Whether planned or unplanned, the cost of a mine shutdown is always substantial. Thejo Australia’s solutions aim to help clients maximise value by reducing these costs.

Thejo Australia recognises the impact a shutdown has on operations and profitability – that’s why it offers a full-service capability, ranging from spares to basic modifications of a plant to a full redesign of various parts of plant equipment.

Thejo Australia’s product focus is on conveyor belts, conveyor care, wear protection systems, transfer point solutions, grinding mills and trommels, screening plants, slurry handling hoses, and filtration.

According to filtration spares, abrasion wear and screening specialist David Wheelhouse, Thejo Australia has reliable and efficient processes in place to reduce the need for shutdowns.

“At Thejo Australia, our focus is on preventive maintenance and serviceability,” Wheelhouse told Australian Mining. “We aim to improve efficiency, improve wear life and reduce downtime.

“Downtime and plant availability are enormous cost-drivers in the mineral processing plant, and if one can improve availability and reduce the number of shutdowns or the time it takes to do these necessary change-outs, it would be invaluable to the customer.”

Abrasion and wear are unavoidable in all parts of mineral processing, as the material transitions from rock to a slurry when moving around the circuit.

Even small improvements in slurry transfer efficiency can have a drastic impact on mining profitability – on equipment such as chutes and launders, grinding mills, trommels, screens and cyclones.

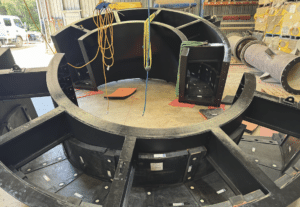

Image: Thejo Australia

All the products Thejo Australia manufactures for the beneficiation and grinding circuit are designed to protect assets with sacrificial liners.

The mills themselves feature internal sacrificial liners and trommels are assembled with screens inside. They are designed to resist the continued wear-and-tear action of the processed materials as it goes about segregation of sizes.

“In a very aggressive environment, some of these products might have to be changed out on a six-monthly basis, and some of them, in a less arduous situation, could go a year or two before they need to be replaced,” Wheelhouse said.

Meeting Australian demands

Thejo Australia offers solutions for the mining, mineral processing and corrosion protection segments of the local industry.

Manned with technical sales experts, and a warehouse carrying a wide range of inventory, the company’s focus is on the growing demands of specialised custom solutions for its clients across Australia from its headquarters in Perth.

“We’re a solution-based organisation that assists customers in product selection, installation and product monitoring,” Wheelhouse said. “We feed the information we receive from the customer back to our designers and engineers at our head office in India to work on improvement of the designs.”

Wheelhouse said every effort is made to reduce unplanned shutdowns, which means product integrity and reliability is especially critical.

“During a planned shutdown, we want to minimise downtime with systems that are easily and safely replaceable,” he said. “Safety is a primary concern, so we’re looking for products that can be easily and safely handled.

“Any hours that can be saved in a shutdown translate straight back to savings to the customer.”

Trommels with screen panels, dams and spirals are critical elements that Thejo Australia has focused on for improvements.

“It is not just the wear life, but also efficiency in terms of how effectively the trommel screens can segregate between oversized material from the size that you require,” Wheelhouse said.

“No mine would appreciate even an hour of unplanned shutdown, as that can translate into millions of dollars of lost production, and that’s where we add value to our clients.”

Thejo Australia is also focused on reducing the number of planned shutdowns a mine may require. This is a highly customised process, as each site has its own shutdown schedules.

The length of shutdown periods also varies from site to site. To offer extended time between each shutdown, Thejo Australia alters its product and service designs to the specific needs of the site.

“You have to look at what’s best suited for that customer, so you can extend the life of the products,” Wheelhouse said. “We customise our process for each customer.

“For example, if a customer is on a 12-week shutdown cycle, then extending life to, say, 15 weeks may not be beneficial.

“Our objective is to try and get at least 24 weeks life in order to skip an entire shutdown.”

One of Thejo Australia’s major customers in the Goldfields-Esperance region of Western Australia recently went through a reorganisation of its shutdown periods. The mine was having a shutdown every 15 weeks, with the second shutdown of the year mainly for the changeover of trommel panels.

Thejo Australia designed a screen panel that lasted 35 weeks, meaning the miner could eliminate the second shutdown, which saved 40 hours of lost production equating to a huge cost saving.

Image: Thejo Australia

“We eliminate that stress for them, so they don’t have to shut down and now they’ve moved it out to be one to two shutdowns per year in that sort of circuit,” Wheelhouse said.

“That’s what we want to try and achieve with all our clients – to get the best part for their plant and best timeframe to reduce those costs.

“An unplanned shutdown could cost a minimum of $100,000 per hour and could be up to $500,000 per hour – it’s a cost that adds up quickly.”

Thejo Australia engineers visit customer sites and collect data by observing the plant. They then use that data to determine what is required for a client to get the best performance out of a product.

“There are frequent process changes in plant operations, which are periodically monitored and studied by our engineers,” Wheelhouse said. “Based on the data, we make alterations to the design of the screens if necessary to maintain the required optimum output desired by the clients.

“It’s a constant cycle of taking feedback from the site and passing it on to the technical and design team in order to design a product or solution that will be best suited for the client.”

Thejo Australia has an extensive research and development (R&D) department that tests its products and solutions in some of the harshest working conditions in leading Australian mines.

“We constantly receive varied needs from the mines and industry, enabling us to continually innovate and improve the product line,” Wheelhouse said. “Whenever such requirements arise, we consider it a product development opportunity.

“It could be in terms of a process change or it could be through an engineering design change. Either way it is pointed towards our R&D team to be addressed.”

Wheelhouse emphasised Thejo Australia’s aim to optimise availability of customers’ plant by understanding their needs and how to address them.

“We spend time understanding the process and trying to improve the product,” he said. “But there’s also the relationship we have with the customer, and we spend a lot of time understanding them and making it easier for them.”

To find out more, visit thejoaustralia.com

This feature appeared in the October 2024 issue of Australian Mining.