Water is a critical component for nearly all mining operations. Unfortunately, most mining operations are located in areas where water is scarce, so this resource must be carefully conserved and recycled as much as possible.

In this article, KeeChong Lee, Emerson Industry Sales Manager, focuses on two of the larger water users in a mine, grinding/classification and flotation. Lee has 19 years of diverse experience at Emerson, specialising in both technical and marketing roles for Fisher™ FIELDVUE™ products. He currently focuses on driving innovation.

KeeChong Lee, Emerson Industry Sales Manager

Both processes require tight control of water flow to optimise performance, but that water is often heavily recycled and contains abrasive sediments, and even small rocks. Proper selection of the control valves in this application is critical to achieve maximum efficiency, throughput, and reliability.

Once the ore has been removed from the mine, it undergoes two major process steps in preparation for mineral extraction. The first step is crushing/classification, where the ore is first crushed, and then ground into even finer-sized particles in preparation for the extraction steps downstream. Water is used to transport the particles (in the form of a slurry), and hydrocyclones are used to separate and classify the particles, with larger particles being returned to the mill for further grinding.

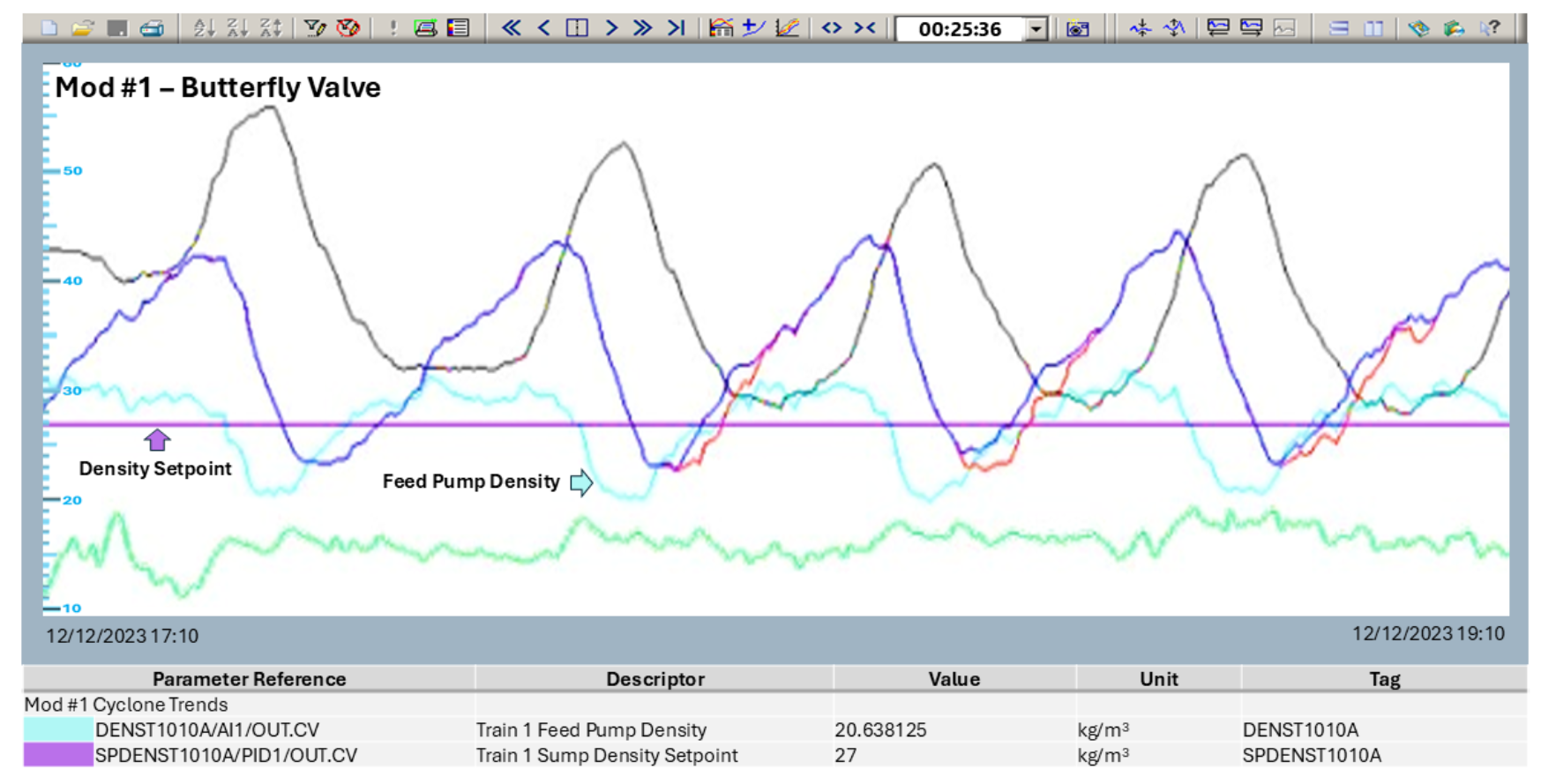

Lee: “Water addition to the mill feed and sumps must be carefully regulated using control valves to maintain a consistent circulation of slurry density and allow proper hydrocyclone operation. Tight control of these water flows is difficult due to the abrasive particles present in the recycled water.”

Once the ore has been properly ground and classified to the correct range of particle size, the slurry is fed to the flotation section. Flotation tanks use entrained air to bubble up through the ore slurry and separate the extractable minerals from the tailings. The configuration of the tanks will vary by ore type, with the product either floating to the top or sinking to the bottom.

Once separated, both the tailings and concentrate are thickened to remove water, with the latter recycled back to the process. The flotation process requires water addition at the conditioning tank and at the pump box, with flows regulated by the control valves. Lee comments: “Flotation separation efficiency is strongly dependent on a very tightly controlled mix of slurry density and chemical concentration. Any variation significantly impacts the process and can result in product loss through the tailings stream.”

He continues: “As indicated above, optimised process control of the grinding and flotation areas is largely dependent on tight water flow control. Unfortunately, this task is not so straightforward due to complicating factors, including water quality, flow variation, and pressure drops. Process water in most mining operations is heavily recycled. As a result, it usually contains significant quantities of sediment, and even small rocks and gravel, all of which can be punishing to valve internals. Pipe sizes tend to be quite large (see article title image) and the flows variable, making it difficult to size the valves for a particular application. Sizing is further complicated when large pressure drops are involved because these tend to create valve cavitation at low flows, a condition which can further erode the valve internals, and cause damage to downstream piping.”

Lee says large pipe sizes tend to favour butterfly valves due to their inherent cost advantage at higher pipe diameters. However, this price difference can be quickly erased due to less than optimal performance beyond its control range. “Butterfly style valves have limited turndown and can only control across a small range of flows (25-50%), so they are ill suited for applications like grinding and flotation processes that must accurately throttle water at low, medium, and high flows. Butterfly style valves will typically cause cavitation when handling large pressure drops, creating valve and pipe damage. As a result, the valves and downstream piping may require routine replacement or repair in these types of high pressure drop applications.”

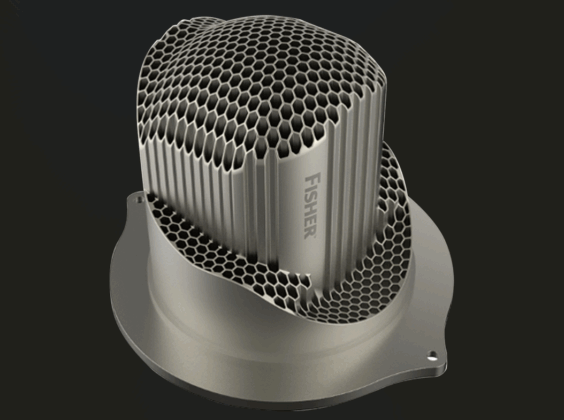

Emerson offers a better body style that it says is much more suited for this application. The eccentric plug v-ball design (see below) is a ball valve style with a modified ball that provides tight flow control over a much broader range, along with very tight shut off, in these types of scaling/sediment applications.

Eccentric v-ball valves provide accurate flow control over a much broader range of flows than butterfly valves

The valve internals can be fashioned from hardened trim designs, and the wiping action of the eccentric ball allows this valve style to consistently achieve very tight shutoff, even with entrained sediment and scaling in the process media. The V-shaped ball provides greatly improved turndown and control at low flows, allowing this valve style to throttle across a much broader control range than a butterfly valve.

Lee: “One of the big advantages of the eccentric v-ball design is the ability to install anti-cavitation trim. Such trim enables the valve to handle very high pressure drops with minimal cavitation. The large ports pass bigger particles and sediments, and the trim can be made from a high hardness R31233 alloy for long lasting service, even in very erosive conditions.”

V-ball valves with Fisher™ Cavitrol™ Hex Trim from Emerson provide large bore, anti-cavitation trim. These trims reduce cavitation across the full range of flows and can be fashioned from very high hardness alloys for long service life

Anti-cavitation trim protects both the valve and downstream piping, allowing the valve to better handle and control flow in high pressure drop applications, where a butterfly valve would tend to perform badly.

A mine site was struggling with poor control and short service life of their grinding and flotation water addition valves. High pressure drops were creating cavitation conditions that reduced the average valve service life to about three months.

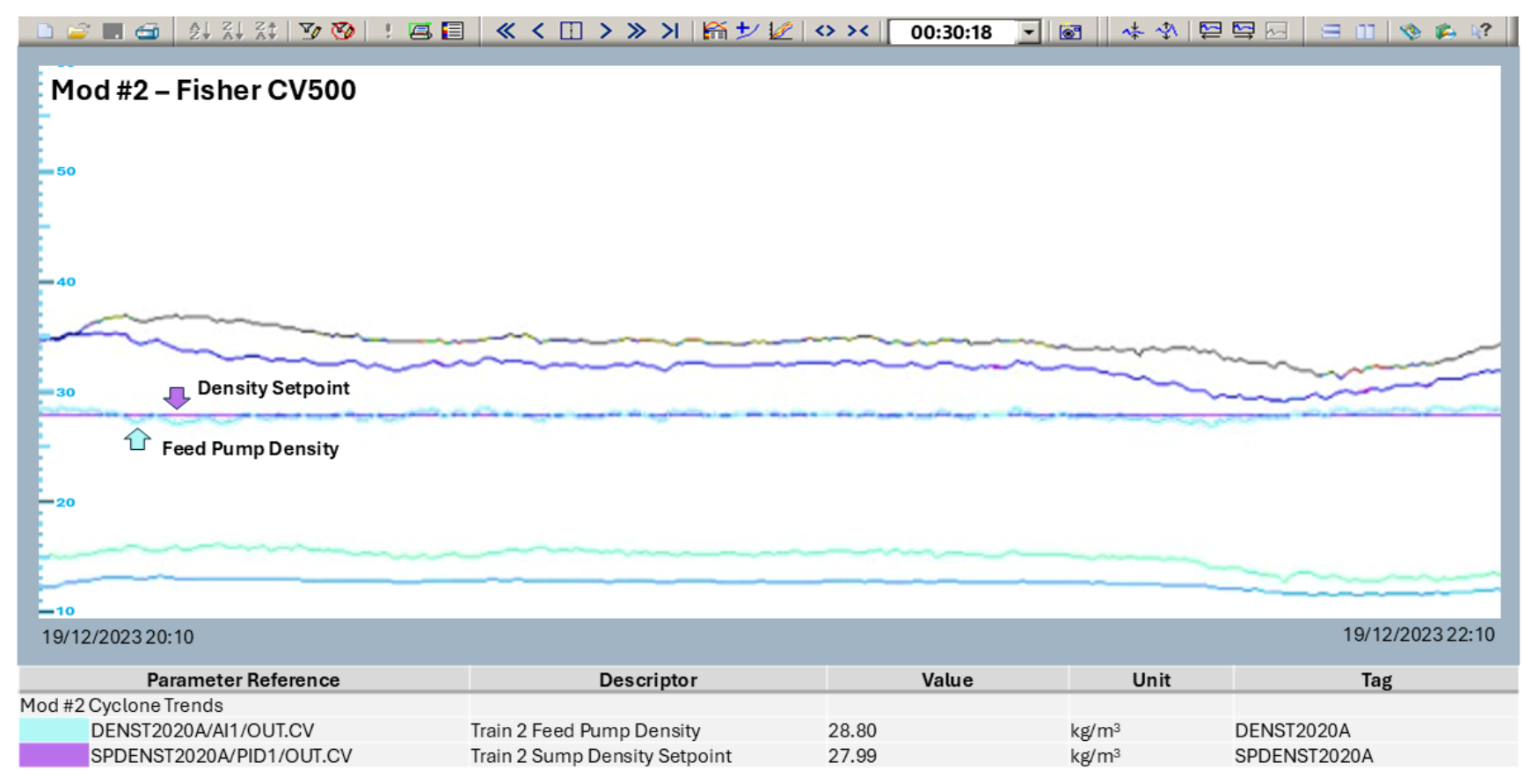

After consulting with an Emerson Accredited Service Provider, the site decided to replace their 42 existing butterfly valves with Fisher™ CV500 Eccentric Plug Valves, and they noticed immediate improvements in both process control and service life. The broad flow control range of the v-ball valves provided far superior water flow control, allowing the system to tightly control slurry densities. This immediately translated to better product recovery and higher process efficiency.

In addition to the significant process improvements, the service life of the new valves was lengthened considerably. While the butterfly valves required replacement every three months, the new valves were pulled after 12 months in service and showed minimal signs of damage.

Despite the higher initial investment in the new valves, the project paid for itself in the first year of service. The new valves provided:

- Reduced operational cost due to better control, which reduced recycle flows and pumping energy consumption.

- Reduced maintenance costs with valve service life extended from three months to over a year, and counting.

- Improved process control, resulting in density control improvements, which increased product recovery and yields, while reducing tailing processing costs.

- Reduced water usage due to better upstream control, which prevented flooding of downstream filters, while enhancing water recovery.

Lee concludes: “If your mining operation is struggling with poor slurry density control and short service life due to issues with water addition valves, it may be time to evaluate a valve replacement project. While eccentric v-ball valves have a higher purchase cost than butterfly valves, that price difference is more than justified by the significant gains in process improvements and service life.”