CiDRA Minerals Processing’s innovative P29 system has the potential to form the heart of future mineral processing flowsheets. Unlike other options that take effect further downstream, grind-circuit roughing with P29 offers the possibility of increasing grind size and directly reducing the recirculating load in grinding mills, increasing mill throughput by 20% or more at a constant grind size.

More and more big mining houses are seeing its potential in existing plants to free up capacity and throughput. And in addition to brownfield, its potential is also being looked at in coarse recovery in greenfield flowsheets, with traditional grinding replaced by other technologies like vertical mills and high-pressure grinding rolls, leading to even greater near term value of a P29 grind circuit rougher.

With so much potential, and the urgent need for solutions to be made viable, CiDRA has partnered with Worley and Weir and formed an integrated collaborative team for the P29 technology development and implementation. Worley brings full EPC delivery capabilities, including technology development and commercialisation, and Weir provides experience in flowsheet and product development, as well as access to their market leading solutions including pumps, HPGRs and cyclones. The integrated team working on P29 solutions is advancing this innovative technology to a market ready solution for our industry. Worley has been working alongside CiDRA for four years, and in May 2025, CiDRA and Weir announced that they had signed a global collaboration agreement alongside a strategic investment by Weir in CiDRA’s mining business.

IM spoke to Mark Holdsworth, CiDRA COO on where the heart of the value of P29 lies: “If you are pulling out this -1 mm material, using the Bond power equation it is already a 60% drop in specific energy per tonne. You then use that energy to increase your througput rate or reduce your grind size – and that’s in a brownfield mine. But if you think about those energy savings, that can then lead you to greenfield mine future flowsheets with VRMs and HPGRs in place of tumbling mills. The other thing we are now having discussions about is coarse tailings. At 1 mm your water recovery in tailings goes from about 25% recovery up to 70%+ recovery, plus it means a far more stable stacked tailings. This then is unlocking additional value from an ESG perspective in terms of social licence to operate.”

Any P29 introduction commercially would certainly be timely as the world needs more minerals to deliver the technology to electrify the world to reach net zero. It takes time to develop new mines and that is not fast enough to meet global demand. Deposits themselves are becoming more difficult to commercialise – they are becoming more remote, often in arid areas with water scarcity and with a lack of existing infrastructure

Many mining groups are now looking at ways to lock coarse recovery in combination with technologies like roller milling and dry processing because it means significant power and water savings, which means an improved licence to operate. Lack of fines and slurry also means greater tailings disposal safety and stability.

Holdsworth adds: “Going from a typical p80 of 100-200 µm to p80 of 600-800 µm is a reduction of 50 to 60% in comminution energy. What if we can reject 70-80% of the feed mass at this size? Rejecting feed at this size also increases water recovery. A P80 of 600-800 µm also unlocks VRMs and HPGRs as comminution methods, replacing SAG and ball milling. Depending on the ore, this can also mean improvement in breakage at mineral boundaries to improve recovery and quality. CiDRA’s P29 technology continues to show good coarse mass rejection with high metal recoveries out to P80’s of 1,000 µm, plus it works well in hyper saline water. The P29 flowsheet also vastly reduces or removes any rougher flotation requirement – with 80% mass rejection. P29 concentrate can then be reground to conventional flotation cleaning.”

He adds: “Weir is working with us and supporting us across the board, from pump design, to dewatering design, comminution equipment modelling and modelling of the cubes.”

Where did P29 come from? CiDRA started out looking for an alternative to conventional flotation and came up with the use of an open cell polyurethane foam media as a substrate. An engineered hydrophobic coating is applied to the substrate enabling it to attract hydrophobic particles. The substrate foam is in the form of small cubes which is mixed with the ore slurry in a rotating drum. The slurry penetrates around and through the foam and contacts the foam surface and the reagent chemical, the same that is used in flotation, attracts the hydrophobic particles. The foam substrate can be engineered with different pore sizes and the media can be tailored for the particle size distribution for the specific application. The pore size in the media defines the available surface area for mineral attachment and is analogous to the bubble surface area in froth flotation. The advantage of engineered foam media as a mineral collection mechanism is that it can be optimised for durability, surface energy, compliance, and flexibility, as well as the shape and size of the media. The industrial reticulated foam is coated and cured through industry standard processes; the cured foam sheets are then cut into cubes and vacuum packed for shipping. The contactor is a simple mixing device designed to contact the mineral slurry with the collection media. Embodiments of the contactor are a sump/pump and pipe or a horizontal rotating drum.

The circuit configuration will be a function of the feed slurry mineralogy, rheology and application space. The loaded media is separated from the slurry via a screen, either attached to the end of a horizontal drum contactor or as a standalone vibrating screen. A recycled water rinse is used to remove the entrained gangue from the media which results in high upgrade ratios and low mass recoveries. The media is dewatered prior to the mineral removal stage with either a vibrating screen or a belt-on-belt rolls press. The mineral is removed from the media by passing the loaded media and a release agent through a series of pumps. The release agent used in the mineral removal stage is reclaimed using a centrifuge or nano filtration stage. The reclaimed release agent is returned to the process.

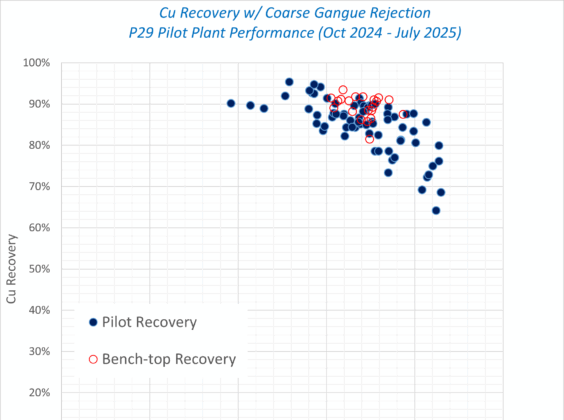

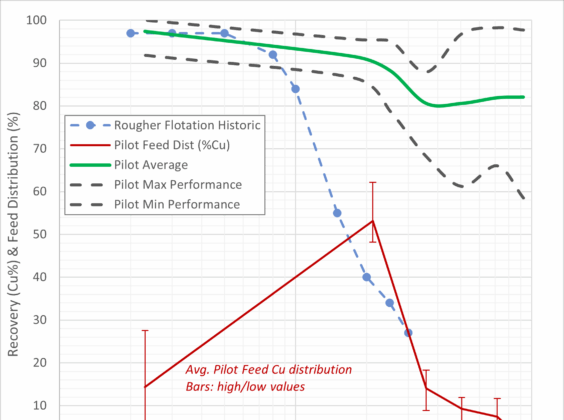

The most significant P29 pilot plant site testing to date has been BHP’s Carrapateena copper operation in South Australia, where a pilot plant in October 2025 will reach a year of operation. Holdsworth: “The first two campaigns of running the plant in November and December 2024 delivered the metallurgical performance that BHP Carrapateena wanted to see, as they had a threshold of copper recovery and we exceeded that, which they were very pleased with. This period saw us carry out multiple tests, so that gave them confidence. They then basically handed the pilot plant operation back to us, which allowed us to do our development work, plus set our operating boundaries etc. And then in June 2025, we were requested to repeat previously achieved recoveries, and we have done that – so we have demonstrated an ability to deliver consistent results.”

Pilot plant trial recovery results from BHP Carrapateena

In the meantime, CiDRA have done some Class 5 engineering studies together with Worley. For both BHP and for Rio Tinto, with whom CiDRA is also in discussions with, the most important factor is P29’s potential to bring a significant reduction in comminution energy. It also translates into significant reductions in overall CAPEX and OPEX depending on application. “So the future value proposition is exciting for our potential customer base. The pilot plant has demonstrated repeatable metallurgical performance. So I think what we are now seeing is that everyone is aligning. The next step is to do a demo scale plant. So we are currently discussing the early phases of that programme. We are working with BHP on that and it will likely be located at an operational site in Australia. We expect the demo plant will be advanced by a consortium including us, Weir, Worley, and industry partners. The basis of it is how do we advance this technology for everyone’s benefit in the industry. But because it’s first of a kind technology, we are looking at how do we accelerate it fast but reduce the risk across multiple parties. To move forward, there are questions around what happens at scale. A pilot plant and pipes at 20 mm with 12 mm cubes is different than a 300 mm pipe with thousands of cubes.”

The focus of these miners is future greenfield coarse recovery, lower comminution energy, and lower water usage plus coarse dry stack tails, and safer tailings. Holdsworth: “But it is also looking at testing new combination methodologies, because now you can recover coarse particles, can you break the particle along the mineral boundary and get better performance? This could even include novel rock breakage technology using roll crushers.”

Holdsworth added that BHP’s Carrapateena site team in particular have shown a high level of commitment, support and drive – from Rhys Jones and before him Joe Seppelt. They see the mineral processing optimisation upside but also the sustainability benefits, especially in energy and water usage terms.