Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

The auto industry can become a lead market for low-carbon steel production in Europe if lawmakers set content requirements.

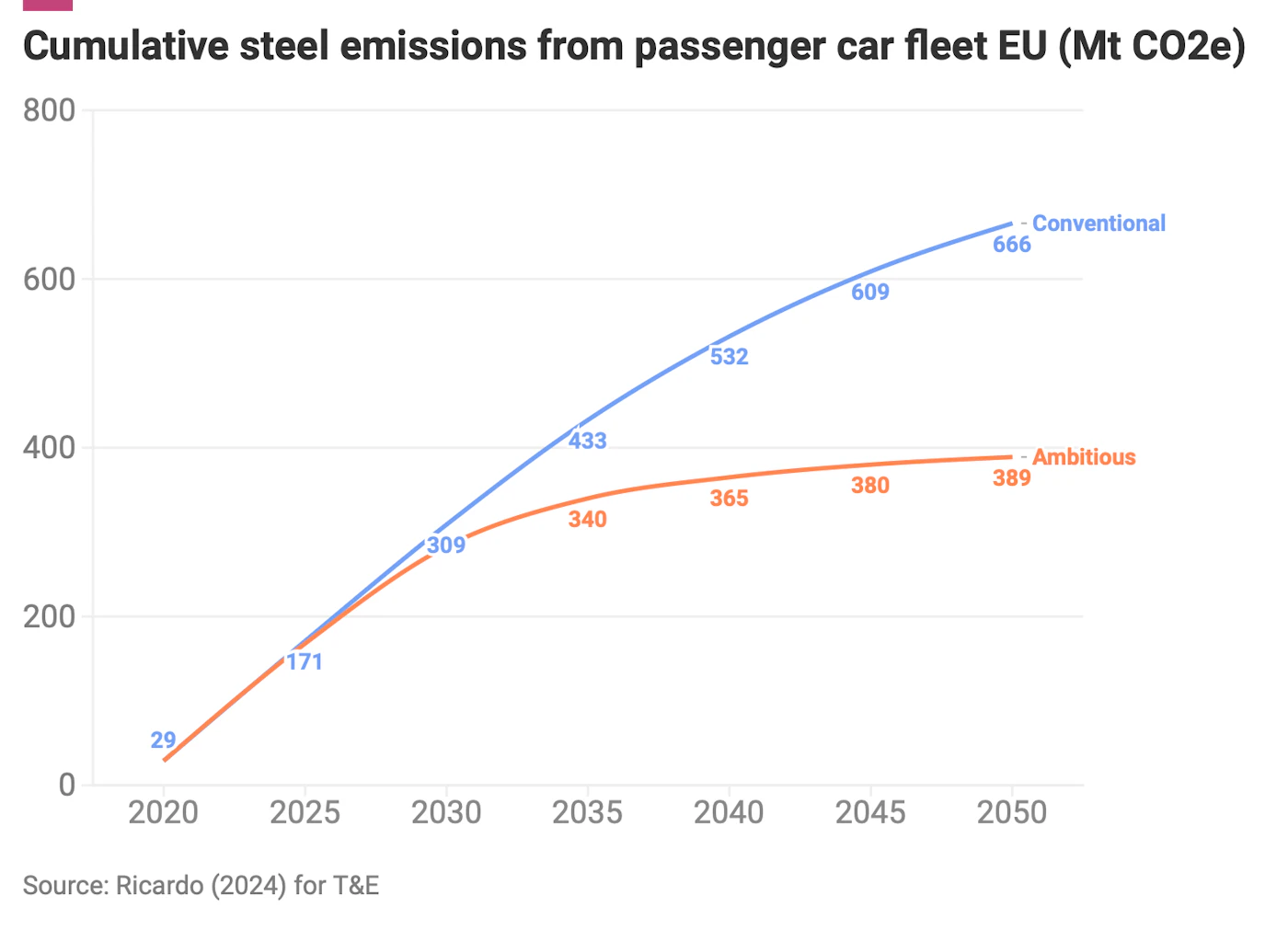

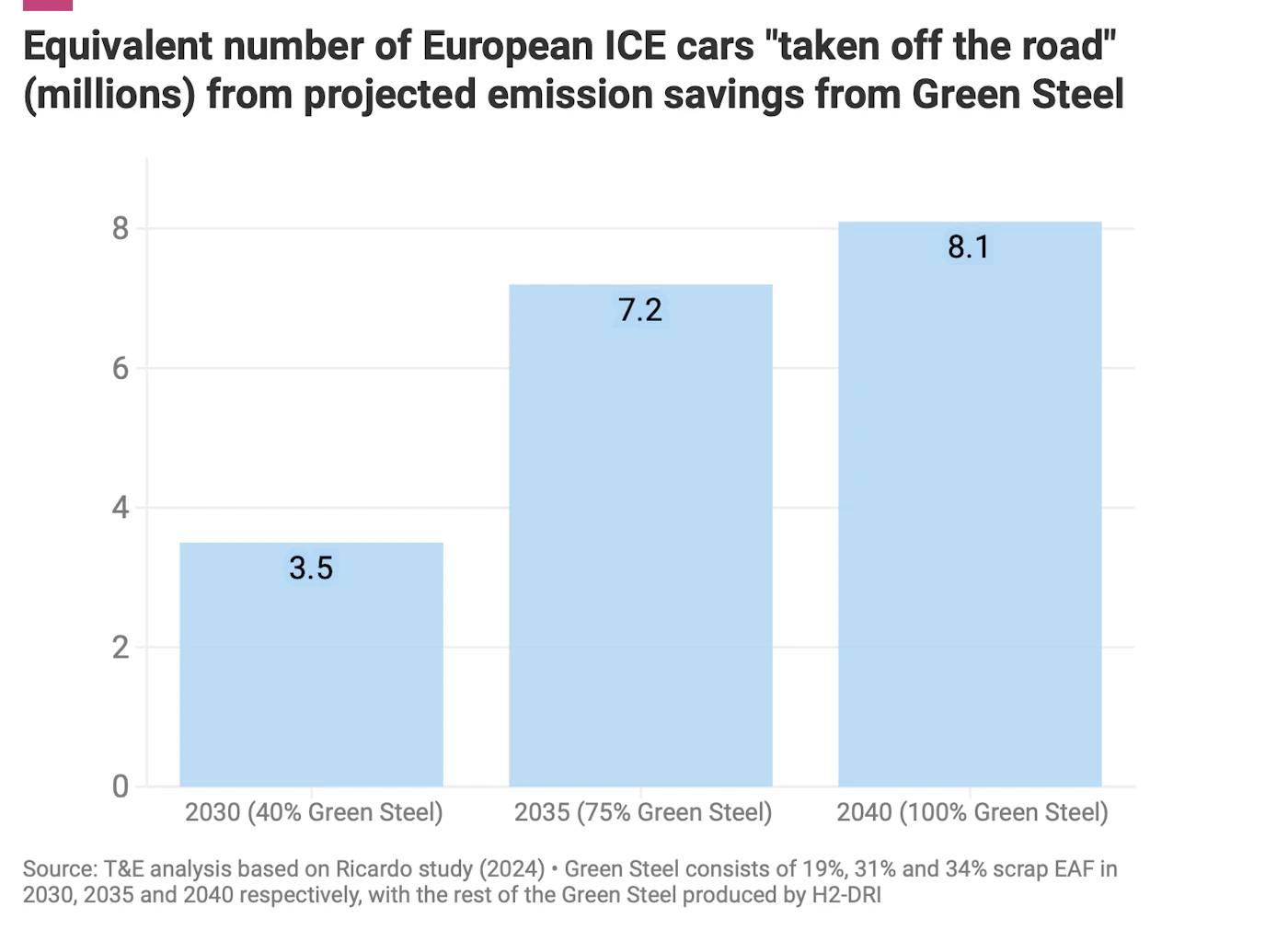

Steel made with green hydrogen and electric arc furnaces, or produced from scrap, can reduce the CO2 emissions of producing cars in Europe by 6.9 Mt in 2030, new analysis shows. That’s equivalent to avoiding the annual emissions of 3.5m fossil fuel cars. The climate impact of producing cars is increasingly under the spotlight as tailpipe emissions reduce to zero and the car sector strives to become net zero by 2050.¹

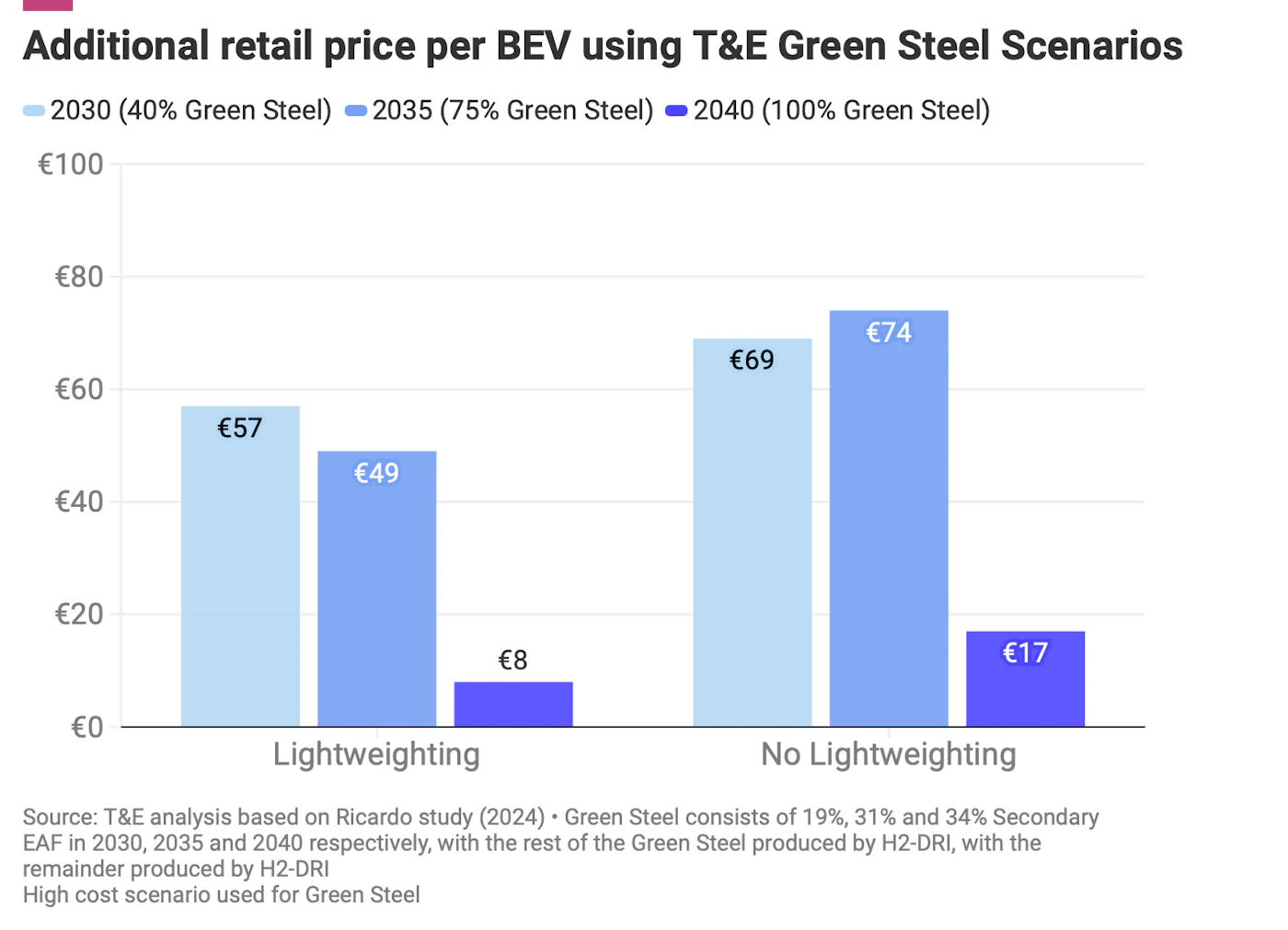

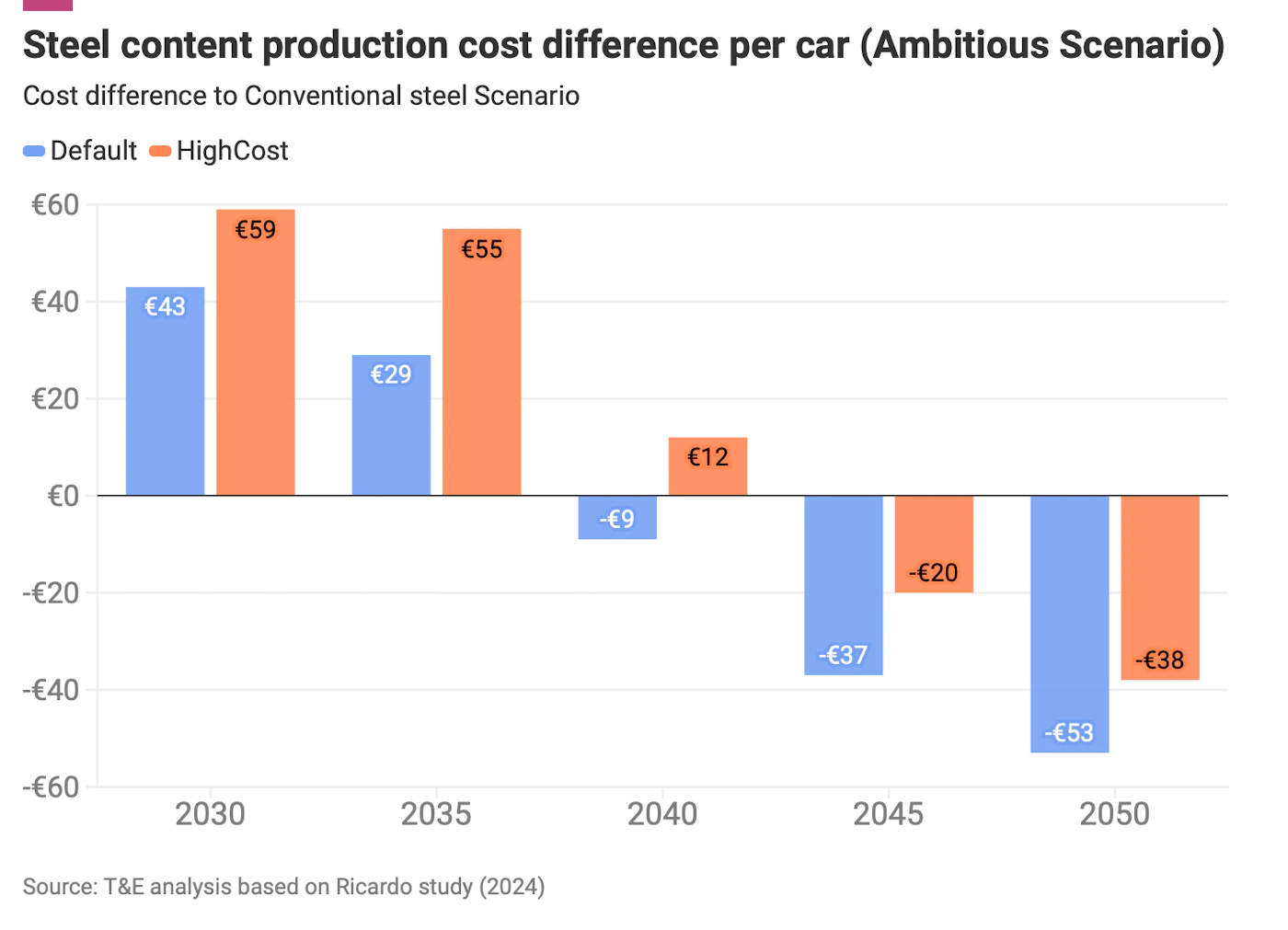

Switching to 40% green steel would add just €57 to the sticker price of an electric vehicle in 2030, according to the analysis by Transport & Environment (T&E) based on a new study by consultancy Ricardo.² Switching to 100% green steel by 2040 will cost only €8 — compared to using conventional steel — due to CO2 pricing as well as the falling costs of green steel production. But securing the billions of euro in investment needed for low-carbon steel production will be highly dependent on having a reliable offtake market for producers.

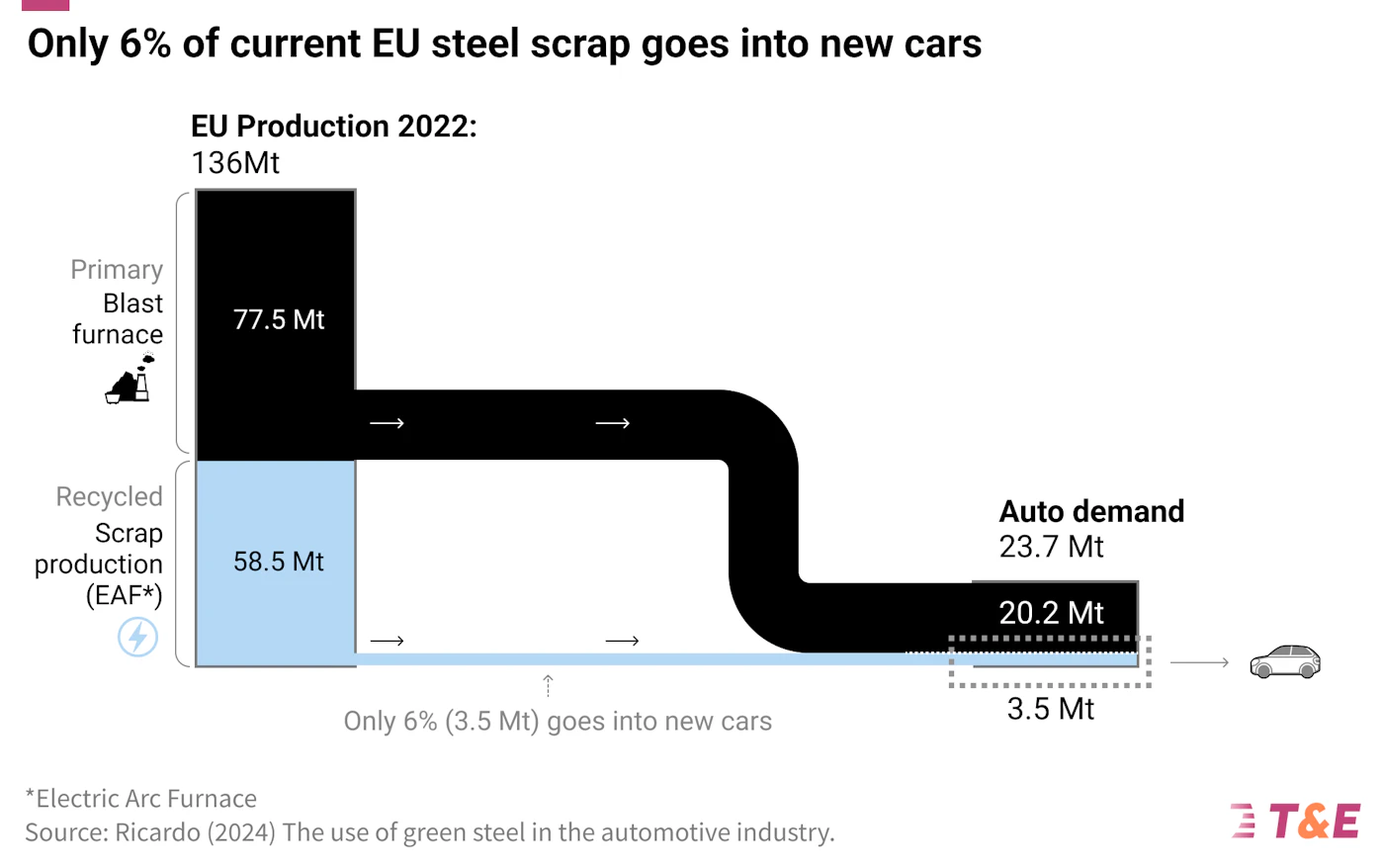

The automotive sector is very well positioned to create this demand as it currently consumes 17% of steel in the EU. T&E called on lawmakers to help create a lead market for green steel in Europe by setting targets for carmakers to use an increasing amount of it in new cars from 2030.

Alex Keynes, cars policy manager at T&E, said: “For less than a tyre change, Europe can build a green steel industry. The extra cost will be negligible and in time it will be cheaper than conventional steel. But we first need lawmakers to kick start the shift to low-carbon steel in the automotive industry.”

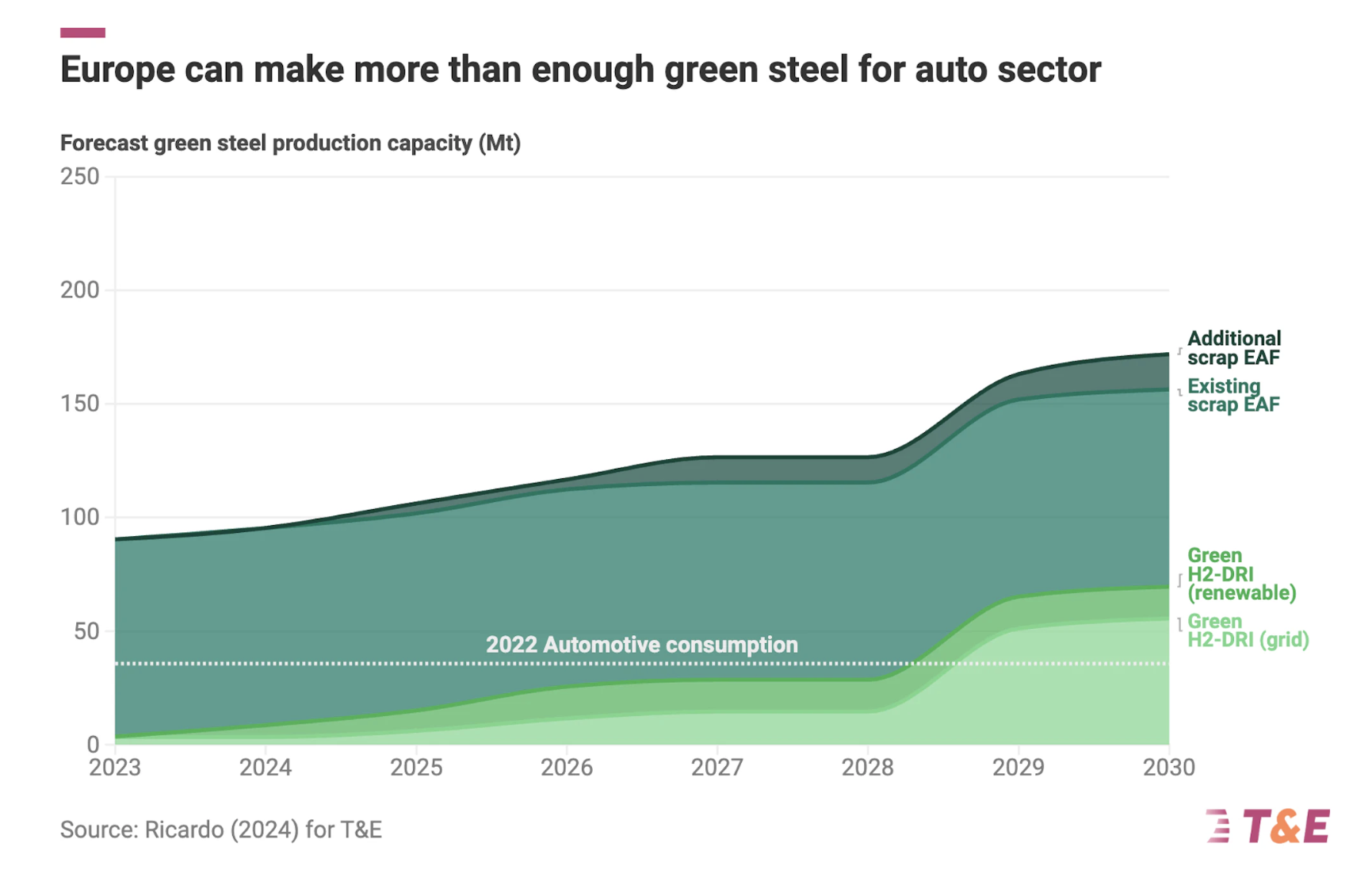

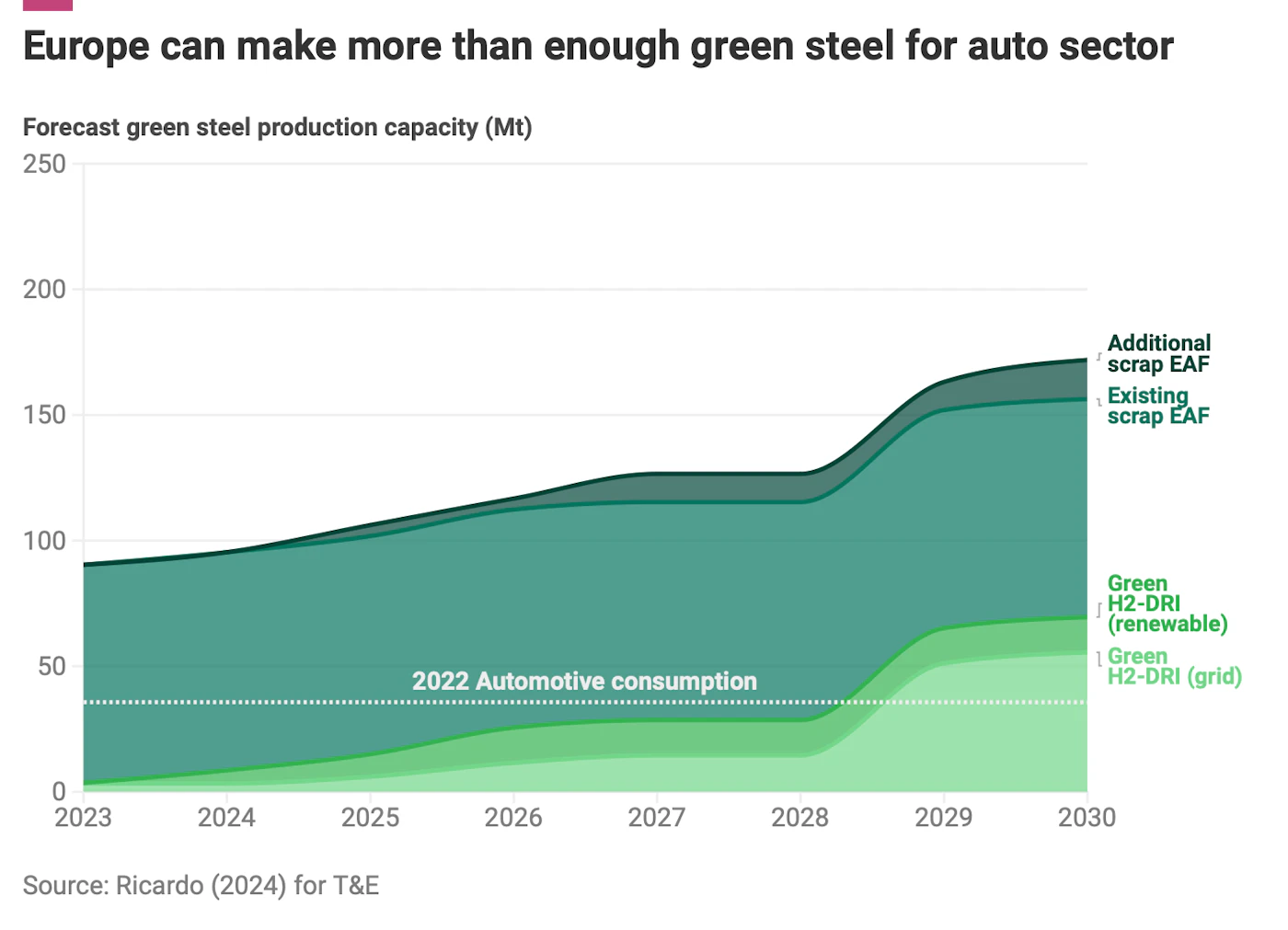

Europe will be able to produce up to 172 Mt of low-carbon steel a year by 2030, the report finds, based on Ricardo’s tracking of production announcements. This will be more than enough to meet the total demand for steel by the automotive sector, which consumed 36 Mt in 2022. The research also finds a shift to lightweighting will decrease the use of steel in the car sector in the next decade.

T&E said at least 40% of steel in new cars should be required to be green by 2030, rising to 75% in 2035 and 100% in 2040. Carmakers should be given an average target that can be met across all their new cars, allowing them to absorb the initial cost via premium models. This target can be introduced via the EU End-of-life Vehicles (ELV) regulation which is currently being revised by lawmakers.

Alex Keynes said: “The automotive sector is the second biggest consumer of steel and well positioned to be a lead market for green steel in Europe. The relatively high value of cars, especially premium brands, means they can absorb the short-term green premium of low-carbon steel.”

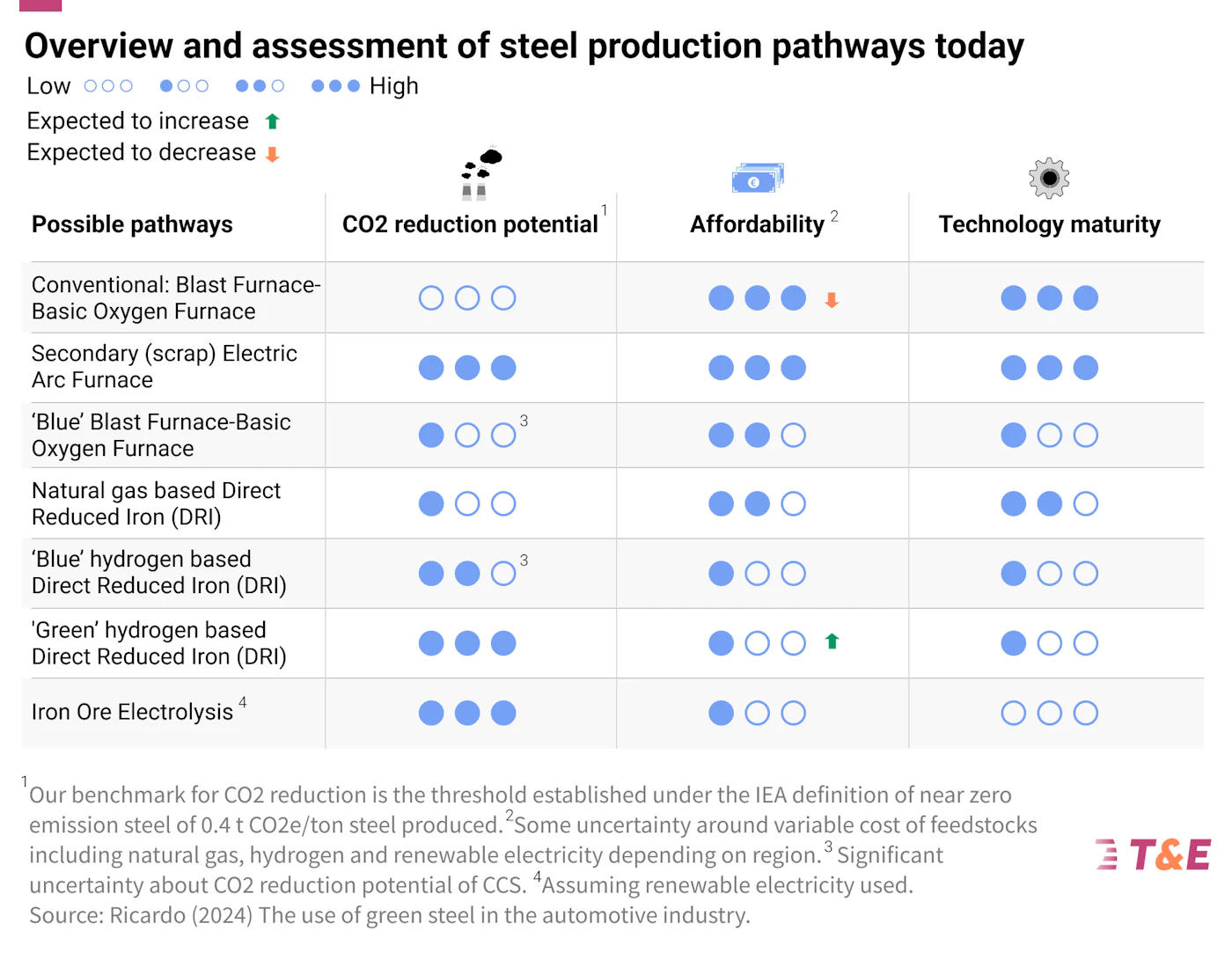

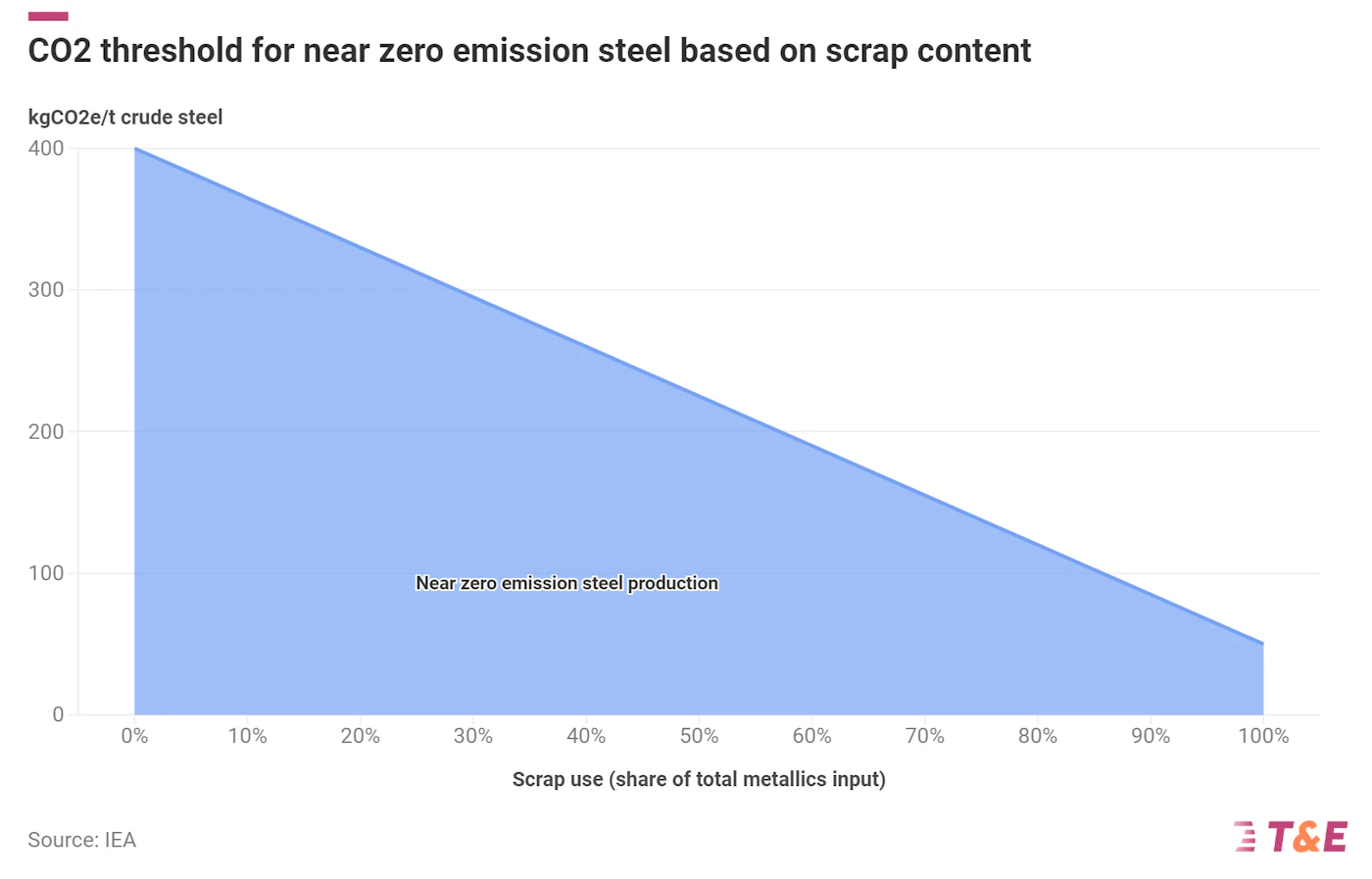

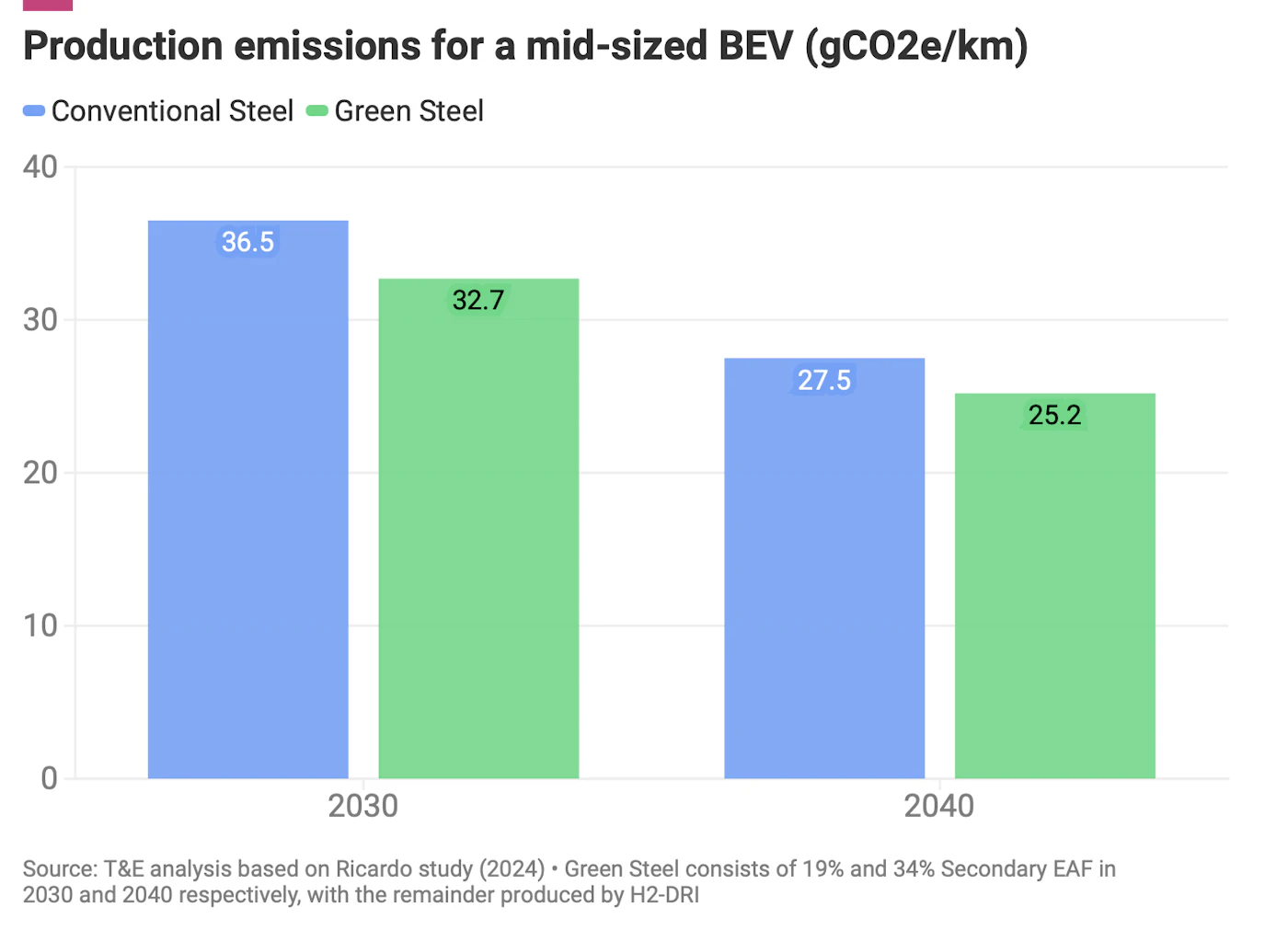

¹ Green steel should be defined as having a climate impact of between 50kg and 400kg of CO2 equivalent per tonne of steel produced, T&E said. This compares with between 1,800-2,250kg CO2 eq per tonne typically associated with producing conventional steel.

² T&E analysis of CO2 savings and cost is based on the findings of Ricardo’s study for T&E, The use of green steel in the automotive industry (2024). The study assumes that a shift to lightweighting will decrease the use of steel in the car sector in the next decade.

See full report.

Charts below from full publication: Cleaning up steel in cars: why and how?

Article from Transport &Environment.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica.TV Videos

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy