Groundbreaking materials have the potential to provide life-altering cooling to millions who lack it. How do they work? And how can they be scaled?

This year’s scorching northern hemisphere may be in the past, but, we cannot let it recede from view. With every possibility that the summer of 2024 — and each summer beyond that — will be worse, we need to make real progress on cooling technologies and solutions now.

At Third Derivative and RMI, we’re particularly excited about a class of advanced materials that provide a passive daytime radiative cooling (PDRC) effect, greatly reducing indoor temperatures — and their potential lifesaving and emissions reduction benefits.

PDRCs hold great promise for areas most impacted by extreme heat — where electricity is often scarce and where many families cannot afford air conditioning. Deployed at scale in the form of cool roofs across informal (self-built) settlements and low-income housing in India alone, PDRC materials could save 317,000 lives and over 68 million tons of carbon dioxide equivalent (tCO2e) in cooling-related emissions between now and 2030 — and far more when scaled to other countries.

What’s at stake?

Without concerted action, 8.3 billion people globally — 74 percent of the projected global population in 2100 — could be exposed to deadly heat conditions (more than 20 days during the year in which ambient air temperature and humidity cross survivability thresholds when body core temperatures exceed 37°C [98.6°F]), up from 30 percent today. The vast majority will be in low-income countries, with 1.1 billion in India alone. Even with major emissions reductions, 48 percent of the global population will be at risk.

In many of the world’s hottest countries, the majority live without air-conditioning — and the ability to escape life-threatening heat. Many of these deaths will occur in informal or self-built settlements, home to over 1 billion people worldwide.

Power outages make the problem worse. Demand for electricity typically peaks during heat waves as people need more and more mechanical cooling to stay comfortable. That strain on the electricity grid can lead to blackouts — and heat-related mortality risk more than doubles when blackouts occur during heat waves.

At the same time, as the world gets hotter, incomes rise and countries urbanize, exploding demand for mechanical cooling that will worsen global warming. Under a business-as-usual scenario, residential AC could consume 7,700 terawatt-hours (TWh) of electricity and account for over 160 billion tons of CO2e by 2050. For perspective, that is over three times greater than the emissions reductions anticipated by 2050 from the US Inflation Reduction Act, the biggest piece of US climate legislation in history.

Put simply, we cannot air condition our way out of this problem. We need alternatives that are more equitable, effective, and energy efficient.

What is PDRC? Is it just painting my roof white?

Not quite. Passive daytime radiative cooling products can cool even during the daytime, even when exposed to direct sunlight, and without any energy input (it’s passive, not active). They take full advantage of the physical properties of radiation — more on that in a moment. PDRC solutions have been developed in many forms, including coatings, thin films, fabrics, cellulosic microfibers, porous structures (like delignified wood), and aerogels.

While painting roofs white to cool buildings has been standard practice in hot climates like the Mediterranean for generations, PDRC-equipped roofs take things one step further. PDRC materials don’t just reflect the sun’s rays back, they are both highly reflective and highly emissive. They emit more heat than they absorb by taking advantage of longwave infrared thermal radiation — in a nutshell, they can bypass Earth’s “greenhouse” and send the sun’s heat back into space.

This means that PDRC solutions are able to radiate heat even with the sun beating down on them and can reduce surface temperature to at or below ambient outdoor temperatures. Their almost magical-seeming, counter-intuitive properties mean that a PDRC material is cooler when placed outside in the sun than it would be inside in the shade.

The impacts of this can be substantial. For example, a sheet metal or asbestos roof typical of many informal settlements can heat up to 88°C (190°F) in direct sunlight when ambient air temperatures are around 38°C (100°F). A PDRC solution can reduce roof surface temperatures to at or below ambient temperatures — a potential 30°C–50°C (54°F–90°F) difference.

This can translate to indoor temperatures that are 5°C–10°C (9°F–18°F) cooler on a hot day (i.e., to temperatures far below those seen in a typical informal settlement home). Typically, summertime indoor temperatures in these dwellings are higher than temperatures outside. This is illustrated with an example of a 32°C (90°F) day in Exhibit 1.

Exhibit 1.

What impact could PDRC solutions have?

The impacts on quality of life — especially for those in developing countries — could be enormous. Let’s look at India as an example.

Our analysis suggests that there are over 400 million people in India alone for whom PDRC solutions could be a critical health and quality-of-life solution. These are people living in informal or self-built settlements as well as low-income residents living in single-family homes. These communities tend to be much hotter than neighboring, wealthier areas due to less tree cover and shade, poorer quality construction, and a higher proportion of heat-absorbing materials like asphalt and concrete.

Large-scale PDRC material adoption among this population could prevent 317,000 heat-related deaths between now and 2030 (for more on methodology see our unabridged blog on the Third Derivative website). For perspective, that is roughly equivalent to one-tenth of the lives saved by COVID-19 vaccines in the entire WHO Southeast Asia region (which includes 11 countries, including India, and nearly 2 billion people).

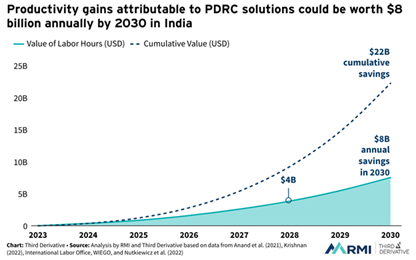

It could also prevent the loss of 73 trillion labor hours (worth $22 billion in direct income). For the average low-income beneficiary household, this would mean 136 labor hours gained in the year 2030, worth 7 percent of annual household income (INR 3,500).

Exhibit 2.

Rapid deployment of PDRC solutions would also save 80 terawatt-hours (TWh) of cooling-related energy consumption and avoid over 68 million tons of CO2e in cooling-related emissions by reducing the need for AC use and other mechanical cooling. In 2030 alone, that’s 27 TWh in annual energy savings — 63 percent of the annual savings achieved by India’s UJALA scheme, heralded as one of the world’s most ambitious and impactful energy efficiency programs.

So how do we get this to happen, and happen fast?

Despite the rapid evolution of PDRC solution research and development, most solutions have not grown beyond the lab scale. While the performance of PDRC solutions have been proven in small testing projects, it will be critical to validate this performance at larger scales in real-world housing conditions. There are a few key criteria PDRC solutions will need to achieve to be competitive: affordability, reliable supply chains, and the right deployment model.

Since PDRC solutions are not yet manufactured at scale, they have not been subject to “learning rates” and have much higher unit costs than commercially available cool roof paints. That said, since the primary inputs (like quartz and titanium dioxide) are cheap and the manufacturing process is relatively simple, the learning rate for PDRC solutions will likely be high, quickly bringing them into the same ballpark as regular paints.

Exhibit 3.

It is also important to ensure that the embodied carbon (the emissions from material sourcing and product manufacturing), and broader environmental footprint of these products are as small as possible. As with many products, there is a range of input materials that can be used, with varying carbon impacts (the highest-carbon polymer option has around 70 times the carbon impact of the lowest-carbon polymer option).

We need more research to show how these inputs can be sourced in an environmentally sustainable and socially responsible way, and that the manufacturing process is efficient and renewably powered.

Voluntary carbon markets could play a critical role in defraying the first cost of these solutions and enhancing affordability for low-income households — especially if they can develop a “stacked” credit that includes attributes other than carbon reduction (e.g., health impact).

At Third Derivative and RMI, we are exploring how to get PDRC solutions to market and scale, including by:

- Testing the leading products in real-world conditions.

- Brokering partnerships between PDRC developers and leading paint manufacturers capable of production at scale.

- Forging a coalition — led by government but including corporations and philanthropy — that makes an advanced market commitment, guaranteeing a certain volume of offtake at a certain price, assuming the products pass certain tests.

- Distributing the product to grassroots institutions with a track record of solution deployment in vulnerable communities (e.g., Mahila Housing Trust and Barefoot College in India, BRAC in Bangladesh).

- Working with a carbon credit company to develop a “stacked” product that could potentially create an important revenue stream for the implementing organizations, enabling them to get paid for deployment on a per household or per square foot basis.

This will be a complex, multi-stakeholder exercise that will need careful, robust planning. It will also take real leadership — from governments in particular. But the potential climate and health impacts will more than justify the effort.

© 2023 Rocky Mountain Institute. Published with permission. Originally posted on RMI. By Lindsay Rasmussen, Rushad Nanavatty, Colm Quinn, This article originally appeared in its unabridged form on third-derivative.org