Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

In mid-2023, Green Builder Media’s CEO Sara Gutterman reached out to me to see if I were interested in presenting at their annual Sustainability Symposium. It’s been running annually for close to a decade, and with COVID it transitioned to virtual and won’t be going back. That event occurred a couple of weeks ago, and I was privileged to present my optimistic perspective on the transformation between RMI CEO Jon Creyts and Jeremy Rifkin, author and advisor to governments on multiple continents. Over a thousand participants were online for the virtual event. The following is the lightly edited transcript of my remarks and the question and answer opportunity.

For those who like videos and talk talk, here’s the YouTube.

Thank you for the wonderful introduction, and thank you, Jon, for the overview of the excellent work that RMI has done and continues to do. I have more future-oriented stuff. You’ll see a lot of themes out of Jon and RMI’s excellent work that will be projected forward into the future. Our low carbon future is coming fast, and it’s coming amazingly quickly, and it’s very spiky. I look for pockets of the future, and the pockets of the future are very broad.

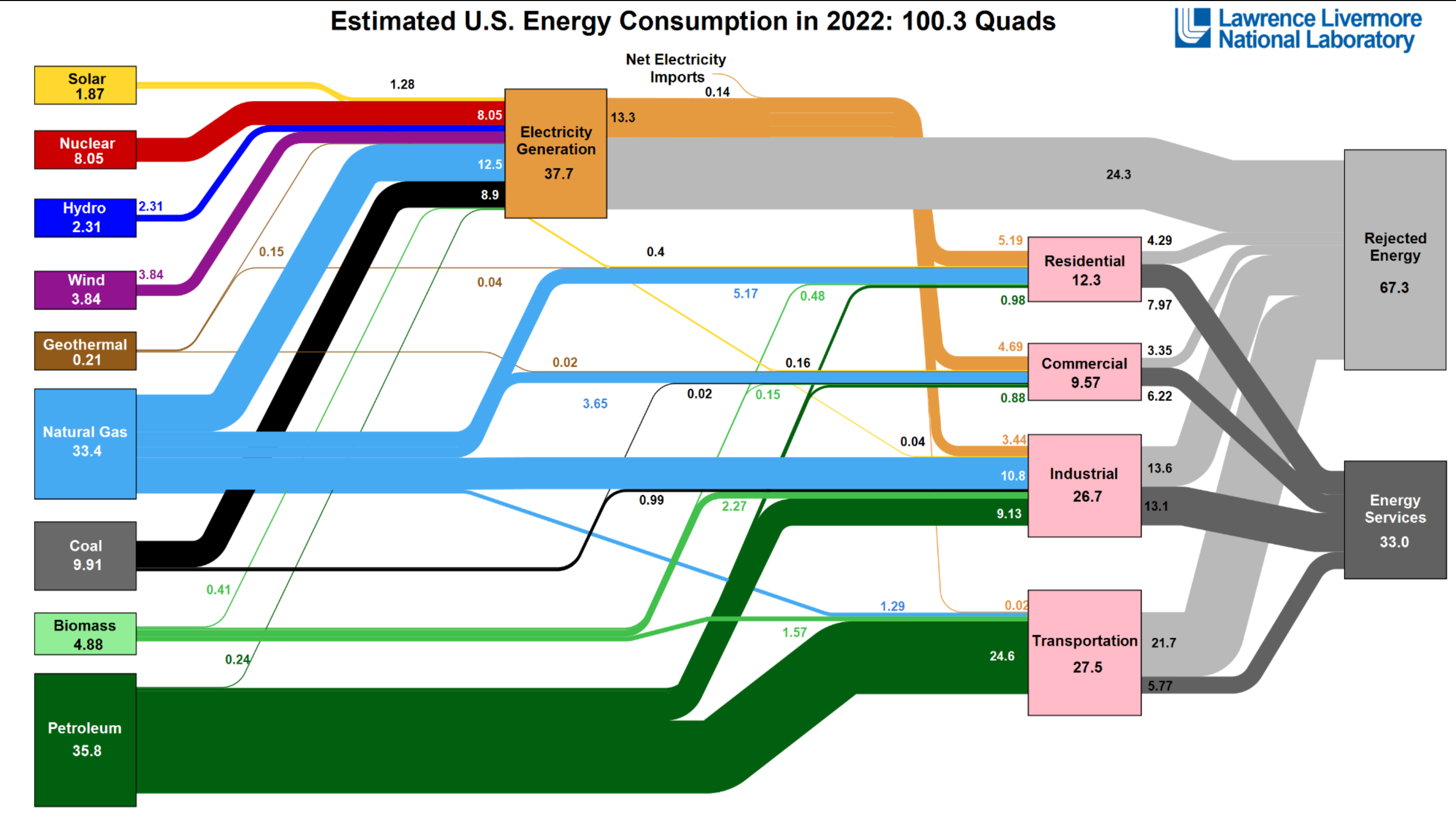

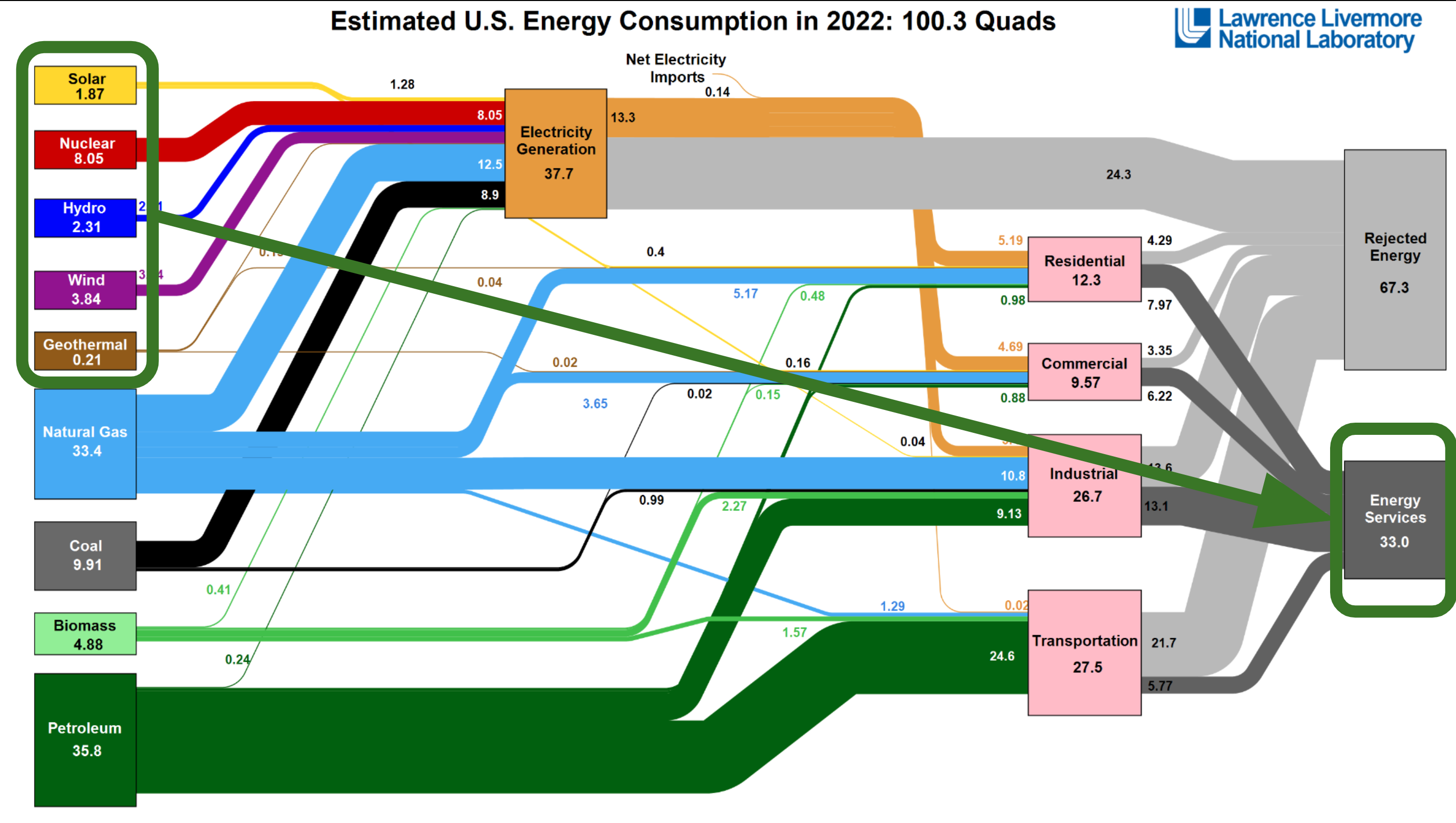

I like to start with this. It’s not as bad an eye chart as some, but this is a Sankey diagram of energy in the United States for 2022. What it says is, here’s all the energy that comes in on the left hand side into the United States economy. This is extrapolatable to every economy. The energy goes through electrical generation, goes into residential, commercial, industrial, and transportation and use cases and comes out here.

The reason this is important is because of this big gray box up here on the right, rejected energy. Rejected energy is the energy that comes in out of primary energy, which Jon mentioned, but we don’t actually get any use out of it. That’s because virtually all this stuff down here in the lower left, the petroleum, the coal, and the natural gas., when we burn it for energy, that’s a very inefficient process. We throw away a lot of the energy as waste heat, and we actually make a lot more carbon dioxide.

This is why we’ve got a problem today as we consider those energy pathways. One of the ways I like to describe fossil fuels is that when we burn them, they create CO2 and waste heat. And, oh, by the way, some useful work for us. That’s something that’s going to change.

As we look by comparison at those low carbon forms of generation up in the upper left hand corner — solar, nuclear, hydro, wind, and geothermal — there’s a lot less rejected energy. We don’t actually have to replace all of the energy on the left, we just have to build out the much more efficient pathways, drive them through electricity, and electrify all these end points, and we get to radically lower energy requirements for the same economic and comfort values for a society.

I’ve done the math on this. I do napkin math on enormous numbers of subjects, which is part of the reason I’m privileged to be here today with Jon and with Jeremy Rifkin, who follows me. But other people have done really deep math on this, like Mark Z. Jacobson and team out of Stanford. They are the ones who are responsible for the projections of 100% renewables by 2050. A very credible scenario, imperfect in some ways, as are all of mine, and I’ll share mine, but they’ve done the same math. And under 50% of the primary energy coming into the United States is actually required when we move to renewables and when we move to electrified energy services. Saul Griffiths also did that work, and he calculates that only 42% of the energy we actually use today is required to get everything we need and to not lose any comfort.

This is why I annoy long-term efficiency boffins, because I consider efficiency to be a secondary question. Electrification is first, efficiency is used to make it cost beneficial and more economical.

A heat pump takes three units of energy from the environment for every one unit of electricity, because we can do that with electricity. So all of the transportation is three to four times more efficient when electrified than non-electrified. Is that an efficiency measure, or is it an electric benefit of electrification? I tend to call it a benefit of electrification, which is why my short list of climate actions that will work starts, as so many do, with electrify everything.

Of course, the big question is, what electrical generation are we going to do? Jon talked about the plummeting costs of wind, solar, and batteries. That’s been absurdly beneficial. We now are building more wind and solar than the rest, than anybody could have projected.

The IEA got it wrong, famously, as Jon pointed out with one of his charts, but they’re getting better. The IEA was formed as an oil, gas, and coal organization about 50 years ago, and Fatih Birol is slowly turning the helm of an ultra-large crude carrier.

More to the point, we see amazing grid reliability. All the questions, all the concerns about intermittency of renewables are being answered. California is seeing 100% delivery of electric generation needs by renewables for many days, for many hours over many days.

Over the past few years, Denmark regularly sees over 100% from wind energy alone, and Germany is now approaching 60% renewables on its grid. Denmark and Germany have among the most reliable grids in the world, 13 minutes of outages per customer per year. This is not actually that hard to do. It’s a transformation. We are transforming our grids and our generation, but we’re doing it very effectively.

The more renewables are on our grid, it turns out the slightly more reliable the grid becomes. The transformation enhances things. This is an indication that this is where we’re going. I’m not going to dwell on it, because it’s one of the more obvious things.

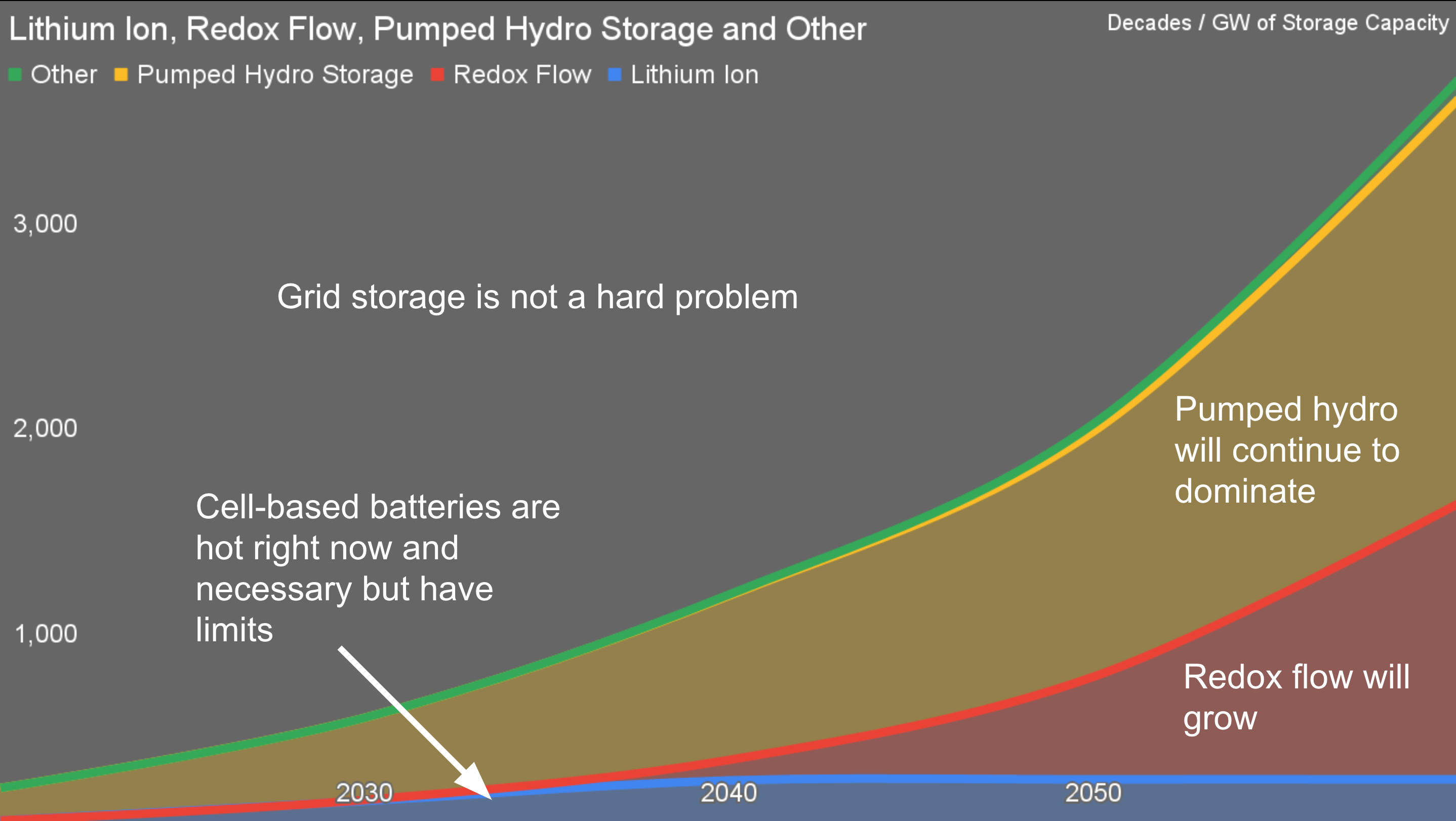

But what about longer duration storage? One of the big questions is how do we store all this electricity? What happens when the wind doesn’t blow and the sun doesn’t shine? There are a couple of answers to that. This is my projection of grid storage requirements through 2060. It’s slightly adjusted based on the decline in cell-based battery costs recently, but it still holds true in my opinion.

The first question about intermittency that we have to ask is how intermittent are wind and solar in reality? The wind doesn’t blow all the time. That’s not quite true. The wind doesn’t blow as strongly all the time. The sun doesn’t shine as brightly all the time. And at night, of course, it doesn’t shine at all. Wind farms actually generate electricity 85% of the year, just not at 100% of their maximum potential.

We actually get 85% coverage of some demand from wind farms. And for solar farms? Whenever the sun is shining from the beginning of the day to the end of the day, some electricity is coming out of solar farms. So we actually have overlapping curves with wind and solar, which are easier to accommodate than you might think. It’s not like a nuclear plant. If the nuclear plant shuts down, as happened in Texas a couple years ago in the ice storms, that’s just off. There’s no degradation, there’s no slow ramping down of a nuclear plant.

But what will work? Pumped hydro is going to be the dominant one for energy storage on grids, just as it is today, just as it’s been since 1907 when the first one was built. This is a highly commoditized solution. It’s great for coal country. I’m fascinated that the discourse in the United States does not include turning coal workers in coal country to building pumped hydro more. It’s just an obvious thing using very strongly overlapping skills and domain knowledge.

It’s going to continue to grow. I have a proof point for that. One of the things I’m doing is an ongoing series of discussions with India’s utilities under the auspices of India Smart Grid Forum. That means I’m spending more time learning about India.

They have 19 gigawatts of pumped hydro under development, and they have projected a capacity of 106 gigawatts. I think that’s light, based upon the work of the Australian National University. Their GIS model shows enormous closed loop off-river pumped hydro resource capacity just north of the highly populated New Delhi region in northern India. I’ll be talking about that explicitly within a couple of weeks.

We also have redox flow, which is basically big tanks of chemicals with the battery part in between instead of all the chemicals inside the battery. You can scale up energy storage and have the power storage decoupled from that. I’m bullish on redox flow as we move forward.

Cell-based batteries are really hot right now, lithium-ion especially, but they have limits. They are cost effective for 4 to 8 hours. They’re great for putting sunshine from the afternoon into the evening, but we need longer duration than that.

When I talked to Mark Wilson of Intelligent Land Investments in Scotland recently, he had just sold his developed pumped hydro facility on Loch Ness to Norway’s Statcraft, which is building pumped hydro globally. Mark and company are also delivering cell-based battery solutions at a tremendous rate in the UK. His perspective, however, is that the entire projected demand for that short term battery storage, which is so highly valuable in the UK, will be finished in 2028 or 2029. It’s a short term opportunity to put those in. Then it’s a replacement as they age out.

The growth potential for cell-based grid storage is not nearly as big as assumed. Some of that is because we’re going to build more renewables, and some of it is because we’re going to build a lot of high voltage direct current interconnecting major geographical regions.

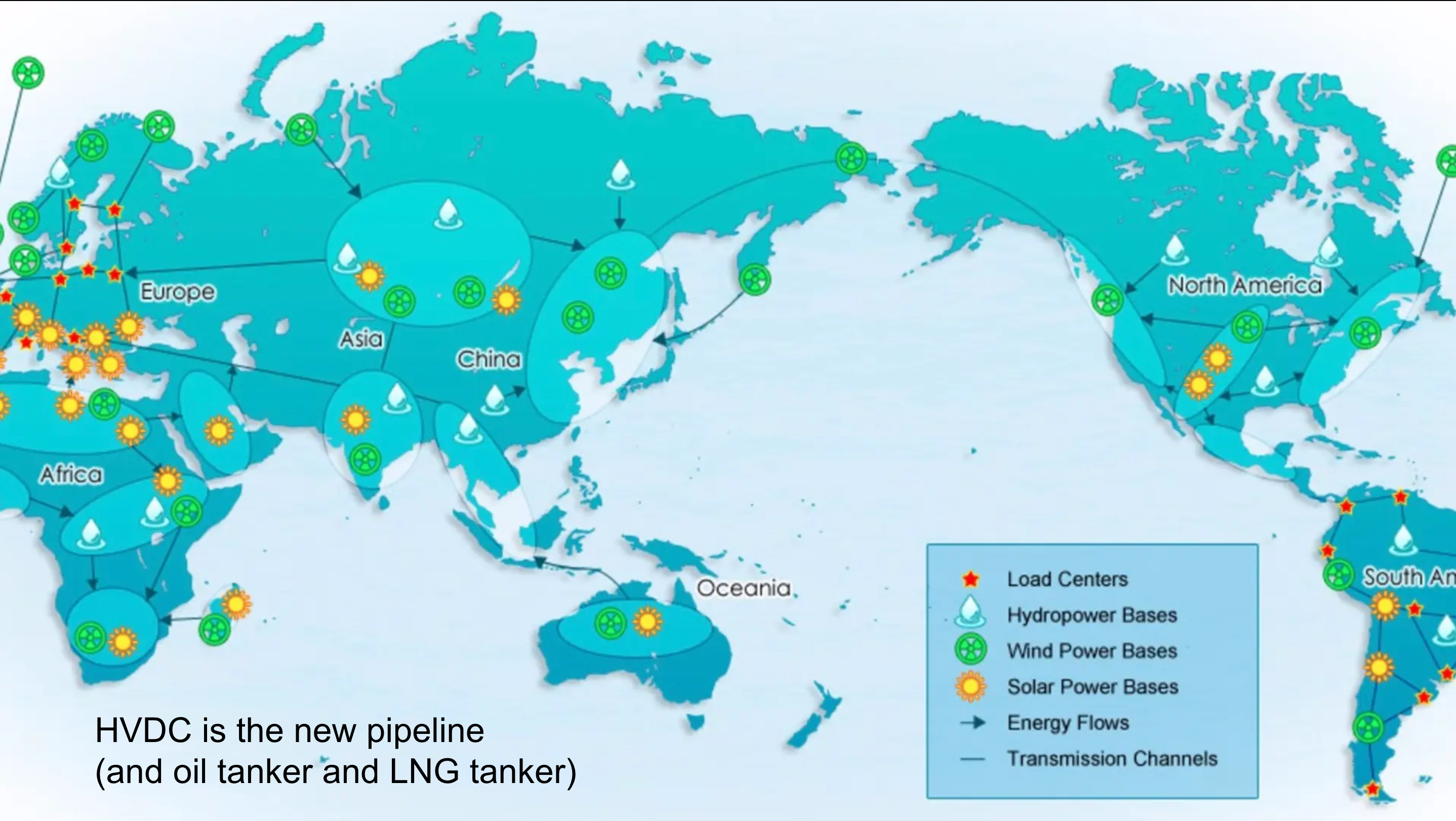

I like to say that high voltage direct current transmission is the new pipeline, but it’s also the new oil tanker and LNG tanker. As we generate a lot more electricity inside countries and because we’re using it so much more efficiently in electrified solutions, we don’t actually have to import as much energy into fossil fuel poor areas.

Every place has sunshine. I lived in Singapore, the tiny dot at the bottom of Malaysia here. Even Singapore can reach 15% of its electricity demand today with solar, and it’s building a lot of solar on top of all its rooftops. Local renewables inside a country, and much more efficient use through electrified systems, means a lot less energy needs to come into the country or region through pipelines or tankers or LNG tankers.

This diagram is from GEIDCO, which is the global energy interconnection development cooperation organization. It’s a UN organization, but it was kicked off by China in 2015 or 2016. To consider how seriously China takes this, the premier of China was at the launch. The executive chairman of GEIDCO is the single person at the top of all grid planning and development and deployment in China, and the person responsible for the development of the Asian Supergrid. This is a massive component of what we’re talking about.

As one proof point on this, the Belt and Road Initiative is in almost the same countries as GEIDCO. The Belt and Road Initiative and GEIDCO were involved in a 12-country, 10,000-kilometer sub-Saharan Africa Supergrid assessment to link the western sub-Saharan part of Africa across to the east, into Kenya and down south into South Africa, providing a strong backbone for electricity sharing across renewable zones in Africa to assist in electrifying the billion people that live there.

There’s a tremendous amount of work that’s being done in this space and it is somewhat invisible to North American audiences. There’s really good news happening globally around the world with these types of things.

When we start talking about the efficiencies of use, I always like to start with transportation. This is a fun ChatGPT and DALL-E generated image of a futuristic San Francisco with all electrified transportation.

Right now, battery-electric cars have won globally. There is no alternative that is delivering the same value proposition. Their range is increasing. Prices are coming down. There’s a blip in the west around slowing purchasing of electric vehicles right now, but I like to compare that to when I flew from Singapore to Las Vegas in 2014 for WindPower 2014 under the auspices of the American Wind Energy association.

Everybody in Vegas was depressed because of the looming end of the investment tax credit. And I was wandering around thinking, why is everybody so down-faced? Because I’d been in Singapore and I was paying attention to China’s wind energy development, to Latin America’s wind energy development, where I spent time in São Paulo talking wind overlapping with hydro in that great country, and also looking at Australia, and everywhere else wind was booming.

What we’re seeing in terms of the narratives around electric vehicles right now, in other words, are a blip and they’re more of a geographically constrained blip. Growth in the biggest car market in the world, China, is not of internal combustion vehicles and EVs are not slowing down. Similarly, India, where I’m spending a fair amount of my attention these days, they’re expected to have 50,000 electric buses on the roads by 2027. And they actually have thousands of electric buses on their roads right now.

One nice thing that India has is they don’t have the expectations that we have of having a 100% replacement for our current best-in-breed solution. They’re much more interested in right-sizing. One of the things that they’ve done with their buses is they said, how much battery do we need to service our different routes? They’ve bought buses with smaller batteries for shorter routes, medium batteries for medium routes, and bigger batteries for bigger routes, and put a lot more buses on the roads. Instead of having every bus be able to service the maximum route, they have buses to serve their minimum routes. It’s an obvious thing, not really done in North America or Europe in the same way, but tremendous stuff there.

Similarly, on trucking I spent quite a lot of my time in the past six months going through international organizations and research papers on electrification and decarbonization of freight trucking on the ground. I was involved with a Swedish study, which was simulating all freight trucking for Europe. Once you tear apart the assumptions, the reality is battery-electric freight trucking is going to dominate.

We’re already at a point where in the North America, the North American Council for Freight Efficiency’s Run on Less program in September of 2023, a couple of Tesla semis had service days of over 1000 miles each. That was an electric truck with two or three drivers over the course of the day, a couple of fast charges, driving 1000 miles in a single day, delivering lots of Pepsi, flats of Frito Lay, and the like. While the Tesla Semi is head and shoulders above the rest, because it’s built from the ground up for battery-electric trucking, it is not alone. There were five or six other vendors, all strong battery-electric trucks. All were doing service deliveries of 500 miles a day.

It is obvious that with the battery improvements that we’re seeing and megawatt-scale charging, like the 960kW liquid cooled charging system that a Chinese manufacturer just unveiled, which provides 400 kilometers or 250 miles of range in 36 minutes of charging for a freight truck that’s bigger than a class eight freight truck in the United States, that this is all technically doable — it’s engineering and economics.

The rest of the world outside of North America is just electrifying railroads. The Trans Siberian railroad, 9300 km through some of the most inhospitable terrain in the world is running, is electrified. China’s massive growth of high speed rail, now 45,000 km, is all electrified. India is actually going to be finished electrifying all of its heavy freight rail this year. I will say the United States is really recalcitrant on the point of electrifying rail. There are reasons for it, but the United States is lagging in terms of rail and it’s lagging in terms of freight trucks and buses. China has 1.2 million electric trucks and buses on its roads while the United States is just getting started.

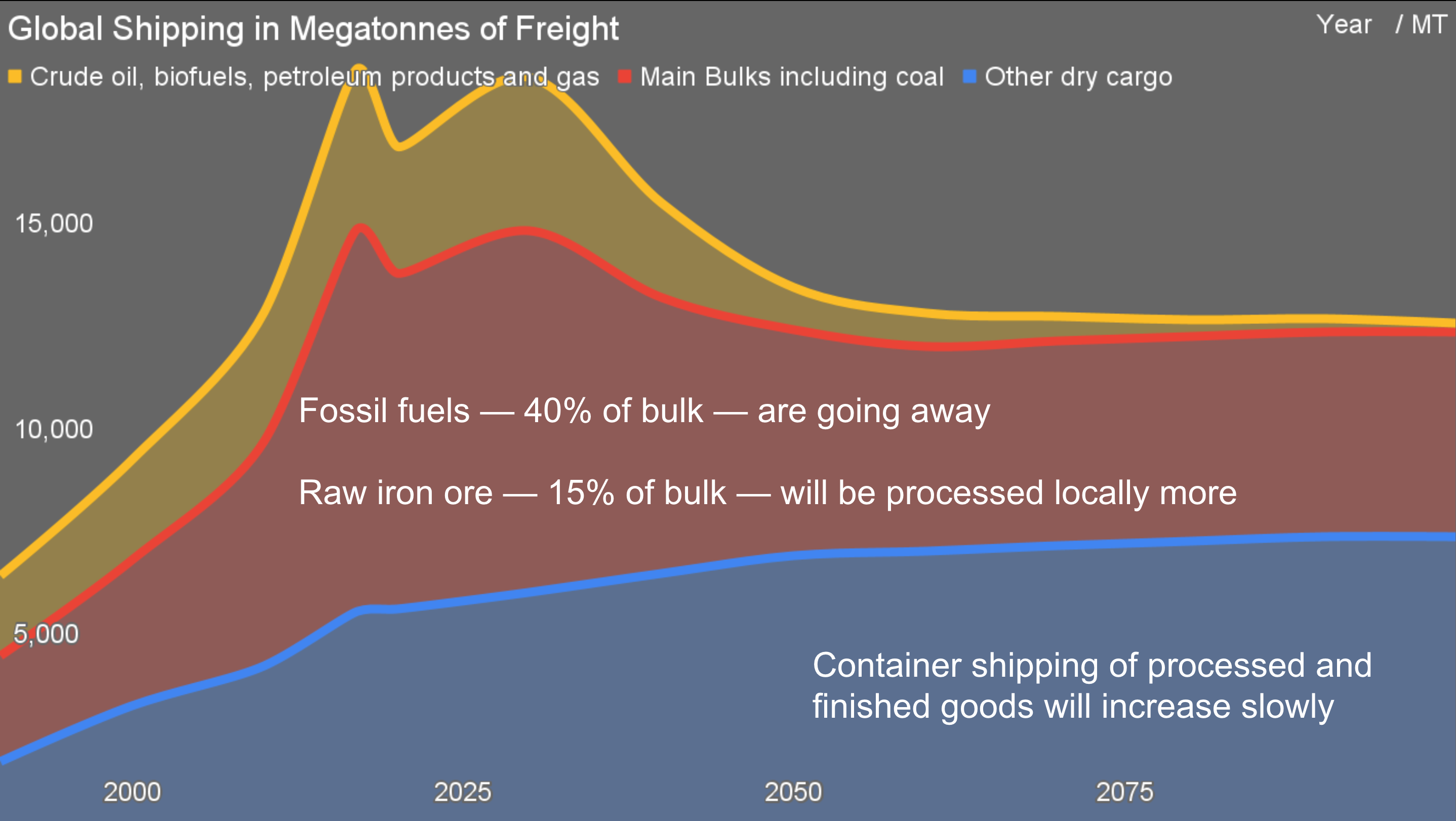

So great news around the world on ground transportation. But what about the hard-to-abate sectors like maritime shipping? There’s some great news there too. Did you know that 40% of bulk shipping that’s crossing our oceans is coal, oil, and gas? And that’s going to go away in the next few decades. In other words, all the fossil fuels we burn to move bulk cargo across the oceans are going to diminish naturally as we stop using fossil fuels. And that’s not all. Another 15% of bulk is raw iron ore. Most of those ship loads are steaming to the same ports the coal ships are going to, where they’re put into blast furnaces. As we decarbonize maritime shipping, the cost of fuel will go up a bit.

As we decarbonize raw steel, which I’ll talk more about later, we’re going to stop using coal for that and we’re going to start using green electricity for it in a couple of different ways. That means we’ll actually be able to process the raw iron ore into iron, or even steel products much closer to the mines, and ship just container loads of iron as opposed to bulks of iron ore.

While container shipping of processed and finished goods will increase, it won’t increase as rapidly. We had a very rapid increase from 1980 to 2019, but a lot of that was due to the unprecedented speed of growth of China’s manufacturing capabilities and delivering stuff to the west for our consumer economies. While India, Brazil, and Indonesia are growing, they don’t have the conditions for success to grow as rapidly as China did. Their growth will be slower than China’s, while still enviable to those in the west whose rapid growth periods are mostly behind us. They’re going to be bringing their populations out of poverty, and as Jon said, leapfrogging, in most cases more slowly than China.

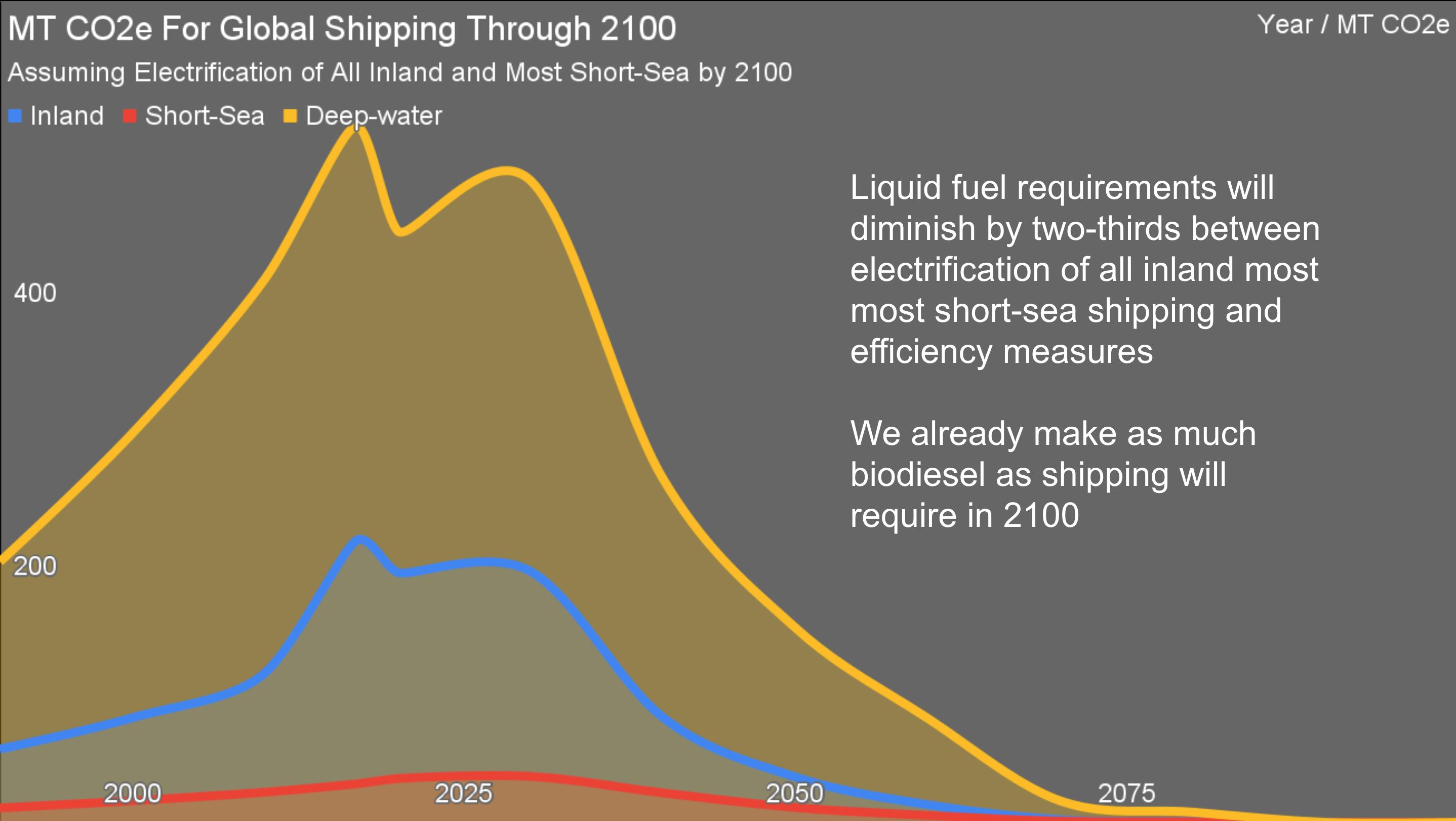

The combination is really good news as we move forward, but there’s also more good news. We don’t actually have to burn fuels in a lot of the ships. In my projection of maritime shipping through 2100, I looked at all inland, short sea, and deepwater shipping requirements, and I worked out the math on it. I unified the datasets because they’re different segments in the way the shipping industry thinks of them, so they don’t have a unified data set. And all the inland shipping, the stuff that goes up the Mississippi or the Yangtze, that can all electrify. Most short sea shipping, like in the Caribbean, for example, or between Norway and Germany or Denmark and Sweden, that can all electrify. These are routes that are just not that long.

But length of routes isn’t really the point, it’s the economics. A 2022 study that was published in Nature did the math and said, if we had batteries that cost $100 per kilowatt hour of capacity, for example a Tesla 60 kWh battery pack would cost $6,000, if we had that freight journeys of up to 1,500 kilometers, about 900 miles would be viable with batteries with virtually no loss of cargo capacity.

When we talk about batteries and ships, ships carry massive amounts of stuff, and they have lots of volume. Batteries don’t take away that much space. $100 per kWh was breakeven for 1500 km, except that we’re already below $100 now. This year CATL, which Jon mentioned a couple of times, are projecting that they’re going to be selling their basic batteries for $56 per kilowatt hour this year. We’re seeing very likely $30 per kilowatt hour, a third of that $100 breakeven point, in 2030. The transformation in this space is going to be tremendous.

Here’s another proof point. Last year, a Chinese shipping organization launched two 700-container ships. They’re not huge. The biggest container ships are 24,000 containers. But 700 containers is not something you put in your garage. This is 700 containers that are eight and a half feet tall, eight and a half feet wide, and 20 to 60 ft long. 700-container ships, two of them, they’re traveling 1000 km — that’s 600 miles — routes on the Yangtze with containerized batteries. They winch the battery container off and drop it on the transshipment port where it gets plugged in to recharge, and they winch a full battery back onto the ship. This is very easy to do. It’s already being done.

That doesn’t mean that we don’t need some burnable fuels for crossing oceans, but we need a lot less than most people think. In my projections, I don’t claim to be right, I merely claim to be less wrong. Take this as a projection that is likely from one individual. There are other projections which should also inform any strategic decision making you make.

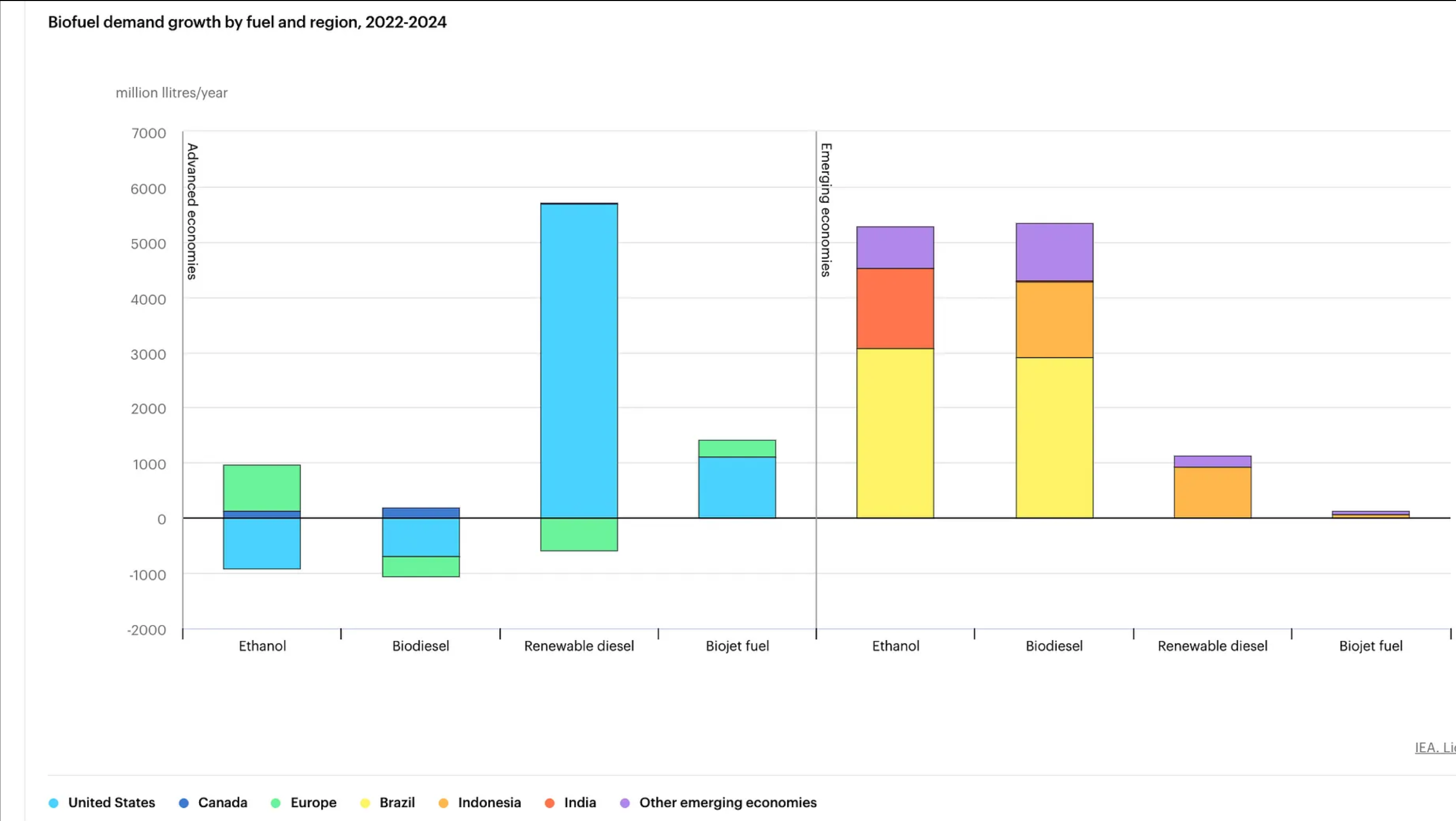

But if my projection is accurate, we only need about 70 million tons of maritime diesel or equivalent to burn for all shipping in 2100. And per the International Energy Agency’s renewables update from late last year, we already make 70 million tons of biodiesel, we just waste it on ground transportation, which as I shared, is all going to be electric.

So there’s really good news. That means the carbon curve for shipping is going to plummet. Biofuels are becoming increasingly beneficial as we use them with waste biomass. I’ll talk a bit more about that later.

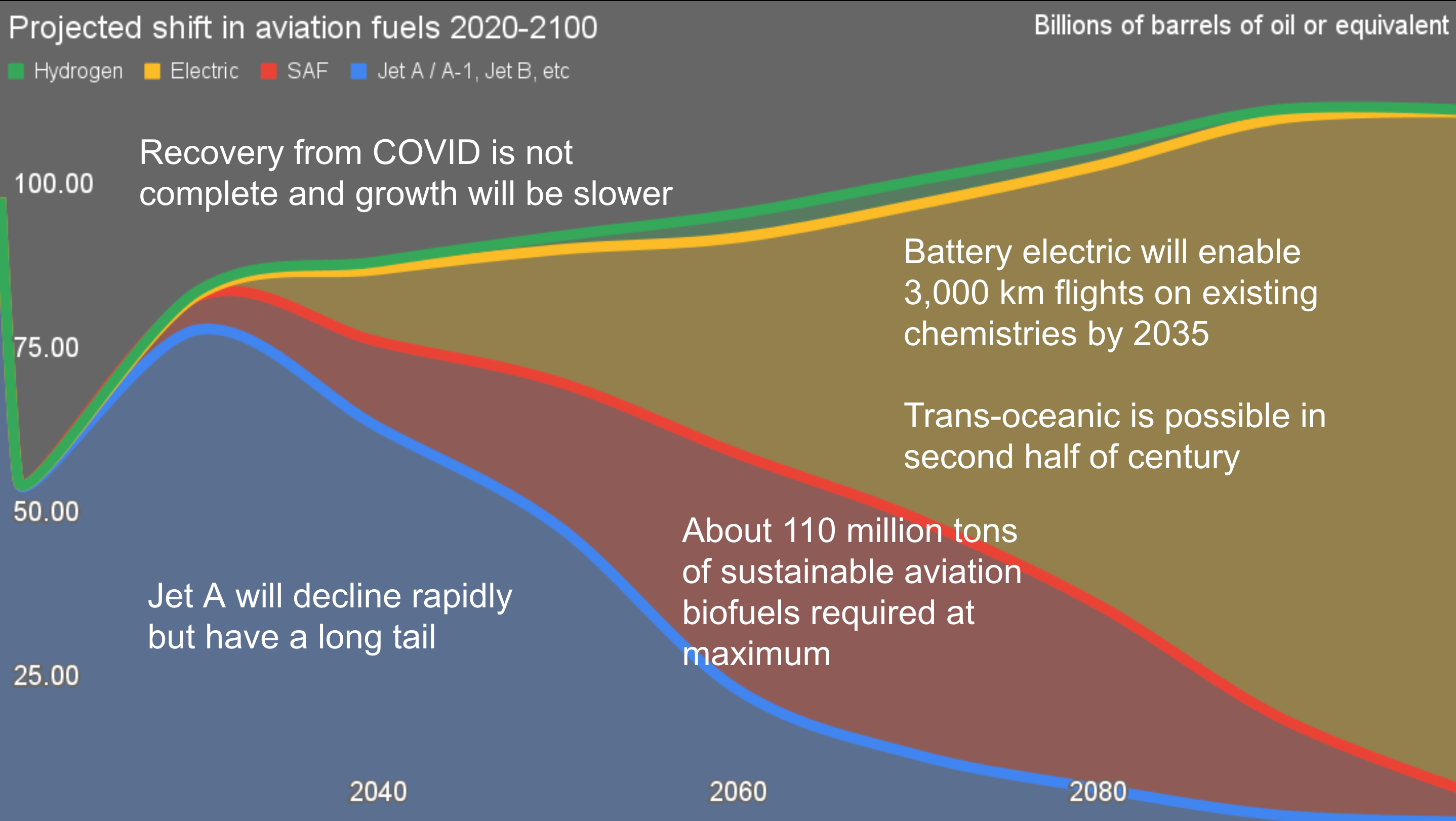

But what about aviation? What can we do with aviation? It’s another hard-to-abate segment.

COVID was proof that we don’t have to fly as much as we do. We just like to fly. The recovery from COVID isn’t finished, and it’s not going to have the growth projections that it had in the past. Once again, the rate of global change of affluence between 1980 and 2019 was unprecedented. I don’t expect it will continue as much.

There are several inhibitors on the growth of aviation. One of the key ones is simply that as we decarbonize aviation and we replace that with sustainable aviation biofuels, they’re going to be more expensive than current fuels. The airline industry has 19% of their expenses as fuel. If that doubles or triples in price, those get added to tickets. It’s a significant enough purchase for most people that it will reduce their likelihood of taking flights.

Further, high speed rail is growing globally. We’re seeing enormous numbers of passenger miles being taken in China, where people have just said, why would I bother to fly when I can go downtown by subway, get on a train, get off a train without going through much security. A couple hours later and I’m in Beijing. It’s just more convenient to take the train if the train is going 350 kilometers per hour. We’re seeing a significant reduction in flight growth there.

There’s more high speed rail in India, Indonesia, and even in Africa than there is in all of North America, which is quite remarkable to me. Europe has about 19,000 kilometers of high speed rail and is seeing a significant shift of passenger aviation, passenger movement to rail through policy and governments. France has made it a policy that if there’s a rail line that goes between two cities, and under 2.5 hours, they’re not going to allow flights between those places. Why would we support aviation between those when the train gets here fast enough?

The battery energy density that Jon was talking about, in terms of CATL’s 500 watt-hours per kilogram. Many organizations thought we wouldn’t see that till 2050, and we saw it in 2023. We’re seeing much more rapid progress than most thought. Battery-electric drivetrains are vastly more efficient. They’re 80% to 90% efficient versus 50% efficient for modern jets when the modern jets are at 38,000ft at optimum cruising speed.

Battery-electric is just as efficient on the tarmac when it’s taxiing, when it’s taking off, and when it’s landing. We’ll start with smaller airplanes. Battery energy density right now are sufficient for a hybrid drivetrain in a turboprop that would carry 100 passengers 600 km, with divert and reserve.

That we’re not doing that already is in part because of certification to ensure safety, in part because the major OEMs in aviation have unfortunately had some really interesting times and are having trouble innovating. They can invent and they can do demonstrations, but the challenges that Boeing had recently with its major new airplane are indicative of a problem in the aviation industry that’s going to go away.

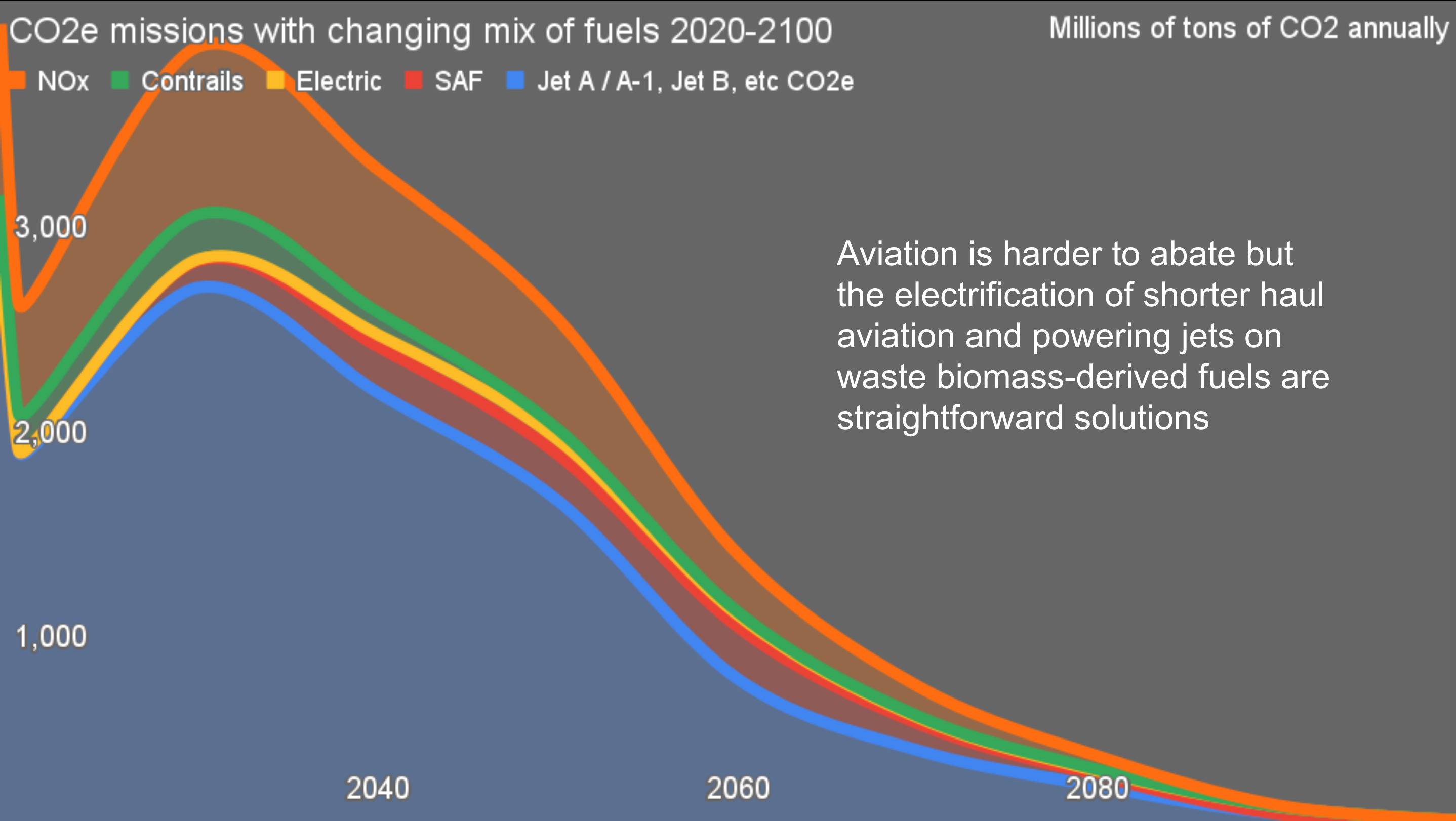

Only about 110 million tons on top of the 70 million tons of diesel for maritime use is required at peak. We already make 100 million tons of biofuels, and we have a lot of waste biomass capacity, which I’ll talk about a bit more.

Here’s the CO2 projection. It goes down a lot. Contrails go down, the nitrous oxides go down, and agriculture and waste biomass derived fuels actually could arguably make aviation fuel carbon negative.

This is a positive story about aviation growing more slowly, but still growing, and decarbonizing much more rapidly than you might think. This is real zero, not net zero, in my projection. We don’t get down to real zero in 2050, but we’re close.

Singapore Airlines has Neste providing 1.5 million tons of sustainable aviation biofuels in Singapore for its operations today. There will be carriers who are actual zero by 2050 quite easily.

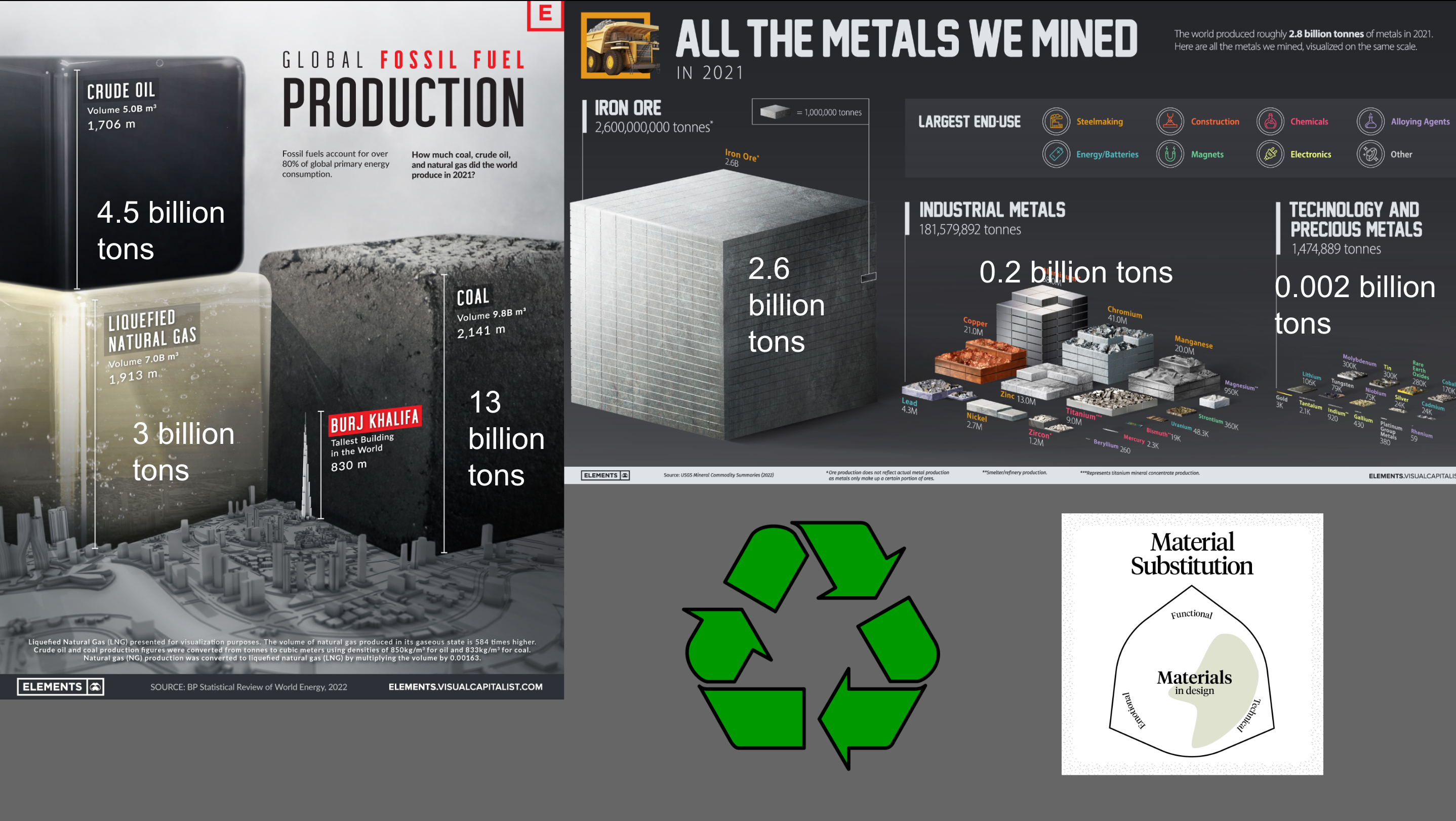

What about the minerals? Thank you to Visual Capitalist for the infographics. Over on the left, we have about 20 billion tons of fossil fuels between coal, oil, and gas that we extract, process, refine, and distribute, mostly to burn once. It’s not reusable, there’s no recyclability.

Despite discussions about carbon capture and carbon capture use, we can’t reuse or recycle that much waste because 20 billion tons, when we burn them, turns into 40 to 60 billion tons of carbon dioxide. The entire global market for carbon dioxide today is 230 million tons, many orders of magnitude below that. About 90 million tons of that CO2 is used for enhanced oil recovery. Be skeptical every time somebody says we’re going to capture carbon and sequester it as a way out of our dilemma.

On the right, here’s some quantification of that question that was asked earlier. The industrial metals are 0.2 billion tons, three orders of magnitude below fossil fuels. Recyclable long term durable goods, aluminum, copper, chromium. Technology metals, which is to say the battery metals like lithium, is 0.002 billion tons.

It’s a rounding error compared to the extraction of fossil fuels today. The range between those two is enormous. Yes, we have to double or triple our extraction of some of those metals, but it’s from a very small base. Part of the reason our lithium shortage last year and the blip in battery prices disappeared was because firms just turned on more capacity.

There are a lot of minerals under the earth, and there’s something else going on, material substitution. Material substitution says, I have a copper electricity wire. Well, I could have an aluminum wire instead. Most overhead wires that we see as we drive around actually have aluminum cores with steel for a bit of reinforcement.

Now we’re seeing composite transmission lines and reconductoring. The composite cable has a carbon fiber core instead of a steel core, with annealed aluminum conductors around it. It’s stronger and lighter than steel core transmission cables, doesn’t sag as much when it heats and can tolerate higher heat. We can actually reconductor existing transmission lines with these new composites and put 30% or 40% more electricity through them quite easily.

We can build new transmission lines with the pylons further apart, and they’re cheaper. So in the space of electrification, we have vast ability to substitute while in the space of fossil fuels, you can burn coal or you can burn liquid natural gas or you can burn crude oil, but you don’t have much other substitutability there. Substitutability is a key message that gets missed in the materials discussion.

We’re already recycling enormous percentages of metals. There’s a disinformation meme out there saying we’re only recycling 5% of batteries. That’s the 5% of the batteries in my Apple Watch. When we come to EVs, where there are big batteries, we’re already at 95% recycling of EV batteries, even at this nascent stage, because there’s so much high quality, pure minerals in them in a single accessible ton.

The last lever is just reuse. Call it 80 kilograms of lithium in a battery in a Tesla Model 3. It operates for ten years and gets recharged thousands of times. It’s just being used over and over again without being depleted at all, without creating CO2. Then, we will take a bunch of them out of the Model 3s at end of life and stack them all together and create a behind-the-meter battery storage facility for a light industrial site so that we don’t have to increase transmission to it. We use it for another ten years until it’s degraded to 70 or 80%, and then we mine those batteries and turn them into new batteries.

Michael Liebreich refers to this as one of the superheroes of the transition. As we get even more efficient at all these things, we get close to the point where we have a fully circular economy for battery minerals. The degree of disinformation in this is rife.

To pull a thread from the beginning, we don’t have to replace the energy in 20 billion tons of fossil fuels, we have to replace the energy services because of all the waste that comes from those. Then we get over and over and over reuse, we get material substitution and we get recyclability. Our requirements for minerals are a tiny fraction of fossil fuels, and we’ll just be using them more and more.

I promised a bit on biofuels. This is the chart from the International Energy Agency 2024 Renewables update. If you count it all up, we’re already manufacturing 100 million tons of biofuels annually, and about 70 million tons of it is biodiesel. Between renewable and renewable diesel, there are different categories and ways to cut it. We’re already bunkering biokerosene in jet aircraft and biodiesel in ships.

Here’s a slightly stinky story. The EU has 1.4 billion tons of livestock dung waste a year now. Livestock dung, you think? One of the things you can do is turn it into kerosene for jets. It’s an engineering problem and an economic question, not a scientifically difficult thing. It’s just biomass. Every ton of dried biomass turns into about 0.4 tons of high quality biofuels. And so if you have 1.4 billion tons of livestock dung and say 50% of that mass is water you’re down to 700 million tons. At 0.4 tons of biofuel per ton of dried biomass, that’s 280 million tons of biofuels just from livestock done in Europe, which right now emits a lot of high global warming potential methane.

That’s not the only waste stream. We also have 2.5 billion tons of food waste. That’s a full third of the calories we manufacture every year globally. We throw it in landfills. There is no caloric poverty, there is a distribution problem when it comes to calories. There is no “biofuels competing with calories for people” problem except in micro local places. We’re wasting vast amounts of biomass, which frequently turns into methane, and we have to fix that. Part of the fix is turning it into the relatively small numbers of biofuels we require for long haul aviation and shipping when we electrify everything we can.

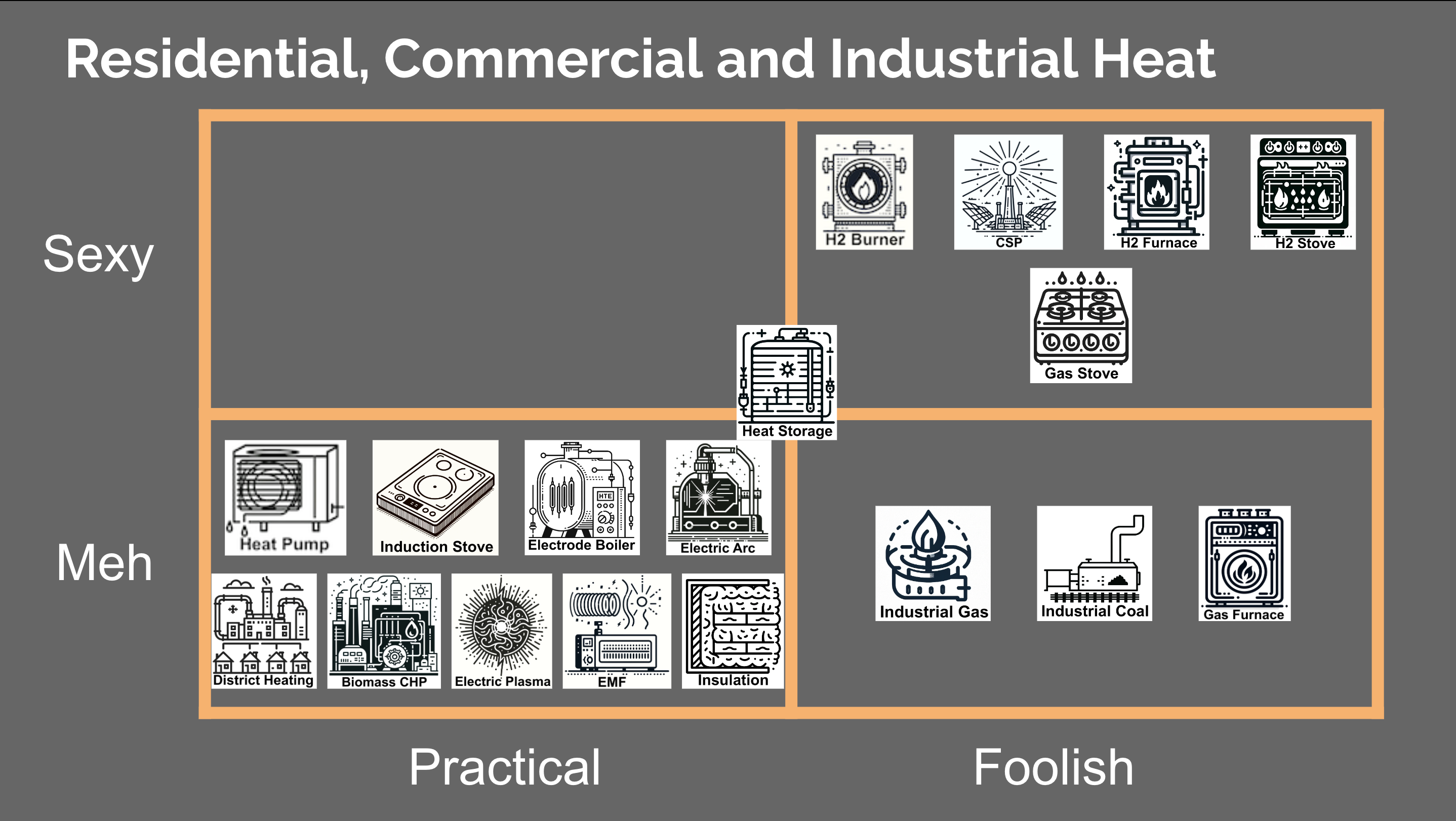

But what about heating? I’d like to draw your attention down to the bottom left corner of the sexy versus meh, practical versus foolish quadrant chart. I did a series of these charts across multiple decarbonization dimensions, and I’ve iterated them couple of times. Just look at all the technologies in the practical and meh quadrant.

Heat pumps, they’re amazing. 45% of industrial heat is under 200° Celsius. We have heat pumps that can deliver 200° Celsius heat.

Induction stoves are better to cook with than gas innumerable ways, and they’re all over much of the rest of the world. I was doing a digital nomad spell in New Zealand last year for a few weeks, doing a speaking tour about transformation of radical electrification of transportation and other things. Every unit we stayed in had an induction stove. It’s just common across Asia. Electrode boilers, electric arc furnaces. I’ll talk a bit more about the up to 3,000° Celsius heat used in electric arc furnaces for scrapping steel. We have all the heating solutions we need. District heating is huge. Combined heat and power with biomass, as long as it’s combined heat and power, I’m somewhat okay with it, but I’m considering moving it over to the foolish quadrant.

Electric plasmas are now up to the temperature of the sun and are used for certain classes of ceramics that are fascinating. Electromagnetic frequency, like microwaves. Industrial microwaves are there. And yes, insulation. Insulation helps too.

We also have the emerging area of heat storage. It’s not a slam dunk, it’s a bit overhyped in some ways. It’s too much into the sexy and foolish space, especially when it talks about being used for storing electricity and then retrieving electricity, that’s a very inefficient pathway for electrical storage. But when we talk about industrial heat, where we have one process which creates heat, and a process a few hours later which needs heat just because of the mechanisms, heat storage makes sense. Heat storage makes sense even down at the domestic level. I spent time with Harvest Thermal’s CEO, and they’ve built a hot water heater that’s a CO2-based heat pump that puts hot water into a big tank of water and then uses that for domestic heating and domestic cooling. California innovation and now being applied to mobile unit residential buildings in Brooklyn and elsewhere.

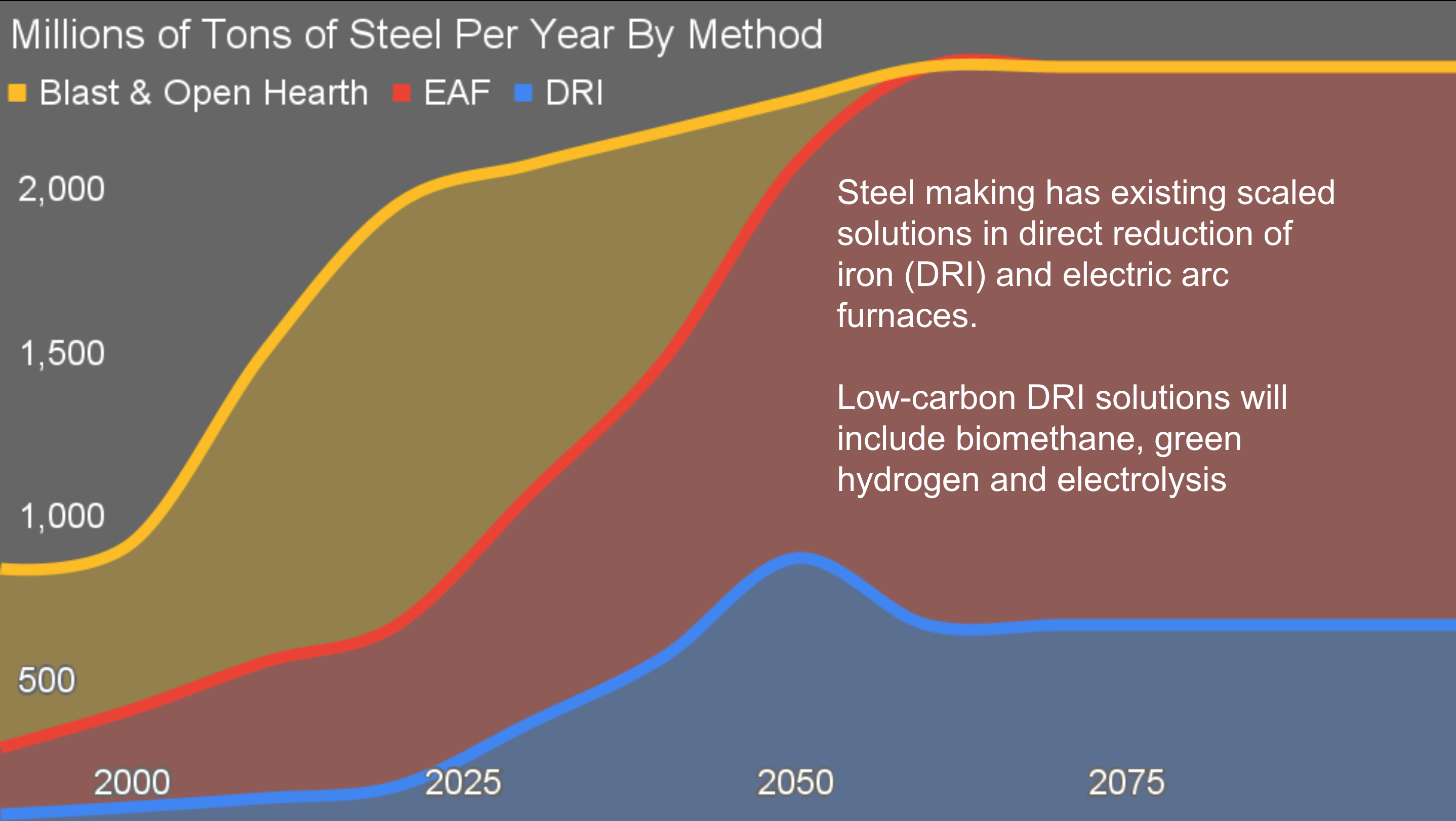

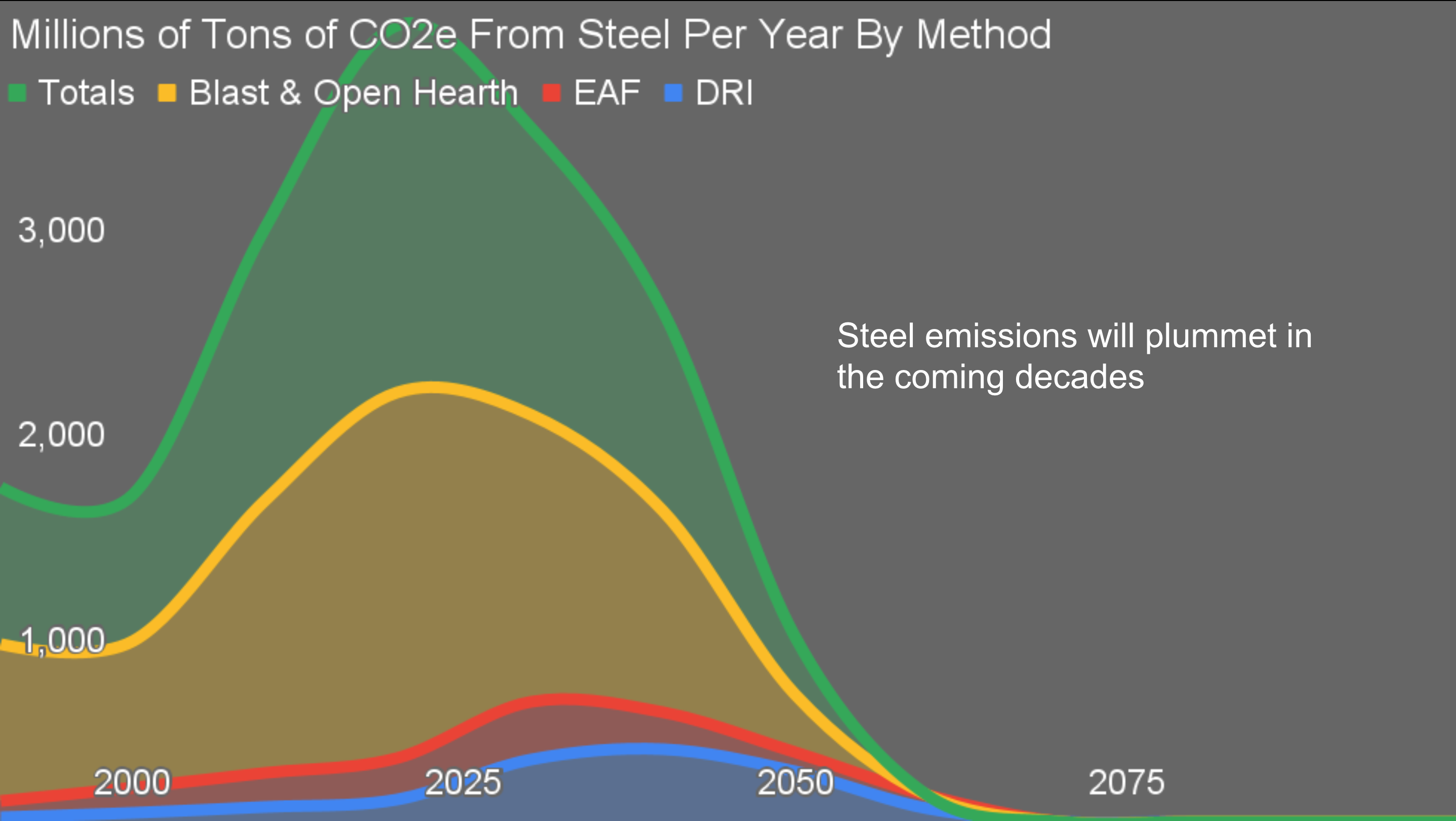

One of the things I did is a broad view of steel. I looked across all the existing steel, the growth of steel since 1990 over here, and that rapid ramp-up when China was building absurd amounts of infrastructure. Here’s a data point for Americans. At the beginning of 1988, China did not have a highway. Now it has 177,000 kilometers of highways, second only to the United States in length of highways. The United States has, I think, 350,000 km. That’s part of China’s massive infrastructure buildup.

In 2007, they didn’t have high speed rail anywhere. Now they have 45,000 km of high speed rail, they’ve built cities, they built highways, they built railroads, they built bridges, they built enormous amounts of stuff, and that’s what that curve is. But they’re at the end of that curve. Their domestic demand for infrastructure is now tailing off. They’ve built enough infrastructure for their entire economy and their entire population, and now they’re replacing things like the worst coal plants that they built with hyper critical coal plants.

On that note, by the way, coal is projected to peak in China this year. Gasoline was peak last year in China, per the head of Sinopec, the biggest gasoline refiner and retailer in China. And as Fatih Birol has pointed out, the International Energy Agency says peak fossil fuels is this decade. After this, the decline.

For steelmaking, we already make 100 million tons with direct reduction of iron. That’s basically taking a synthetic gas and mixing it with a high temperature process with raw iron ore and derusting it, turning rusty iron ore into unrusted iron. We put that into steel manufacturing facilities.

The nice thing about DRI, that synthetic gas currently comes from methane from coal or natural gas. We can use biomethane instead. We also have, and I’ve looked at and done the math on the HyBrit green steel solution and H2Green Steel solution, northern European green hydrogen reduction of iron ore to create iron, to create steel. I’ve also looked at the Boston metal solution and the Fortescue solution, which used electrolysis and no hydrogen at all to turn any grade of iron ore into iron, and then hence steel.

There’s another piece, the EAF piece here. EAF is electric arc furnaces, electric steel mini-mills. This is a place where the United States has been leading globally for a long time. This is a place where the United States can definitely pat itself on the back. 70% of US steel demand is met from steel from electric arc furnaces. Comparably, Europe is only 40%. That means they’re not scrapping their steel and making new steel with it. They’re making new steel from iron ore for their steel demands.

The optimum is probably about 75%. That electric arc furnace 1500° to 3000° Celsius heat can be powered by renewable electricity and increasingly is, so great news there.

Once again, a plummeting carbon dioxide emissions from steel. In the coming decades, we’ll see a flattening of demand, we’ll see much more scrapping, especially of fossil fuel infrastructure, like the 912 very large crude carriers floating around the world, or the 3 million miles of pipeline of fossil fuel pipelines in the United States. I like to think of them as linear mines that are buried 6ft deep. And so they’ll stop being needed because HVDC is the new pipeline. Why do we need pipelines when we have electrons? We’re going to be starting to see much more scrapping and much more low carbon production with DRI of multiple types.

Steel is actually a solvable problem with technologies we have in hand. It’s an economic and transformation and capital question, not a technological one. This might be a bit optimistic, but it’s entirely doable.

A bit on agriculture. This is another DALL-E generated image I put together for my India discussions. Agriculture is a major climate problem. Green ammonia made from green hydrogen is a big part of the climate solution, but drone-based agriculture is also a big part of it.

We’re already doing drone seeding across large farm areas. We’re seeing Hylio, out of the United States, with 200 pounds of product being applied from a single 14-foot-diameter wingspan hexacopter and two of those units with all the base station and everything costing about 200 grand. A tractor from Jon Deere, which can do the same spraying per day and compacts the soil when used, is about $700,000 to buy. The tractor burns about 13 gallons of diesel an hour. Drones sip at electricity.

Drone-based agriculture is an amazing transformation. We’re seeing crop dusting replaced with electrically powered drones. We’re seeing aerial surveillance and oversight for data gathering, for precision agriculture, replaced with drones with sensor packages. We’re seeing that all integrating in online platforms powered by machine learning. It’s a tremendous area of growth and a tremendous area of decarbonization.

And once again, agricultural waste. When we divert that into biofuels, it doesn’t turn into methane and it stops being a greenhouse gas problem.

We don’t have an arable land problem. What we have is a lack of most effective automation for industrialized agriculture. We need to move subsistence farmers off the land. This is all solvable. It’s all occurring just because of demographic trends. The rural areas globally are diminishing in population. Cities are burgeoning. Automation is occurring.

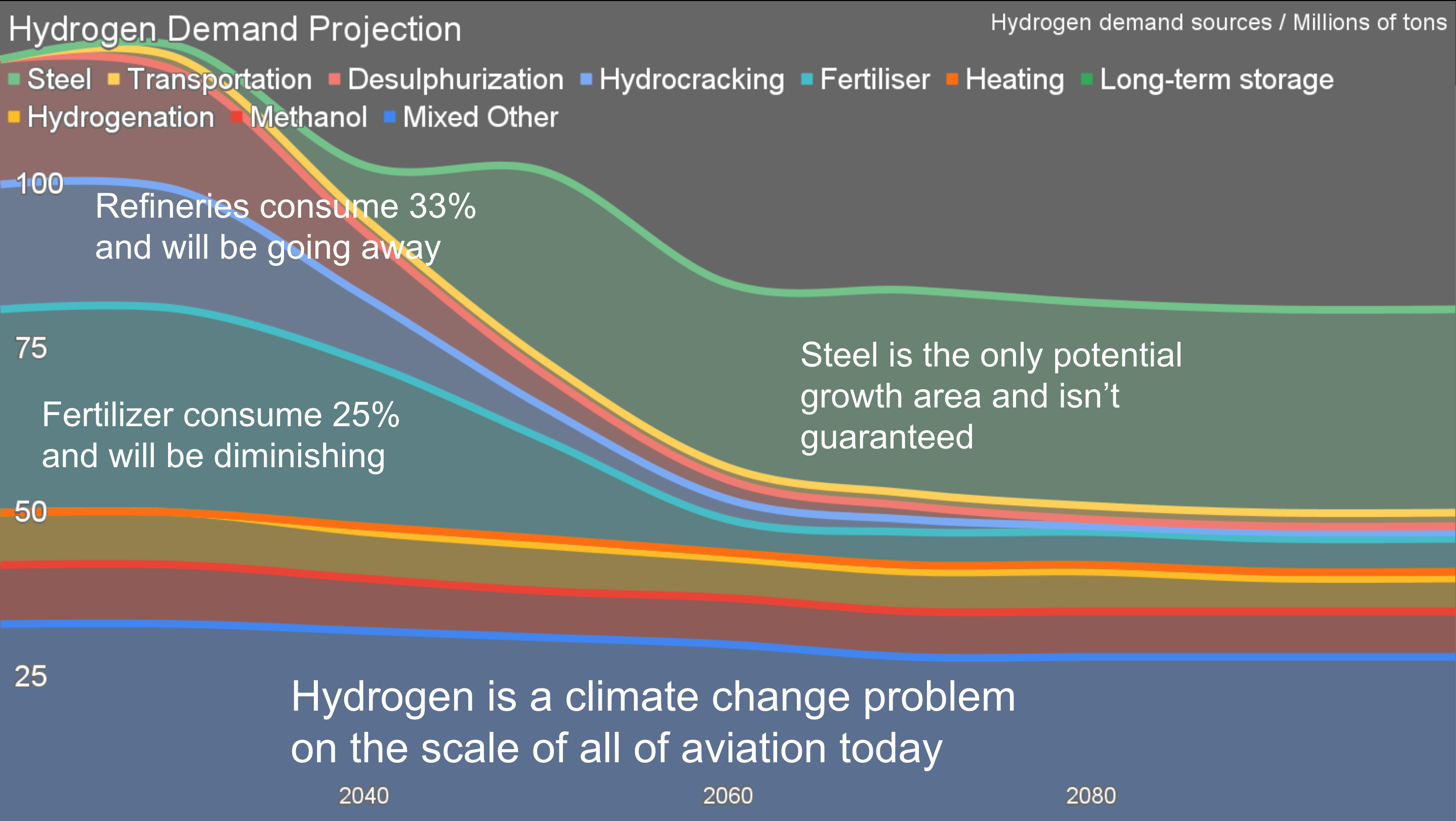

This is a heterodox projection on hydrogen through 2100. The thing that doesn’t get told often enough in the hydrogen story is that right now it’s a climate change problem on the scale of all of aviation, about 1.5 billion tons of carbon dioxide and equivalent per year from manufacturing hydrogen. There’s a really good news story about how we’re going to solve that problem.

Part of it is a full third of that is being used in refineries to make gasoline, diesel, and kerosene for jets. And guess what? Well, that’s going away. We’re not going to be eliminating refining fossil fuels because we still need petrochemicals. But we’re not going to be taking Alberta’s crude out of the ground and spending lots of hydrogen on it to turn it into diesel for tractors or gasoline for cars. The use cases are going down. As we decarbonize hydrogen, it will be more expensive, so the petroleum we extract will be the lighter, lower sulfur crudes which don’t need as much hydrogen.

Next is fertilizer. A full quarter of hydrogen today is used for ammonia and that comes from natural gas or coal. When we make that into green hydrogen, it’s more expensive. But with precision agriculture we reduce the requirement for fertilizer for the same crop yields. Biogenetic solutions, like Pivot Bio out of the United States, turn off the nitrogen sensor in microbes that exist around plant roots anyway so they keep fixing nitrogen regardless of how much fertilizer we add. Normally, if there’s enough nitrogen, they say, I’m just going to get fat, happy, and multiply. Instead, they just keep making more nitrogen at the root of plants where it’s needed. Pivot Bio already has over a million acres of corn in the United States under use with their product and are seeing a 25% reduction in fertilizer.

Hydrogen is going to stop being a problem, but it isn’t a transportation or energy solution. To be really clear, this is a case where electrification is being proven so effective and so efficient there are very few use cases left and every one proposed keeps falling off.

I have ten minutes or so for questions, so let’s talk.

Host Question: Michael, thank you so much. Just like with Jon, your presentation was riveting and my head is spinning. You did a wonderful job of outlining the market factors that are driving these enabling technologies and creating transformation. So thank you so much for that. So many good details. I have one question and then I know Mike has a question for you as well. So let’s see if we can get to both of those in the few minutes that we have left. You had mentioned that you don’t think that carbon capture is feasible. And I certainly understand that because we’re talking about technologies at scale that are very expensive. And you clearly outlined that there are better ways to phase out highly emitting products, production, things like steel. And we all know concrete’s in there as well, looking at solutions that inherently reduce carbon emissions.

But I am curious to hear a little bit more about why you think that carbon capture at scale is not feasible and that you don’t believe the hype.

Answer: Let’s be clear about what I assert about carbon capture and sequestration. It’s entirely possible to capture carbon dioxide. We’ve been doing it in industrial processes for 150 years. The Solvay process, which makes the baking soda we put in our fridges to keep them odor-free, that captures CO2 in one part of the process, to use it in the next step in a process. We know how to do this, and we’ve been doing it at industrial scales for a long time.

Similarly, we’ve been shoving carbon dioxide underground for decades as well, in enhanced oil recovery, and we’ve been putting it in pipelines for that purpose as well. None of this is technically non-viable. There are significant problems of economics and alternatives. It gets really expensive really fast and there are alternatives.

Boundary Dam in Saskatchewan tried to plug carbon capture onto its coal plant in order to use it for enhanced oil recovery to get some economic benefit out of it. And they, at the end of the project, said we’re never going to do this again because it’s too expensive and it’s a waste of time. This is a coal plant that wants to persist, and enhanced oil recovery that wants to persist. They said, this is just economic suicide.

Similarly, as we look around the world, the places where you can put carbon dioxide in high volumes are rarely near where the carbon dioxide is created. A cement plant has to be near to the market for cement because cement is a really heavy substance. You want to minimize the transportation of it. But cement plants aren’t near great places for carbon capture and sequestration — under the North Sea in Europe, for example. You have to build massive CO2 pipelines.

Satartia, Mississippi, is a cautionary tale for CO2 pipelines. It’s a tiny town, population 41, halfway up Mississippi on the western side. A CO2 pipeline that’s used for enhanced oil recovery in the region had dense phase CO2 in it, which means it was compressed and liquefied. The pipeline sheared because of a landslide because of excess rain. That dense phase CO2 turned into 590 times the volume of gaseous CO2. CO2 is heavier than air.

It rolled downhill in a thick blanket into Satartia a mile away across a highway, put 46 people into convulsions, unconscious on the ground, and caused the evacuation of over 200 people. 46 people were hospitalized for observations and probably have some significant ongoing health challenges. Internal combustion, emergency vehicles, and evacuation vehicles didn’t work because they need air too.

Any significant growth of carbon capture sequestration would require significant numbers of CO2 pipelines through heavily populated areas in North America and Europe in order to get the CO2 from where it’s being created to where it needs to be sequestered. The safety concerns are not a policy discussion right now and must be.

This doesn’t mean we won’t use carbon capture and sequestration. You mentioned cement. Once we electrify everything else in a cement plant, when we bake the limestone to turn it into quicklime, that chemical process releases a lot of carbon dioxide, but it’s almost pure, easy to capture. We still need to do something, but even there, that’s much more expensive than today, because they just use the atmosphere as an open sewer today. In the future, what alternatives exist and will they be cost competitive?

My assertion is, in many cases, alternatives to carbon capture will be cost competitive, and so we will use electrochemistry and other solutions instead of traditional solutions bolting on carbon capture.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica.TV Video

CleanTechnica uses affiliate links. See our policy here.