Martin Engineering shines a light on resolving vibrator downtime in the dewatering screen process.

Sand is a nuanced and essential commodity, valued for different grades and qualities due to its wide application across nearly every manufacturing, scientific and construction process.

After fresh water, sand is the most widely consumed natural resource on the planet. The annual worldwide consumption of sand is estimated to be in excess of 15 billion tonnes, with a respective trade volume of $70 billion.

According to the Observatory of Economic Complexity, Australia is the second largest producer of sand in the world, exporting 206 million tonnes in 2021. It is considered one of the fastest growing industries in Australia.

Whether extracted from a dry inland quarry or underwater resource, impurities and biological material must be removed, otherwise the sand can contaminate the end process.

Image: Martin Engineering

Removing impurities from the product further saturates it, causing it to enter the processing and drying system as a slurry. Liquid adds tremendous weight and sand is generally sold as a commodity with a very low moisture level. Although some end users don’t require dried sand, most do, so the water needs to be extracted.

To remove water, the sand is passed through a screening process that involves industrial vibrators.

The volume and sustained operation of the process can put a lot of strain on the vibrators, so it is not uncommon for them to break down. This is accompanied by downtime and lost production, which makes lead time in being able to replace units and reliability of the vibrators extremely important.

This article walks through the process of one of the largest sand mining operations in the southern US and discusses the impact quality vibration has on the operation.

Clean sand makes strong concrete

The first stop for mined and quarried sand is the sanitisation plant, where the sand is washed of impurities such as clay, silt, salts and mica, as well as organic matter that can propagate the growth of bacteria.

In addition to improving the adhesive quality of the end product, the removal of organic impurities and bacteria can eliminate odour, reduce the potential for illness and remove other elements that can hinder the curing of concrete or mortar and weaken the final product.

In construction, sand that is 75–85 per cent clean is sufficient for cement.

Image: Martin Engineering

Having a larger surface area than sand, clay creates a filmy barrier around sand particles that prevents or reduces the adhesion of cement by increasing the amount of water needed, in turn lessening the strength of concrete or mortar. A high presence of mica can have structural implications due to the smooth surface of the particulate. The corrosive effect on reinforcement means the sand also needs to be periodically tested for coal residues.

Although most purified sand is used for voluminous applications – cement, golf courses, playgrounds, etc – some industrial applications such as the manufacturing of optical lenses and microchips require a greater purity devoid of iron, titanium and aluminum oxides.

This detailed processing may not be done by the mine or quarry but is often performed by a specialist entity catering to specific industries.

Dancing sand

Leaving the sanitation process as a slurry, the sand is conveyed to hoppers connected to rubber tubes, which direct the gritty flow to the screening racks. Several tonnes of heavy wet granules are vibrated across the screens per hour, so the water extraction process needs to be fast to meet production demands. It is then dropped on a conveyor to be transported to the drying kiln or the outdoor storage area.

The processing plant that services the sand mine has three dewatering racks with sloped screens covered with a specially made porous cloth that allows moisture to pass through, but none of the fines.

Image: Martin Engineering

The racks sit on spring stabilisers to absorb the force output of the two high-powered electric vibrators mounted on top that counter-rotate to create a linear force through the rack’s centre of gravity. With enough torque to move tonnes of wet material up and down, the vibrators cause the sand to ‘dance’ down the screen with the help of gravity.

Each impact against the screen cloth forces water from the material and through the screen openings, which then runs into troughs and is collected for proper treatment and disposal. By the time the material skips down to the end of the screen and discharges onto the next conveyor, it has the consistency of a dense meal.

Breakdowns, downtime and maintenance

The intense demand and stress on the vibrators can be punishing, sometimes causing them to break down.

Shutting down a single rack translates to a proportional loss in production, so to avoid downtime operators have the option of recalibrating a single vibrator when back-up units are unavailable. Although production is considerably reduced in this instance, the material still passes slowly through the process, releasing considerably less water and putting a tremendous strain on the shaker screen and the single vibrator, reducing their operational life.

Maintenance on the unit is also a burden and a possible safety concern. When one breaks down it must be sent to a local motor repair shop to be fixed, which can take weeks. Weighing more than half a tonne, a crane is used to remove the vibrator and load it for transport. Removal requires several employees, and working around unsupported heavy equipment can be hazardous.

“When the customer contacted us, it was one of those impossible situations with a screen out of commission, no back-ups left, the OEM unable to respond to their needs and nothing returning from the repair shop for weeks,” Martin Engineering vibration account manager Grant Burton said.

Counter-rotating forces

Martin Engineering technicians matched the type of electrical vibrator with the correct output to that of the previous manufacturer.

“OEMs often promote the myth that only their equipment will effectively operate their machine when the reality is that all another vibrator needs is similar horsepower, speed and torque,” Burton said. “Properly wire the vibrators to counter-rotate and match the force output by adjusting the eccentric weights, and the two units will naturally synchronise.

“By doing this we found that our MM series vibrators fit nicely within the customer’s existing parameters.”

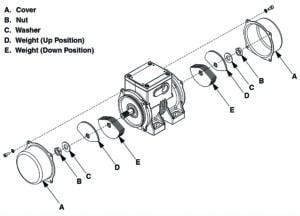

Image: Martin Engineering

With two sets of weights mounted on each end of the motor’s shaft, as the vibrator shaft rotates, the unbalanced mass of the eccentric weights is used to generate centrifugal force. To produce the proper force in a single vibrator, the two sets of weights can be adjusted so they are a mirror image.

When synchronising two vibrators, it is important to ensure the vibrators are counter-rotating and that the weights are properly adjusted to the same value. Once mounted to a piece of equipment, any adjustment made to one unit must also be done to the other.

Although the function and general design are similar to competitor units, what sets Martin Engineering designs apart is durability, service life and the fact Martin is the only US manufacturer that offers a three-year guarantee on its continuous-duty, high-output/low-frequency industrial vibrators.

Engineered to stay running for long periods under punishing conditions, the Martin MM-series electric screen vibrators use only the highest quality components, such as SKF or FAG bearings with a C4 clearance and Kluber grease.

Image: Martin Engineering

A 10–11hp motor produces a centrifugal force of 14,061kg. The unit incorporates O-ring seals and machined surfaces for a dust-tight/water-tight enclosure. The extended equipment life and reduced maintenance requirements deliver a quick return on investment due to reduced downtime.

Results

The vibrator was delivered and mounted more than a week earlier than expected, returning the operation to full production. The customer replaced old broken-down units with Martin Engineering MM series vibrators in two of its plants. Having installed 10 more units since the initial order, operators were impressed with the quality, service and long life of the equipment.

“It goes beyond just initially helping us get back to production,” a manager close to the project said. “The vibrator lasts longer and Martin is more responsive to our needs because lead time is so crucial to our operations.

“This is the level of service and type of relationship we extend to our customers and it’s nice to have partners who demonstrate the same values.”

This feature appeared in the February 2024 issue of Australian Mining.