Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

We don’t spend a lot of time tackling the issue of plastics here on CleanTechnica. It’s a massive problem, and we touch on the problem from time to time, but it’s not a daily beat of ours. That said, some friends of the site have been working on a solution to help out, and they’ve got notable news today to share.

The startup Heartland has developed a natural fiber plastic additive that reduces scope 3 emissions, particularly in chemical and automotive industries. Now, Heartland has received a significant investment from BASF subsidiary Chemovator. “This investment builds on the partnership that BASF and Heartland have strengthened over the years to develop a natural fiber-filled polyamide (nylon) for automotive component parts. There is a growing demand coming from the automotive sector to reduce the cost, weight, and carbon footprint of plastic products without compromising performance,” Heartland writes.

It’s a little thing, a hidden thing, but something that adds up to make a big difference — at least, that’s the hope and dream and goal of the innovation and investment. We’re not going to get super deep in the weeds here (no pun intended), since this isn’t my area of expertise, but let’s look a little more at what the company says it is doing so special here. “Heartland’s Imperium Masterbatch solves all of the major problems associated with processing natural fibers in plastic: dust, flammability, moisture, bonding, dispersion, bulk density, and thermal stability,” Heartland writes. “These challenges have historically prevented natural fibers from being viable market opportunities to reduce the product carbon footprint of plastics.”

Notably, for those like me who were not aware, “Chemovator has been known as the business incubator within BASF that spins out new commercial opportunities. Chemovator recently announced that they were going to expand their portfolio from Europe to North America (this is their first investment in a North American company).” Naturally, this is a big nod to how effective and promising Heartland is that BASF’s Chemovator is starting its path here with this investment.

Details of the investment were not noted in what was shared with CleanTechnica, but they did share a little more on the history between the two: “BASF and Heartland previously worked alongside Magna International in 2022 during a Greentown Labs program focused on automotive plastics. BASF’s use of Heartland’s natural fiber is on track to create a breakthrough in sustainable material innovation with sizable reductions in cost, weight, and carbon footprint of polyamide 6 (nylon 6).”

Furthermore, as far as how the partnership helps, Heartland writes: “This investment will enable Heartland to expand its supply chain, rapidly deploy its masterbatching technology, and help customers achieve their Scope 3 carbon emissions reduction targets by 2025 and 2030.”

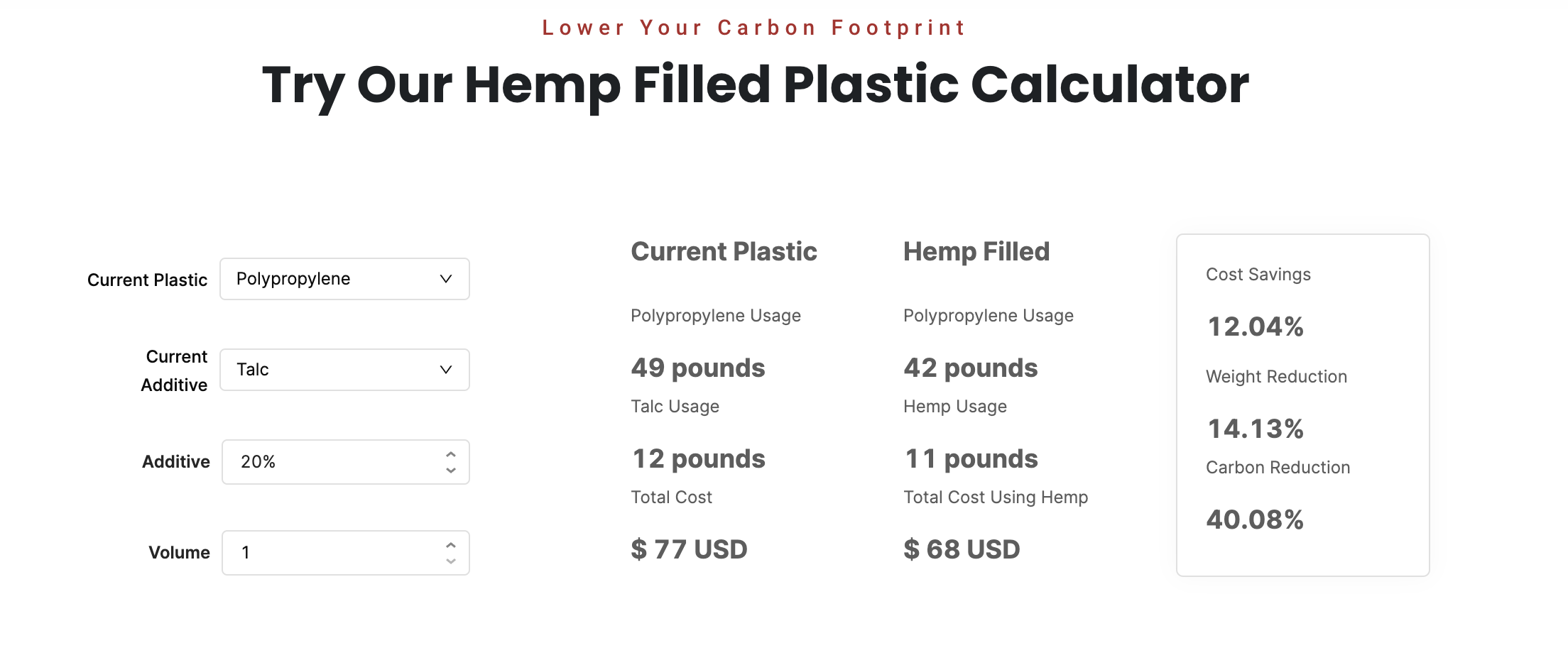

As challenging and, frankly, depressing as the plastics industry can be, it’s nice to get a little light here. Hopefully we will have more positive news here before long that includes significant estimated emissions reductions. In the meantime, note that Heartland has a tool on its website for calculating cost savings and carbon savings.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica.TV Video

CleanTechnica uses affiliate links. See our policy here.