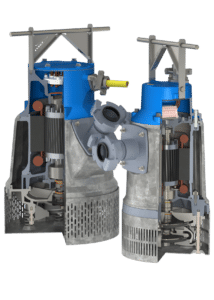

The Flygt Bartail range is Xylem’s new solution for the harshest underground dewatering applications.

As the Australian resources industry responds to the increasing mineral demands of a decarbonising world, underground mines are getting deeper and more challenging.

This is placing greater stress on submersible pumps, which play a critical role in keeping underground mines dry.

In response, Xylem – which has been helping the mining sector solve water problems for over a century – has added to its Flygt submersible pump range with a new premium extension.

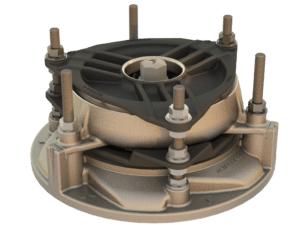

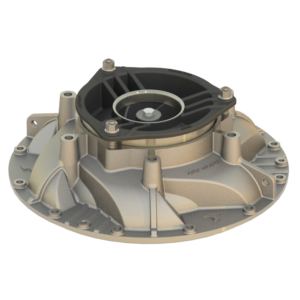

The Flygt Bartail duplex white iron and duplex stainless steel hydraulic end has been specifically engineered to survive highly erosive and highly corrosive dewatering applications.

This is exactly what the Australian mining industry has been crying out for – a hydraulic pump end that can handle the harsh contaminants modern-day underground dewatering throws at it, with longer-life and lower operating expenditure (opex) the end goal.

Xylem dewatering product and marketing manager – Australia and New Zealand, Cameron Pate, explained in more detail.

“Our standard Flygt 2125 (8kW) and 2151 (20kW) offerings have continued to be the market leader for over 30 years,” Pate told Australian Mining.

“The premium Bartail range will be a welcome addition to handle those harsh applications as well as improve pump life on-site.”

“While the standard Flygt product still does an excellent job, this premium extension in our Flygt range is more superior and gives customers a longer-lasting product. It is also the go-to option for aggressive duties.”

Not only has the design of the hydraulic end been improved to support more efficient pumping but the metallurgy of the part has been enhanced to make it more durable.

By combining duplex white iron and duplex stainless steel, the hydraulic end was engineered to combat very erosive and corrosive underground conditions.

While dewatering pumps are designed to pump water rather than slurries, as the mining industry continues to raise performance targets to meet increasing mineral demand, some responsibilities are going by the wayside, such as sump management.

“Sumps collect underground runoff materials such as shotcrete fibres, fines and mud, but as mines get busier and busier, sumps are being cleaned out less and less, which means they end up pumping a much more aggressive product, almost a slurry-like product,” Pate said.

It is for this reason that underground pumps should be installed with longevity in mind, something the Flygt Bartail range can ensure.

The fact the Flygt Bartail hydraulic end can be retrofitted to all existing Flygt 2125 (8kW) and 2151 (20kW) pumps as well as competitor equivalents means mining operators can easily upgrade their existing fleets to the longer lasting premium Flygt Bartail product.

Pate said this is a key consideration for Xylem customers.

“If you think about it, there’s thousands of assets out there in the Australian mining industry and there’s extreme risk to the customer if they install a new product and it doesn’t work,” he said. “This could have serious business implications in having to swap out entire fleets.

“Our underground mining customers aren’t always looking for a completely new pump. Many of them are looking for the same product they’ve used for 10, 15, 20 or 30 years, but a better version of it.

“So we’ve created a solution where our customers can keep the same pump and drive unit, but upgrade to an improved bottom end.”

A more durable hydraulic end not only keeps dewatering operations running for longer but eases the load on maintenance teams. This is particularly significant considering some mine sites have up to 400 pumps on-site.

“Most of the time underground dewatering makes up a small percentage of operational costs – often less than one per cent – but dewatering issues or water issues can create a huge amount of risk to the business,” Pate said.

“If a mining company or contractor doesn’t get it right and a pump fails, the flooding and cost to production can be huge.

“Customers are not normally thinking about costs to remove an asset or change an asset; they’re more focused on mitigating risks and ensuring pumps last longer – to reduce risks of flooding and having to change them out.”

Pate said Xylem’s standard Flygt product continues to perform strongly in underground environments, with the premium range focused on improving the customer experience and really solving the harshest water challenges.

“We’re marketing the Flygt Bartail range as a premium extension for tough applications and tough duty points – anything that is low pH, high erosion, high fines and high shotcrete,” Pate said. “This is where the product really shines.”

And Xylem has ambitions to apply the unique duplex white iron and duplex stainless-steel metallurgy to other products.

“We currently offer the Bartail hydraulic end for our 8kW 2125 and 20kW 2151 Flygt pumps, but we plan to extend this metallurgy to other Xylem brands and ranges,” Pate said.

Not only able to keep operations running for longer, the Flygt Bartail hydraulic end enables greater dewatering efficiency, reducing a miner’s overall carbon footprint and delivering improved environmental, social and governance (ESG) outcomes.

Xylem knows it’s onto a good thing with its Flygt Bartail range, with possibilities to support an Australian mining industry entering deeper and harsher underground environments.

It’s uncharted territory for the sector, but as technologies continue to expand and original equipment manufacturers (OEMs) such as Xylem evolve to support the growing demands of their customers, the Australian mining industry is in good stead.

This feature appeared in the December 2023 issue of Australian Mining.