Martin Engineering discusses long-term solutions to managing fugitive materials in a conveyor.

Most conveyors handling bulk materials have some material loss from spillage, leakage, dust and carry-back emissions, collectively called fugitive materials.

The root causes are often obvious but rarely addressed; rather, the standard approach is to treat the symptoms.

Failing to control fugitive materials can lead to unplanned downtime, excessive cleaning costs, regulatory actions, poor public relations and safety incidents, while addressing the issues with long-term solutions improves availability, housekeeping and safety, ultimately enhancing a company’s cashflow.

Reducing visible dust emissions (typically defined as particles larger than 40 micrometres [µm]) from conveyors is often a primary goal, partly because it attracts the attention of workers, neighbours and inspectors.

Quite often the use of respirators is seen as an acceptable alternative, but a closer evaluation shows these devices can reduce productivity by as much as 19 per cent, and prolonged use can affect cognitive and sensory abilities significantly. These decreases in productivity alone justify making improvements to conveyor dust containment.

Skirtboards

The skirtboard enclosure is essentially a low-efficiency settling chamber. The basic concept is that a dust particle will settle out of a laminar air stream based on the speed of the airflow and terminal velocity of the dust particle.

There are many rules of thumb for skirtboard sizing and dust curtain placement to contain dust in the skirtboard enclosure. Most of these practices are without proof of performance other than, “That’s the way we’ve always done it”.

Image: Martin Engineering

A current practice for conveyor skirtboard enclosures is to optimise airflow by increasing the height of the enclosure. Two common rules of thumb for enclosure length are two times belt width or 0.6m for every 1.0m/s in belt speed. If height is increased, the distance the average dust particle must travel also increases.

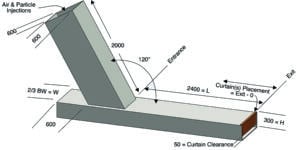

A detailed design study of airflow and particulate settling was performed using flow simulation software.

A “standard conveyor” was established as the baseline for the study. The standard conveyor is a 1200mm-wide belt with a 35-degree trough angle, travelling at 2.0m/s.

A generic material was used to produce the baseline data, with a bulk density of 1442 kg/m3 and a nominal 50mm minus particle size distribution with a 20-degree surcharge.

The discharge chute was sized based on a material volume equal to or less than 40 per cent of the chute cross-section. A drop height of 3m, an open area of 0.9m2, an average particle size of 25mm and bulk flow of 1680 tonnes per hour were used to calculate the induced air volume.

Several variables were investigated to simplify the analysis. The complete conveyor with discharge and receiving belts was modelled and, while there were significant regions of recirculation in the upper discharge section, the airflow in the chute was reasonably consistent.

So the chute was simplified to that shown in figure three, with the air volume and dust particles injected into the last 2m of the chute.

Both external and internal analyses were conducted, with complete moving discharge and receiving conveyors. The bulk material surface was set to absorb particles and the walls set to reflect particles. The effectiveness of the enclosure variations was determined by counting the number of each size particles that escaped the end of the enclosure compared to the number injected.

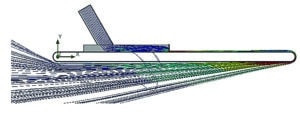

The results of the external analysis indicated that escaped dust particles increased in speed, with the air current affected by travelling around the belt and the discharge pulley. This phenomenon is known as the Magnus Effect and emphasises the need for effective belt cleaning as close to the discharge as possible.

A space of 1mm between the bottom of the skirtboard and the belt was used to simulate leakage.

Curtain designs

Several experienced maintenance technicians were surveyed and their preferred curtain arrangements modelled. In addition, multiple curtain designs and placement schemes were studied, including staggered, slit, curved, angled, with and without slits, with holes and no curtains.

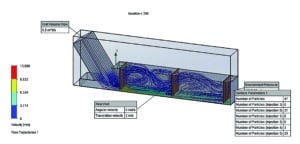

Several unconventional skirtboard enclosures were modelled in an attempt to create recirculation in the enclosure and improve dust settling. The optimum design for the standard conveyor was determined to be a conventional enclosure with a height of 600mm, a length of 3.6m and three dust curtains placed in defined locations (see figure five).

Image: Martin Engineering

Worn exit curtains were also modelled, and as the spacing above the load increased, the dust settling performance deteriorated. The use of a single curtain at the exit proved problematic in all cases, acting to speed up the exit airflow even further when close to the belt and re-entraining dust in the exiting air stream, while being ineffective in creating recirculation within the enclosure.

When the curtain placed at the exit was worn too much, it was as if there was no curtain at all. A curtain placed at the exit and adjusted close to the load creates another fugitive material problem, sometimes called the popcorn effect, where the curtain causes spillage by knocking material off the belt.

Results

Particle density

Solid density had little effect on the settling of nuisance dust particles from 100 to 25µm. In every case, all of the 100 and 40µm particles settled almost immediately and as the bulk density increased, there was a moderate reduction in respirable dust emissions.

Discharge chute and tailbox

The junction between the discharge chute and the skirtboards was found to be an important design detail for creating recirculation. Making the width of the discharge chute narrower than the width of the skirtboard helps to fold the airflow going into the first curtain, encouraging distribution of the airflow towards the top of the enclosure, rather than along the surface of the material.

Image: Martin Engineering

The tail box had little effect on dust emissions out of the exit end of the skirtboards. In most configurations, the height of the tail box was set at 300mm, while the tail box length was set at 600mm to match the 600mm idler spacing used in the load zone by most conveyor manufacturers and engineers.

Length of skirtboard

It was found that for most situations a 3600mm-long skirtboard produced the best results. Increasing the length to 4800mm and height to 900mm had marginal effect but may not be worth the extra investment.

Height of skirtboard

An enclosure height beyond 600mm for the standard conveyor with a single exit curtain did reduce nuisance emissions but tended to increase respirable dust discharge, because the average settling path was greater with the higher enclosure.

Airflow

As would be expected, the average air velocity through the skirtboards was directly proportional to the induced airflow and cross-sectional area. Average velocities in the skirtboards due to induced air ranged from 0.8 to 2.8m/s.

Belt speed has a minor effect on average velocities. High air speeds kept the respirable dust suspended, so reducing induced air into the chute is also important in improving the performance of a conveyor system.

Image: Martin Engineering

Curtains

The best results were obtained with three or more curtains. The design of the slits in the curtains is important to allow air to pass through, enabling the airflow paths to fill the entire chamber and not just flow at high speeds.

It was found that the individual flaps should be about 50mm wide, with slits at least 5mm wide and the curtains extending the full width of the enclosure.

While some improvement is seen with increased skirtboard height and length, it’s doubtful these adjustments can be economically justified on the reduction of respirable dust alone.

A return on investment for the control of nuisance dust can be based on reduced cleaning labour, increased equipment life and/or the elimination of dust collection for new and retrofit designs.

If the improvements reduce the time-weighted average of respirable dust emissions to the point where engineering or administrative controls could be less stringent, then a financial case could also be made based on improvements in labour productivity.

This feature appeared in the February 2025 issue of Australian Mining.