we can’t imagine a hydrogen car. We can’t tow a zeppelin balloon like the Goodyear blimp full of hydrogen behind a car. We have to compress it down.

And so that gets to the normal process, which is pressurizing it to 350 to 700 atmospheres of pressure in special tanks designed for that, using special compressors. And this is a problem area that most people don’t think about. Most people don’t think about compressors, but compressors have gaskets and internals, and the higher the pressures, the more exactingly they have to be machined, the better the tolerances have to be. The more expensive the materials have to be. And the more, the smaller the molecules that they’re compressing, the higher. The more. The more expensive the materials, the more expensive the tolerances, the more expensive the machining. And so hydrogen, because it’s such a diffuse gas and requires such high pressures, actually has the most expensive compressors around for 700 atmospheres of pressure. These things are non trivial kit.

I did an analysis of California’s hydrogen refueling stations, and they were seeing significant failures, 50% of which were related specifically to the compressors. Failing gaskets go on compressors for hydrogen all the time and have to be replaced. They’re not cheap. They’re one of the most expensive components in this process. They’re up there in terms of expense with the very expensive storage mechanisms, with the very expensive storage mechanism we’re looking at here. So this still isn’t very dense. A Toyota Mirai has just about 5 kilograms of hydrogen, the energy equivalent of about five gallons of gasoline in a tank, at 700 atmospheres. It’s quite a remarkable testimony to safety engineering that none of them have exploded like a kinetic bomb. So it’s quite fascinating. So people have been looking for other alternatives. Liquid organic hydrogen carriers have been discovered and been around for a long time.

They lock hydrogen into something that’s more dense, a liquid, and it’s more expensive, and it’s slow to get in, it’s slow to get out, and it’s more energetic requirements. Similarly, liquid hydrogen, chilling it down to about 20 degrees above absolute zero, is viable and we do it, but it’s also more expensive. It creates greater density. But then you have something which is 290 degrees below what we consider a comfortable temperature. Well, although I am speaking to an audience in New Delhi where 30 degrees Celsius is considered a comfortable temperature. So it’s 300 degrees below what you consider a comfortable temperature, and it boils off, and it’s highly problematic. Then we get to metal hydride storage, where it locks it into a metal substrate, and that’s even more expensive and more problematic in terms of getting the hydrogen in and out.

Each of these increases the amount of energy required to do this. For example, liquid hydrogen, about 30% of the energy that’s stored as liquid hydrogen is. Is required to turn hydrogen into liquid hydrogen. So this is part of the problem. Every time we open up part of the problem of hydrogen, it just gets more and more expensive to solve the problems. And there’s more and more problems. There are solutions, but they’re not cheap solutions. And expense matters because hydrogen is competing with other alternatives. It’s competing with direct grid tied electrification. And, you know, for those, I’m sure all of the people on this call know that India is on track to have its heavy freight rail fully electrified with overhead wires. This year, Reji mentioned rail. Well, guess what? We’ve been electrifying rail directly for over 100 years. This is trivial technology.

We know how to do it. We know how to deliver the energy that way. Hydrogen doesn’t have a play there, and yet people make the assertion. Similarly for cars, batteries, or heat pumps, et cetera, et cetera. And they’re all much cheaper. All these approaches that are alternatives to hydrogen are much cheaper and more reliable than using hydrogen.

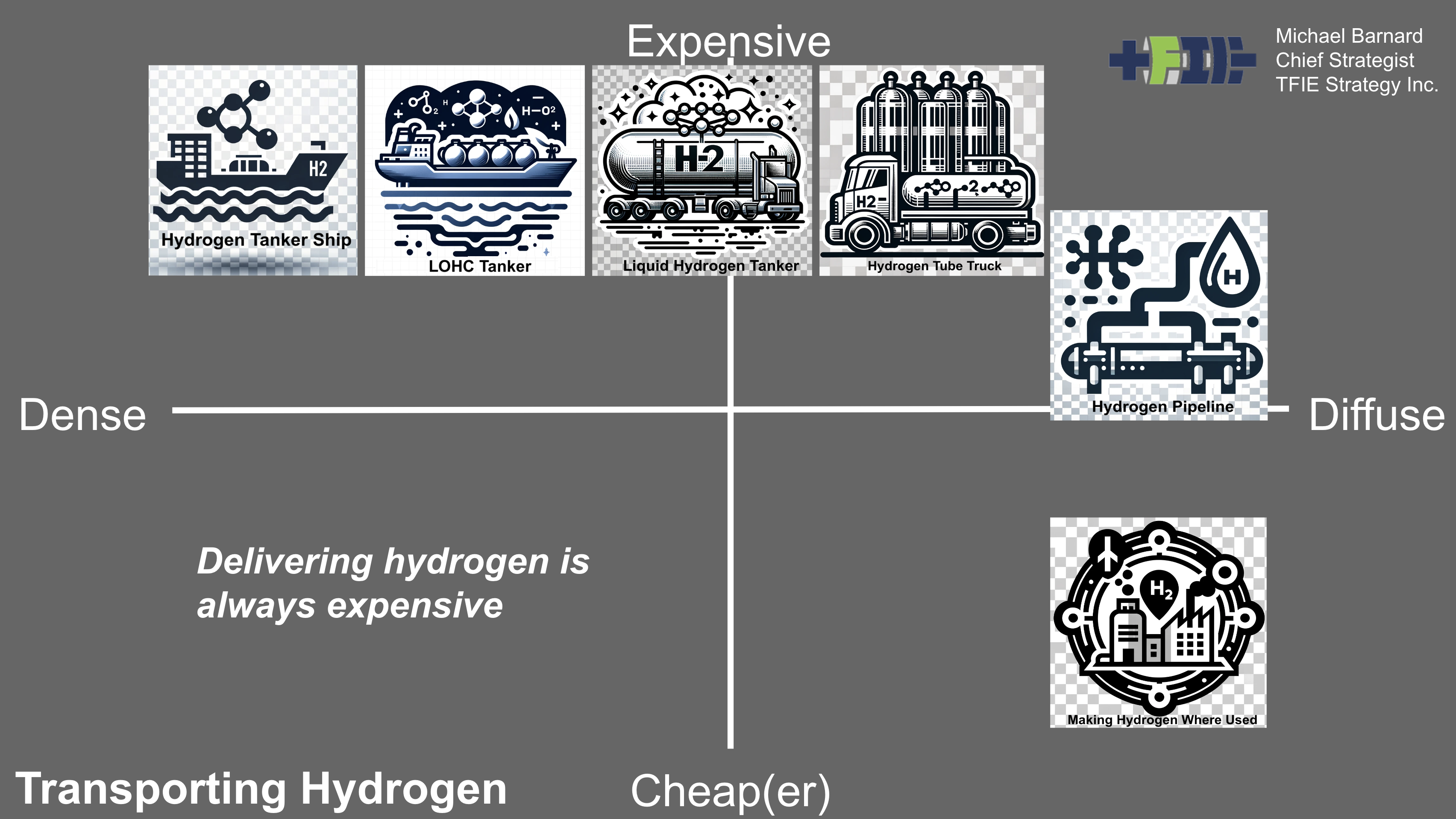

So there’s moving it around. Moving your hydrogen around because it’s once again so diffuse is another place where it’s expensive. The only cheap way to move hydrogen around is to deliver the feedstocks, water, and electricity, in the case of green hydrogen, natural gas, in the case of unabated gray hydrogen, to where the hydrogen is required. And to be clear, 85% of all hydrogen consumed globally today, about 100 to 120 million tons we manufacture, 85% is manufactured at the point where it is used.

And that’s because moving it around is really expensive. The next cheapest way is hydrogen pipelines, and this is still cheaper, by the way. I’ll just say that making hydrogen where it’s used, we use none of it for energy today because alternatives, including just using electricity directly, are still cheaper on a per. You know, pick your. Pick your unit of energy on a per BtU, on a per MMBTU, on a per megajoule, per kilowatt hour. It’s always cheaper to use the natural gas or the electricity directly rather than make hydrogen and then use the hydrogen for energy, you know, that’s why, you know, the mass majority of hydrogen vehicles in the world today are using gray hydrogen, and it’s costing them anywhere from $15 to $35 per kilogram to fill up. It’s just not cheap. But hydrogen pipelines exist.

There are some of them in Germany, in the industrial area, where they go from a steam reformation facility to a plant, and there’s some in the United States where they go from steam reformation plants to refineries. But those hydrogen pipelines in Germany carrying fossil hydrogen, that’s unabated, they’re charging $6 to $8 US per kilo for that. And that’s the cheapest hydrogen that can exist. The pipelines aren’t very long. They are industrial scale pipelines carrying industrial scale volumes of hydrogen, and yet it’s still $6 to $8 per kilogram for that hydrogen. And then we get into other more and more expensive ways to move hydrogen around. Hydrogen tube trucks, basically carrying pressurized gaseous hydrogen. Well, you need about 14 of them to carry as much as a diesel fuel tube truck, and that’s just not a feasible or realistic way to deliver hydrogen.

Liquid hydrogen tankers, liquefying hydrogen and putting it in tanks that drive on roads with school buses, is actually being seriously proposed. And to be clear, we do it, but we do it in very specific circumstances where we need liquid hydrogen as the only thing that will work. And very specially trained people deliver that at high cost. Then there’s the proposal of the liquid hydrogen carrier, liquid organic hydrogen carrier tankers, whether that’s, you know, ammonia or something else, you know, some other carrier. And I just keep stepping on the energetic quantity of these things. It just gets very expensive.

I worked out that if we shipped ammonia, for example, it would be nine times as expensive per unit of energy for Japan as the coal it’s supposed to replace. That’s with dirt cheap hydrogen. And every benefit of the doubt is just expensive to ship hydrogen. So we don’t do it today, and we’re not going to do much of it tomorrow. Then there’s hydrogen tanker ships, where people propose to liquefy hydrogen and put it in tankers, and somebody’s demonstrated that it’s just incredibly expensive. I worked out that it would be five times as expensive for shipping as liquid natural gas in one case. So this is kind of the problem. It’s much cheaper to deliver electricity to places than it is to deliver hydrogen to places. And the wires mostly already exist where we actually need energy, we need to beef them up. We need to beef up the transformers and converters, but that’s just the nature of the beast.

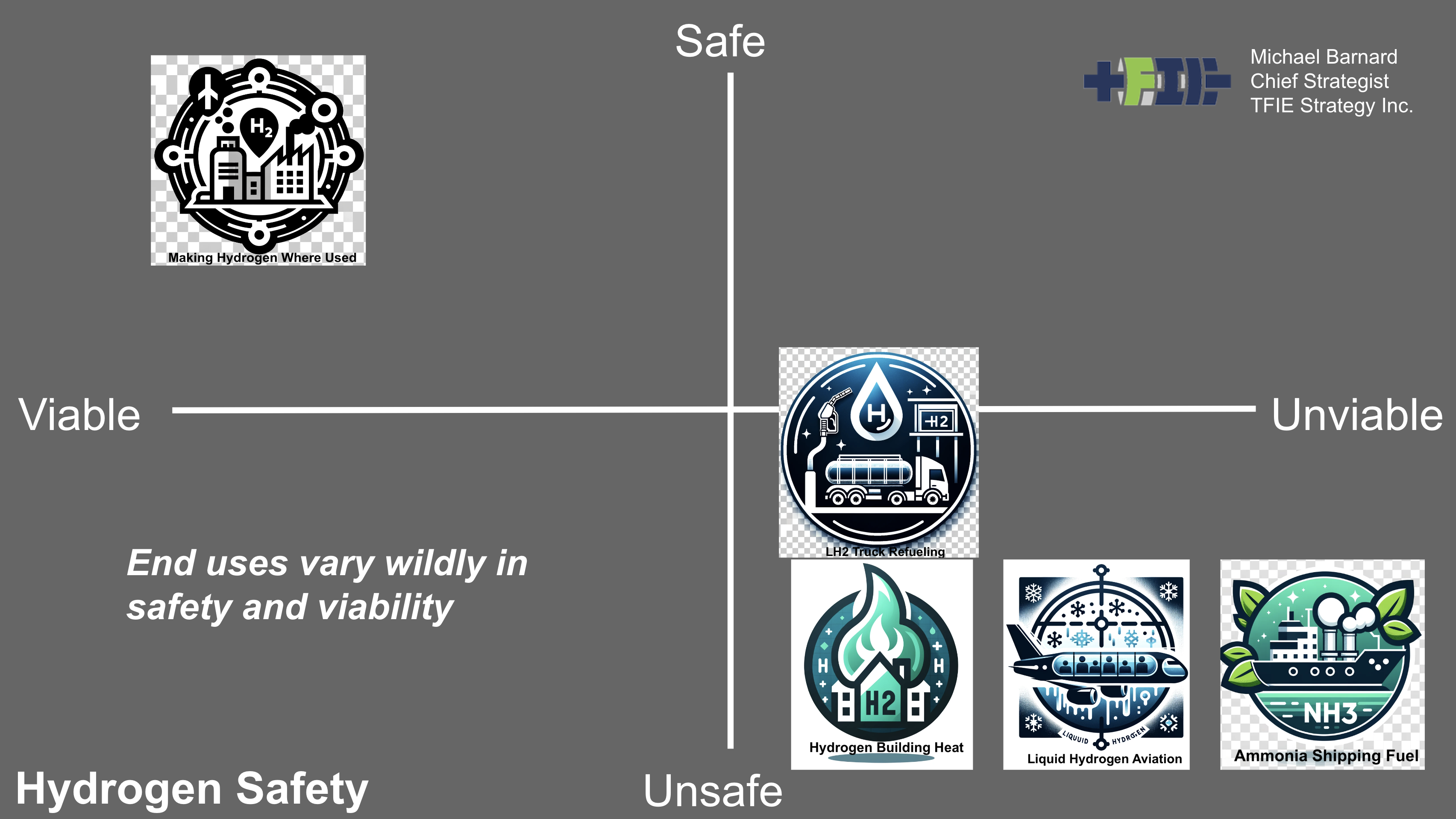

Then there’s safety and how we actually use hydrogen. You don’t hear many stories, although some, about hydrogen failures.

One of the big reasons is that mostly we make hydrogen where it’s used in industrial settings, where people know how to use hydrogen safely, and they have hydrogen sensors, and they have all sorts of safety procedures. But even there, I think it was Linde, one of the big hydrogen providers in Europe, recently had a little bit of a safety problem. You might have heard about it simply because there’s lots of news these days about people not being able to get hydrogen. So hydrogen fleets being suspended, like hydrogen trains in Germany are unable to run because they can’t get hydrogen. Hydrogen trucks and hydrogen school buses and hydrogen cars are begging for hydrogen because there’s no hydrogen. And why?

Well, because a tanker of gaseous hydrogen in a Linde plant that was being filled with hydrogen for delivery to a fueling station, had what’s called a deflagration event, which is a subsonic explosion. Basically, it caught fire and exploded, which is a problem with hydrogen, more so than with diesel or gasoline. And they had some damage that blew out a lot of windows within a significant radius and damaged some of the facility. So they had to shut it down and they had to recall all the tube tankers safety checks. And so as we get from here, safe up here, safe, making hydrogen where it’s used unsafe, pretty much everything else is questionable, viable versus unviable in terms of using hydrogen as an energy carrier. So liquid hydrogen, liquid hydrogen, truck refueling.

You know, Daimler is exploring this with Linde in Europe, and it’s just a silly idea. Moving liquid hydrogen around in trucks to put into other trucks, to drive around on highways to carry Kleenex is just not a sensible idea. When we can just use electricity and batteries, that’s vastly safer and much less likely to explode. I just read an analysis of one proposal for a liquid hydrogen for a hydrogen refueling station in Europe, where they superimposed the safety setbacks for humans lives not being lost and significant infrastructure damage not occurring as two radiuses around this thing, and looked at the number of residences and buildings around that. And yet this proposed hydrogen refueling station safety wasn’t even a requirement of the remit. Hydrogen is a highly explosive gas. We use it industrially, in large quantities, where we have specific safety measures in place.

And like many dangerous substances, we know how to do that. We know how to do that in industrial settings with highly trained people, not in gas stations and not around other people. We don’t put massive amounts of ammonia beside a school. We shouldn’t put massive amounts of hydrogen beside a school either.

Hydrogen for building heat. That’s just a bizarre concept. I just spent 90 minutes talking with one of the world’s experts on natural gas in homes, and natural gas leaks all the time. He. He is the chair of the Global Carbon Project, which annually produces the emissions and budgets for all greenhouse gases, their carbon budget, their methane budget, and now they have a hydrogen budget.

And part of his research historically has been to measure natural gas appliances in residences to see how much methane is being emitted, but also how many other pollutants are being emitted. Now, the methane leakage is already significant. Methane slippage from things that burn methane, you know, unburnt methane coming out of things which are theoretically burning it, is quite high, but methane actually doesn’t explode that easily. It only explodes easily enough that 4000 buildings a year are significantly damaged or destroyed in natural gas fires and explosions in the United States. Now, 4000 against a building stock for a country of 330,000,000 people, maybe that doesn’t sound like much, but hydrogen, per the best analysis available with safety measures, would be four times as likely to have explosions and unsafe conditions as methane because the molecule is smaller. You know, our infrastructure that’s delivering gas to homes is not designed for tinier molecules than methane. And hydrogen is just the Houdini of molecules. It loves to get out of places. It loves to embrittle stuff.

Similarly, hydrogen safety, putting 20 degree Kelvin hydrogen in the fuselage, where it would be required because of the nature of aerodynamic balancing inside the fuselage with human beings, is just a recipe for a disaster. It’s just very difficult to square the safety of human passengers with liquid hydrogen as a fuel. And yet people are seriously reporting it. It’s one of those cases where it’s uncertifiable and certification and aviation is critical. So while there’s a lot of discussion about it it’s just not going to happen.

And ammonia as a shipping fuel. That’s a recipe for disaster as well. Ammonia, which is one nitrogen, three hydrogen, burns cleanly, which is to say it burns without emitting greenhouse gases, but with lots of nitrous oxides. Ammonia, as it sits, is toxic to humans. And when it mixes with water, which ships are around, it turns into a highly corrosive substance, which, if we breathe, will destroy our lungs. And then after that, it turns into a different substance, which is just bad for human health and for wildlife health. So ammonia as a shipping fuel, as a hydrogen energy carrier, is a non starter. It’s a boat that won’t float. And it’s just remarkable to see the amount of attention that it gets. So safety is a concern and it adds expense.

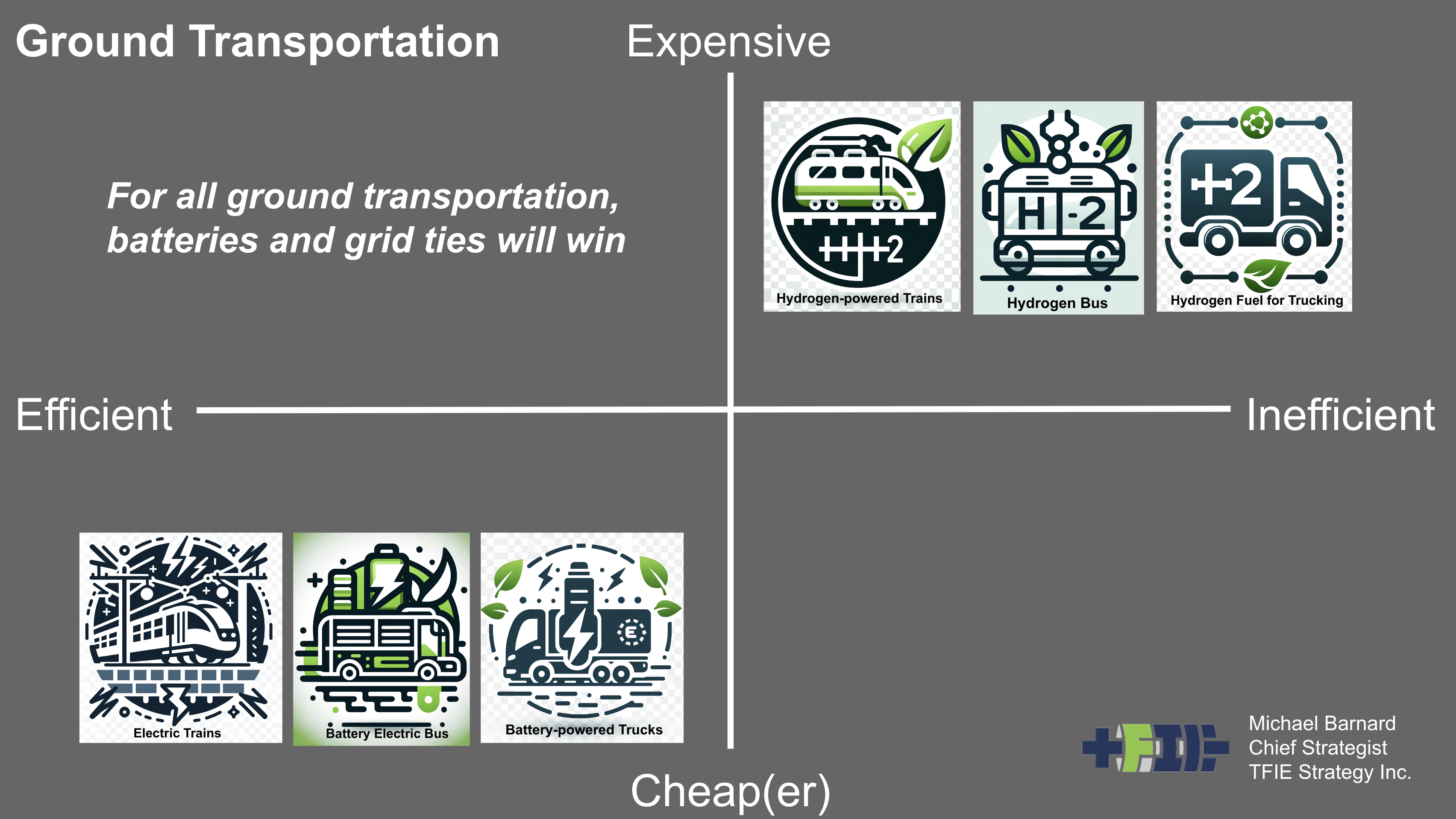

We can do any of these things with a reasonable degree of safety and unlimited loss of human life. But it costs an awful lot more than alternatives to achieve safety with these technologies, which adds to the lack of viability, then, for ground transportation, expensive, cheaper, inefficient, efficient.

Let’s just look at the alternatives here up here. Hydrogen fuel for trucking. Well, hydrogen fuel for trucking. Once again, we’re seeing $15 to $35. That’s for gray hydrogen delivered to trucks.

The refueling stations in California are an abject lesson. They have 55 refueling stations for public vehicles. And those refueling stations as of 2021. I did the analysis of their highest use, most mature period that was public record, which was six months in 2021, after five to six years of operation. And I found that the hydrogen refueling stations were out of service for 2000 more hours when they were pumping hydrogen.

Hydrogen refueling stations fail frequently because it’s hard to store and pressurize hydrogen. Once again, those compressors go regularly. This adds to the cost. The cost of delivering hydrogen to refueling stations is a very significant addition to the cost. Farming of energy did a study and said the cost of just delivering hydrogen by tube truck to a refueling station would add $8 to $10 to the cost of the hydrogen. So it doesn’t matter what it costs to make the hydrogen, it doesn’t matter what it costs to pump the hydrogen, and to deal with the cost of the low reliability of refueling stations. It’s $8 to $10 per kilogram just to get the hydrogen to the refueling station. It is once again non viable.

Hydrogen buses have similar problems. I did an analysis of California’s bus fleet because they’ve been experimenting with this. There are pockets of irrationality around hydrogen. Their hydrogen buses are 50% less reliable than their diesel buses and twice as unreliable as their battery electric buses. Diesel buses will be out of service for x hours. A hydrogen bus will be out of service for x hours times 1.5. So one and a half times the hours out of service because they’re just not working. Fuel cells are finicky things. A fuel cell requires pure hydrogen at a specific time, you know, reasonably temperature, with no pollutants like water or other substances. It requires pure air. It requires air that is bone dry and free of pollutants.

Achieving that in a bus or a truck that drives through city streets with all the particulate matter and all of the air pollution in cities, it has to filter that down to hospital grade operating theater air quality and temperature in order for the fuel cell not to degrade and fail rapidly. Buses in Spain that were delivered, well, accidentally, some coolant from another part of the drivetrain got into the fuel cells and destroyed the fuel cells entirely. And the buses have never moved. So there’s five buses, I forget the city in Spain, it’s not Barcelona, it’s one of the other ones, but they got buses and they’re just sitting there. They’re bricks. This is a problem with hydrogen. It’s just hard to make things work. We can do it, but they’re less reliable than alternatives. And reliability adds money.

Hydrogen powered trains, same thing. I’ve talked about trains, basically. Overhead wires, batteries for the bits that can’t be done. It just makes sense. India is so far ahead of the rest of the world, even ahead of China on electrifying trains, that I won’t talk about it.

And of course, down here we have the alternatives. Well, can we have battery power trucks? Yes, and we do. Can we have battery electric buses? Yes, and we do. Can we have electric trains? Yes. And they’re efficient and cheaper. And so, you know, once again, it’s a competition. Hydrogen is not the only way to do most things, and it’s certainly not the only way to do things in energy. And every time we ask the question, we have to say, what are the alternatives? Are they economically advantageous? And the answer is always yes.

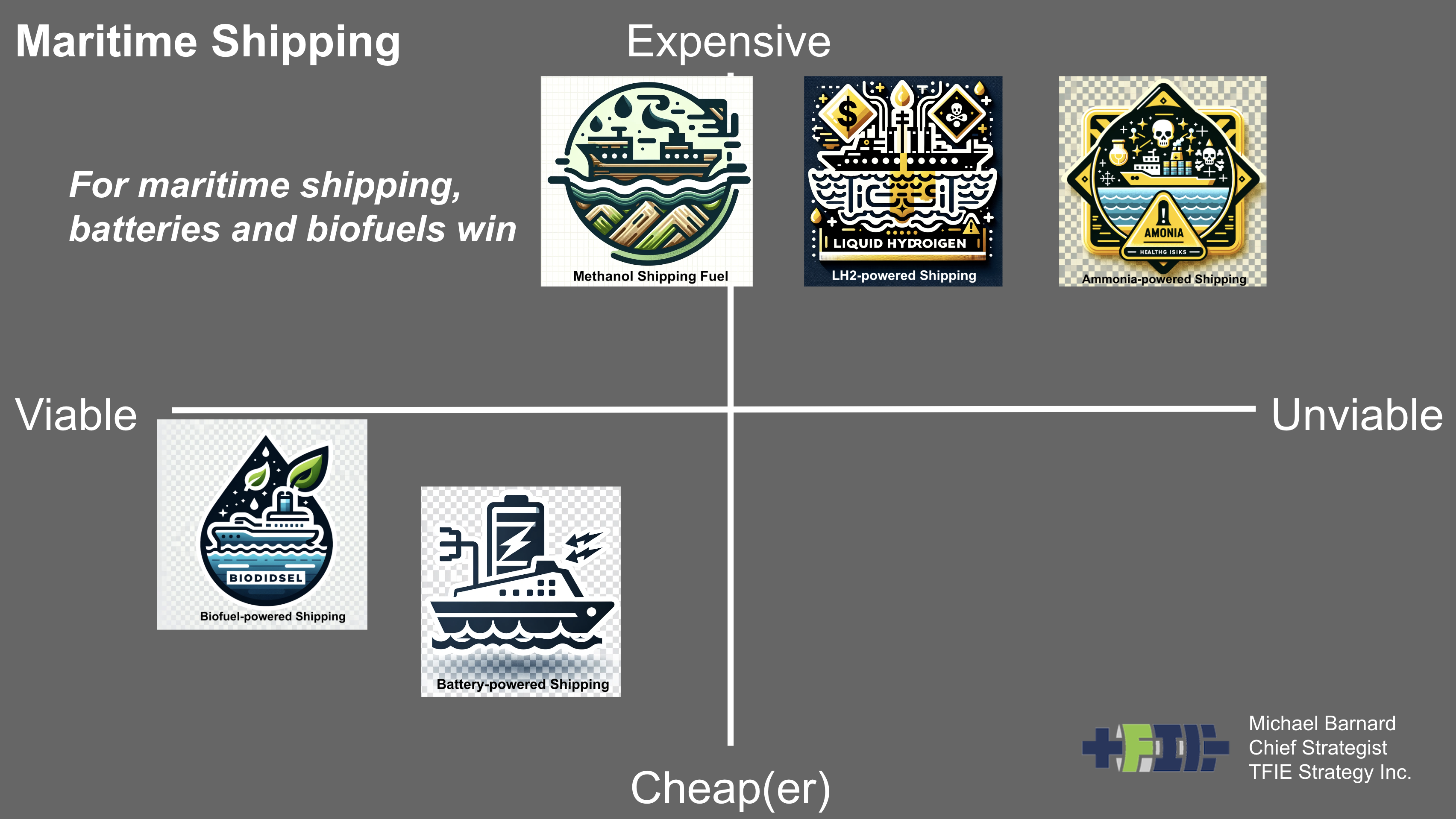

Then there’s maritime shipping, another purported area. So expensive, cheaper, viable, unviable. Back to ammonia powered shipping. I’ve talked about this. It’s nuts. Then there’s liquid hydrogen powered shipping. I will say this. I spend a lot of time looking at the maritime industry. I spend a lot of time talking to maritime professionals about repowering stuff. I’ve been flown to Glasgow to debate maritime decarbonization. I’ve spoken to people at the Maersk McKinney Institute for Maritime Decarbonization. People from the Wallenius group just interviewed me for what needs to be done around maritime shipping. And I’ve got a projection of maritime shipping decarbonization through 2100. I’m far from expert, but I’m fairly deep in this subject. And the thing I’ll say is a bunch of think tanks are talking about liquid hydrogen and the maritime industry is ignoring liquid hydrogen. Yeah, they’re not stupid.

They look at it and go, wait, you want us to do what with that stuff? And you want us to power ships with that? That’s just silly, man. Like maybe Maersk does it and we find out that it’s cheap. But until then, please go away. Nobody is using liquid hydrogen to power ships. And yet think tanks keep proposing it.

Methanol as a shipping fuel. Methanol is basically wood alcohol. It’s one of those alcohols that if you drink it, you go blind and die. So don’t do that. And it’s a fairly common industrial substance today and a climate change problem today. And it does burn modified ship engines like an alcohol would. It’s actually okay, but it’s only about 45% the energy density of maritime variable sulfur fuel oil. It’s more expensive, so it’s competing with alternatives. And the alternatives include battery powered shipping.

Right now there are a couple of 700 unit container ships sailing the Yangtze on thousand kilometer routes that are running on batteries. They’re batteries in containers that are winched out of the ship, put on shore to be charged, plugged in, just like refrigerator cars. Refrigerator containers and charged refrigerator charged battery containers are winched onto the ship and plugged in just the same way refrigerator containers. Reefers are today. And batteries are slowly taking over the bottom end of shipping. And they’re going to all inland shipping, most short sea shipping. My projection is that battery hybrid shipping with biodiesel will take over the entire space for batteries. We’ll run the ships in ports and national waters to minimize air pollution and noise pollution for all the residents and the marine life near shore and crossing oceans. They’ll burn biofuels.

And the biofuel, I expect, will be biodiesel. There’s arguments that are reasonable to suggest that we’ll end up with methanol, biomethanol as a shipping fuel, but we certainly won’t end up with methanol synthesized from green ammonia. Biomethanol is much cheaper than methanol synthesized from green ammonia. So we’re not going to end up using synthesized methanol or any synthesized fuel. It just doesn’t make any sense because it’s more expensive and nobody’s going to pay more for something which doesn’t do more. And synthetic methanol doesn’t do more than biologically sourced methanol.

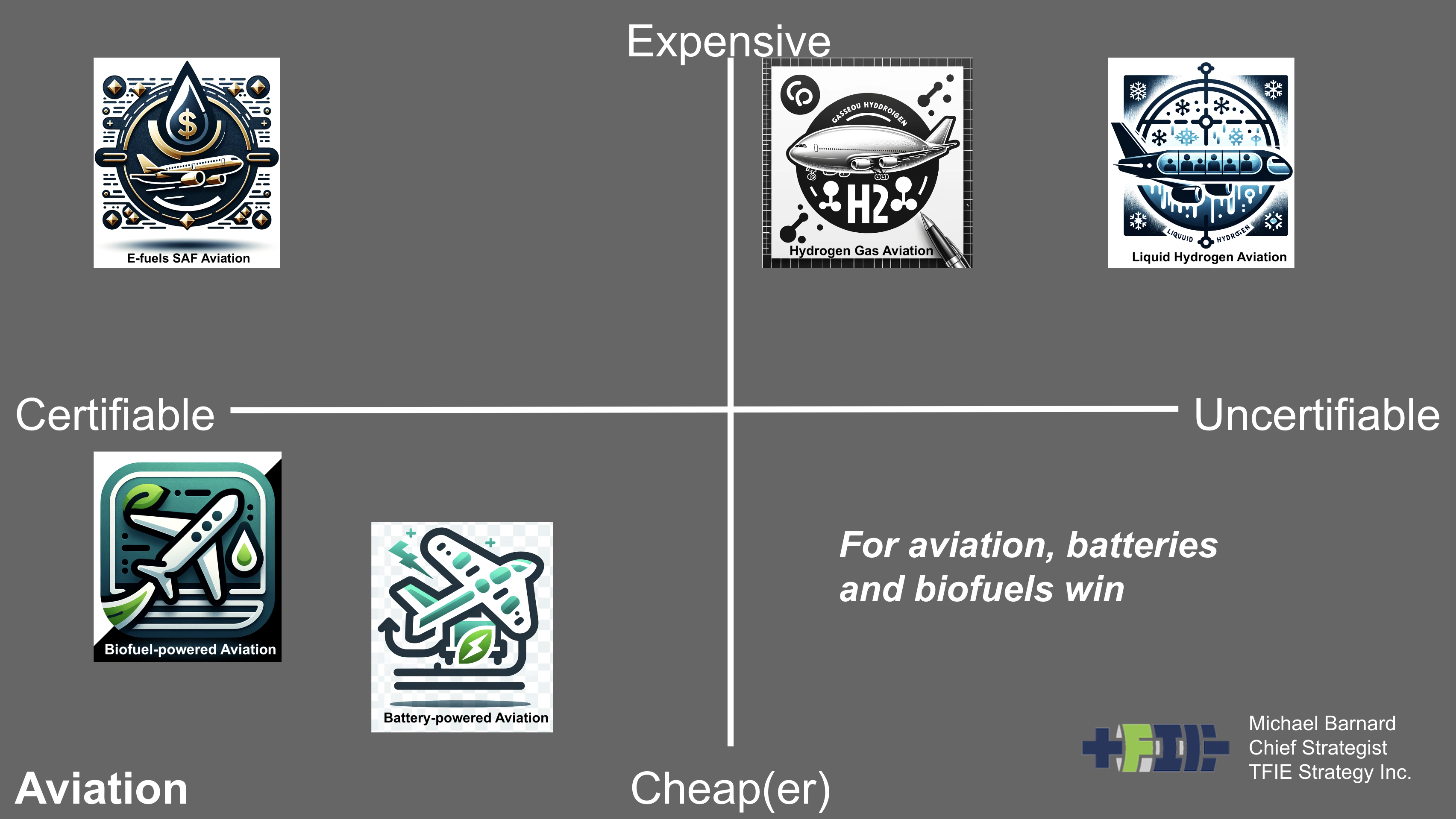

So aviation, expensive, cheaper, certifiable, uncertifiable. Now, certifiable doesn’t mean they’re crazy. It doesn’t mean we’re putting them into an asylum to assist them to recover their mental health, to find the right mood stabilizers and pharmaceuticals and talk therapy to assist them to reintegrate with society.

It means that operators can fly a certified machine with human beings inside of it as a commercial service, or they can fly machines with packages inside them as a commercial service over places where there are people. So everything above tiny aircraft has to be certified. Have to be certified by national aviation boards. Most aviation boards globally respect and adopt a certification. If the FAA does it or EASA does it, then many just respect and adopt those and say the national certification boards adopt those. I would say if there are any aviation people on board from India associated with India’s equivalent of the FAA, you should really rethink grandfathering FAA certified planes because the FAA was captured by Boeing, and it’s just a real problem area right now in aviation. But certification is required, and it’s expensive.

It’s an n-times-n process that says you have to manufacture, design planes in a certain way, manufacture planes in a way that is safe, and then test all the failure conditions in an n-times-n way in flight tests to prove that a plane won’t fall over the sky and kill people. The Boeing Max disasters that killed hundreds of people were a failure of certification because Boeing captured the FAA over the years. But as we go through these, battery powered aviation is easy. We know the failure conditions of batteries and batteries to electric motors have virtually no moving parts. An n-times-n certification process for a very simple aircraft, like a battery, electric one is much cheaper than a more complex one.

Biofuelled aviation just replaces kerosene that’s used today with biologically sourced kerosene that’s actually really easy to certify as well, because it’s just a common pathway, the same molecules, different sources, and every major, manufacturer, civil aviation aircraft, is certifying their planes on certifiable aviation, unsustainable aviation fuel that come from biofuels today. We just like, look at the common carriers. They’re all doing it. We’re bunkering, you know, millions of tons of biofuel, sustainable aviation fuels today.

Now, up here, efuels. This is synthetic kerosene made from green hydrogen and then combined into making the attributes of kerosene. Kerosene being a kind of a classifier of attributes, not a real specific chemical formula. And you can do that. It’s just really expensive. It’s easy to certify because it’s exact, it’s almost identical to the jet fuel that’s used today. It’s just as certifiable as biofuel powered aviation.

But it’s just going to be really expensive. Biofuels are two to three times as expensive as current fossil fuels. In most cases, e fuels are four to six times as expensive. And if a carrier has the option between, if it’s forced to pay two to three times, that’s one thing, but they’re not going to pay four to six times if they have a two to three times cost alternative. So let me get over into stuff that just doesn’t make any sense. Hydrogen gas and liquid hydrogen. The failure conditions are so high and the design transformations for aviation are so high to avoid failure conditions due to those problems, just make it a non viable to certify.

I will say that the certification people must be having a field day, because normally they’re over here in really well trodden pathways, they’re filling in checklists that have been filled in hundreds and thousands of times before. Over here, every day they find a new way for an airplane to go boom or fall into the sky and kill a lot of people, and they have to come up with tests to validate that it won’t occur. That’s an exciting thing for the certifiers to do, which is why the certification agencies are spending so much time on it. But that doesn’t mean it’s going to lead to certification for aircraft. So you can get really expensive, uncertifiable aircraft, or you can get aircraft that look a lot like the ones today, and battery electric ones, and get there and solve the climate problem.

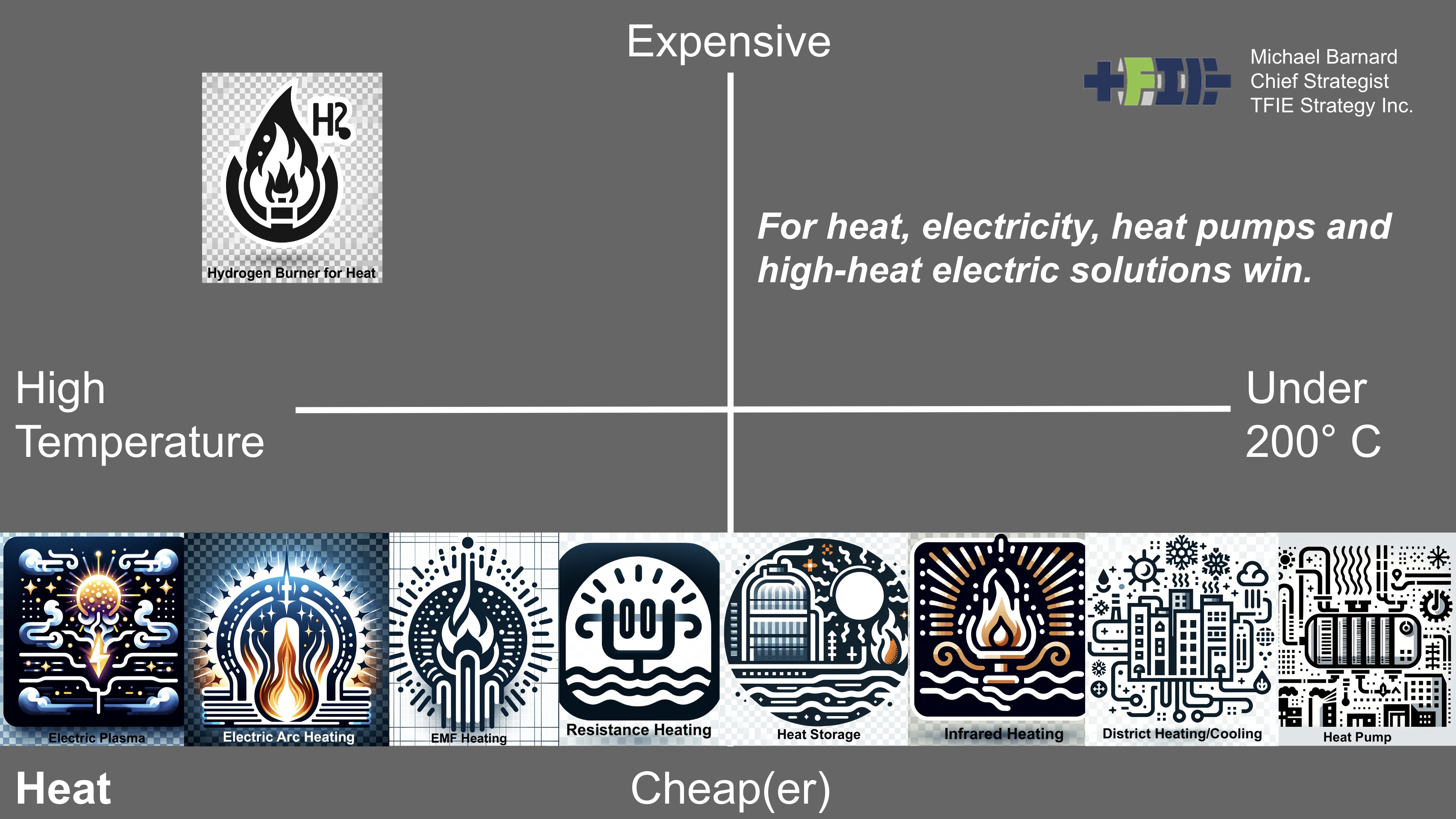

So then there’s heat. I’ll just say that burning hydrogen to make heat works. Nobody does it today because it’s really expensive. There’s some stuff you have to change that characteristics of the flame are different. You have to change a bunch of stuff. That’s all just fairly minor engineering, but it’s expensive. Meanwhile, people say, what about high temperature heat? Well, electric plasmas, we have the temperature of the sun under our control with commoditized technology we can deliver today and integrate into heat. Electric arc heating, we already use that for steel manufacturing. EMF heating, resistance heating, up to 600, 800 degrees Celsius. I talked to the former chief technical officer of Kanthal, now the EVP for global business development, a couple of years ago. Yeah, their product is just a resistance heating element that goes to 600 to 800 degrees.

Thermal storage, now infrared heating. We have district heating and cooling. We have heat pumps. Every single range of heating can be done with electricity. It may not be trivial or inexpensive to change something which is designed for fossil fuels to run on electricity, but all new facilities should be designed from the ground up to run solely on electricity. Matter of fact, when I speak to Paul Martin, they all are. It’s only when the business case is committed that they add gas where it’s necessary to make the business case. And so as we move forward into a decarbonized world and carbon pricing applies to fossil fuels, these technologies are all there. They’re all commercial today. They’re all completely reliable, commodified things. We’re just not using them because burning fossil fuels and using the atmosphere as an open sewer is cheaper. Hydrogen doesn’t have a play here. It’s just always going to be more expensive and a lot harder and a lot less safe than just using electric alternatives.

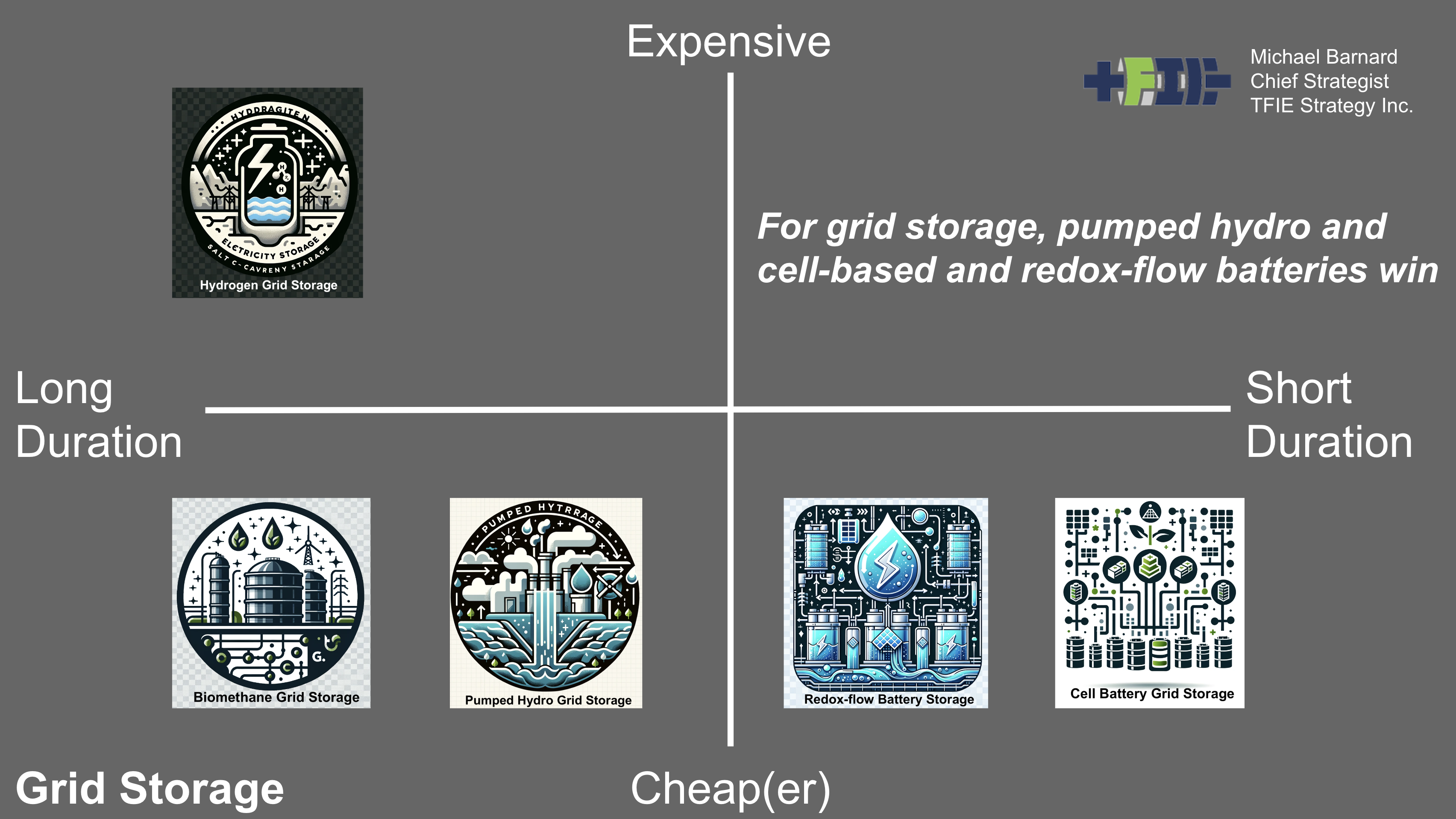

So then grid storage, same problem, hydrogen grid storage, it’s “I have a hydrogen molecule. What else can I do with it?” It’s like having a Swiss army knife. Oh, what does this little blade do? Oh, it’s a long duration energy storage. Yeah, hydrogen for long duration energy storage. Well, no, for shorter duration storage, we have cell based battery grid storage. Huge, huge market these days. Very successful. We have redox flow technologies, which are commercializing today. I sat on the advisory board of one. We have pumped hydro, which is growing radically.

In the grid storage discussion, I pointed out how vast the resource India was recommended to the ISGF, that they reopen the study into grid storage because off river, closed loop grids, pumped hydro grid storage is really easy to build and it’s fit for purpose. Then we have biomethane. We had this big problem. Part of the reason I was speaking to the head of the global carbon project, Rob Jackson, this week was because we are emitting massive amounts of high global warming potential methane today from our agricultural food waste stream processes. Rice farming, for example, India, but also food waste. We throw away a full third of the food we manufacture every year that ends up in landfills or middens, where it’s piled, decomposes anaerobically and creates methane. So our land management processes are produced, for example, beef cattle and ruminants, with their belching of methane from their digestive processes.

Well, the methane from that source is twice as big as the methane emissions from the fossil fuel industry, which have been climbing radically. We have to minimize our biomethane because it’s a huge global warming problem. And my theory is we just capture it at point sources like dairy barns and landfills and other stuff, and we fill our strategic natural gas reserves with biomethane instead. And then when we need that strategic reserve of gas, of energy, we just burn biomethane. I think that makes a lot more sense than manufacturing hydrogen. But if hydrogen ends up being the silly thing, if people start manufacturing salt caverns and creating, you know, dealing with all that, it’s the. It’s not the most pressing problem.

We have technologies for everything, except we’ve got commercialized, commonly used, very reliable technologies for everything except strategic energy stores for long regional outages of wind and solar.

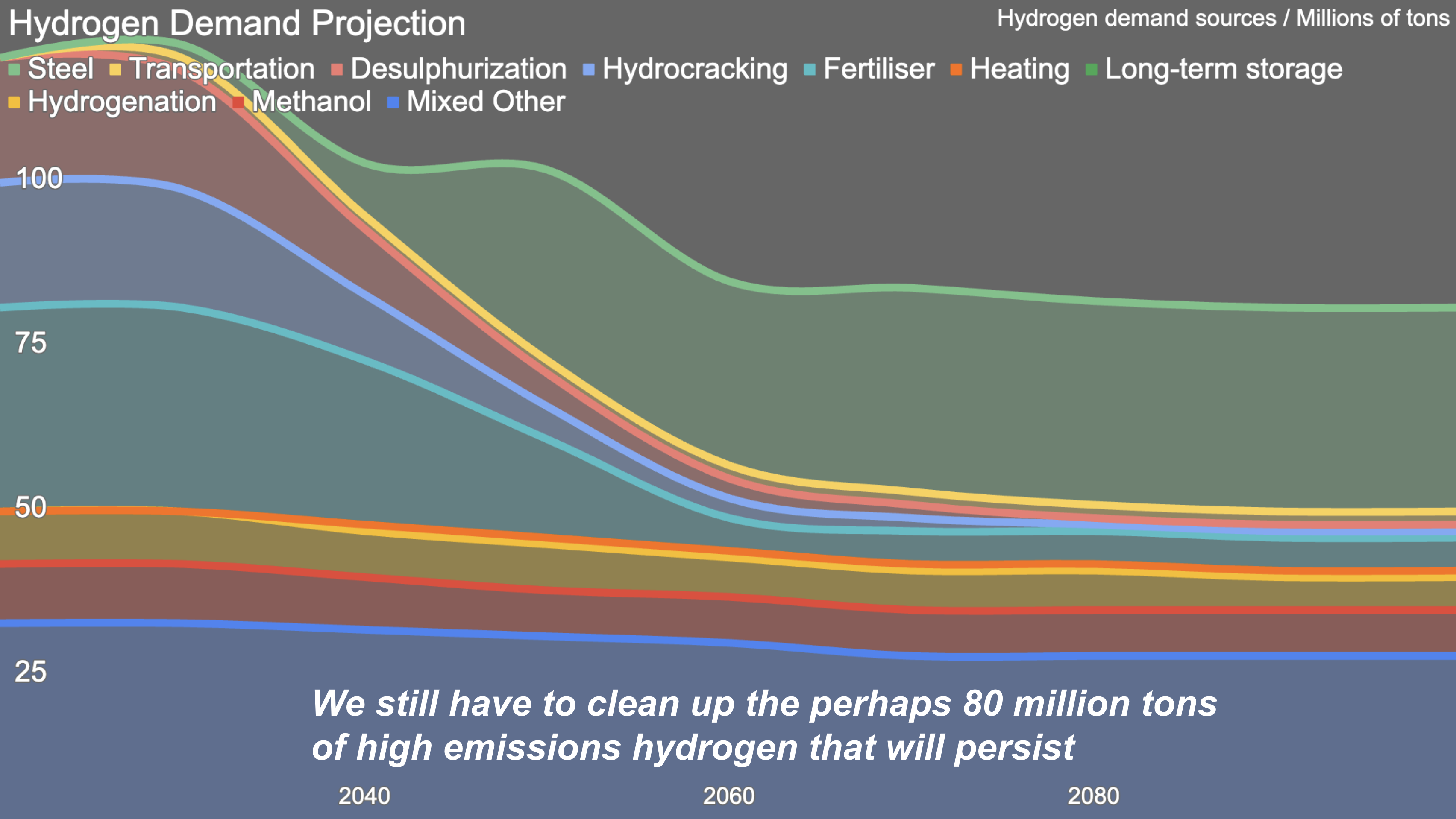

This all turns into my hydrogen demand projection through 2100. You’ll notice that unlike every other hydrogen demand projection you’ve ever seen, it goes down because green hydrogen is a lot more expensive than unabated gray hydrogen. Blue hydrogen is double the cost of unabated current hydrogen. That means that as the feedstock cost goes up for industrial processes, where we use it, our expectation of using it, people will find alternatives. There are alternatives to hydrogen in some cases. In other cases, there are no alternatives. But if the cost goes up, people will say, well, how else can I achieve the same outcomes? Oh, well, let’s do that.

But even more, look at this big chunk here, these two categories. The biggest consumers of hydrogen today are oil refineries. They use it to strip impurities out of hydrogen, like sulfur. And they also use it to crack hydrogen into, or crack crude oil into lighter and heavier portions. The heavier and the higher sulfur, the crude, which is to say Alberta oil sands crude, the more hydrogen you have to use. For light, sweet crude, you have to use a kilogram or a kilogram and a half per barrel of oil, for Alberta’s product you have to use seven or 8 kilograms per barrel of oil. We’re going to stop extracting and refining a lot of our oil. We’re going to get down to only extracting oil for petrochemicals. And the petrochemicals, the oil we’re going to extract is mostly going to be lighter, low sulfur, because we have lots of oil.

So we’re not going to be consuming nearly as much hydrogen in oil refineries. And that’s going to happen fairly quickly. The heaviest, lowest quality crudes, like Venezuela’s and Alberta’s, will be first off the market. So that’s going to plummet. This is fertilizer, the next biggest demand area. And we have alternatives for a lot of fertilizer. Low tillage agriculture requires less fertilizer. Drone based crop spraying of fertilizers requires a lot less fertilizer. Agrigenetics is displacing fertilizer additions with genetically modified microbes, which already exist in the soil, which already fix nitrogen in the soil for plants. But they have a nitrogen sensor. They just turn off the nitrogen sensor, and it just keeps making more nitrogen at the roots of plants. It’s very efficient.

Last time I spoke to Karsten Temme, the PhD geneticist who heads Pivot Bio, they were at the point where they were seeing a million acres of corn under management in the United States, and they’re reducing fertilizer requirements by 25%. Their goal is 100% across rice, corn, and grain by 2030, stretch target, but a really good sound bite. So we’re going to be pulling all those levers, because fertilizer is going to get more expensive as we decarbonize fertilizer, a huge climate problem today because it’s made from natural gas. Natural gas turns into hydrogen. We put the hydrogen into the Haber Bosch process to combine with air from the atmosphere to make ammonia to make fertilizer. We’re going to reduce that. So significant declining demands in the biggest source demand areas for hydrogen.

Steel is a potential area. I’ve currently got it there. Making hydrogen, making new steel with hydrogen. Well, the hydrogen replaces coal in reducing the iron ore, which de rusts it basically into iron. That’s all it does. And there’s a demand point there. But we have alternatives there that are direct electrification, Boston Metals and Fortescue using molten oxide electrolysis achieve the same outcomes with no hydrogen step. And basically any place where they can not use hydrogen, as we have an alternative to hydrogen, we’re probably going to use it. It has to be cheaper. And so right now I have increased demand for hydrogen for steel making in my projection, but that’s at risk. In the end game I think we’re only going to have 80 million tons of hydrogen that we use in our economy, as opposed to the under 120 million tons that we use today.

We still have to clean it up. It’s still a big climate problem area. We still need all the work on electrolysis for this market of expensive hydrogen.

That’s it. Let’s talk. Any questions, Reji?

RK: I would request you to give the latest status of the announced green hydrogen projects and buyers, the committed buyers and what trees, what percentage of total projects which are financially close to projects which are under some stage of development or construction, and who have signed up to buy the green hydrogen. At what price? What statistics do you have?

MB: So a year ago, Boston Consulting Group published with Oxford Global Projects a kind of a white paper on how to make green hydrogen projects as low risk as possible. Not low risk, just lower risk. And they included a bunch of statistics, about 1300 projects that Boston Consulting Group had in their database. Those 1300 projects, I think it was only 0.7% by tonnage actually reached final investment decision and operation. It was only 5% by number of announcements, but only 0.7% by tonnages actually reached final investment decision. So we don’t have a situation where they’re getting through, because as they go through final investment decision, due diligence, they actually have to put real numbers into spreadsheets, not imaginary consensus numbers about cheap hydrogen.

They actually have to actually cost stuff. And then when they do that, they find out that hydrogen is expensive, which we’ve known for a long time. I just assisted Professor Joe Romm, who’s working with Michael Mann at University of Pennsylvania with the 20th edition of his book, The Hype About Hydrogen. Joe Romm did his work 25 years ago and said, why would we be considering this? It’s always going to be expensive. Bruce McCabe, another PhD out of Australia, did this work 25 years ago and said, this is really expensive. As I said, I’m a slow student. I’ve only done the math on this in the past decade, looking at done techno economic workups on hydrogen solutions for the past ten years. And every time I do it, hydrogen comes out really expensive.

The price point is interesting. Boston Consulting Group also published something saying, the consensus of €3 per kilogram green hydrogen in Europe by 2030 is turning out not to be correct. It will actually be €5 to €8 per kilogram. And I agree it’ll be €6 to €8 to manufacture hydrogen. But that’s not delivering it, that’s just making it. And so, once again, every time we have to store it, every time we have to transport it, every time we have to pump it, the cost goes up and up. Safety stuff adds costs. So when we hear the cost point for hydrogen, you have to ask, is it, what’s the cost delivered? And the best cost delivered for consumer purposes, for hydrogen, is what’s being paid at gas pumps around the world, which is $15 to $35 per kilogram. And that’s for gray hydrogen.

It’s not going to get cheaper than that average price point. For all the deals that were actually struck last year, to Reji’s point, the average price point was €9.35 euro cents per kilogram. And that, once again, just to manufacture it.

Okay, we have another question. Please explain why hydrogen use serves fossil interests. It’s the title of the presentation, so I’m glad you asked. Michael Liebreich says it best. The fossil fuel industry can’t lose by promoting hydrogen for energy, either. Hydrogen for energy becomes a major part of our energy mix, and we can’t make enough green hydrogen at all, because it would require vastly more renewables than we have today, which would require blue hydrogen, then the fossil fuel reserves that the fossil fuel industry has is the only source of all that hydrogen.

And in order to do that in a somewhat low carbon way, somewhat not really, they’d have to do carbon capture and the governments would have to pay them to add carbon capture to their hydrogen manufacture. So they win that way and their hydrocarbon reserves are good and governments and taxpayers give them lots of money. Or the other way they win is they delay real climate action with electrification by another decade and they keep pumping their oil, coal and gas for another decade without real action. It’s an obvious strategy for them. As you look at the funding for hydrogen advocacy organizations, what you find is the fossil fuel industry is all over this space. They are promoting hydrogen far beyond its level of capacity. Do we have other questions? I know Puranima Gupta has had their hand up. I’m not sure if they’ve put a question into chat.

What about mixing hydrogen in with natural gas and existing pipelines? This is one of the great hopes of the industry. We’re going to put methane, we’re going to put natural gas into existing natural gas pipelines and then we’re going to reduce the CO2 output of burning natural gas. And it’s going to be great. Well, it’s not. The maximum you can put into pipelines is about 20%, but hydrogen is a lot less dense than natural gas, so you end up with less energy at more cost. You only get about a 7% carbon emissions reduction from the maximum mixture of natural gas with hydrogen. So that’s problem one. Problem two, natural gas already leaks all the way through the distribution system. And the older the distribution system is, the more it leaks.

Amusingly, I was talking with, once again, the gentleman who chairs the Global Carbon Project. And he spent quite a bit of time in cars driving around Boston, Manhattan and Washington with methane sensors looking for leaks. What they found is the older parts of the city that were the most gentrified with the most rich people had the highest leaks. So it was quite counterintuitive that it wasn’t an inequitable situation as it normally was. It just leaks a lot. Now, why I bring this up is methane leaks a lot less than hydrogen. So when you put hydrogen with natural gas in a pipeline, any leaks that exist are going to disproportionately leak the hydrogen. And who pays for all the leaking natural gas today? Well, consumers do. It’s undelivered gas. It’s part of the expense that utility passes on.

So all that expensive hydrogen that goes in with the natural gas will be much more expensive, it’ll leak a lot more and you’ll pay a lot more. So it’s just basically a dead end. It’s quite fascinating. So existing steel pipelines, can we use the existing steel pipeline network for hydrogen transportation or do we need some modifications in general? Yes, you need modifications. You can do those modifications. The thing with hydrogen is because it has to be higher pressure to deliver less volume, because once again, it’s a lot less dense as a gas. You have to pressurize it a lot. And pressurizing causes the pipes to flex. As the pipes flex, we have micro fractures in the weld joints of the pipes.

Hydrogen does what methane doesn’t, which is it gets into those weld joints and it bonds with the metals and it embrittles them. And so we have to actually reduce our pressurization. We can only get about a third of the energy through the same pipeline with safety. Now we can get a bit more by coating the insides. We have to coat the insides of all the pipelines with moderately expensive internal coatings. We have to run pigs down them, spray them, test them, and that’s just to get to the point where we can deliver a third of the energy so we can do it. But once again, much more expensive than piping natural gas, and it requires modifications. And the next bit is all those compressors that are used on the natural gas pipelines aren’t fit for purpose for a hydrogen pipeline.

They once again need higher pressure compressors with better fits. Otherwise they’ll leak hydrogen like sieves. So all the compressors on the natural gas pipeline have to be replaced and then all the electronics. Methane doesn’t attack electronics. Hydrogen is really reactive. It attacks electronics. You actually have to get a different certified set of sensors and electronics on your hydrogen pipeline than exist on the methane pipeline. So it’s not a slam dunk. You can’t just say, I’ve got a pipe, I’ve got pumps. I’ll just put hydrogen instead of natural gas. You have replace all your compressors. You have to upgrade all your electronics. You have to coat the inside of the pipeline. And guess what? That all adds cost to deliver less energy. It’s not a slam dunk. Any other questions?

RK: Madam Puranima Gupta was asking, she is still not clear how hydrogen is not good to decarbonize? It’s good to decarbonize, provided you can make it cheaper to other technologies and also the difficulties about storing it and transporting it and overall energy. Inefficient solution is what Michael explained in the previous slide. So the webinar recording will be available in just two days to all the people who registered. Thank you very much, Michael. Good day to you.

MB: Well, I will add one point to that comment. It’s absolutely necessary to decarbonize all the hydrogen that we currently use and will continue to use for the next decades as industrial feedstocks. Right now, that’s a climate problem we have to solve. Green hydrogen is the answer to it, and that means that we have to do that. But that’s the climate, that’s the decarbonization solution we have to work on for hydrogen, which is reducing it from a problem the size of all aviation globally down to something that’s not the size of all aviation globally. So decarbonization and hydrogen don’t think of it as a solution set. Think of it as a problem area that we have to solve. So that would be the thing. Back to you, Reji.

RK: Thank you. Good day. Good evening. Good night to all the participants from India Asia region. Good night.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica.TV Videos

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy