Nuton’s CEO Adam Burley lays out a partner-first, modular path to closing the copper supply gap for the energy transition—combining award-winning bioleaching with a scalable delivery model that cuts water use by up to 80% and emissions by up to 60%. With market‑leading recoveries, data‑driven predictability and ISO‑verified transparency, Nuton aims to replace heavy infrastructure with site-ready cathode production, replicate success through “learn by doing,” and embed Positive Impact across water, energy, land, materials and society.

Under Adam’s leadership, Nuton achieved a triple-category win in the 2025 Mining Technology Excellence Awards.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Mining Technology (MT): Nuton has been recognized for transforming copper production. How does the company’s long-term vision align with the evolving needs of the global mining industry and the energy transition?

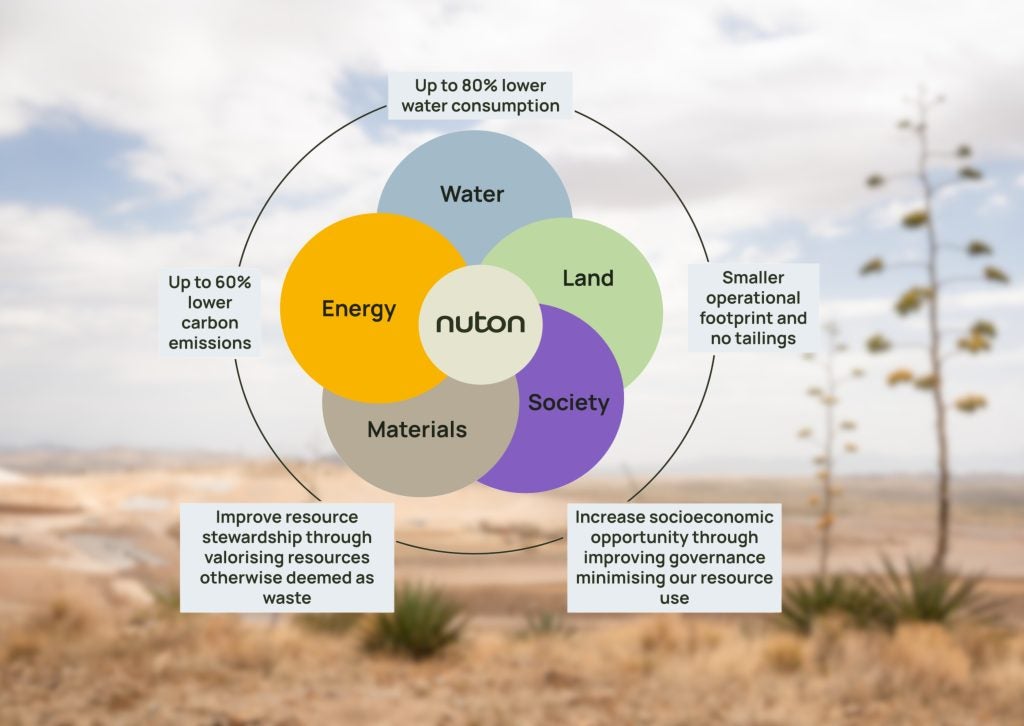

Adam Burley: The world needs more copper—and better ways of producing it. Nuton’s long-term vision aligns closely with the mining industry’s shift toward sustainability and the growing demands of the energy transition. As electrification expands—from power grids to electric vehicles—copper demand is surging. Nuton meets this challenge by unlocking copper from ores traditionally considered difficult to process while significantly reducing water requirements by up to 80% and carbon emissions by up to 60% compared to traditional processing methods.

The approach eliminates the need for concentrators and tailings dams and produces copper cathode directly at mine sites rather than shipping concentrate to smelters. This reduces reliance on energy- and land‑intensive infrastructure, while achieving recovery rates of up to 85%. Nuton’s integrated model of innovation, sustainability, and strategic growth offers a compelling blueprint for the future of copper production while closing the widening copper supply gap.

MT: What aspects of Nuton’s culture and leadership have been most instrumental in driving the company’s rapid growth and success since its inception?

Adam Burley: Nuton’s rapid growth and success are driven by a distinctive culture and operating model that blends innovation, agility, and shared purpose. Our mission to “do copper differently” has energized teams across disciplines and created a shared sense of responsibility and impact. Our team is as diverse as the challenges we’re solving: visionaries and specialists, scientists and strategists, builders and doers. It takes different people to do copper differently. Leadership at Nuton has been instrumental in shaping this culture. We learn by doing. When working across so many innovative new fronts, it’s impossible to advance through study alone. Our approach is to make a start, get stuck in, and be ready and capable to overcome challenges as they arise. In turn, there are no “mistakes,” only opportunities to learn and improve next time. We work hard to capture those learnings and share them across the team.

MT: Apart from your award-winning bioleaching technology, what other forms of innovation—organizational, operational, or business model—have been critical to your journey?

Adam Burley: Nuton’s journey has been shaped by a deep commitment to innovation—not only in technology, but in how we work, lead, and grow. While our award‑winning bioleaching technology is a cornerstone, our delivery model truly sets us apart. Rather than operating the technology ourselves, Nuton’s business model is built around partner enablement. We support site owners in deploying and operating the technology, ensuring they are fully prepared and equipped to succeed. This includes engineering a continuous, scalable process that can be safely and efficiently maintained, and providing hands‑on support for operational readiness and performance optimization.

We also ensure that sustainability is at the center of what we do. We’ve learned to scale through both success and failure—each deployment is an opportunity to refine, adapt, and improve. Our “learn by doing” approach has already generated more than 100 learnings, which we’re crystallizing into a commercial‑scale technology package for broader deployment across our partnership portfolio.

Leadership plays a critical role in this model: maintaining focus on objectives, offering timely feedback, and aligning teams through data and KPIs. We believe innovation is a team sport—our people are empowered to solve problems, seek help when needed, and keep momentum even in the face of setbacks. Our partnerships are central to our progress. Built on trust and courage, they enable us to break through barriers and deliver impact. The openness to collaborate—internally and externally—is a key ingredient in bringing Nuton’s technology to life.

MT: How have your customers and industry stakeholders responded to Nuton’s copper products and sustainability commitments, and what feedback has most influenced your approach?

Adam Burley: Our greatest innovation has been the way we’ve brought advances in biology, chemistry, digital, and commercial together, acting as a true systems integrator. By optimizing every component for the ore, the site, and the partner, we deliver the lowest‑impact copper, economically. We’re prioritizing partnerships with copper buyers who value high environmental credentials—especially those focused on low‑carbon copper. We don’t just focus on transactions when selling our copper; we focus on downstream customers who share our commitment to high environmental and social credentials. Our goal is to ensure Nuton copper is directed to its highest‑value uses, whether that’s powering the future of digital capability or enabling renewable energy for economies.

The strongest signal from the market today is around carbon emissions, but Nuton goes further by embedding sustainability through our Positive Impact ambition, across five pillars: water, energy, land, materials, and society. Our approach is twofold: we respond to current market needs while helping shape the future of copper demand toward broader sustainability metrics.

MT: Nuton’s partnerships span diverse geographies and project types. What criteria do you prioritize when selecting new partners, and how do you ensure mutual value creation?

Adam Burley: Nuton selects partners based on strategic alignment, technical feasibility, and shared ESG values. Ideal partners include owners of greenfield, brownfield, or legacy sites with copper resources that are difficult to process using conventional methods. Our initial approach to building our portfolio of partnerships was to learn by doing. As a new venture, we identified a broad range of potential use cases for the Nuton Technology. Our intention was to initiate partnerships in each use case so we could better assess the impact of Nuton in that context and, therefore, where we might choose to prioritize as the venture grows and evolves.

Nuton applies a staged evaluation framework to assess each opportunity, ensuring both commercial and technical viability before advancing to deployment. Mutual value creation is built into Nuton’s delivery model. Typically, partners contribute site access, permitting support, and local expertise, while Nuton provides tailored technology packages, metallurgical testing, and ESG guidance, and we both share in the economic uplift provided by the Nuton Technology. To ensure scalability and adaptability, we modularize our technology to streamline deployment, enabling rapid replication across diverse geographies.

MT: Given the variability of ore bodies and site conditions, how does Nuton ensure its technology remains adaptable and effective across different mining environments?

Adam Burley: We are developing a modular technology package that defines the core engineering, equipment, and process flow while allowing flexibility for site‑specific conditions. That technology package remains consistent across site types and use cases: greenfield, brownfield, or legacy. Before deploying the Nuton Technology at any site, we conduct a thorough assessment of the ore to confirm its suitability. We have a suite of predictive tools that enable us to confidently assess the technical, financial, and ESG performance of the technology. We analyze chemical and physical properties, run predictive models, and validate those models through test work. This rigorous process ensures that we tailor our approach to each site’s unique conditions, maximizing effectiveness and minimizing deployment risk.

MT: What were the biggest challenges Nuton faced in scaling from laboratory to industrial deployment, and how did you overcome them to achieve commercial readiness?

Adam Burley: The Nuton Technology is built on years of rigorous laboratory‑based R&D and test work. What sets our journey apart is how we’ve translated that strong scientific foundation into real‑world impact through thoughtful design and a distinctive delivery model. We’ve engineered a continuous, scalable process that can be safely and efficiently operated and maintained. But rather than operating the technology ourselves, our business model centers on partner enablement—supporting site owners to deploy, run, and optimize the technology. This includes ensuring operational readiness, providing performance support, and refining deployment strategies.

Our flagship scaling partnership with Gunnison Copper at the Johnson Camp Mine in Arizona exemplifies this model. With existing SX‑EW capacity, a permit‑ready leach pad, and a willing partner, we moved from concept to cathode in under two years. Today, we’re producing copper via conventional ROM leaching and commissioning the Nuton Technology circuit for first Nuton copper production in the coming weeks. We’ve embraced a “learn by doing” approach, consciously limiting the scope of studies to accelerate deployment while managing uncertainty. So far, we’ve captured more than 100 learnings, which are being crystallized into a commercial‑scale technology package for future partners. It’s an exciting time—bringing Nuton to market not just as a technology, but as a scalable, partner‑driven solution.

MT: With a tenfold increase in team size, how do you attract, retain, and develop talent in such a specialized and rapidly evolving field?

Adam Burley: Our people are at the heart of Nuton. We’re building something ambitious and transformative, and that purpose attracts and retains exceptional talent. Nuton’s mission to “do copper differently” has created a shared sense of responsibility and impact. We operate with startup‑like agility while being able to leverage the resources of Rio Tinto, a global leader. We position Nuton as an innovation company, not just a mining technology provider. That sense of being at the forefront of something new is a powerful motivator for many of us. We foster a growth mindset across our workstreams and a culture of continuous learning and experimentation, where every project serves as an opportunity to improve and optimize. The team knows their work is meaningful and contributes to solving one of the world’s most pressing resource challenges. We are energized by this ambition. We invest in cross‑functional development, blending technical, environmental, and commercial expertise to build a future‑ready workforce.

MT: What are the most significant risks Nuton faces in deploying its technology globally, and how does the company proactively manage these risks?

Adam Burley: As with any new technology, key risks relate to performance at scale—specifically, translating performance from a highly controlled, laboratory‑based environment into a real‑world operating mine site. We have taken a number of scale‑up steps that have enabled us to learn how best to operationalize the technology. Our industrial‑scale deployment at Johnson Camp Mine in Arizona is designed to validate key aspects of design, delivery, and performance. We have completed construction of the Nuton technology package at Johnson Camp Mine and are well into commissioning. Learnings captured from this deployment will be crystallized in our commercial‑scale technology package—our “lego brick”—which we intend to replicate and deploy across our partnership portfolio.

MT: How do you view Nuton’s position relative to other emerging technologies or competitors in the copper extraction space, and what differentiates your approach?

Adam Burley: Nuton offers market‑leading copper recovery and leach kinetics (the speed at which the copper is extracted). What distinguishes Nuton is the breadth of its toolbox. Rather than relying on a single chemical or microbial tweak, Nuton’s engineers have developed a technology package that unites microbiology, chemistry, thermodynamics, and data analytics into a single, optimized process. Within that process, we have the optionality to deploy different tools as needed to optimize performance.

Nuton stands apart in the copper extraction space through a combination of breakthrough technology, a distinctive partner‑driven delivery model, and a predictive, data‑driven approach to impact. Instead of operating the technology ourselves or managing it in a “black box,” we enable site owners to deploy and run it—offering a lower‑capital alternative to traditional concentrators. This model accelerates scaling and ensures operational readiness and performance optimization.

Backed by decades of R&D, we’ve built a rich data foundation that allows us to predict outcomes based on site‑specific inputs. This precision helps us maximize value, minimize environmental impact, and aim for net‑positive outcomes. Sustainability—through our Positive Impact strategy that aims to give more than it takes—is embedded in our mindset, and our ambition is to lead the industry toward more responsible copper production, setting new standards through innovation, collaboration, and impact.

MT: How do you embed environmental and social responsibility into day-to-day decision-making and project execution?

Adam Burley: Sustainability is embedded across every stage of the Nuton project lifecycle—from commercial agreements to financial modeling and partner selection. It is truly at the heart of our business. We embed Positive Impact into how we think, how we operate as a venture, how our people work, and how we partner. All of this shapes how our product performs. That’s why, wherever we deploy, we strive to produce the world’s lightest‑footprint copper and to deliver Positive Impact in at least one of our five pillars: energy, water, land, materials, and society. Our business cases include environmental value‑adds like carbon and water metrics alongside financial indicators. We actively support partners in improving their sustainability practices, offering technical guidance and helping them engage with industry benchmarks.

MT: How does Nuton ensure transparency and credibility in reporting its environmental and social performance to stakeholders and the broader public?

Adam Burley: We promote rigorous measurement and radical transparency—committing to measurable outcomes and reporting even when not formally required. That’s how we show partners that their environmental footprint can be lightened and Positive Impact achieved with Nuton Technology. Pre‑operational lifecycle assessments (LCAs) set expectations for the impact of the Nuton Technology across five pillars. Real‑time data from sensors and instruments will be benchmarked against these expectations, showing both achievements and areas for improvement. Positive Impact is tracked at two levels: the venture level, where we monitor organizational and team performance across our five pillars; and the product level, where we conduct site‑specific LCAs to measure the added value Nuton Technology brings. Our LCAs are ISO 14040/14044 compliant, with all data peer‑reviewed and independently verified. Transparency includes acknowledging potential areas for improvement and showing our path to reduction—not just celebrating successes.

MT: In what ways is Nuton collaborating with industry peers, regulators, or research institutions to advance sustainable mining practices more broadly?

Adam Burley: Nuton leverages the best minds around the world. While we have strong internal capability, we also draw on a powerful global network of experts to challenge and extend our thinking. Through Rio Tinto’s Innovation Advisory Committee of independent experts, we’ve accelerated our journey by engaging proven entrepreneurs, leading scientists, and senior innovators. We deliberately test ourselves against the best; it’s part of Nuton’s culture and innovative spirit. From day one, we’ve embedded our Positive Impact strategy into partner engagements, including with junior miners. We aim to lift industry standards through peer collaboration, not only through information sharing, but by co‑solving and co‑creating.

MT: What are the next frontiers for Nuton—technologically, geographically, or strategically—and how do you plan to sustain your leadership in innovation and sustainability?

Adam Burley: Technologically, we’re expanding our suite of processes to include recovery of other valuable metals and improving the efficiency of existing unit operations. Digitally, we have decades of data and knowledge that we are integrating, with the support of AI, into a unique digital platform that will enable further efficiencies in areas such as technology performance and technology delivery. From a strategic perspective—while we have a clear and focused strategy—we are keen to retain strategic optionality, so that we are well positioned to respond to the changing needs of our partners, customers, and shareholders.

MT: Looking beyond immediate business goals, what legacy do you hope Nuton will leave for the mining industry and for future generations?

Adam Burley: Our Positive Impact ambition defines the legacy we want to leave—moving beyond “zero harm” to actively regenerating resources and having a lasting, meaningful impact. By demonstrating that mining can be a positive force, we hope to reshape the industry’s license to operate and inspire a new generation of sustainable mining practices.

MT: What advice would you offer to other mining companies seeking to innovate and expand responsibly in today’s market?

Adam Burley: Don’t underestimate the power of partnerships; Embed sustainability from the start as a strategic driver of value; Focus on radical transparency and accountability—share your goals, your progress, and your challenges openly; and welcome and embrace failure.

MT: Adam, thank you for crystallizing how “doing copper differently” can reshape both the economics and footprint of copper supply. Your partner‑enablement model, modular technology package and commitment to radical transparency offer a credible playbook for scaling low‑impact copper at pace. We look forward to tracking first Nuton copper from Johnson Camp Mine and the rollout of your commercial “lego brick” across new geographies—and to seeing how Positive Impact sets a higher bar for the industry.

.jpg)