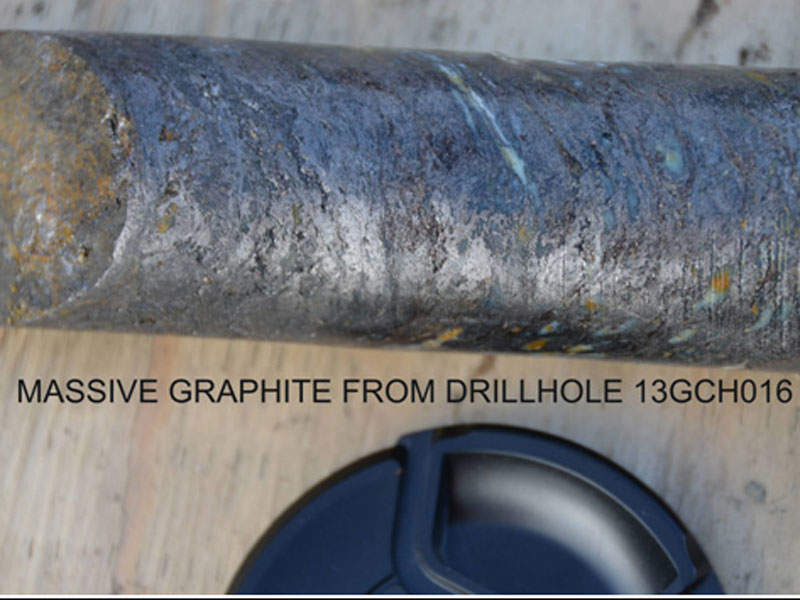

Graphite Creek mine hosts the biggest flake graphite deposit in the US. Image courtesy of Graphite One Resources.

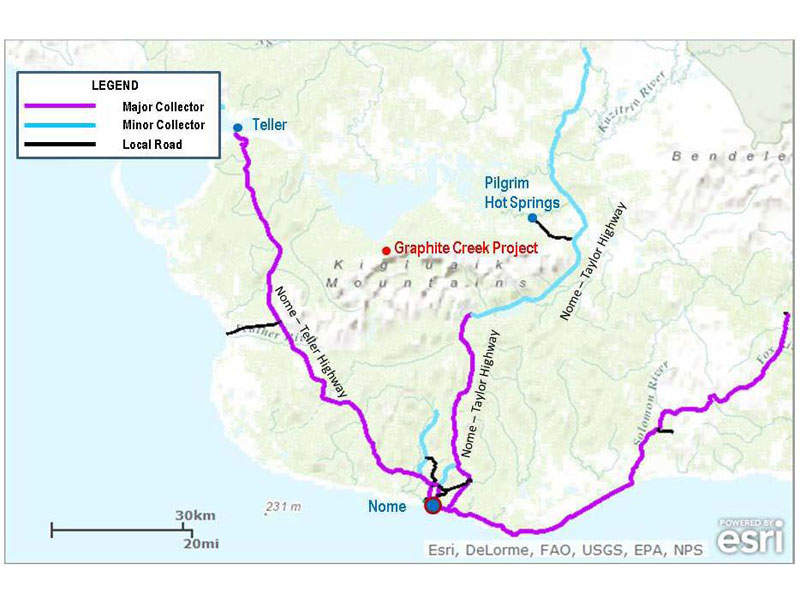

The high-grade graphite mine is located in Seward Peninsula in Alaska, US. Image courtesy of Graphite One Resources.

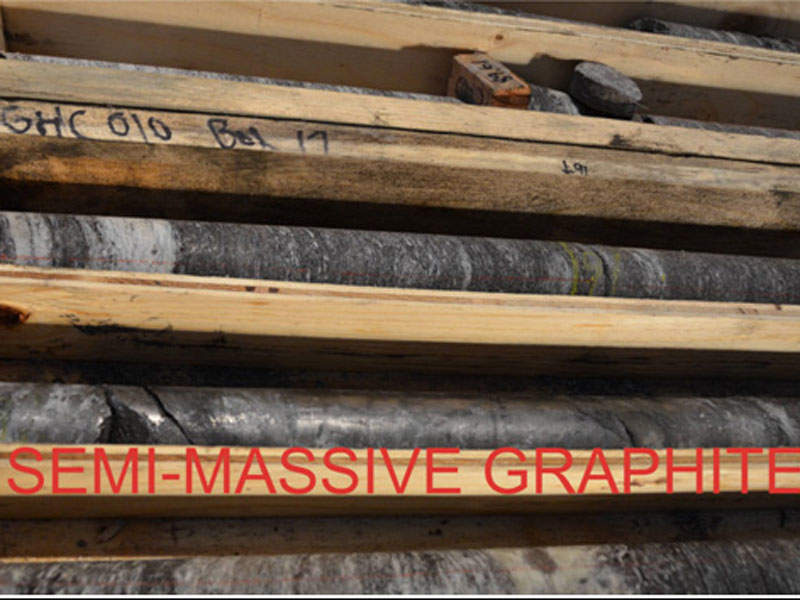

Mineralisation at the Graphite Creek project is characterised by massive and semi-massive graphite segregations. Image courtesy of Graphite One Resources.

Graphite One Resources’ fully owned Graphite Creek Mine is located in Seward Peninsula, 59km north of Nome, Alaska, US. Touted as the biggest flake graphite deposit in the US, the project comprises 165 mineral claims spread over 18,080 acres.

The mine will produce high-grade coated spherical graphite (CSG), which is in high demand due to the adoption of lithium-ion batteries for electric vehicles.

The preliminary economic assessment (PEA) of the mine development project announced in January 2017 estimates an average annual production of 55,350t of CSG, once the mine reaches its full production in its sixth year, through its estimated life of 40 years.

In February 2017, Graphite One Resources signed a memorandum of understanding (MOU) with the Alaska Industrial Development and Export Authority (AIDEA) to collaborate on the development of the project. The collaboration will include activities comprising mining, processing and manufacturing of high-grade CSG.

Construction on the project is scheduled to begin in Q2 2019, upon completion of the necessary studies and obtaining the required approvals, and will continue until Q3 2021.

Commissioning of the mineral processing plant and product manufacturing plant are scheduled for the second half of 2021.

Graphite Creek Mine geology and mineralisation

The graphite deposit is located on the north side of the Kigluaik Mountains. Mineralisation at the site occurs on the upslope and footwall surface trace of the reactivated Kigluaik normal fault.

The mine contains two distinctive graphite-bearing schist intervals, including sillimanite-garnet-biotite-quartz schist and biotite-quartz schist. The first schist contains coarse, massive and semi-massive graphite segregations and hosts higher grade graphite. The second schist hosts graphite as disseminated flakes.

Reserves at Graphite One’s flagship mine

The Graphite Creek mine was estimated to contain total mineral resources of 81.56Mt, including 10.3Mt of indicated and 71.2Mt of inferred resources, both at 6% graphitic carbon mining cut-off grade as of January 2017.

“Construction on the project is scheduled to begin in Q2 2019, upon completion of the necessary studies and obtaining the required approvals, and will continue until Q3 2021.”

The minerals at the deposit are considered superior based on their high-graphite grade, overall size, percentage of large-flake graphite, near-surface mineralisation and other infrastructure availability factors.

Mining and processing at the vertically integrated mine

Surface mining techniques such as the truck and shovelmethod will be used to mine the project due to its significant length of outcrop and relatively shallow dip below the land surface.

The anterial of the mine will be blasted initially to loosen the ore and the blasted ore will be loaded in large trucks for transport to the ore treatment plant. The mining fleet will include four hydraulic shovels, eight rear dump trucks, six bull dozers and other supporting equipment.

Processing at the mine will take place in a proposed mineral processing plant, which is expected to receive 1.018Mt of graphite ore, 60,000t of which will be recovered with 95% graphitic carbon mining cut-off grade. The plant is anticipated to recover 80% of graphite from the ore under optimised conditions.

The processing plant will include equipment for crushing, milling and floatation, classification, filtration and drying.

The graphite concentrate recovered from the processing plant will be packed in one tonne super sacks, placed in shipping containers and trucked to the Port of Nome. The containers will then be loaded on to barges and delivered to the product manufacturing facility.

Infrastructure at Graphite Creek mine

The proposed major infrastructure for the project includes a processing plant, access, connecting and site roads, power supply, mining / processing water distribution / storage facilities, water treatment facility, accommodation camp and administration offices, sewage treatment facilities, communication equipment, and storage facilities.

A 35km-long road connecting the mine site to the Teller highway has been proposed in the PEA. The road will be serviceable for 12 months and will connect the highway at the 54.6 milepost. The road will enable delivery of graphite mill product to Nome and to the processing plant through seagoing barge transport.

The mine operations are expected to require 4MW of power, which would increase to 6MW after five years. The power will be initially generated through two 2MW diesel generators, while a third generator will be added in the fifth year.

Graphite manufacturing facility

A manufacturing facility to produce final spherical graphite product is also proposed in the PEA. The plant will be located at a brown-field industrial site in Washington, which is developed with road and rail infrastructure.

It will house processes and activities, including bag handling, pelletising, spheronising, carbonisation, powder milling and classifying, bagging and warehousing, and administration and control activities.

The plant will receive 60,000t a year of concentrate graphite grading 95% from the processing plant. The concentrate will be stored in silos and sent to pelletising equipment whenever needed. It will be subjected to high temperature and purified under an inert atmosphere to produce 99.95% graphite concentrate.

The output will then be heat-treated in kiln type furnaces to harden its coating and to finally produce spherical graphite product.

The spherical graphite product is usually produced by jet milling the purified natural graphite flake to produce a 20-micron, ground and spheronised flake.

Contractors involved

The preliminary economic assessment for the project was prepared by engineering firm TRU Group.

Subscribe to our Newsletters

Get industry leading news, data and analysis delivered to your inbox