The Coka Rakita project will be developed using underground mining methods. Credit: Mark Agnor/Shutterstock.com.

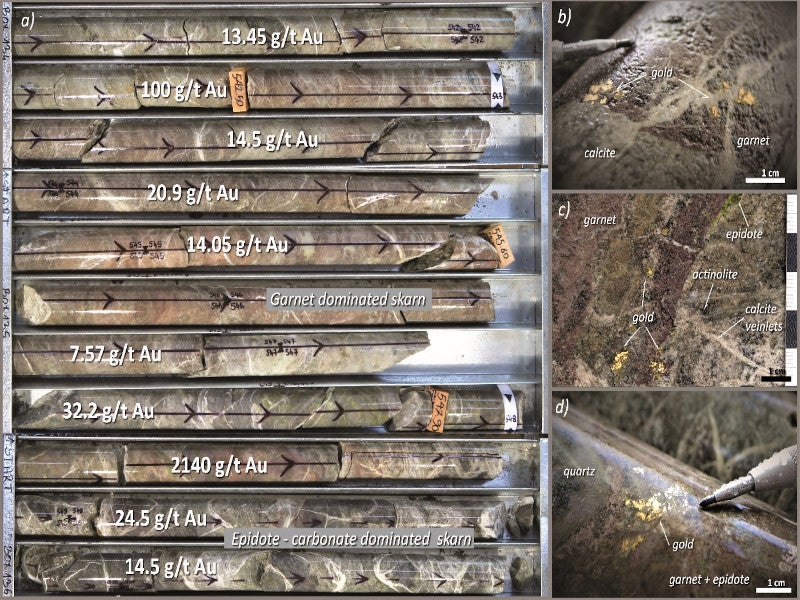

The Coka Rakita project is estimated to hold 9.79Mt in inferred resources. Credit: Dundee Precious Metals.

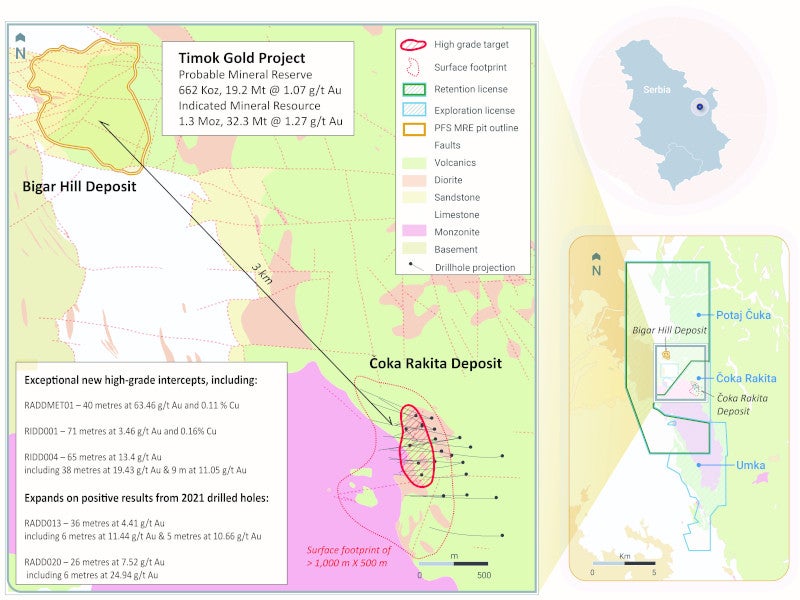

The project is situated 3km southeast of the Timok gold project in the eastern region of Serbia. Credit: Dundee Precious Metals.

The Coka Rakita project, situated in the eastern region of Serbia, is being developed as an underground mine.

The mine is wholly owned by Dundee Precious Metals (DPM), a Canada-based gold mining company.

The preliminary economic assessment (PEA) was completed in June 2024, with an initial capital cost projection of $381m.

The project is estimated to yield 164,000oz of gold in the first five years followed by 129,000oz for the remainder of the mine life.

The Coka Rakita project is estimated to have a life of mine (LOM) of ten years.

The pre-feasibility study of the project is anticipated to be completed by the first quarter of 2025 while the first concentrate production is expected by 2028.

Coka Rakita project location

The project is located in the eastern part of the Republic of Serbia, approximately 25km north-west of the town of Bor. The project lies within the Coka Rakita exploration licence, which covers an area of 13.81km².

The project site is located 3km south-east of DPM’s Timok gold project.

Geology and Mineralisation of Coka Rakita

The property is located in the north-western section of the Timok Magmatic Complex in eastern Serbia. It is part of the Western Tethyan Belt and the broader Tethyan orogenic system extending from Western Europe to South-East Asia.

The primary type of mineralisation found within the Coka Rakita project is high-grade manto-like skarn gold-copper mineralisation.

Resources at the Coka Rakita project

The inferred resource at the Coka Rakita project is estimated to be 9.79 million tonnes (mt), grading at 5.67g/t of gold and 1.21g/t of silver, as of November 2023.

The contained metal is estimated at 1.78 million ounces of gold and 382,000oz of silver.

Mining method at Coka Rakita

The Coka Rakita project will be mined using an underground mining method via a sublevel stoping mining technique, which will involve dividing the ore body into horizontal layers, or sublevels.

The mineralised material between these sublevels will be extracted through a series of stopes. Each stope will be drilled and blasted using long holes, allowing the blasted material to be collected from the lower sublevel’s production drive.

The long holes measuring 89mm in diameter will be drilled in rings. These rings will be spaced with a 2.1m burden and a 2.1m toe spacing, optimising the efficiency of blasting and material extraction from the stope.

The stope design incorporates a width of 20m, measured perpendicularly to the production drive, and a height of 20m with each stope measuring 15m in length. The mining process will follow a retreating sequence, starting by advancing longitudinally toward the crosscut and then shifting to a transverse direction toward the hangwall contact.

The mining fleet is envisaged to consist of six 45t trucks, two production drills, booster compressor, transmixer, shotcrete sprayer and other support machinery.

Ore processing at Coka Rakita project

The run-of-mine (ROM) material will be passed through a vibrating grizzly feeder with the oversize being fed into the primary jaw crusher. The crushed product, along with the undersized material from the grizzly feeder will be fed to a semi-autogenous grinding (SAG) mill.

The grinding operation will consist of a single-stage SAG mill with a cyclone cluster. Part of the cyclone underflow will be diverted to two parallel gravity concentration circuits.

The gravity concentration circuits will separate heavy gold-containing particles from lighter gangue minerals. These particles will be collected in a concentrate pump box and then sent to a bagging facility for dewatering and packaging.

The gravity tailings will be routed to the mill discharge pump box, and this concentrate will then be further processed in a flotation circuit to recover sulphide-rich material.

The processing plant will also include a flotation circuit, equipped with three Jameson cells, to separate the concentrate and tailings. The flotation concentrate will be thickened and sent for filtration while the tailings will also be thickened and either conveyed to a tailings storage facility or used in the paste backfill plant.

The concentrate will be dewatered using a pressure filter, and the product will be stored in a stockpile before being loaded onto transport trucks for delivery.

Site infrastructure

The project site will be accessed via a new road connecting an existing public road to the administration area near the processing facility. The road will be oriented east-west and will provide gravel access with an estimated width of 8m.

The project has two power supply options to meet the requirements for operations. The first is to construct a 35kV line from the Zagubita substation, which will require expansion to accommodate additional equipment. The second option is to build a 110kV line from the city of Bor.

Two diesel generation plants, with an effective capacity of 1.6MW each, will provide backup power.

Contractors involved

DRA Americas, an engineering and consulting company, was responsible for metallurgical test work review, developing design criteria, and recovery methods, and overseeing the process plant and related infrastructure, as well as compiling the PEA report.

Environmental Resources Management, a multinational consultancy company, was tasked with developing the mineral resource estimate, conducting environmental studies, securing permits, and assessing social impacts.

Responsible Mining Solutions, a mining consultant, provided the design of the paste backfill system for the project.

SLR Consulting was responsible for tailings management and waste rock facilities, along with creating a site-wide water balance.

WSP Global, an engineering consulting company, provided the underground mine design and associated infrastructure.